Method for preparing modified ceramic diaphragm through dopamine compound adhesive and application thereof

A technology of binder preparation and ceramic diaphragm, which is applied in the field of electrochemistry, can solve the problems that the ceramic powder and the diaphragm matrix cannot be well infiltrated, affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Mix 0.75g of dopamine hydrochloride, 0.2g of sodium carboxymethylcellulose (CMC), 0.3g of styrene-butadiene rubber (SBR), 10ml of a mixed solution (water-based solvent) of deionized water and ethanol (1:1, v:v) Evenly, adjust the pH to 8.5 to obtain a composite binder.

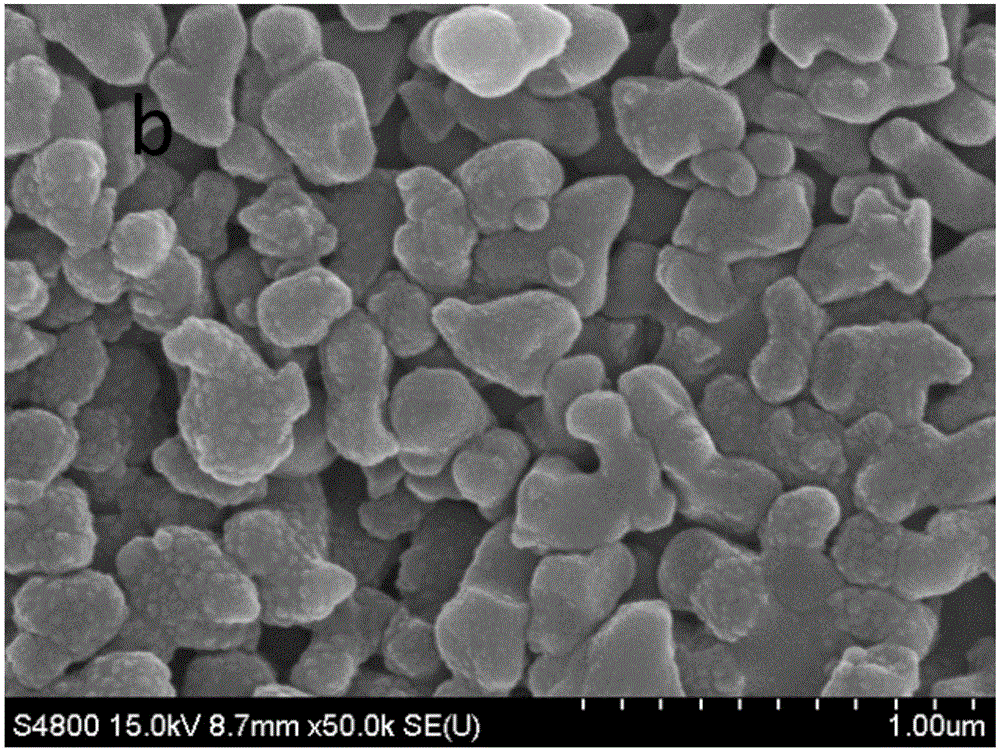

[0054] Put alumina nanoparticles (300nm in particle size) and 1 g of the above-mentioned composite binder in a solid content mass ratio of 95:5 into 10 ml of a mixed solution of deionized water and ethanol (1:1, v:v), Mix to obtain ceramic slurry.

