Patents

Literature

44results about How to "Solve the bulge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat shrink tube and manufacturing method of the same

InactiveCN103138222ATo achieve the effect of exhaust compressionResolve Surface WrinklesCable fittingsEngineeringHeat-shrink tubing

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

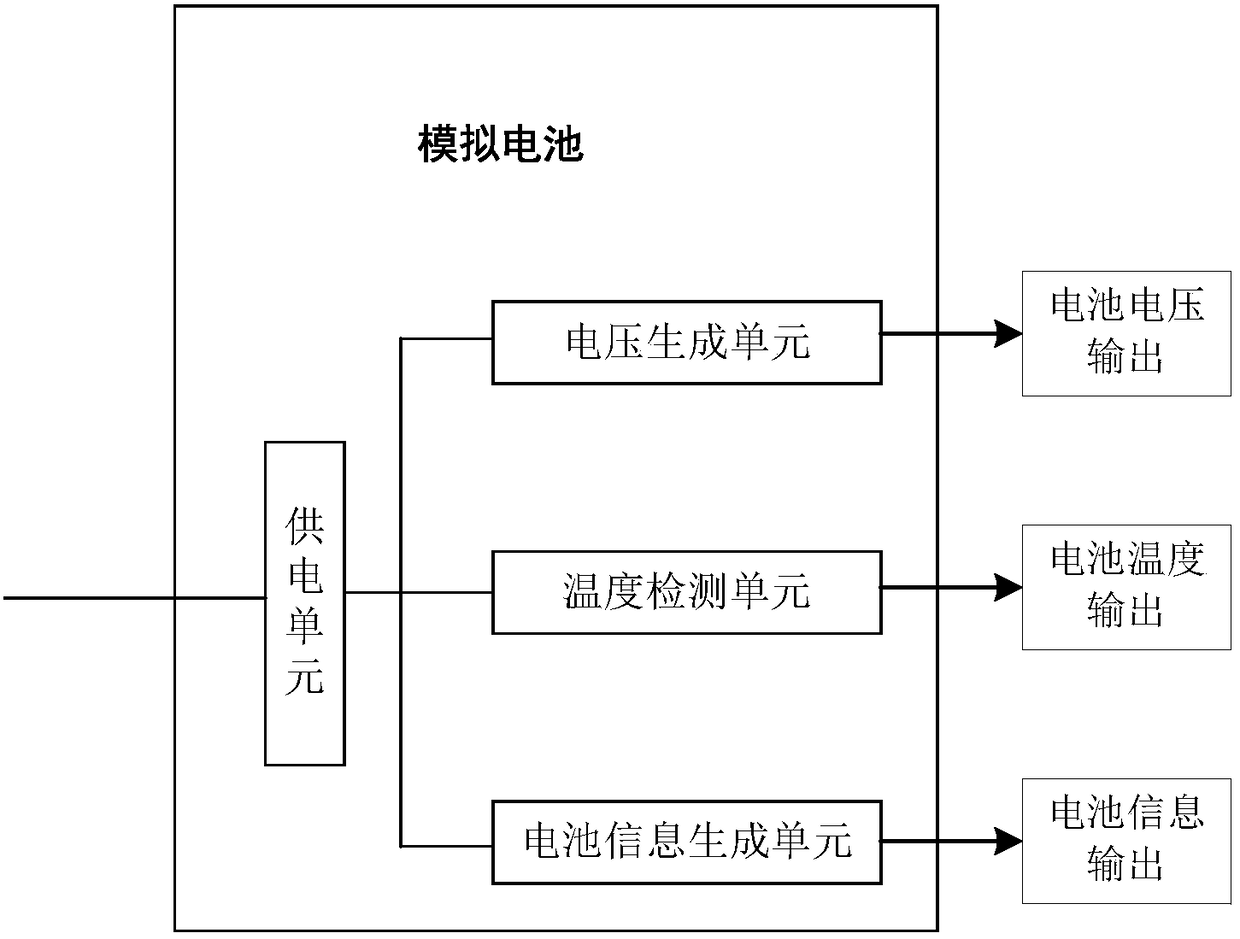

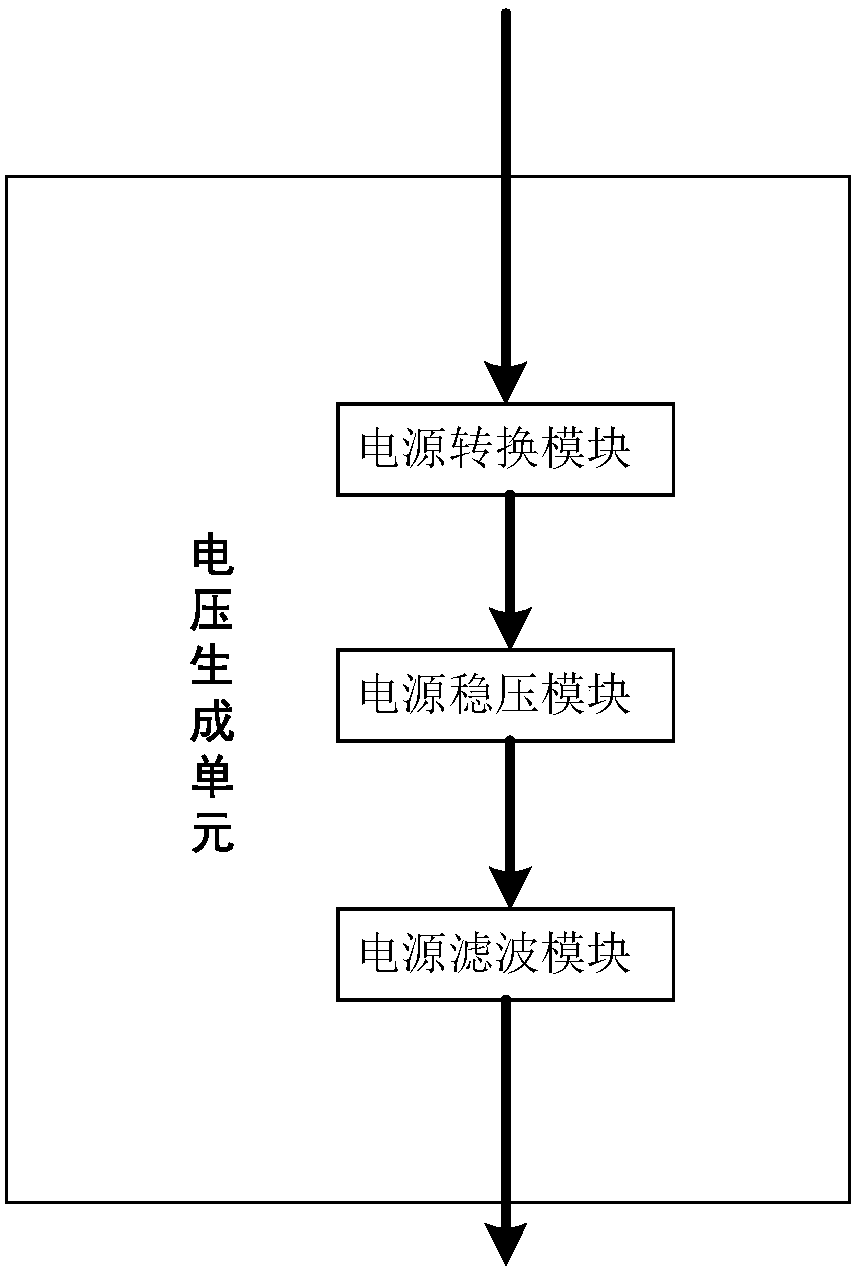

Simulated battery

The invention relates to a simulated battery comprising a voltage generating unit for establishing electrical connection with an external power supply, generating a battery voltage and outputting thevoltage, a temperature detecting unit for sensing temperature information of an electrical device and outputting the information, and a battery information generating unit for generating a battery parameter and outputting the parameter. According to the invention, the battery function is simulated by using the circuit and no polymer battery material is used, so that the battery cost is lowered; problems of potential safety hazards of bump and explosion occurrence and an environment problem in traditional battery application are solved; and the accumulative testing costs of frequent replacementof the traditional mobile phone battery are lowered.

