Articles comprising wettable structured surfaces

An object and area technology, applied in the field of objects containing wettable structured surfaces, can solve problems such as difficulty in maintaining lyophilicity and weakened lyophilicity, and achieve enhanced hydrophilicity and lyophilicity, reduced pipeline clogging, Effect of improving drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

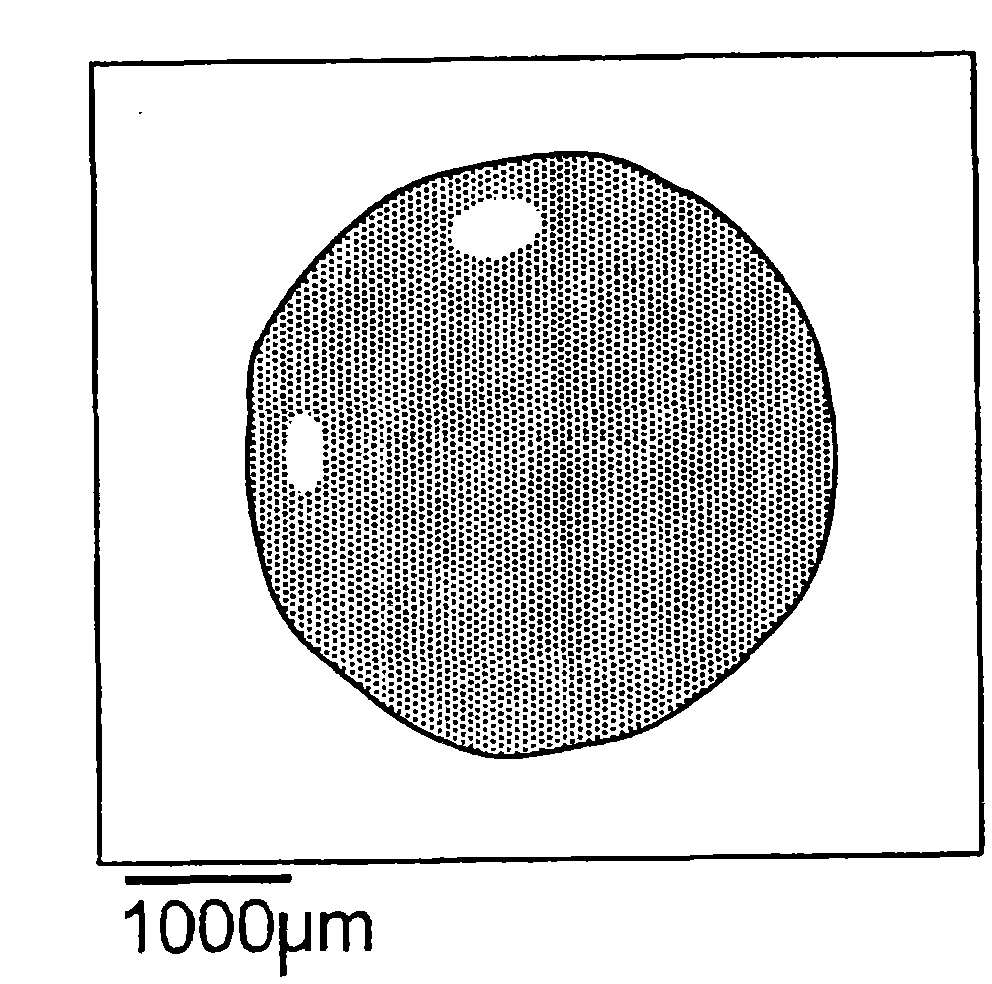

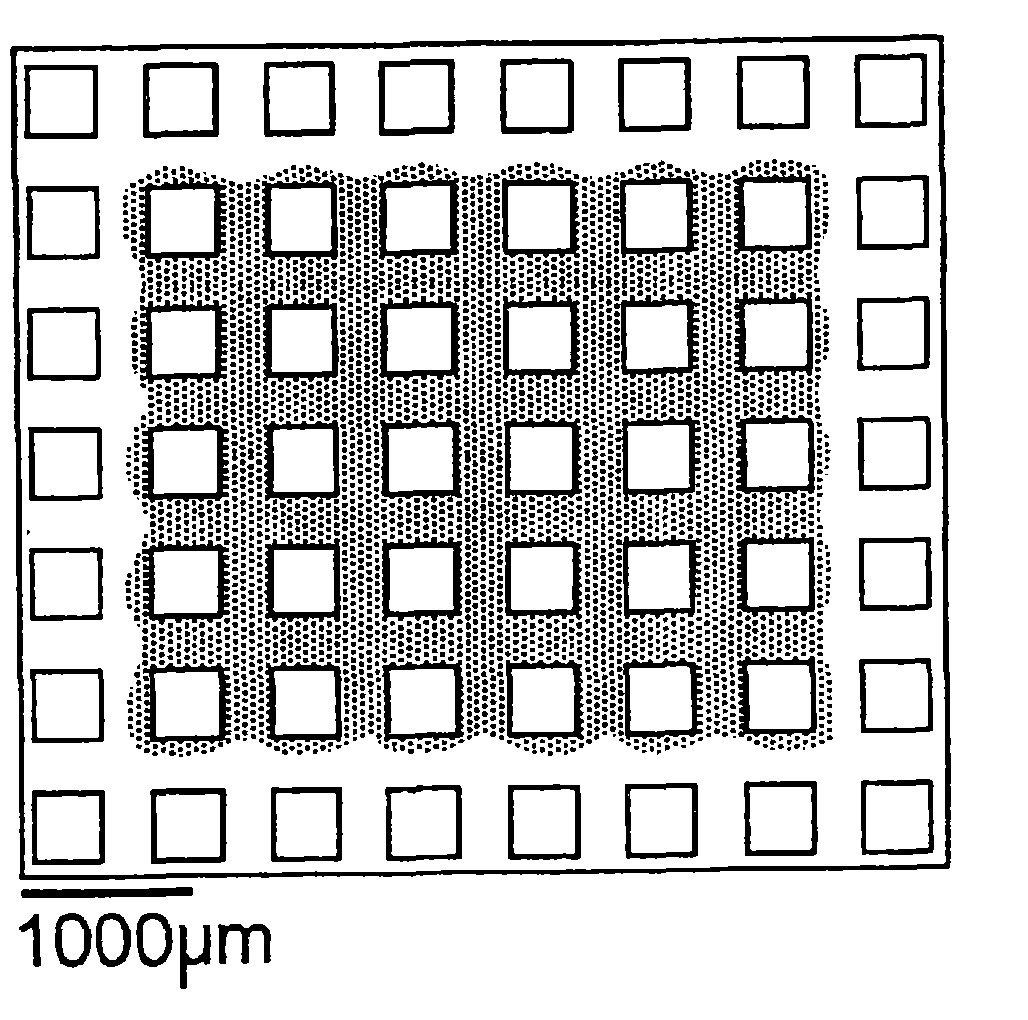

[0122] Structured substrates were machined from 5 cm x 5 cm x 1 cm graphite blocks (Poco Graphite, Inc., Grade: EDM-AF5) using carbide- or diamond-like carbon-coated cutters. The parallel paths are cut in one direction, the block is then rotated and the parallel paths cut again to create a grid array. In each cutting direction, parallel paths are cut such that Figure 4 Divide the upper surface of the board into four quadrants as described in , one smooth quadrant (no stripes, upper right quadrant), two quadrants with parallel grooves (upper left and lower right quadrant) and a quadrant (lower left quadrant) with a regular array of features. Vary the cutter depth and distance between paths to produce a structured surface with the desired feature size and spacing. In most cases, a square head cutter is used to produce square columns and square bottom pipes. Use other cutter shapes to produce features with other shapes, such as frustums.

[0123] The size of the structured su...

example 2

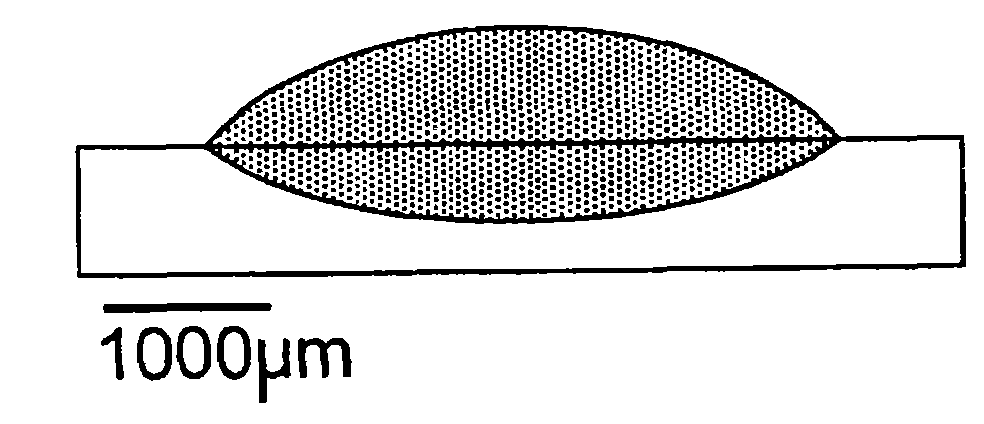