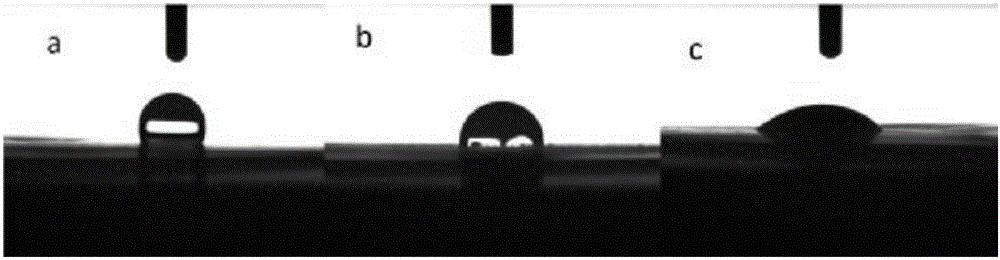

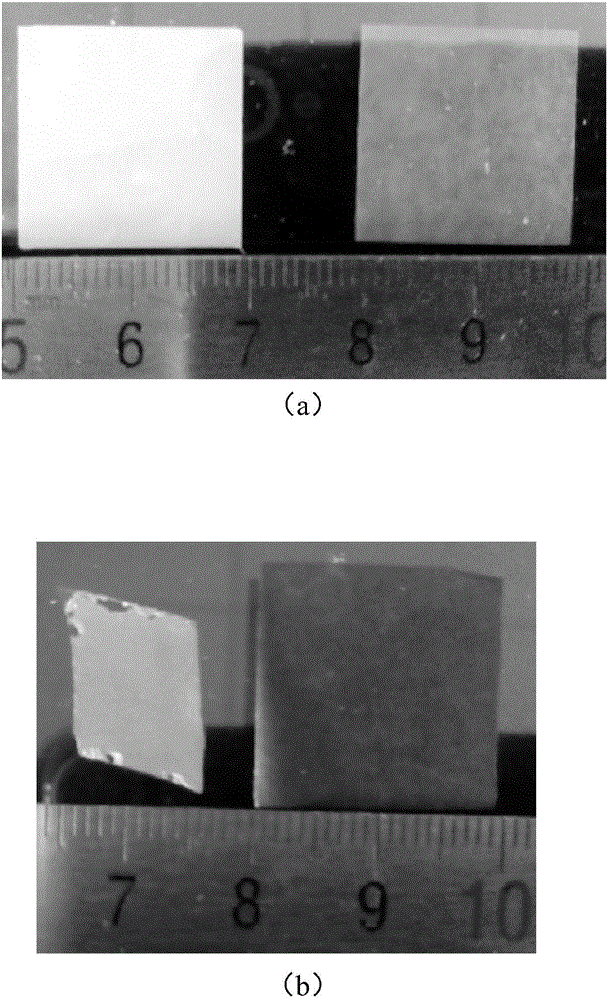

[0055] Ceramic diaphragms were fabricated using commercial polyethylene (PE) diaphragms as the diaphragm substrate. The obtained slurry is uniformly coated on one or both sides of a common polyethylene (PE) separator to form a modified ceramic layer with a thickness of 3um. Place and age at 10-100°C for 8 hours to allow dopamine to polymerize completely, wash away impurities with a water-based solvent, and dry to remove the solvent to obtain a modified cer...

Embodiment 2

[0062] Weigh 10 parts by weight of dopamine hydrochloride and dissolve it in 100 parts by weight of deionized water, adjust the pH to 8.8, and react at room temperature for 10 h. Filter, wash, and ball mill for 12 hours to obtain polydopamine nanoparticles with a particle size of 500 nm.

[0063] Weigh 50 parts by weight of the polydopamine nanoparticles, 25 parts by weight of sodium carboxymethylcellulose, and 25 parts by weight of styrene-butadiene rubber, and disperse them in 1000 parts by weight of deionized water. get composite binders.

[0064] Weigh 20 parts by weight of the composite binder and 50 parts by weight of nano-alumina particles (with a particle size of 300 nm), disperse them in 300 parts by weight of a water-based solvent, and mix them uniformly to obtain a ceramic slurry.

[0065] Ceramic diaphragms were fabricated using commercial polyethylene (PE) diaphragms as the diaphragm substrate. The obtained slurry is evenly coated on one or both sides of a comme...

Embodiment 3

[0068] Mix 0.5g of dopamine hydrochloride, 0.5g of polyacrylate terpolymer latex (LA132, LA133), 10ml of a mixed solution of deionized water and ethanol (2:1, v:v) to obtain a composite binder.

[0069] Silica nanoparticles (particle size is 100nm) and the above composite binder according to the ratio of solid content mass ratio 90:10 1g, put deionized water and acetone 2:1, v:v) mixed solution 10ml, Mix to obtain ceramic slurry.

[0070] The ceramic diaphragm is made of ordinary polypropylene (PP) diaphragm as the diaphragm base material. The resulting slurry is evenly coated on one or both sides of a common polyethylene (PP) separator to form a modified ceramic layer with a thickness of 2um. Putting it into an alkaline atmosphere with pH=8 to age for 5 hours, washing away impurities with a solvent, drying to remove the solvent, and obtaining a modified ceramic diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com