Functional diaphragm and preparation method thereof

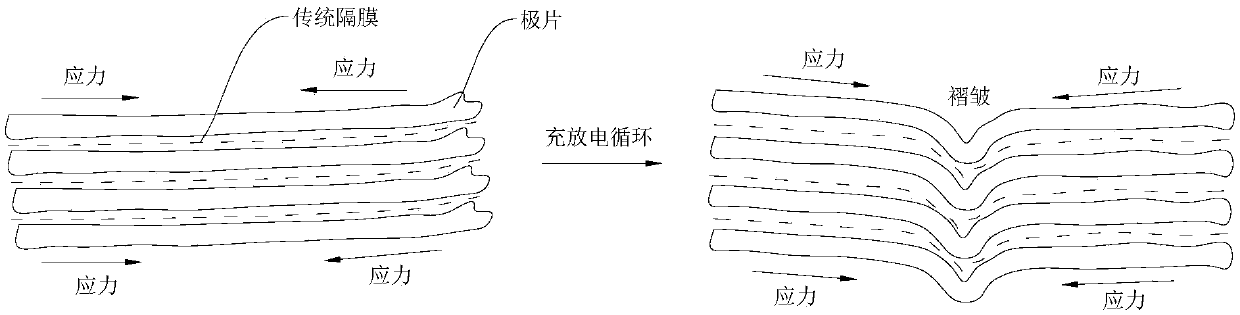

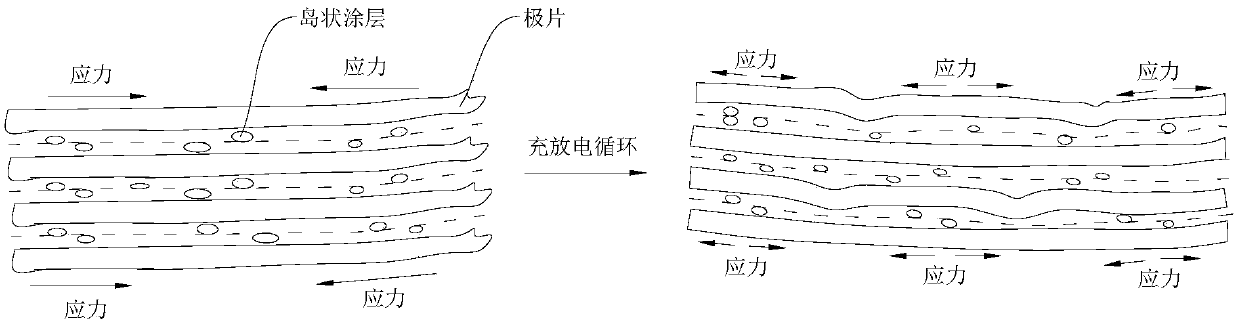

A diaphragm and functional technology, applied in the field of functional diaphragm and its preparation, can solve the problems of battery deformation, large expansion and contraction rate, and easy bulging of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

