Remediation method of hexavalent chromium polluted soil

A technology for chromium-contaminated soil and contaminated soil, applied in the direction of restoration of polluted soil, etc., can solve problems such as no research and report, inability to obtain soil hexavalent chromium content detection results, interference with soil hexavalent chromium detection, etc. The effect of reducing pipeline blockage and promoting recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

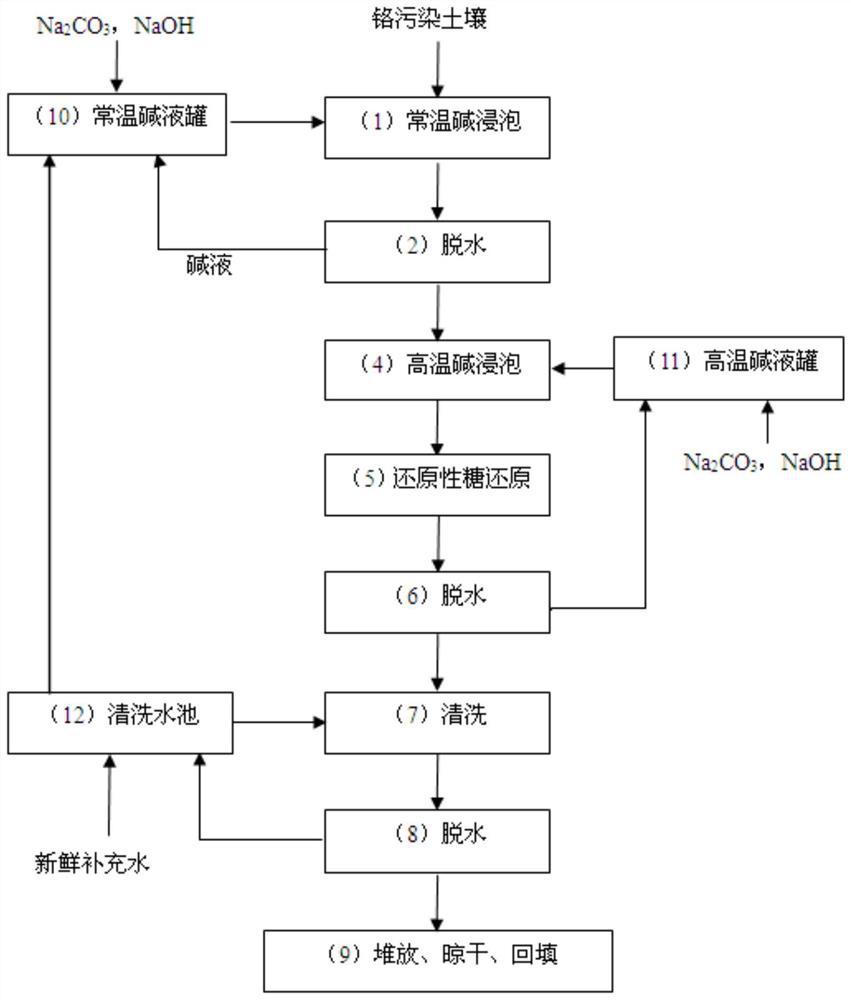

[0032]Repair the contaminated soil of chromium slag storage yard (the soil comes from the contaminated soil of a chromium slag storage yard, its hexavalent chromium content is 630mg / kg, and the moisture content is 4.1%). The technological process in the restoration process is as follows figure 1 As shown, the specific repair method includes the following steps:

[0033] (1) Preparation of lye containing soluble carbonate: add sodium carbonate and sodium hydroxide to water to form lye containing 0.3mol / L sodium carbonate and 0.5mol / L sodium hydroxide, which are stored at room temperature respectively In the lye tank and the high temperature lye tank (the high temperature lye tank has its own heating device);

[0034] (2) Soak the polluted soil in the soaking lye tank containing lye in step (1) for 5 days, carry out solid-liquid separation with a dehydrator to obtain lye (return to the soaking lye tank for the next batch of soil to be repaired soaking) and dehydrated soil I;

...

Embodiment 2

[0040] To remediate a certain chromium-contaminated soil with a hexavalent chromium content of 215 mg / kg, the operation process of this embodiment is the same as that of Example 1, except that the time of normal-temperature alkali immersion and high-temperature alkali immersion is different:

[0041] (1) The time of alkali immersion at normal temperature is 20 days,

[0042] (2) The soaking time in high temperature alkali is 5 minutes.