Owner:DATANG MOBILE COMM EQUIP CO LTD

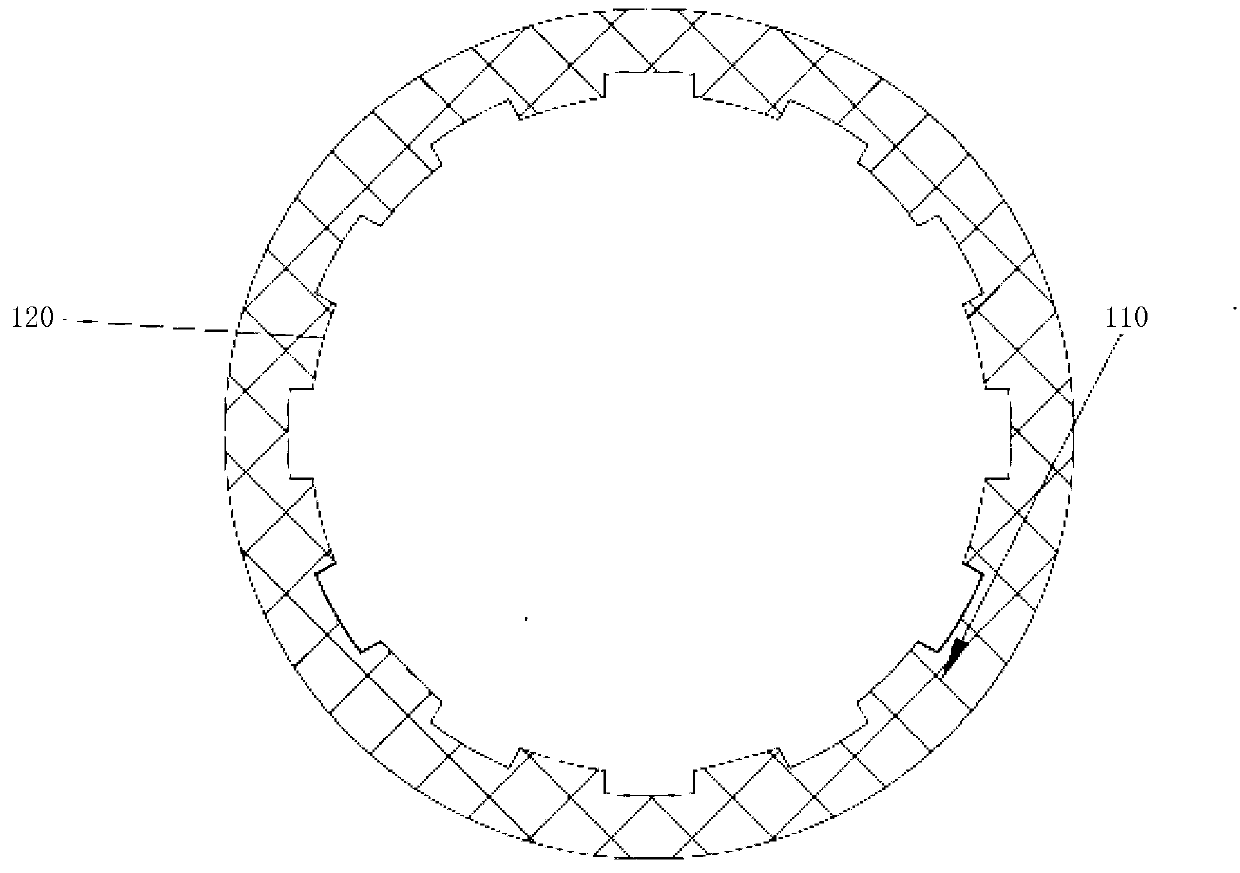

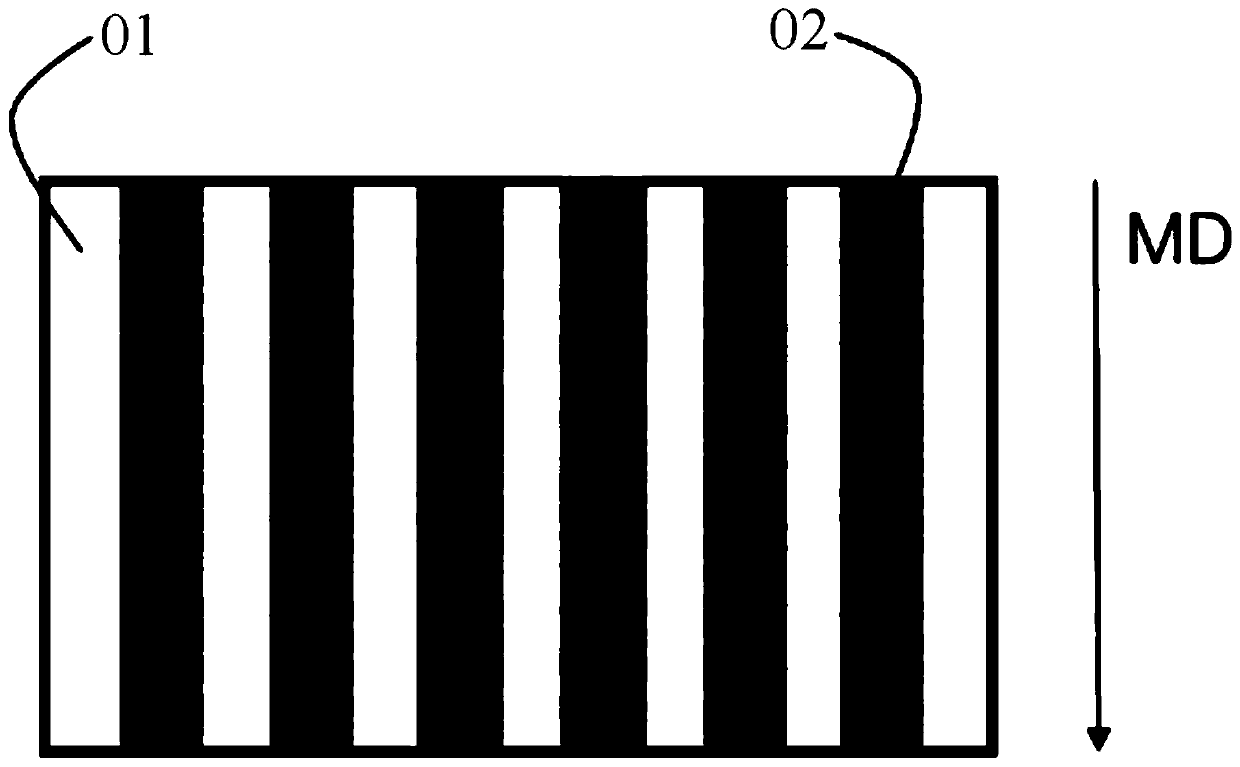

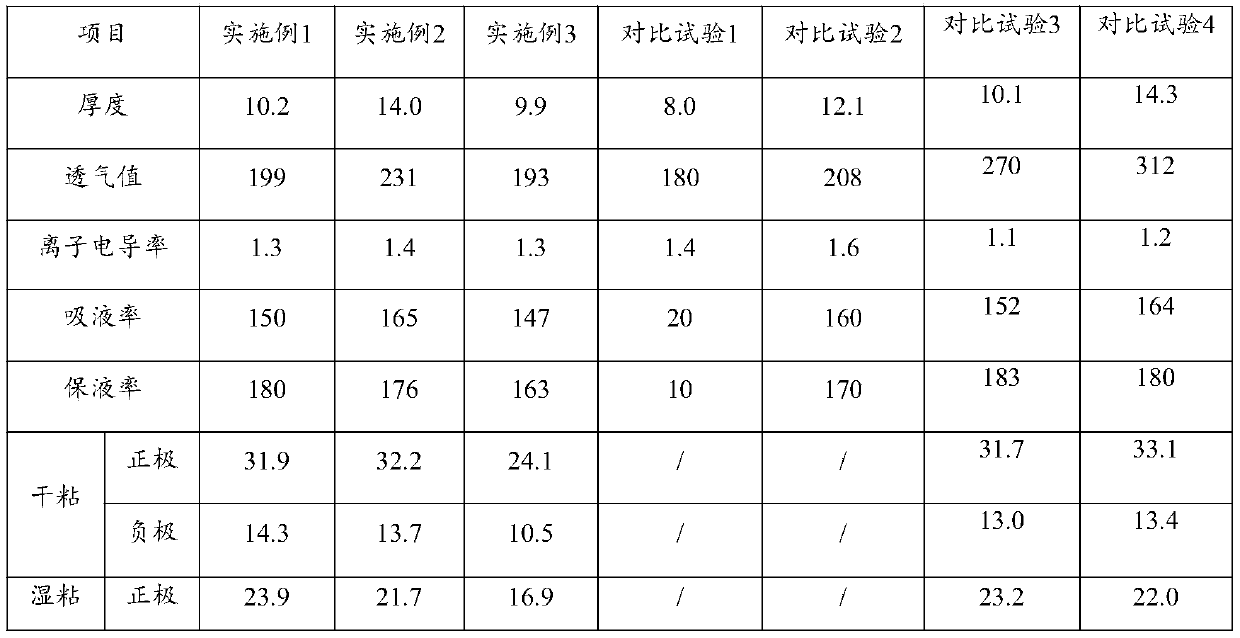

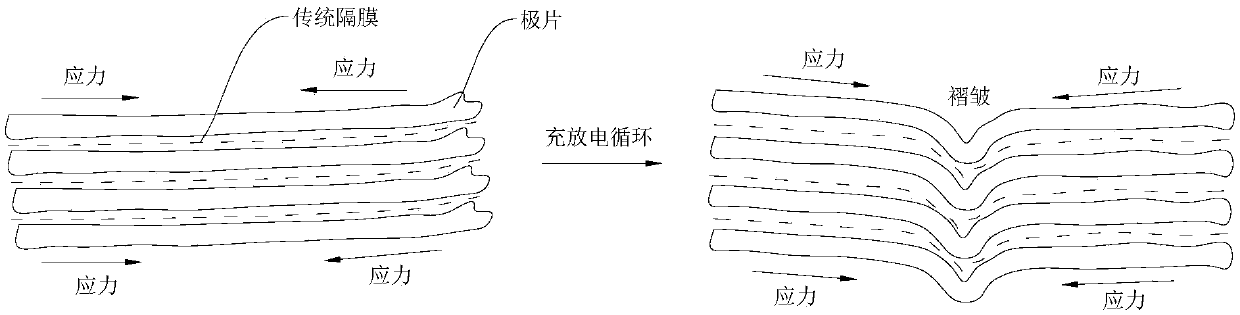

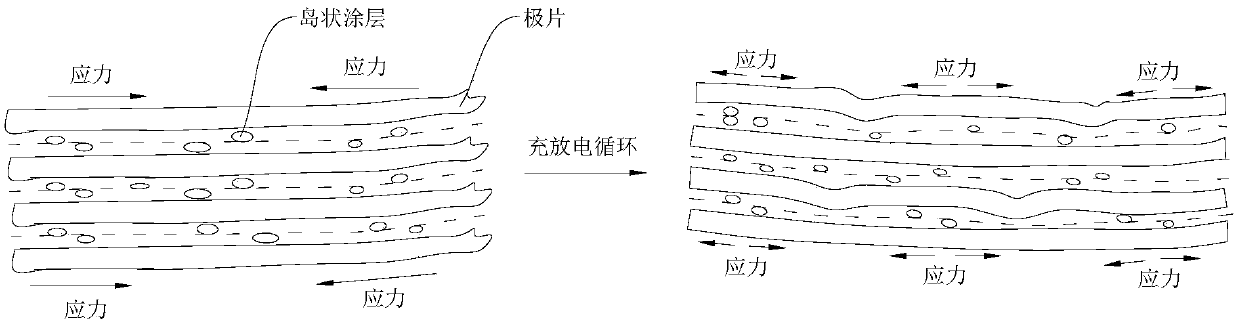

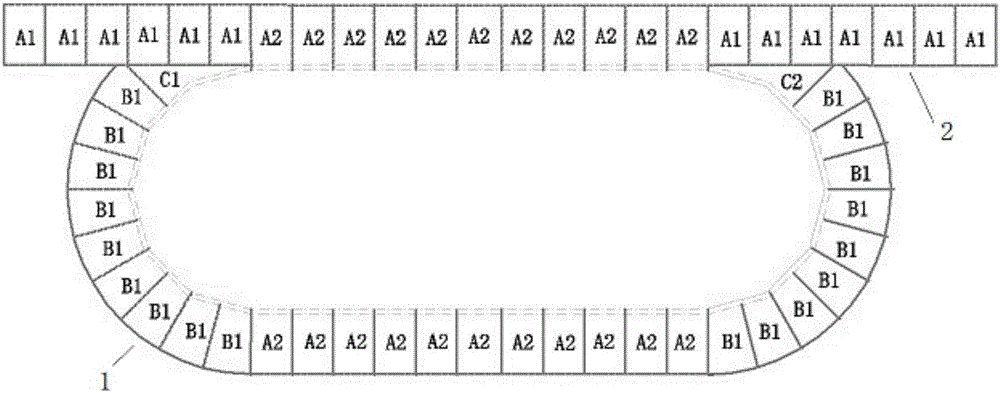

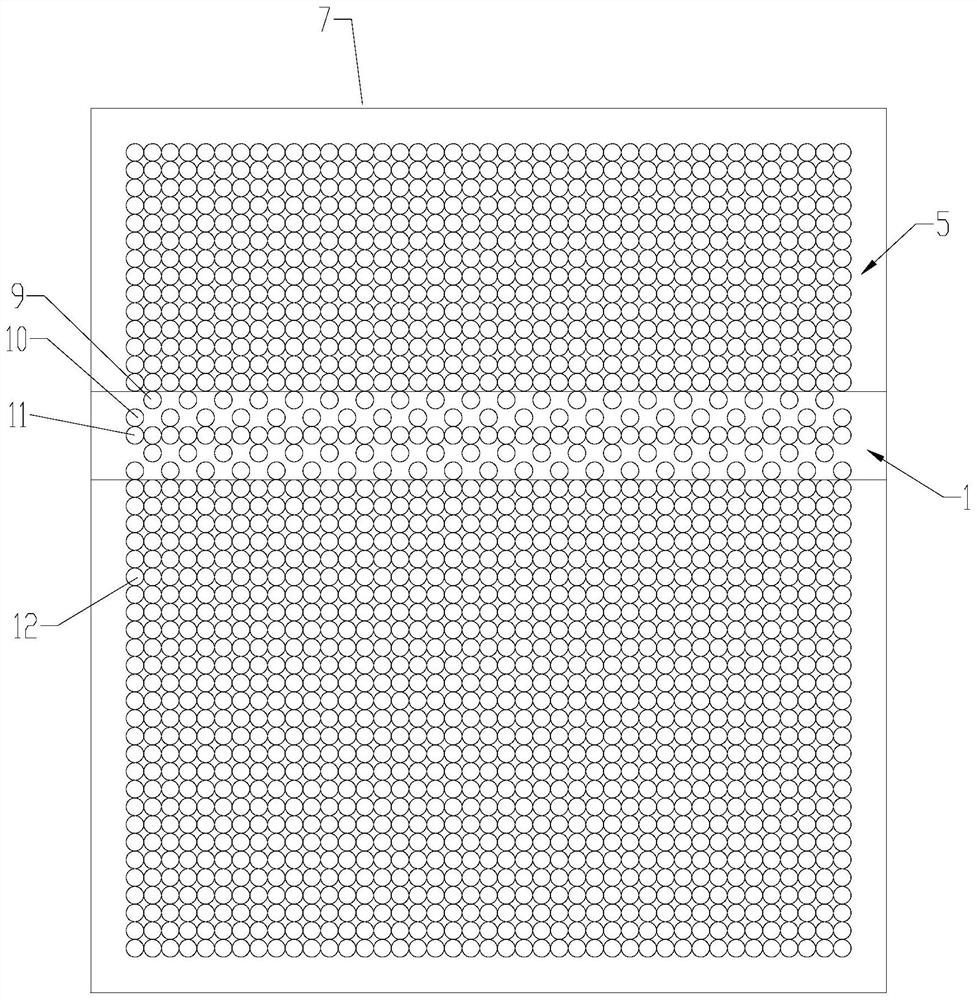

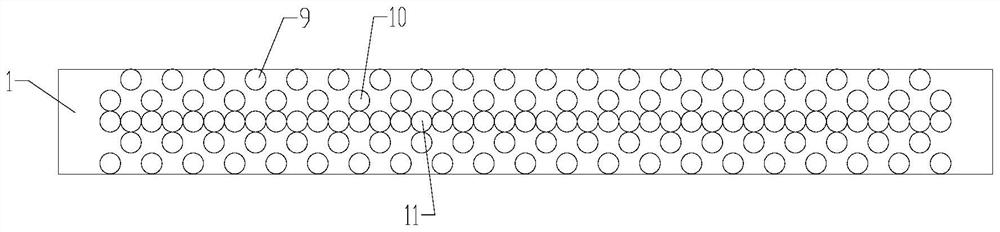

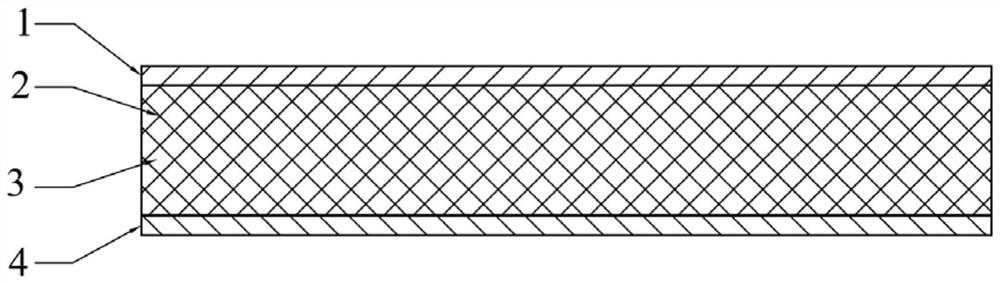

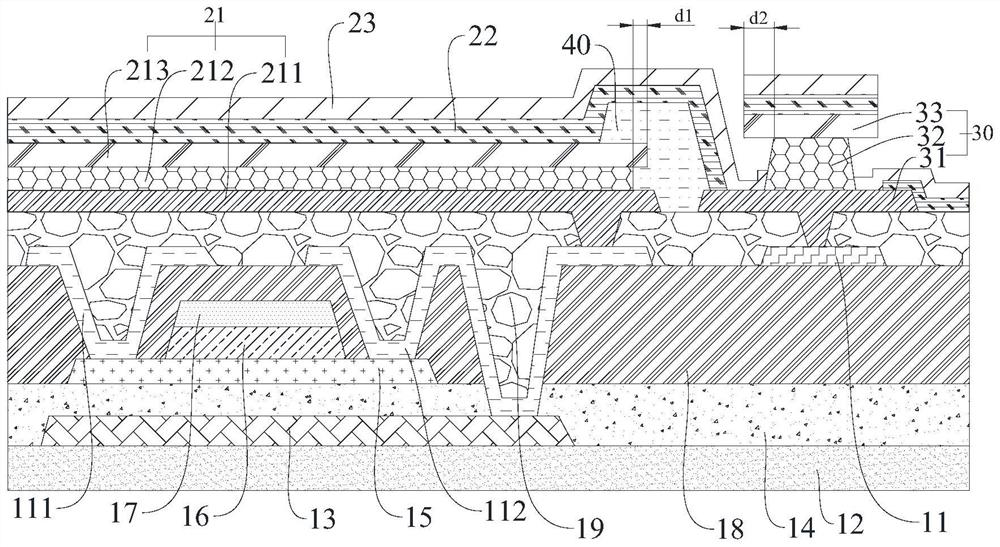

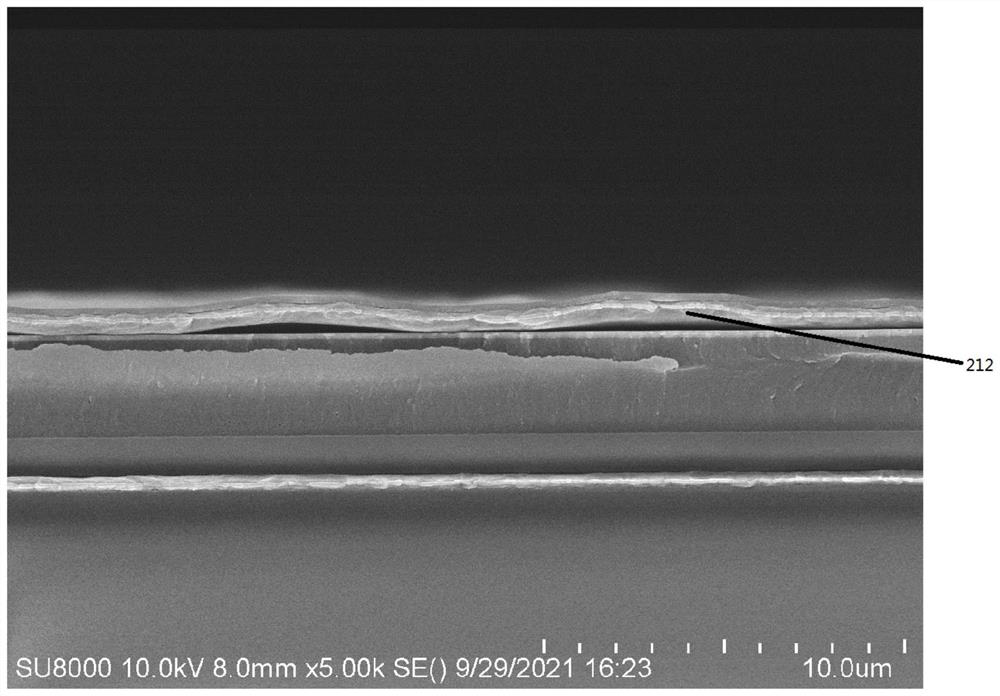

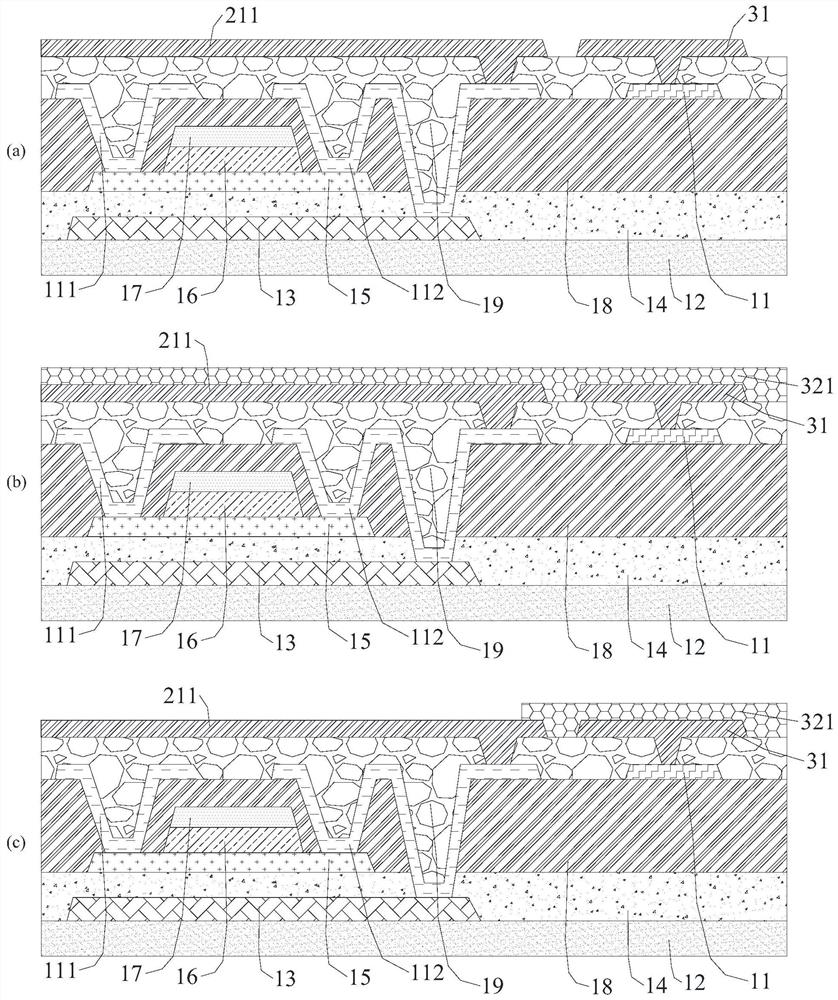

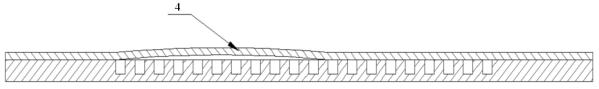

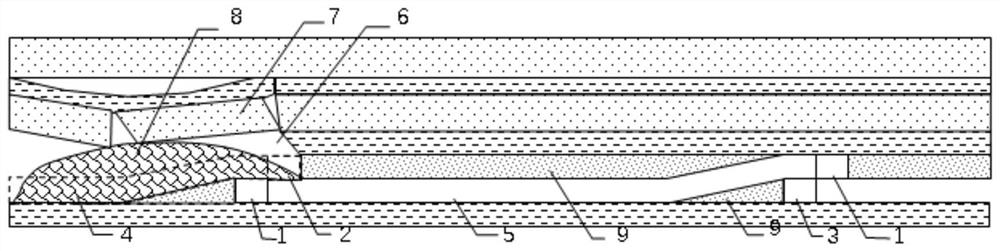

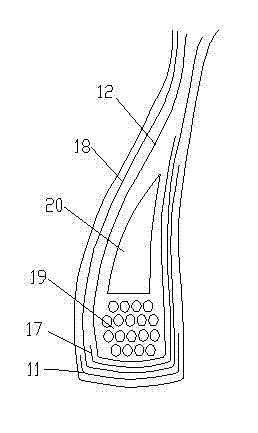

Coating diaphragm with improved structure and preparation method thereof

PendingCN111244374AImprove breathabilitySolve the bulgeSecondary cellsCell component detailsBattery energyLithium electrode

The invention discloses a coating diaphragm with an improved structure and a preparation method thereof. The coating diaphragm comprises a base membrane and a polymer coating coated on at least one surface of the base membrane, and the polymer coating is formed by coating coating slurry prepared from gel polymer particles on the surface of the base membrane. The polymer coatings are distributed onthe base membrane in a line shape in the longitudinal direction, wherein the line width ranges from 0.5 micrometer to 1 m, and the line interval ranges from 0.5 micrometer to 5 m. According to the coating diaphragm disclosed by the invention, through a specially designed striped coating structure, the problems of swelling of a battery cell and deformation of a battery are solved; the safety performance of the lithium ion battery is improved; and the service life of the battery is prolonged. The coating diaphragm disclosed by the invention can be used for manufacturing conventional square andcylindrical batteries and can also be folded to form other strip-shaped and polygonal special-shaped batteries by adjusting the line width and interval of the polymer coatings. The manufacturing direction of the battery cell is expanded, so that the safety of the battery is further improved, and the energy density of the battery is further increased. The cycle life of the battery is prolonged.

Owner:武汉中兴创新材料技术有限公司

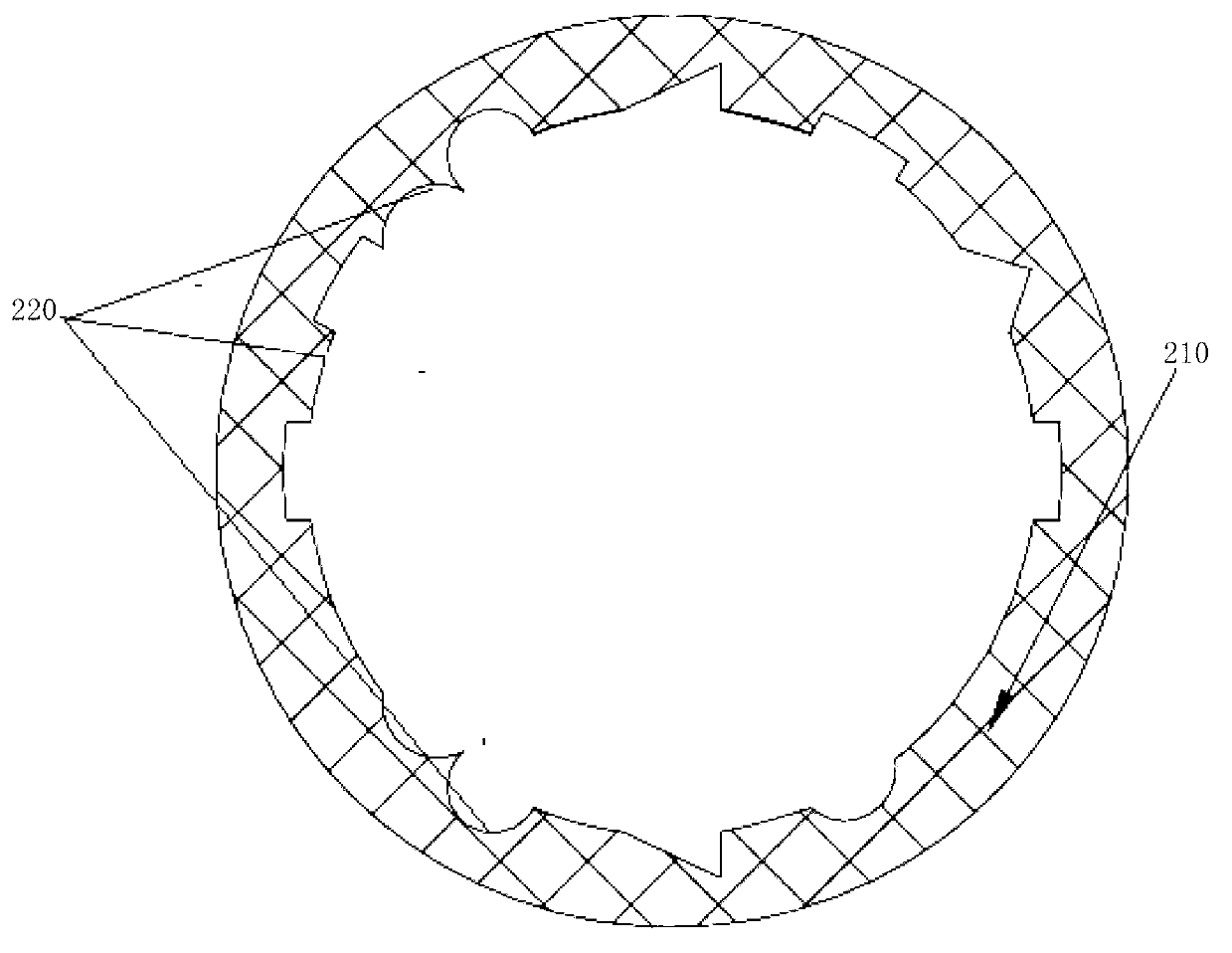

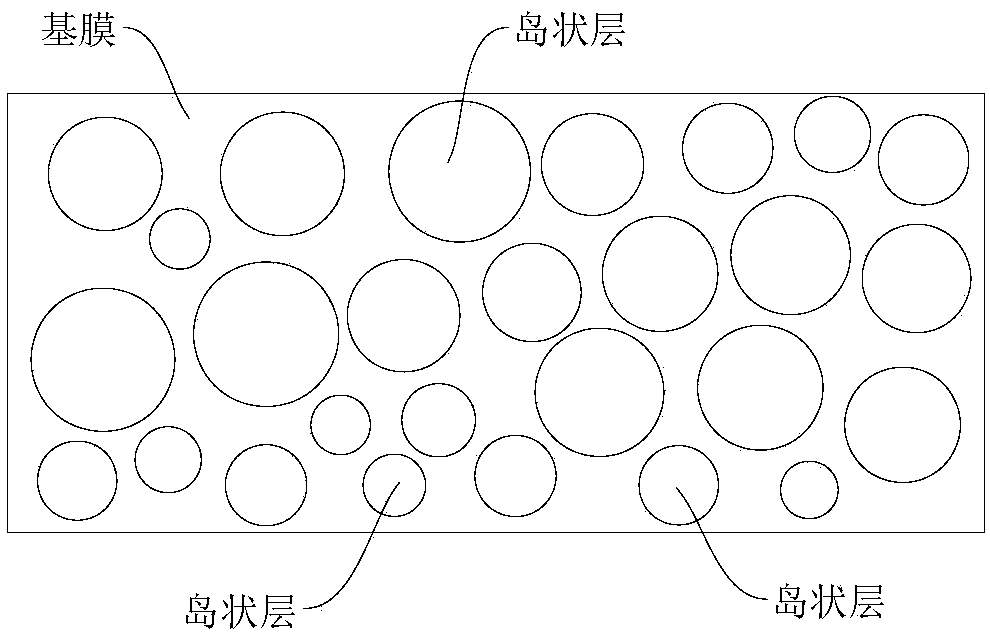

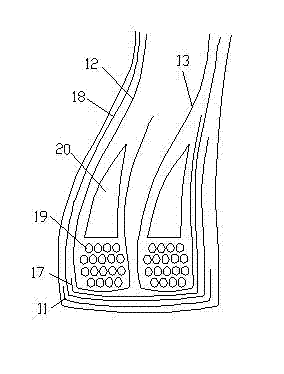

Functional diaphragm and preparation method thereof

ActiveCN109524603AStable structureElectrolyte resistantFinal product manufactureCell component detailsPolyolefinUV curing