[0136] Figure 5 Graph showing the number of water-wetting cells n and the wetted area A versus volume on a structured semi-wicking surface (graphite treated with columnar protrusions) with constant geometry and varying lyophilicity. Lyophilicity was varied by varying the duration of the oxidative surface treatment. A surface similar to Table 1 is covered by square pillars (ω=90°) with x ≈ 380 μm, y ≈ 780 μm and z ≈ 420 μm. Points are experimental data (see Table 2, samples 1-3); solid lines are model calculation results based on equations (20) and (21). It is observed that both n and A increase linearly with V. Wetting is well adapted and thus the proposed model fits the experimental data well. Even if the hydrophilicity of the surface changes: the structured surface is still fully adaptive semi-wicking.

[0137] It was observed that besides the unique shape of the wetting pattern, the structured surface differs significantly from the smooth surface in several other ways....

example 3

[0141] Image 6 The number of wetting cells n and the wetting area A versus volume V for various liquids on a structured semi-wicking surface (graphite treated with columnar protrusions) are shown. Liquids (see samples 4-6 in Table 2) are θ a = ethylene glycol (EG) at 17°, θ a = Formamide (FA) at 26°, and θ a = 40° water. The surface is covered by an array of square pillars (ω = 90°), with x ≈ 380 μm, y ≈ 780 μm and z ≈ 420 μm. Image 6 Experimental data in are shown as dots. Water on this particular surface geometry has an advancing contact angle θ a = 40° and shows fully adapted semi-capillarity, see previous examples and Figure 5 . In other liquids provide lower theta than water a In the case of , the interaction strength between ethylene glycol (EG) and formamide (FA) at the contact line is greater than that of water. Similarly, lower gamma values reduce the restoring force acting at the gas-liquid interface. As shown, EG and FA are also fully compliant (conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com