[0043] The hexavalent chromium in the soil repaired by the above process was tested for this batch of soil, and the hexavalent chromium content was 9mg / kg.

Embodiment 3

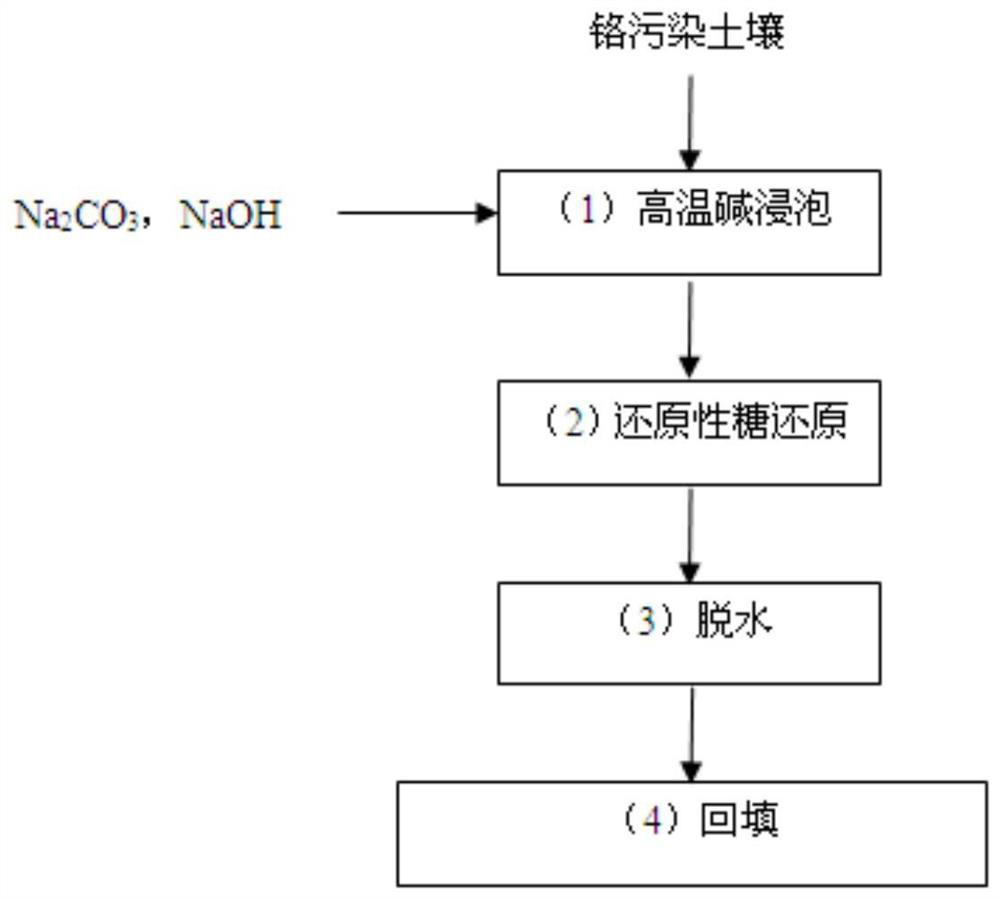

[0045] For the polluted soil of chromium slag stockyard (from the industrial pollution site, the content of hexavalent chromium is 1250mg / kg, and the cubic volume is only 98m 3 ) for repair, the technological process in the repair process is as follows figure 2 As shown, the specific repair method includes the following steps:

[0046] (1) preparation contains the lye of soluble carbonate: sodium carbonate and sodium hydroxide are added in water, form the lye that contains the sodium carbonate of 1.0mol / L and the sodium hydroxide of 1.0mol / L;

[0047] (2) Soak 1000kg of chromium-contaminated soil to be repaired in a soaking tank containing 1000L of 90°C high-temperature lye in step (1) for 3h;

[0048] (3) After soaking, add 27.5 kg of glucose into the soaking tank, stir and react at 50° C. for 10 minutes, cool naturally, and then dehydrate in a sand filter to obtain repaired soil.

[0049] The hexavalent chromium in the soil repaired by the above process was tested for thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com