The invention provides a functional diaphragm and a preparation method thereof, and relates to the technical field of lithium ion battery production. The functional diaphragm comprises a base film anda coating, wherein the base film comprises one or more of a polyolefin film, a polyolefin ceramic coating film, a non-woven fabric and a polyimide film; the coating is formed on the base film and isdistributed on the base film in the shape of an island; the coating is prepared from the following raw materials according to the parts by weight: 10-20 parts of photocurable resin, 5-10 parts of gelresin with an active functional group, 60-80 parts of main solvent, 4-10 parts of cosolvent and 0.01-0.1 part of photoinitiator. The preparation method of the functional diaphragm comprises the following steps of: applying a mixture of the photocurable resin, the gel resin with the active functional group, the main solvent, the cosolvent and the photoinitiator to the base film, and ensuring that the formed coating is distributed on the base film in the shape of island during applying. After applying, the functional diaphragm is subjected to UV pre-curing, pore-forming and UV curing in sequence. The functional diaphragm can solve the problem of battery bulging.

Owner:SHENZHEN SENIOR TECH MATERIAL

Method for bonding foam layer and aluminum alloy skin

The method belongs to the manufacturing technical field of foam sandwich structure composite material aeronautical parts. According to the swelling problem frequently happening to the surfaces of the aluminum alloy skin foam sandwich structure aeronautical parts, a method for bonding a foam layer and aluminum alloy skin is provided. The method specifically includes the several steps of being to bond the aluminum alloy skin, bonding a foam core, and performing vacuum pumping and pressure maintaining.

Owner:SHAANXI AIRCRAFT CORPORATION

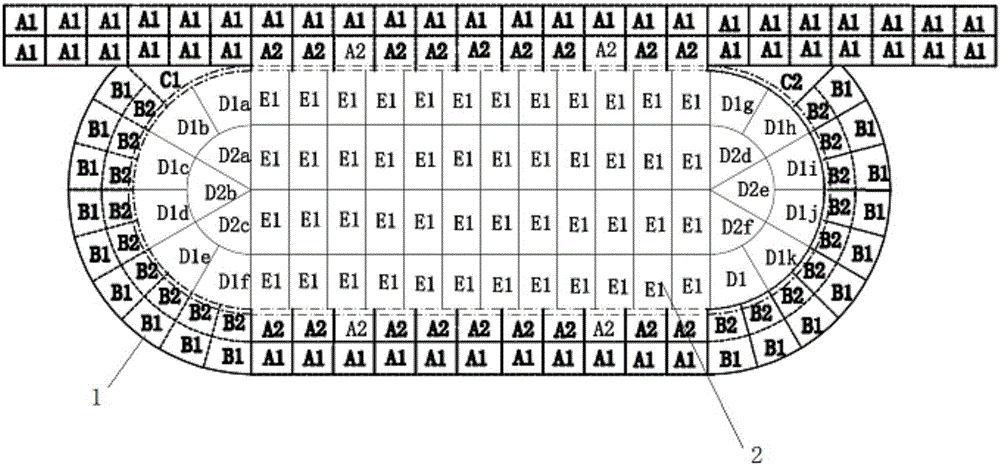

Site base

The invention provides a site base. The site base comprises a plurality of base modules, wherein each of the base modules comprises a first base module and a second base module; the first base modules are spliced to form an arc base; the second base modules are spliced to form a rectangular base; and the inner part of each of the base modules is hollow out, a space which allows a person to enter is formed in the inner part of each of the base modules, and a drainage channel is formed in the inner side of each of the base modules. According to the site base disclosed by the invention, the site base is designed into a plurality of prefabricated base modules; the inner part of each of the base modules is hollow out; the space which allows overhaul staff to enter the inner part of the base for overhauling is formed in each of the base modules, and the base has good air permeability; the drainage channel is arranged in each of the base modules, so that the water level reducing capacity and drainage capacity of the base are improved; the site base has the advantages that the construction is simple, the construction period is shortened, and the resilience of the base is uniform; the service life of the structure of the base is prolonged; and the problems that a conventional site base is long in construction period, poor in venting property and water draining property, low in capacity for resisting frost heaving, easy to be subjected to frost cracking and swelling, difficult in basic maintenance and the like are solved.