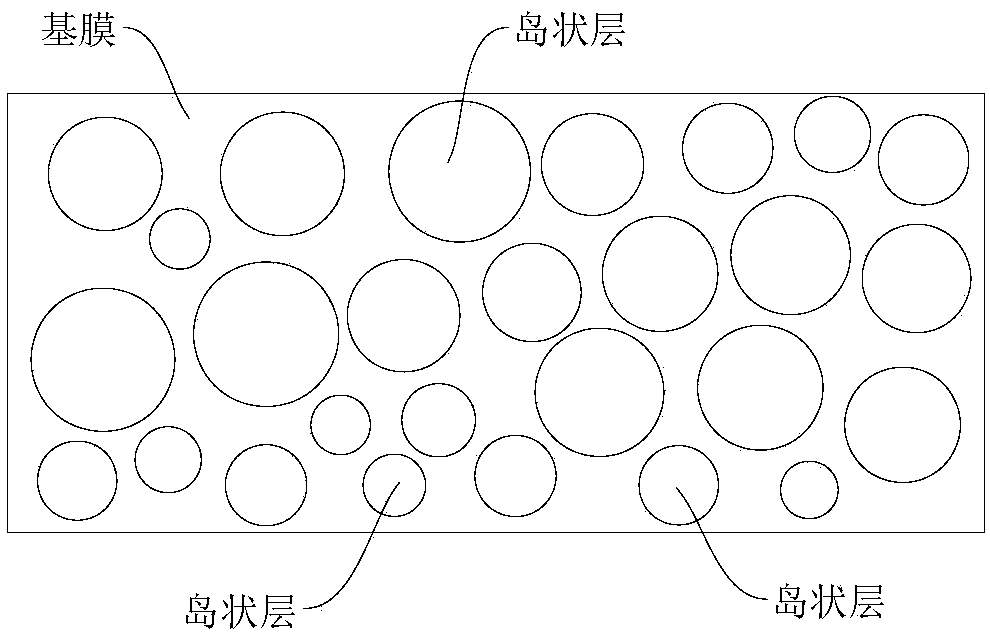

[0041] This embodiment provides a functional diaphragm, the preparation steps of which are as follows:

[0042] Dissolve 10g polysulfone ether ketone resin and 5g polyvinylidene fluoride-hexafluoropropylene resin in 60g N,N-dimethylformamide, then add 4g 4wt% ethanol and 0.01g photoinitiator TPO, stir at high speed for 30 Minutes, evenly, let it stand for degassing. The resulting slurry is sprayed on the surface of a dry-process polypropylene base film with a thickness of 16 microns and a porosity of 40% through a high-speed rotating spray disc, and then undergoes UV pre-curing (pre-curing time 1s), gel washing with water, and UV light curing. (curing time 5s). Finally dry to obtain coating thickness is 3 microns, and the single island-shaped particle (being single island-shaped coating) size is the function of 200-400 micron (island-shaped particle size is different, so what is given in the embodiment is a range value) function diaphragm. The coverage area of the coating...

Embodiment 2

[0044] This embodiment provides a functional diaphragm, the preparation steps of which are as follows:

[0045] Dissolve 10 g of photocurable polyacrylate resin, 10 g of polyester acrylate and 10 g of gel-type polyacrylate resin with active functional groups in a mixed solution of 40 g of acetone and 40 g of toluene. Add 5 g of deionized water, 5 g of 8 wt % ethylene glycol and 0.1 g of photoinitiator α, α-dimethoxy-α-phenylacetophenone, stir at high speed for 30 minutes, and let it stand for defoaming. The resulting slurry is sprayed on the surface of a dry-laid non-woven fabric base film with a thickness of 12 microns and a porosity of 45% through a high-speed rotating spray disc. After UV pre-curing (pre-curing time 1s), gel washing and pore making, UV light curing (curing time 5s). Finally, dry to obtain a functional separator with a coating thickness of 5 microns and a single island particle size of 100-200 microns. The coverage area of the coating on the base film is...

Embodiment 3

[0047] This embodiment provides a functional diaphragm, the preparation steps of which are as follows:

[0048] 5g photocurable urethane acrylate resin, 6g polyether acrylate, 4g photocurable polybutadiene oligomer resin and 8g PVDF-HFP (copolymer of vinylidene fluoride and hexafluoropropylene) gel resin were dissolved in 20g NMP ( N,N-dimethylpyrrolidone), 10g p-xylene and 40g formamide in a mixture. Then add 1g methanol, 2g ether, 3g dichloromethane and 0.0025g photoinitiator 2,4-dihydroxybenzophenone, 0.0035g photoinitiator α, α-dimethoxy-α-phenylacetophenone , 0.02g photoinitiator TPO, stirred at high speed for 30 minutes, evenly, and let it stand for defoaming. The resulting slurry is sprayed on the surface of the wet-process PE-ceramic base membrane with a thickness of 12 microns and a porosity of 45% through a high-speed rotating spray disc. After UV pre-curing (pre-curing time 1s), hot air baking, UV light curing (curing time 5s). Finally, dry to obtain a functional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com