Owner:HUNAN YOUGUAN SPORTS MATERIAL CO LTD

Mattress and electric bed

PendingCN114052433ASolve the bulgeReduce mutual extrusionStuffed mattressesSpring mattressesElectric bedBed boards

The invention relates to the technical field of electric beds, and particularly discloses a mattress and an electric bed. The mattress is provided with a bending area, the bending area comprises at least one deformation area, and the deformation area comprises a first elastic structure and a second elastic structure which are sequentially arranged in a first direction; and the first elastic structure comprises a plurality of first elastic pieces distributed in the second direction, the second direction is perpendicular to the first direction, the second elastic structure comprises a plurality of second elastic pieces distributed in the second direction, and the first elastic pieces and the second elastic pieces are arranged in a staggered mode. When the mattress is bent, mutual extrusion between the adjacent first elastic pieces and second elastic pieces can be reduced, the tension of the first elastic pieces and the second elastic pieces is reduced, the problem that a bent area swells when the mattress is bent is fundamentally solved, and the attaching effect between the mattress and the bed board is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Sandwich structure radar radome and preparation method thereof

PendingCN112993562AImprove environmental adaptabilityMeet the electrical performance index requirementsLaminationLamination apparatusHoneycombMesh grid

The invention relates to a sandwich structure radar radome and a preparation method thereof. The sandwich structure radar radome comprises a skin I, a filling core layer and a skin II; the filling core layer comprises a honeycomb core layer and honeycomb filler filled in grids of the honeycomb core layer, and the honeycomb filler is formed by mixing and curing a resin material and hollow glass beads. The method comprises the following steps: preparing a skin blank; bonding the a honeycomb core layer to the skin blank, and obtaining a prefabricated body comprising the skin I and the honeycomb core layer through autoclave curing forming; uniformly mixing the resin material and hollow glass beads with a solvent and / or a diluent, and filling the mixture into grids of the honeycomb core layer included in the prefabricated body; and finally, pasting a glue film and a skin II prepreg on the surface of the honeycomb core layer, and obtaining the sandwich structure radar radome through autoclave curing forming. The environment adaptability of the radome can be improved, the problem that the skin and the honeycomb core layer are prone to debonding and bulging in the hanging process of the radome is solved, the electrical performance index requirement of the radome is met, and meanwhile the product reliability is guaranteed.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

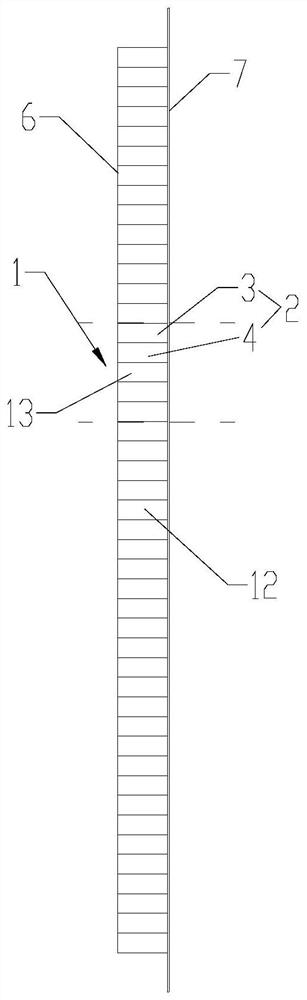

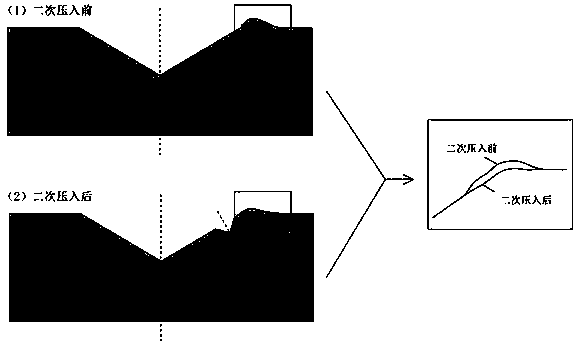

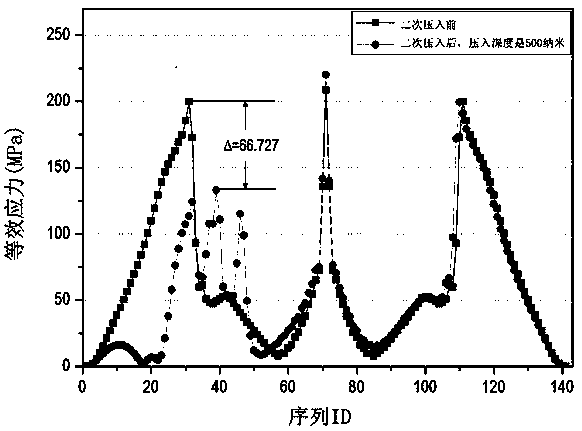

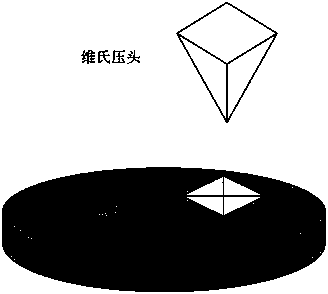

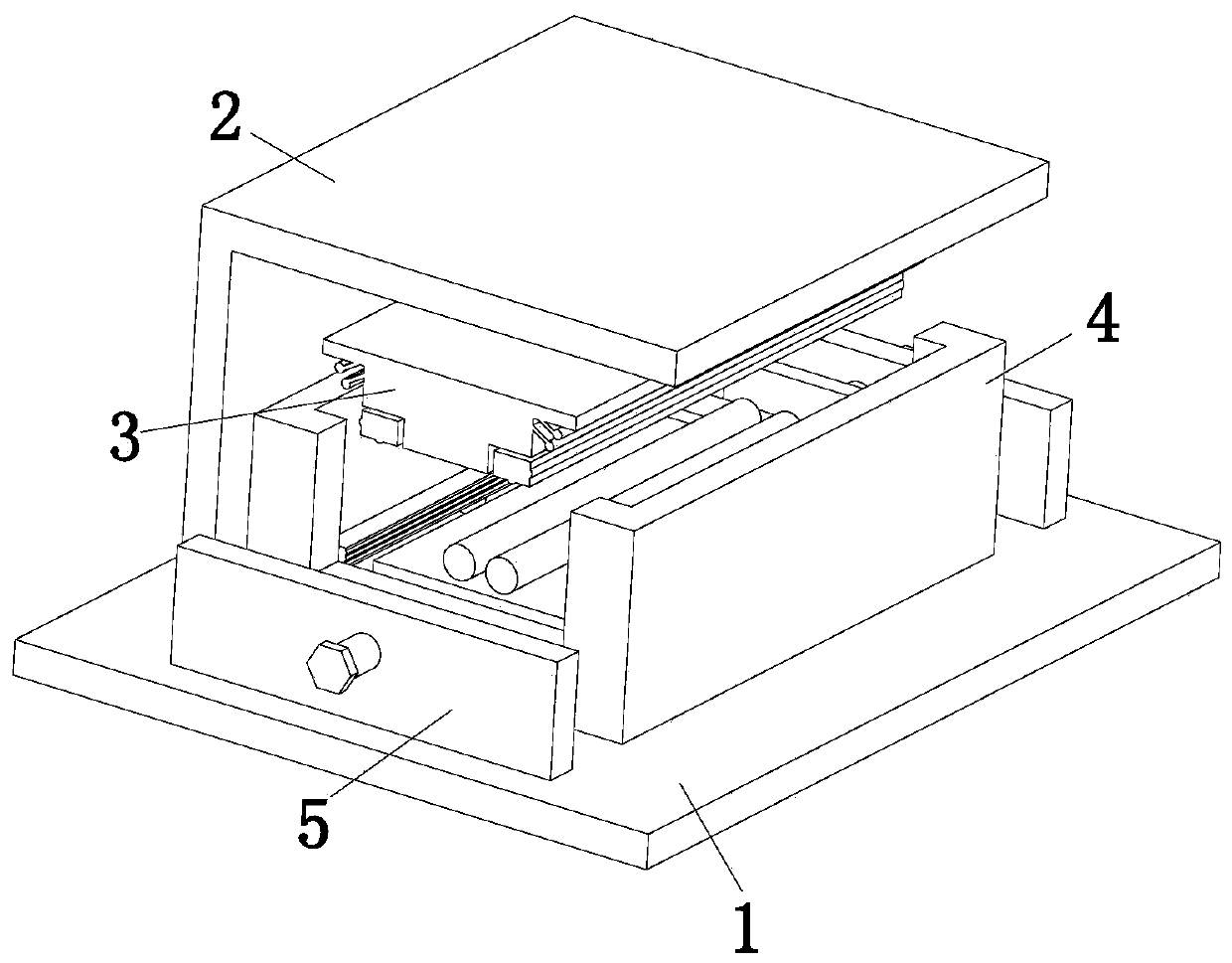

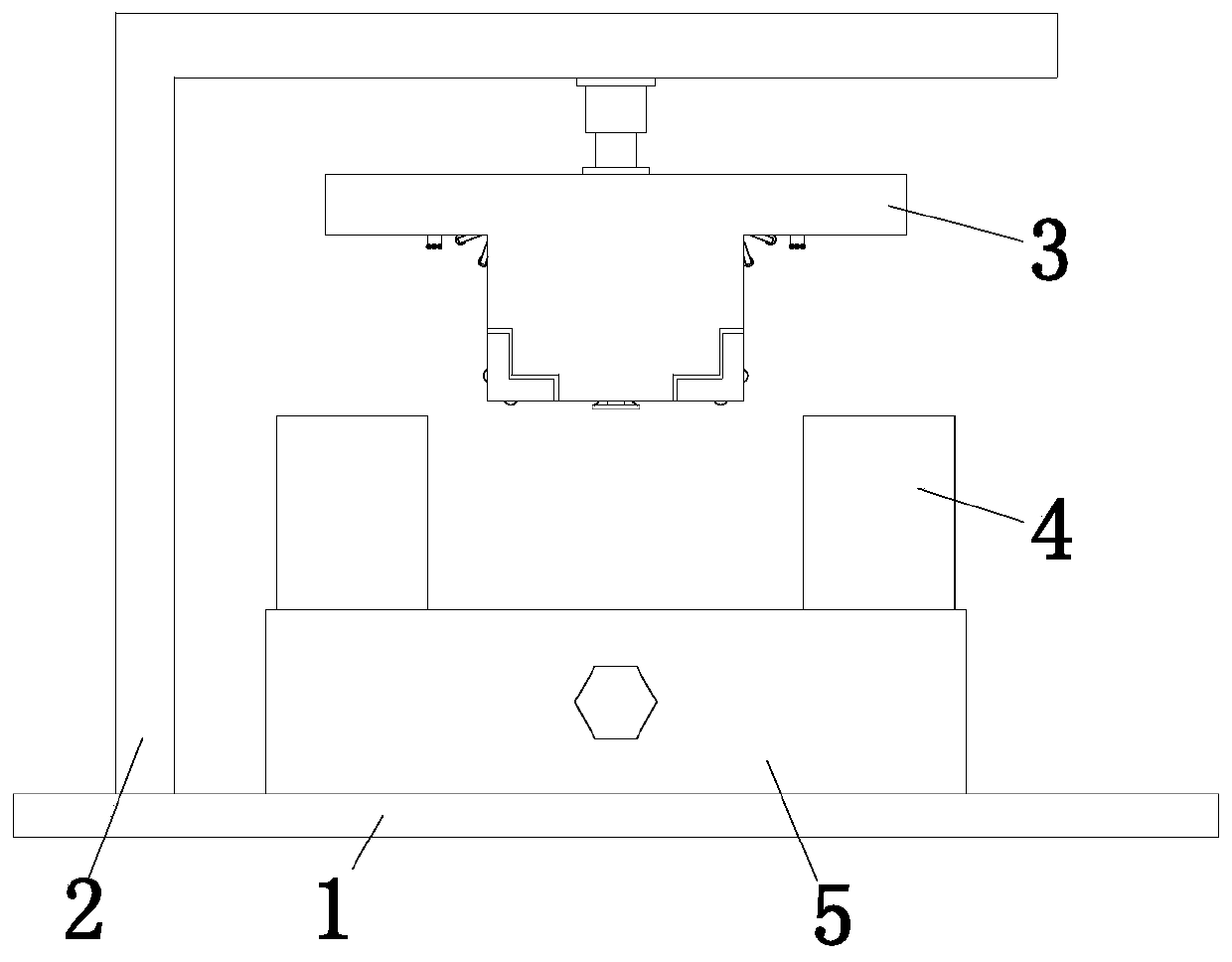

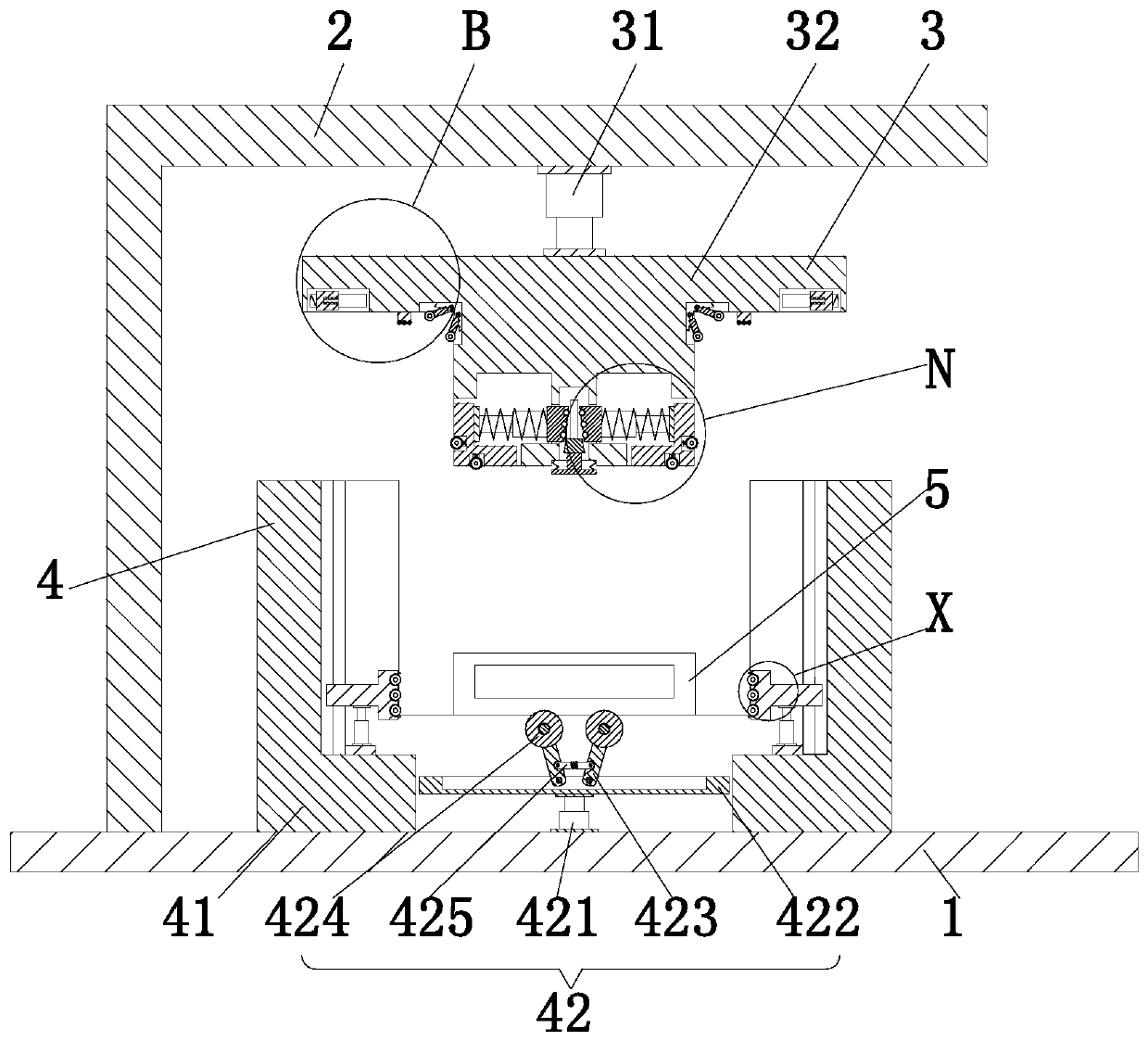

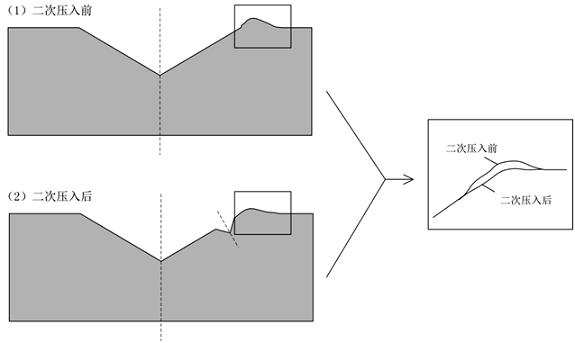

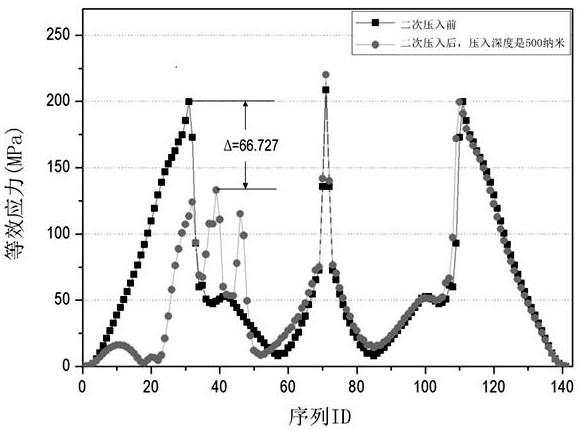

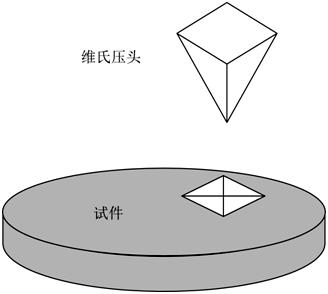

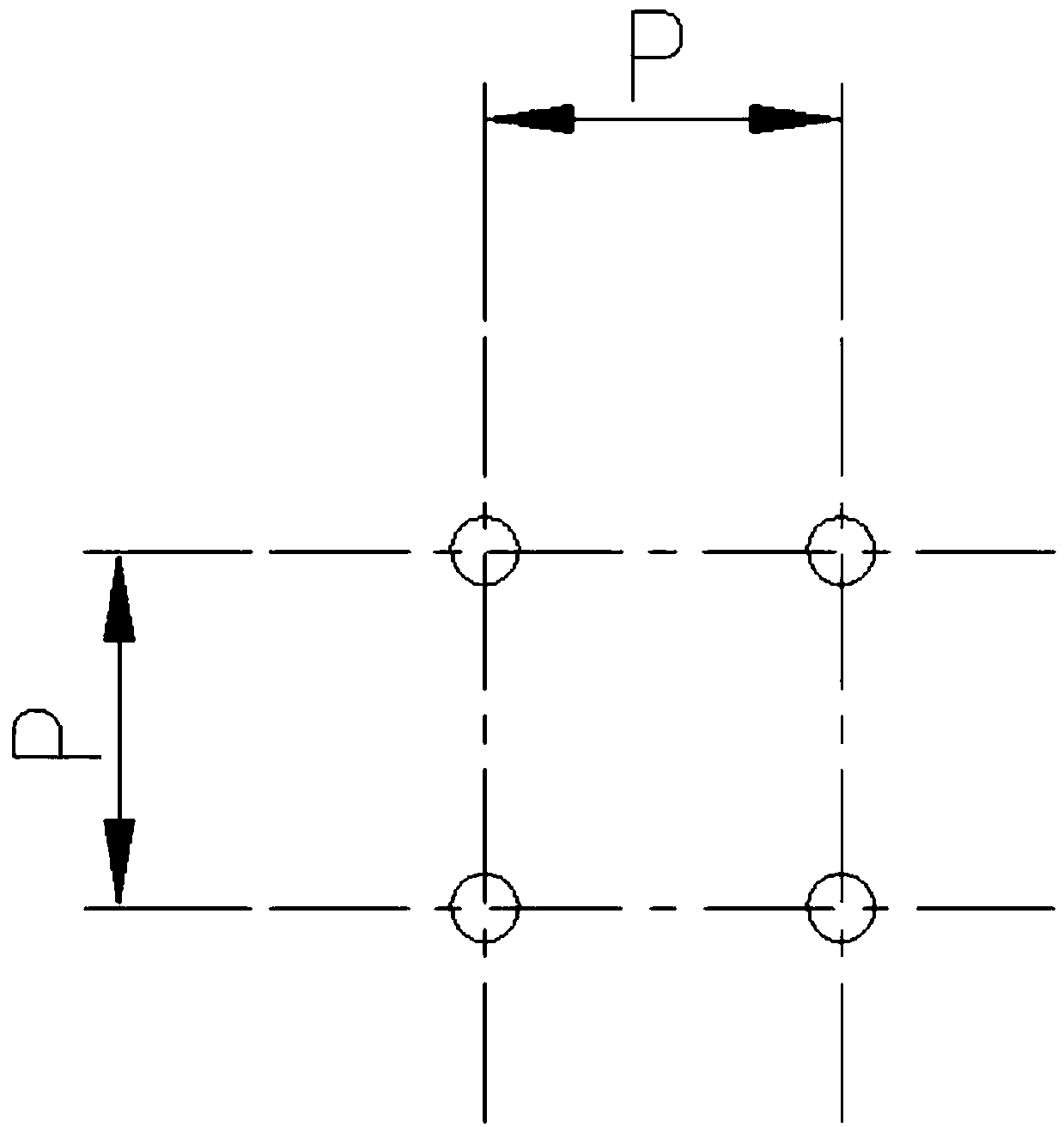

Method for realizing surface planarization of a pit-shaped micro-array structure unit through secondary pressing

ActiveCN109740184ASave energyEasy to operateSpecial data processing applicationsStructure of the EarthEngineering

The invention relates to a method for realizing surface planarization of a pit-shaped micro-array structure unit through secondary pressing, and belongs to the field of machinery. The machining process of the pit-shaped micro-array structure unit is simulated, that is, a Vickers pressure head is pressed into the surface of a material to form a pit unit with the characteristic size being in the micron order, and due to the effect of force borne by the surface of the material, a protruding phenomenon can be formed on the periphery of a pit and exists along with residual stress. In order to flatten the surface and reduce the residual stress of the surface, a cubic angle pressing needle is used for vertically pressing the side faces of the pit units with the feature sizes of micron order to form indentations with the feature sizes of nano order to release the residual stress stored in the material, so that the purpose of flattening the functional surface is achieved. The method provides asurface planarization method for the functional surface of the microarray structure manufactured by the precision machining technology. Operation is easy, equipment functions are rich, and the devicecan be used for large-scale batch machining.

Owner:JILIN UNIV

Aluminum alloy profile surface protection treatment system and protection treatment method

The invention relates to an aluminum alloy profile surface protection treatment system and a protection treatment method. The aluminum alloy profile surface protection treatment system comprises a bottom plate, a supporting frame, an upper die device, a lower die device and a clamping device; the supporting frame is arranged at the upper end of the bottom plate; the supporting frame has an L-shaped structure; and the upper die device is arranged on the inner end face of the upper end of a supporting rod. The aluminum alloy profile surface protection treatment system can solve the problems in existing equipment that a protective film is liable to bulge or fall off because the right-angle position of the inner surface of aluminum alloy cannot be stuck tightly when the protective film is stuck on the surface of the U-shaped aluminum alloy profile, the protective film loses the protective effect and the sticking efficiency and use rate of the protective film are reduced because bubbles cannot be eliminated completely in the sticking process as well as the service life of the protective film is reduced because the tail end of the protective film is liable to warp and fall off in the useprocess of the protective film caused by the fact that the tail end of the protective film cannot be treated again.

Owner:宁波金琪铝合金表面处理有限公司

Display backboard, manufacturing method thereof and display device

PendingCN114709244ASolve the problem of large pressure dropImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhysics

The invention provides a display backboard, a manufacturing method thereof and a display device. In the display backboard, a light-emitting structure comprises a first electrode layer, a light-emitting layer and a second electrode layer, at least part of the light-emitting structure is located in an opening of a pixel definition layer, and the first electrode layer is arranged close to a substrate; the isolation structure is located on the side, away from the opening, of the pixel definition layer; one part of the second electrode layer extends to the side surface, close to the pixel definition layer, of the isolation structure from the opening of the pixel definition layer along the pixel definition layer through a gap between the pixel definition layer and the isolation structure, and the second electrode layer is electrically connected to the isolation structure; the light-emitting layer is not connected at the gap between the pixel definition layer and the isolation structure; in the direction perpendicular to the substrate, the height of the isolation structure is larger than that of the first electrode layer. The thickness of the first electrode layer is small, the problem that a metal film layer of the reflection first electrode layer swells or falls off can be smoothly solved, and then the display effect and the product yield of the product are remarkably improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

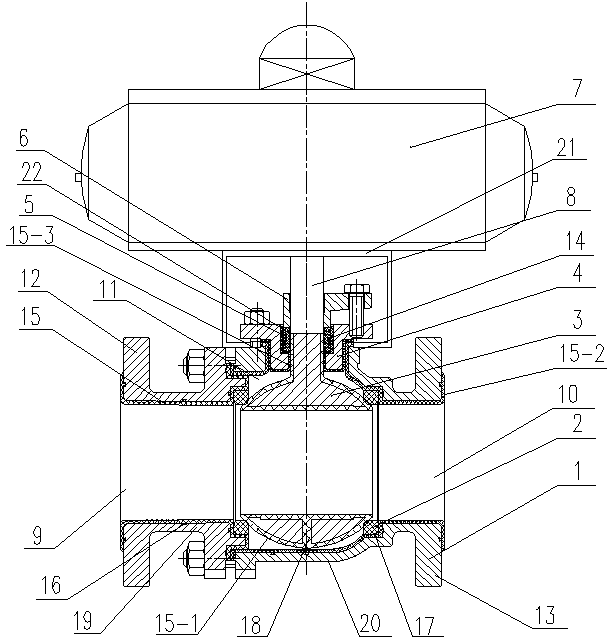

Fluoroplastic full-lining cutting ball valve

InactiveCN108386569ASolve the force problemAvoid accidentsPlug valvesOperating means/releasing devices for valvesFilling materialsEngineering

The invention discloses a fluoroplastic full-lining cutting ball valve, and relates to a special valve. The fluoroplastic full-lining cutting ball valve comprises a valve body, a valve seat, a valve cover, a valve rod and a valve ball. The valve body is provided with an inlet, an outlet and an upper end connecting opening, the inlet and outlet are separately connected with inlet and outlet flanges, the valve cover is fixed to the upper end connecting opening through a bolt and a nut, the valve rod passes through the valve cover to be fixed, and the valve rod is sealed with the valve cover through arranging filling materials between the valve rod and the valve cover. The valve ball is arranged in the valve body, the valve rod and the valve ball are arranged integrally through casting, and afluoroplastic layer is arranged on the inner side wall of the valve body in a full-lining mode. Fluoroplastic layers are arranged on the inner and outer surfaces of the valve ball, and on the valve rod arranged in the valve body, and a fluoroplastic layer is arranged on the inner side surface of the valve cover. The valve rod and a ball body are processed by a machine tool after being whole forged, the problems that the valve rod is prone to being applied with force and a ball body is broken after welding the ball body and valve rod and a valve door cannot open due to the breaking of the valve rod and the ball body, and accidents are avoided; and the valve body and valve ball are fully lined with fluoroplastics, the fluoroplastic full-lining cutting ball valve can run reliably under environment with strong acid and strong base and has high corrosion resistance.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

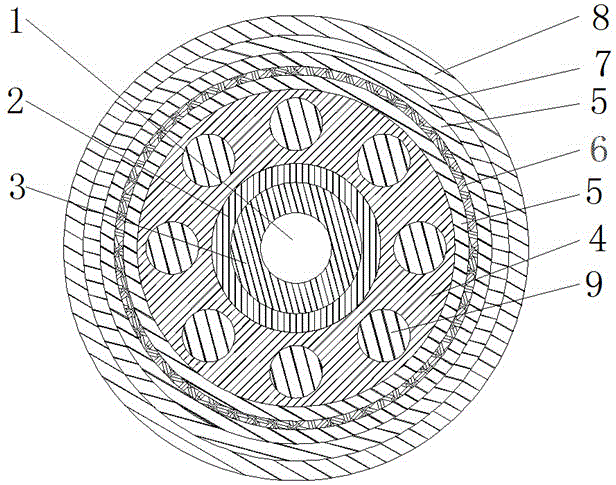

Fireproof, moistureproof and corrosion-resistant photoelectric composite cable

InactiveCN105590686APrevent from being oxidized and corrodedGood waterproof performancePower cables with screens/conductive layersInsulated cablesCorrosion resistantInternal layer

The present invention provides a fireproof, moistureproof and corrosion-resistant photoelectric composite cable, comprising an optical fiber (1), an optical fiber filling gel (2), a steel armour sheath layer (3), a medium filling layer (4), a corrosion-resistant asphalt layer (5), a fireproof layer (7), and an outer sheath layer (8) which are successively arranged from inside to outside; wherein a shielding layer (6) is wrapped in the corrosion-resistant asphalt layer (5), the shielding layer (6) comprises an internal layer copper plastic composite belt and an external layer aluminum magnesium braided belt; the medium filling layer (4) comprises a fiber belt provided with micropores, a flame-retardant layer and a waterproof layer, the flame-retardant layer, the fiber belt and the waterproof layer are adhered successively.

Owner:CHENGDU JETCOM TECH

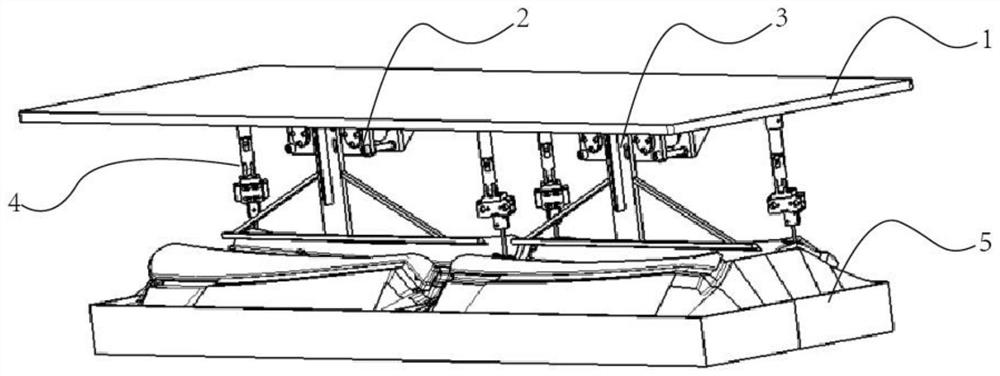

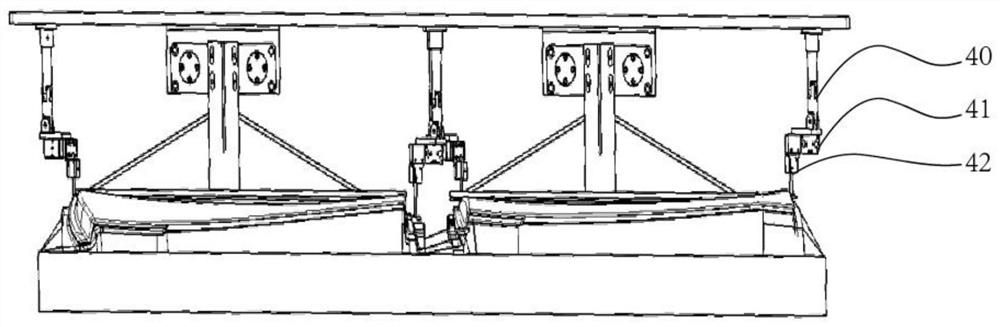

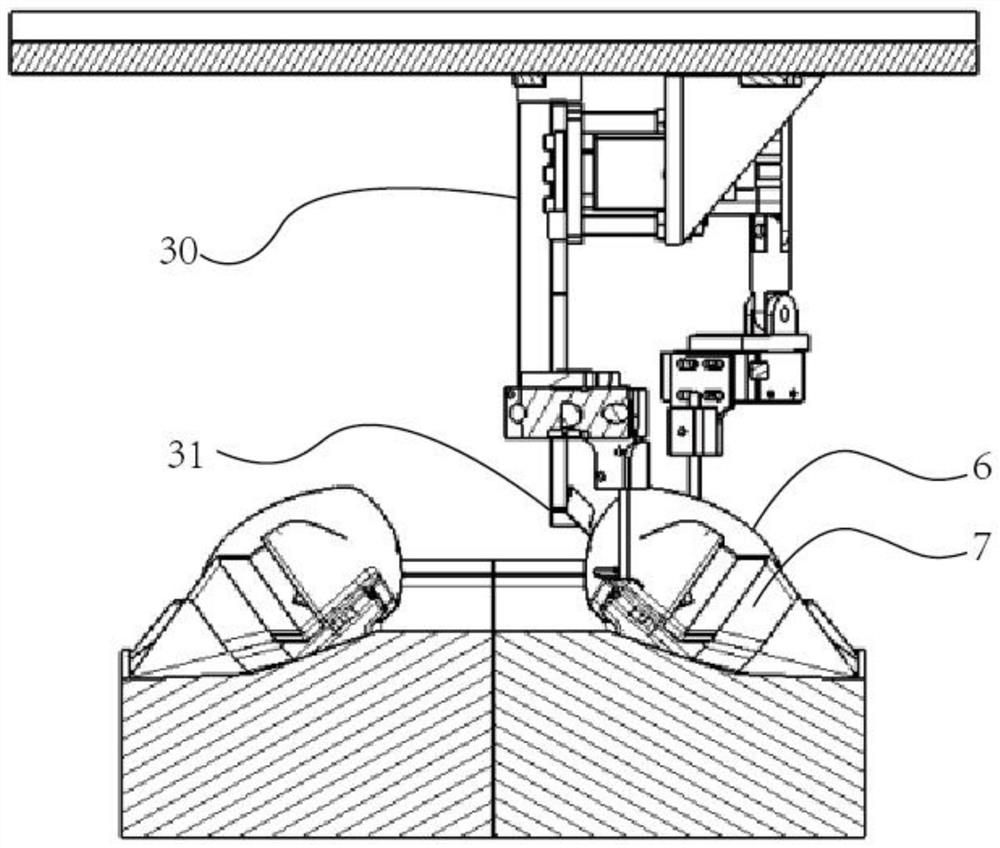

Composite Auxiliary Mechanism and System of Male Die for Upper Guard Plate of Automobile

ActiveCN112046643BSolve the flatnessSolve the bulgeDoorsVehiclesStructural engineeringMechanical engineering

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

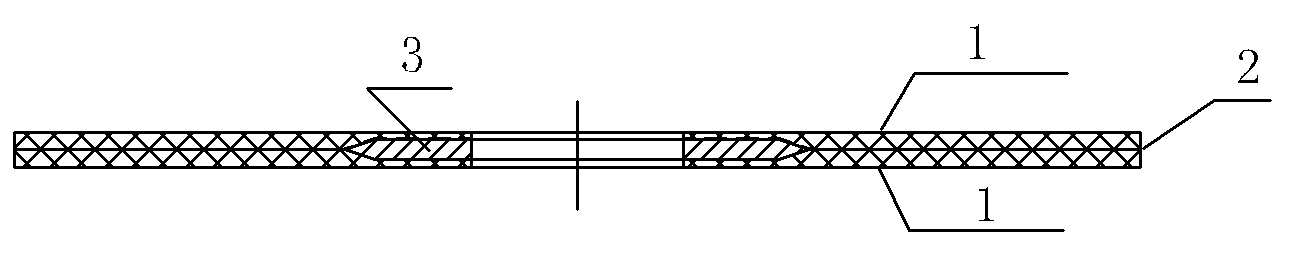

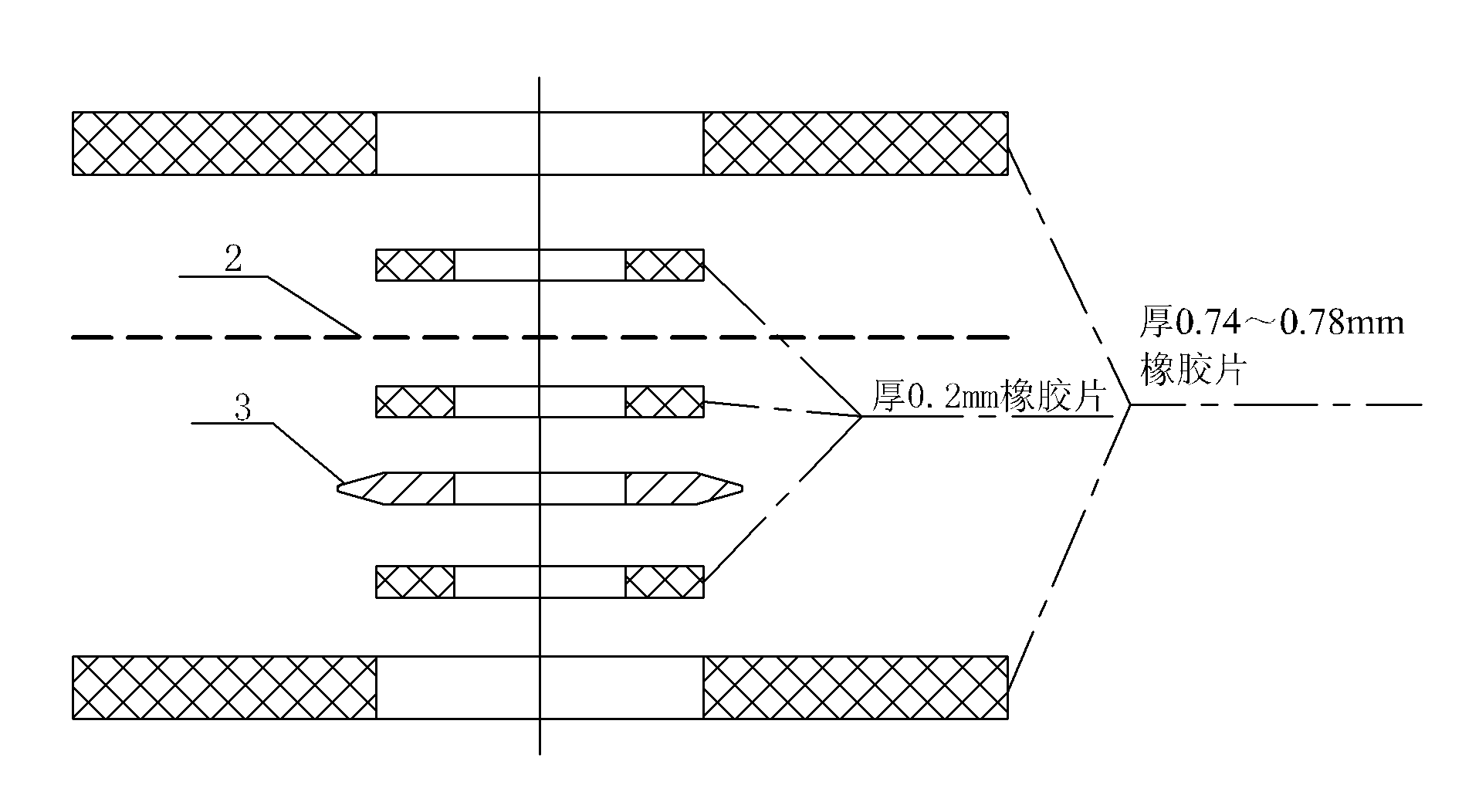

Rubber fabric clamped film sheet and manufacturing method thereof

ActiveCN102563189BImprove fatigue resistanceGood adhesionOperating means/releasing devices for valvesFibre treatmentRubber materialMetal framework

The invention relates to a rubber fabric clamped film sheet and a manufacturing method thereof. The rubber fabric clamped film sheet comprises a rubber material film sheet body which is provided with a central hole, wherein the film sheet body is internally provided with a reinforced fabric interlayer and a disc-shaped metal framework; the shape of the reinforced fabric interlayer is consistent with that of the film sheet body; the diameter of the outer circle of the metal framework is greater than the diameter of the central hole but smaller than the diameter of the outer circle of the film sheet body. The rubber fabric clamped film sheet, disclosed by the invention, solves the problem of mottled surface of the film sheet, the problem that the film sheet after being ground is difficult to separate and the problem that surface bulge and rubber layer fracture of the film sheet are resulted after the film sheet is peeled off forcibly. The rubber fabric clamped film sheet, disclosed by the invention, has the advantages of high pressure resistance, good leak tightness, high stability of pressure adjustment as well as good high-temperature and low-temperature pressure adjustment characteristics, and is particularly suitable for reducing valves of liquid-propellant rocket engines with high requirements on performance and relatively high leak tightness as well as adjustability.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Method for improving edge profile of thin strip steel

The invention belongs to the field of thin-strip continuous casting, and relates to a strip shape control technology of hot-rolled thin strip steel, in particular to a method for improving the edge profile of continuous casting thin strip steel. According to the method, the continuous casting speed of the thin strip steel is adjusted in real time in the casting process, so that the purpose of improving the edge strip shape profile of the continuous casting thin strip steel is achieved. According to the method for improving the edge profile of the thin strip steel, the edge strip shape profile, the secondary edge strip shape profile and the strip shape profile of the strip steel center area in the continuous casting process of the thin strip steel are detected, and a mathematical model is established through extreme values of scatter values of the strip shape profiles of the three areas and the continuous casting speed. The mathematical model is applied to continuous casting speed control in the continuous casting process of the thin strip steel, so that real-time continuous casting speed response is achieved, the overall strip shape profile of the continuous casting thin strip steel is improved by adjusting the continuous casting speed, the edge profile of the thin strip steel is improved, therefore, the problems that the edge thickness of the continuous casting thin strip steel is too large, and the edge of a steel roll of the thin strip steel swells are solved.

Owner:SHAGANG GROUP +2

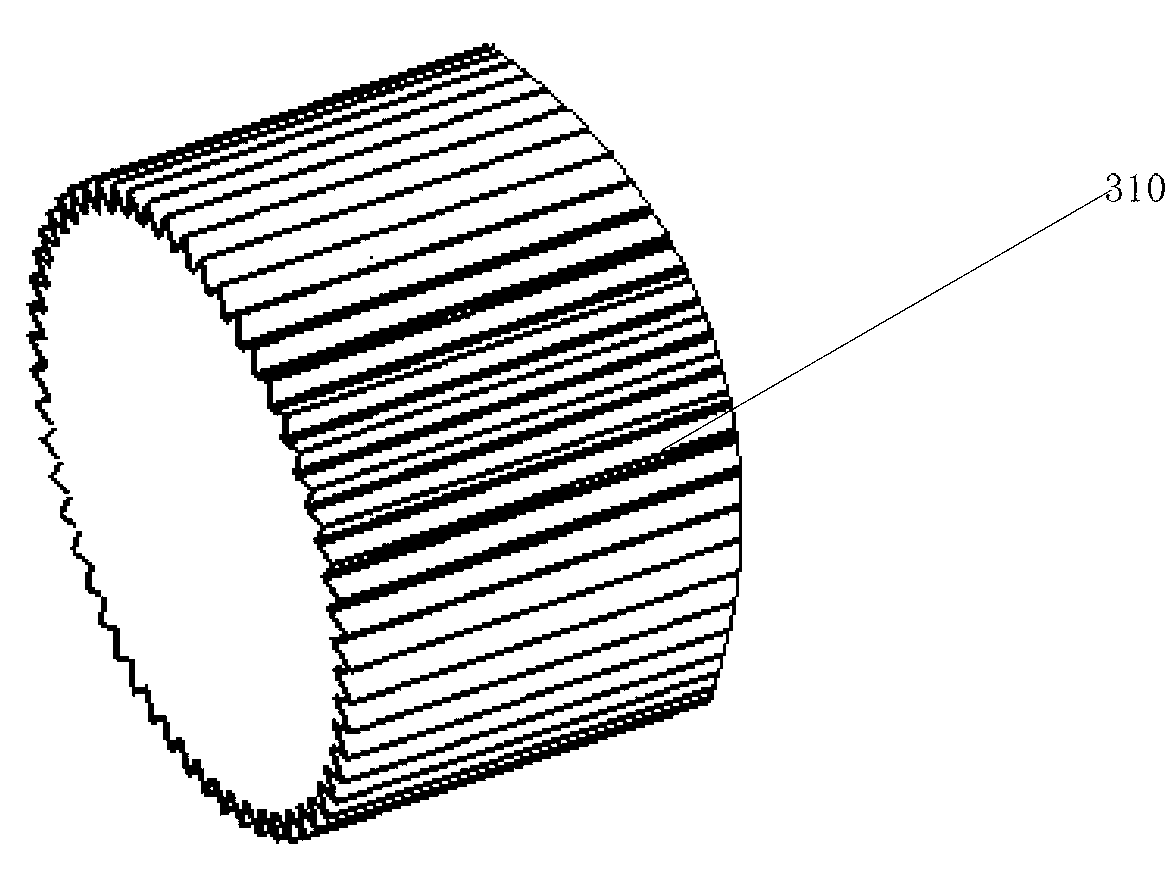

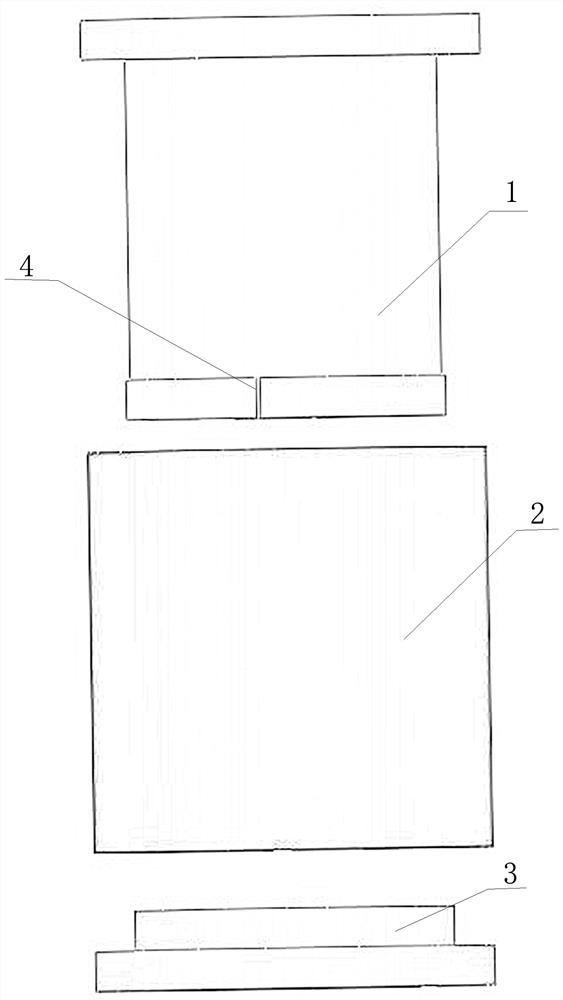

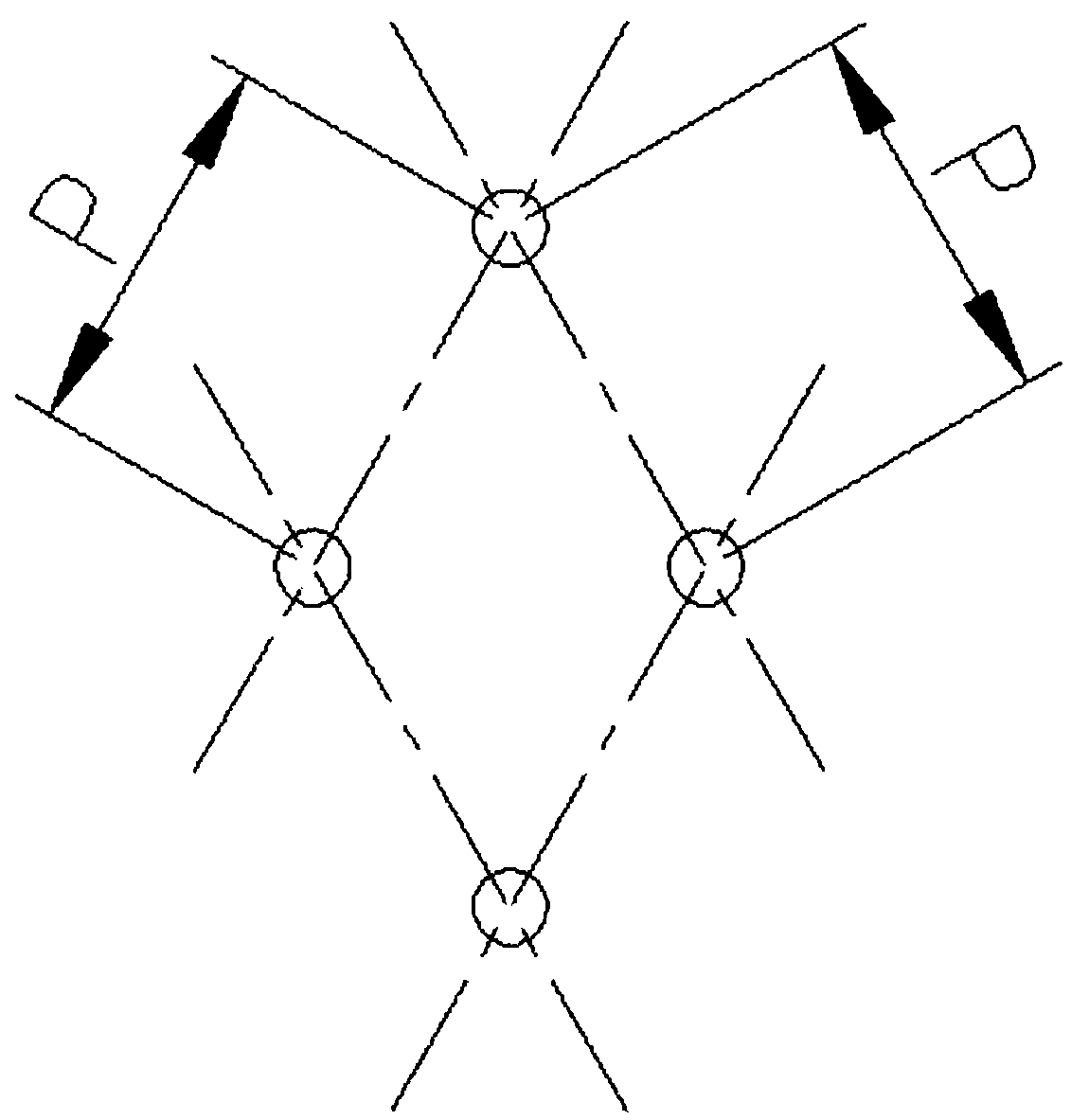

A kind of process of making magnesium oxide composite sheet

ActiveCN108101513BNo pollution in the processImprove working environmentUltra-high pressure processesOxide compositeBoron nitride

The invention provides a process for making magnesia composite sheets. Using the properties and functions of magnesia powder, by adding a certain amount of zirconia powder and pressing with a special abrasive tool, the magnesia composite sheet is specially baked. The process produces magnesium oxide composite sheets for diamond or cubic boron nitride synthesis, which improves its performance, ensures the stability of quality, and improves the synthesis stability of diamond and cubic boron nitride.

Owner:ZHENGZHOU ZHONGNAN JETE SUPERABRASIVES

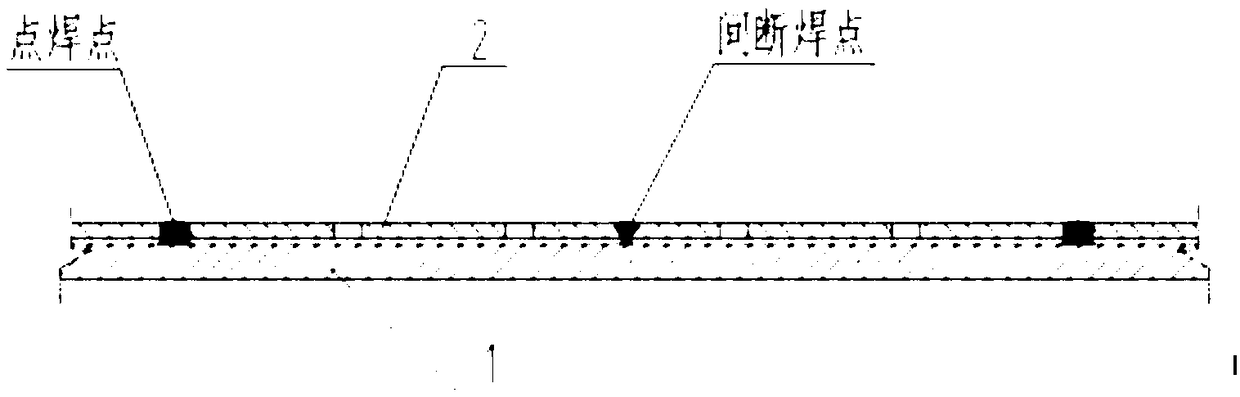

Wire clamping production method for improving tearing strength of carton

PendingCN112455059ASolve the bulgeTroubleshoot normal drivingMechanical working/deformationLamination ancillary operationsCompression moldingPolyester

The invention discloses a wire clamping production method for improving the tearing strength of a carton. The method comprises the following steps: carrying out pre-gluing treatment on 20 / 3 strands ofpolyester threads; adding the treated polyester thread with an adhesive into a specified position in a paperboard from a double-faced machine of a paperboard production line before the paperboard isbonded; carrying out gluing and pressing treatment on the paperboard, so that the upper paperboard, the lower paperboard and the polyester threads with the glue are pressed into a whole; drying the paperboard obtained after compression molding; and after drying, cutting the compressed and molded paperboard. According to the method, 20 / 3 strands of polyester threads are adopted, due to the specificity of the wire clamping material, the problem that normal driving is affected due to the fact that transverse cutter cutting cannot be conducted is solved, and the problem that due to the fact that the polyester wires are subjected to pre-gluing treatment, swelling is caused due to the fact that the clamping wires and the paperboard are not fully bonded is solved.

Owner:吉林化纤东昊工贸股份有限公司

Processing technology of cable sheath

The invention discloses a processing technology of a cable sheath. The processing technology comprises the following steps: (1) vulcanizing an inner sheath; (2) drying polyester yarns before machine starting, and placing for 3-4 hours; (3) vulcanizing an outer sheath, so that the angular difference of a die sleeve and a die core is 15-30 degrees, the matched die distance is 3-5 times of the thickness of the sheath, the bearing diameter of the die sleeve is 3-4 times of the thickness of the inner sheath; (4) carrying out ending operation of the outer sheath, wherein the time for reducing the steam pressure is reduced to be zero. The processing technology can solve the problems, such as die clamping, bulging and cracking, of 10 km cables generated in the extruding process of a cable outer sheath, and thus the production cost is greatly reduced; moreover, the product appearance is beautiful, and the outside diameter is stable.

Owner:ZHANGJIAGANG JINHAIGANG WIRE & CABLE

Method for realizing surface flattening of pit-shaped microarray structural unit by secondary pressing

The invention relates to a method for second pressing to realize the surface flattening of a pit-shaped microarray structure unit, which belongs to the mechanical field. The mechanical processing process of the pit-shaped microarray structure unit is simulated, that is, the Vickers indenter is used to press into the surface of the material to form a pit unit with a characteristic size of micron. The phenomenon is accompanied by the existence of residual stress. In order to flatten the surface and reduce the residual stress on the surface, a cube-corner indenter is used to press vertically into the side of the dimple unit with a characteristic size of micron, forming an indentation with a characteristic size of nanometer, and releasing the residual stress stored in the material to achieve The purpose of functional surface planarization. This method provides a surface flattening method for the functional surface of microarray structure manufactured by precision machining technology. The operation is simple, the equipment has rich functions, and can be used for large-scale batch machining.

Owner:JILIN UNIV

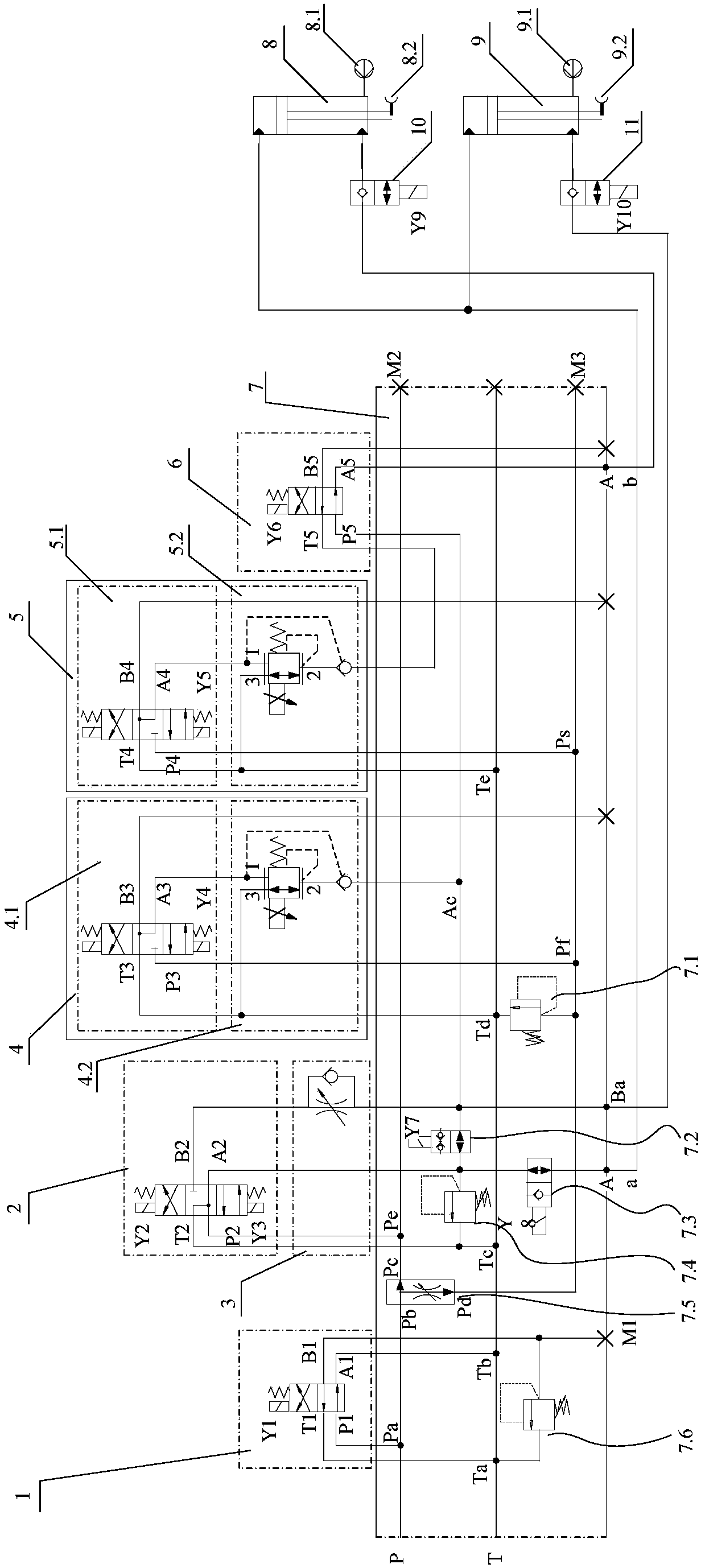

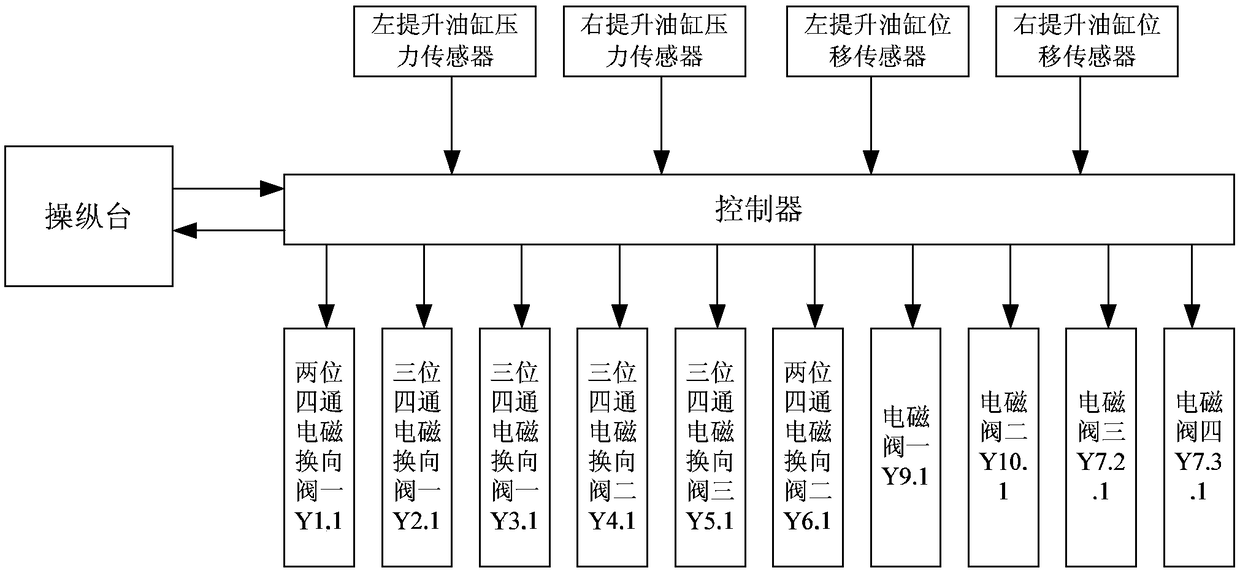

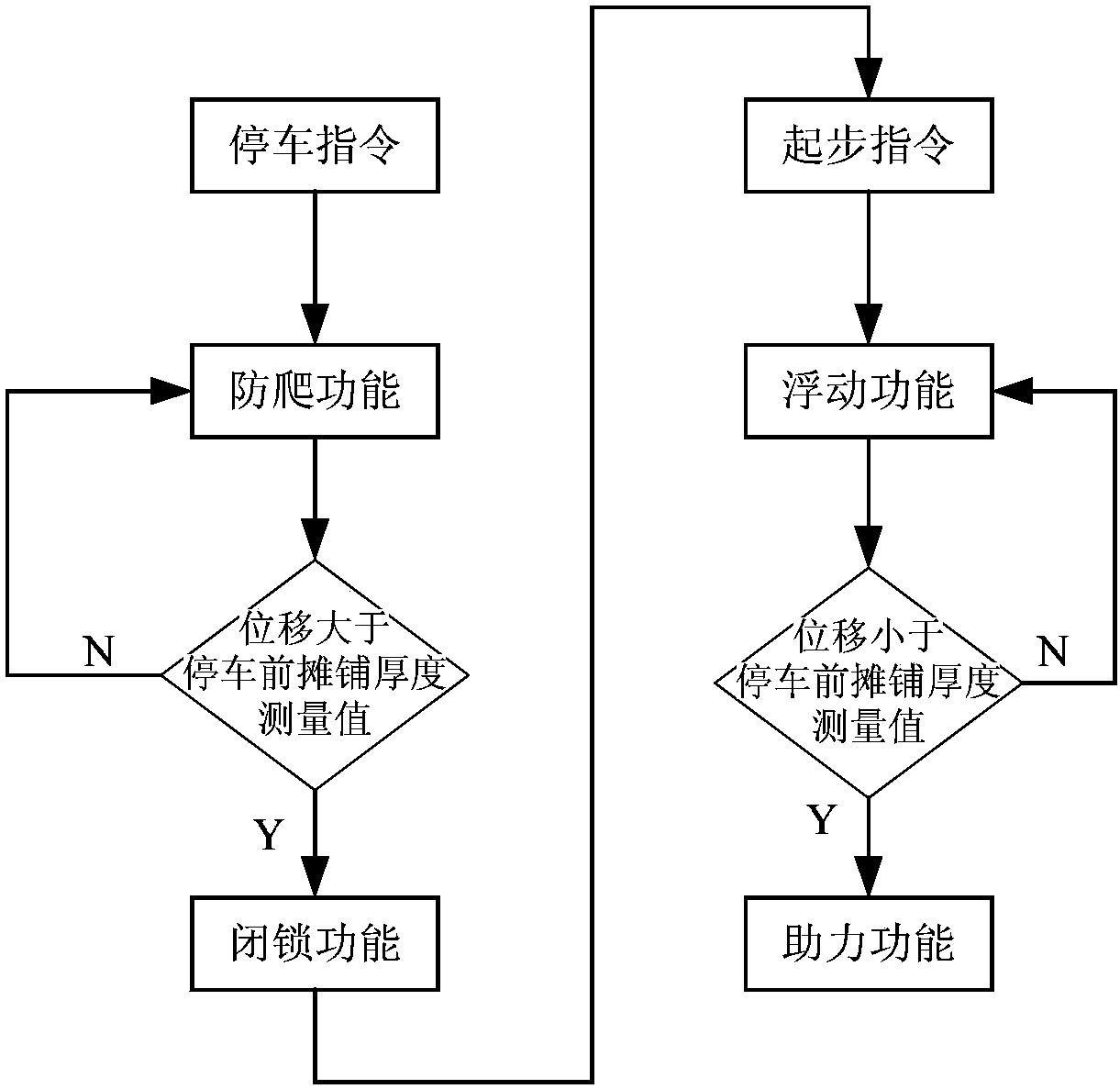

Multifunctional control system of screed of spreader

PendingCN108442213ASolve road bumps or indentationsAchieve riseServomotor componentsRoads maintainenceScreedRelief valve

The invention discloses a multifunctional control system of a screed of a spreader. A hydraulic control system comprises two-position four-way electromagnetic directional valve I, three-position four-way electromagnetic directional valve I, a one-way throttle valve, directional relief valve I, directional relief valve II, two-position four-way electromagnetic directional valve II, a hydraulic valve block and electromagnetic valves I and II mounted in rod cavities of left and right lifting cylinders. The system herein can implement functions, such as rising, falling, floating, locking, assisting and climb prevention for the screed of the spreader; in terms of control for assist functionality of the screed, the left and right lifting cylinders can provide assistance at the same time, or canprovide sole assistance separately; the problems such as pavement bulging or indentation can be effectively solved.

Owner:XCMG CONSTR MACHINERY

A brazing method for repairing bulging defects of thin-walled components

ActiveCN112207514BSolve the bulgeThe connection is tight and firmSoldering apparatusThin walledBlind hole

The invention discloses a brazing method for repairing bulging defects of thin-walled components. Firstly, pressure is applied to the bulging area by means of tooling and a pressure device to level the bulging area, and then the ribs of the runner groove under the bulging area are processed through For the blind hole on the upper plate, the distance between the bottom of the blind hole and the bottom of the upper plate of the thin-walled component is 1~2mm; pour powdered solder into the bottom of the blind hole, apply cream solder around the reinforcement column, and place the reinforcement column Installed in the blind hole; put the thin-walled component with the reinforced column into the vacuum furnace for vacuum brazing, and leave the furnace after cooling; milling and cutting off the part of the reinforced column that is higher than the surface of the thin-walled component, so that the reinforced column and the surface of the thin-walled component flush. The invention solves the repair problem of "blind brazing seam" in the bulging area of thin-walled components by processing blind holes on the ribs of the runner grooves below the bulging area, and fixing the reinforcing column in the blind holes by vacuum brazing, and is easy to operate ,reliable quality.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

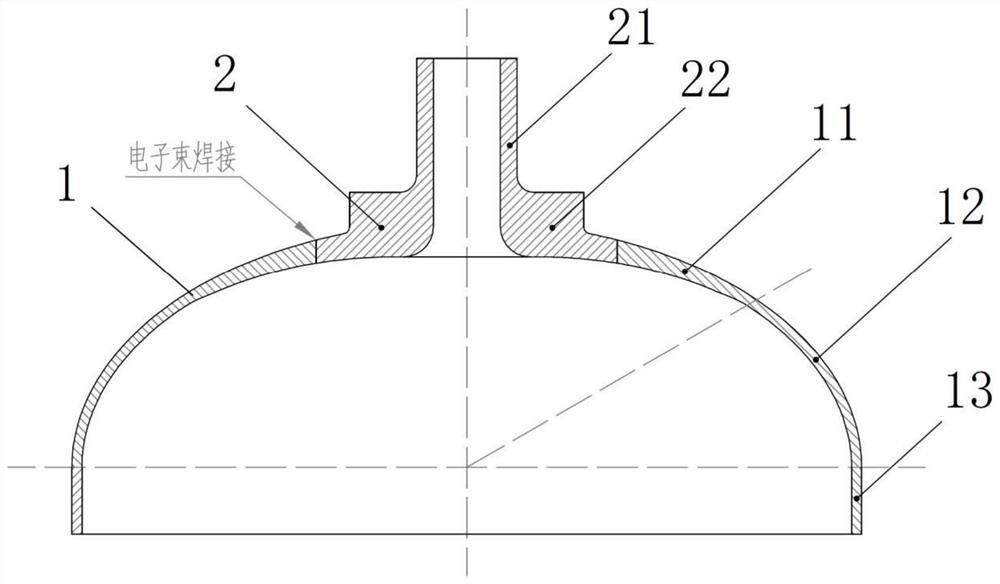

Satellite composite gas cylinder end socket and manufacturing method thereof

ActiveCN113685718ASolve the bulgeResolve the breakVessel manufacturingVessel geometry/arrangement/sizeHigh fractureGas cylinder

The invention relates to the technical field of composite material gas cylinders, in particular to a satellite composite gas cylinder end socket and a manufacturing method thereof. The satellite composite gas cylinder end socket comprises a shell and a connector, wherein the shell and the connector are welded through electron beams; the connector comprises a connector area and a shoulder reinforcing area; the shell comprises a gradual transition area, an equal-wall-thickness film area and a barrel area; and the shoulder reinforcing area is smoothly welded to the gradual transition area, and the gradual transition area is smoothly and gradually connected with the equal-wall-thickness film area. The two materials of TA1 pure titanium and TA3 titanium alloy are adopted, the requirements for high elongation at break and high plasticity of the low-cycle fatigue life of a plastic lining of the end socket shell are met, meanwhile, the requirement for high strength of rigid constraint of the end socket connector is met, the problems of damage, failure and the like of bulging, fracture, buckling, fatigue cracks, permeation and the like of the plastic lining in the fatigue cycle of a gas cylinder are solved, and the satellite composite gas cylinder end socket has the advantages of ultra-thin wall, light weight, high structural precision, good strain displacement matching performance with a composite layer, long low-cycle fatigue life and the like are achieved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

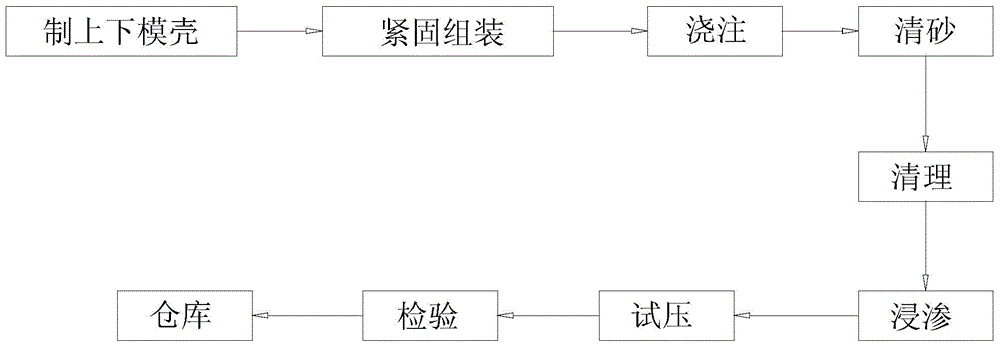

Method for producing automobile axle rear cover by using precoated sand process

InactiveCN103464681BAvoid damageStrong hardnessFoundry mouldsMoulding machinesMolten steelBlasting machine

The invention discloses a method for producing an automobile axle rear cover by using a precoated sand process. The method comprises the following steps: (1) producing a precoated sand upper mould shell and a precoated sand lower mould shell; (2) fastening and assembling the upper mould shell and the lower mould shell to form a pouring mould shell; (3) injecting molten steel into the pouring mould shell to form a casting; (4) cleaning sand on the casting by utilizing a shot blasting machine; (5) cleaning the casting by utilizing a grinding machine; (6) placing the casting into a negative pressure impregnation device for impregnation; (7) machining the casting to form a finished product; (8) carrying out a pressure bearing test on the finished product of the automobile axle rear cover by utilizing a pressure testing device; (9) carrying out inspection on the finished product; (10) warehousing the qualified finished product. The method can shorten the production process, save the time and improve the efficiency, the product cannot bulge or deform, and is uniform in thickness without a shrinkage cavity phenomenon, and after pouring, sand on the surface of the automobile axle rear cover can be automatically dispersed, so that the automobile axle rear cover is prevented from being damaged by an external force in a sand cleaning process.

Owner:湖北谷城县东华机械股份有限公司

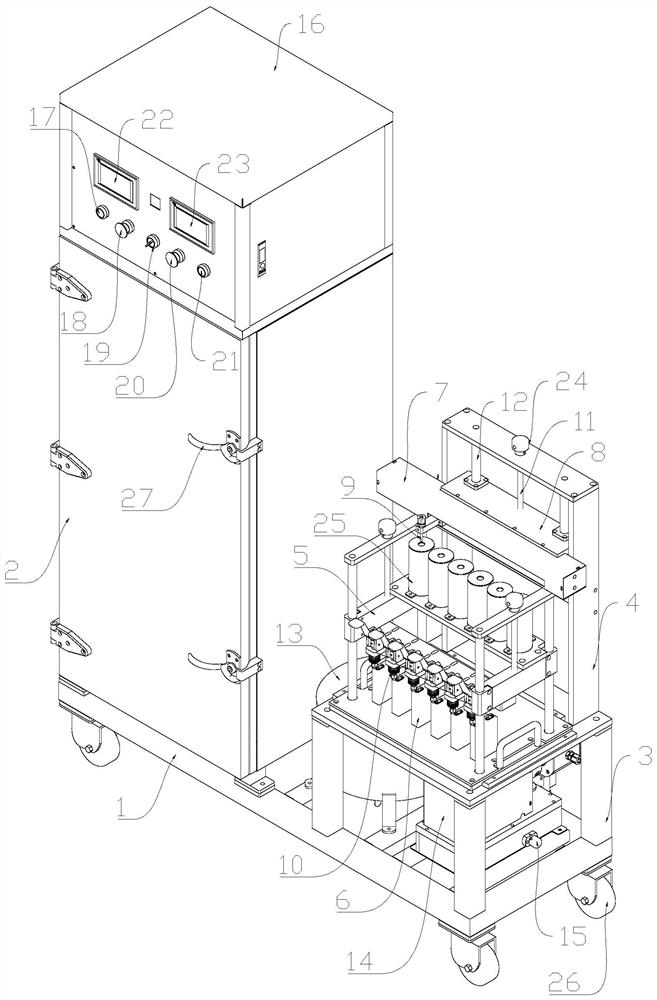

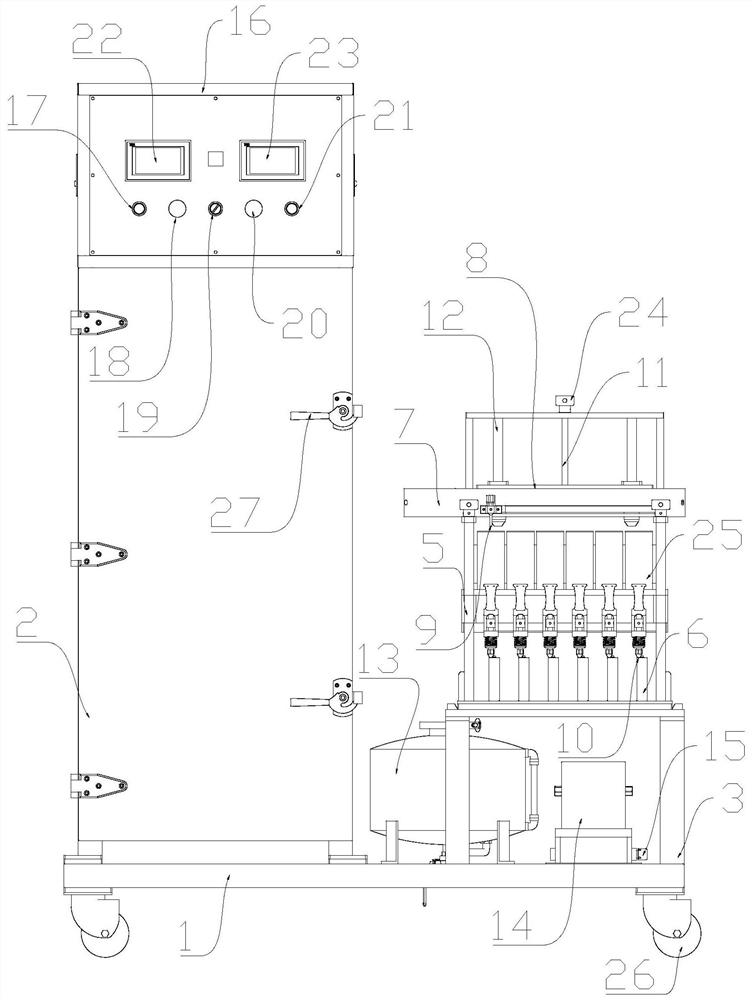

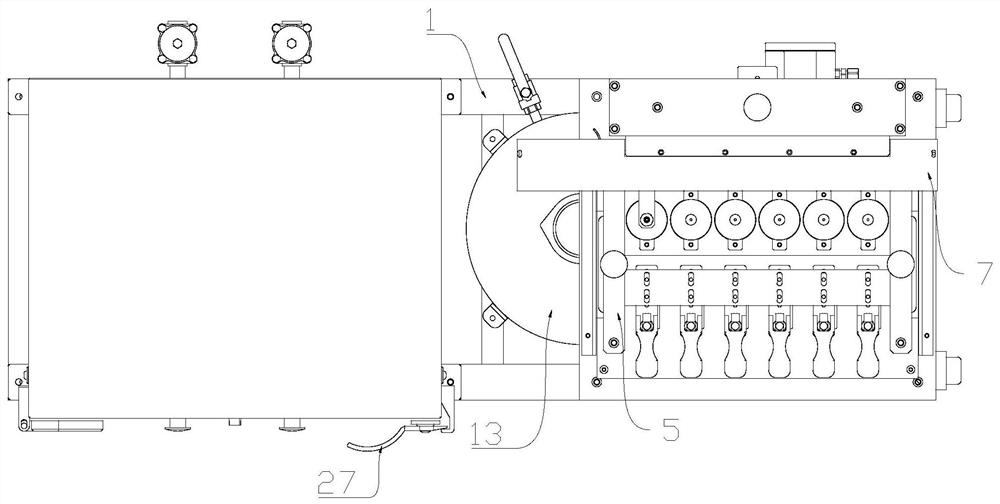

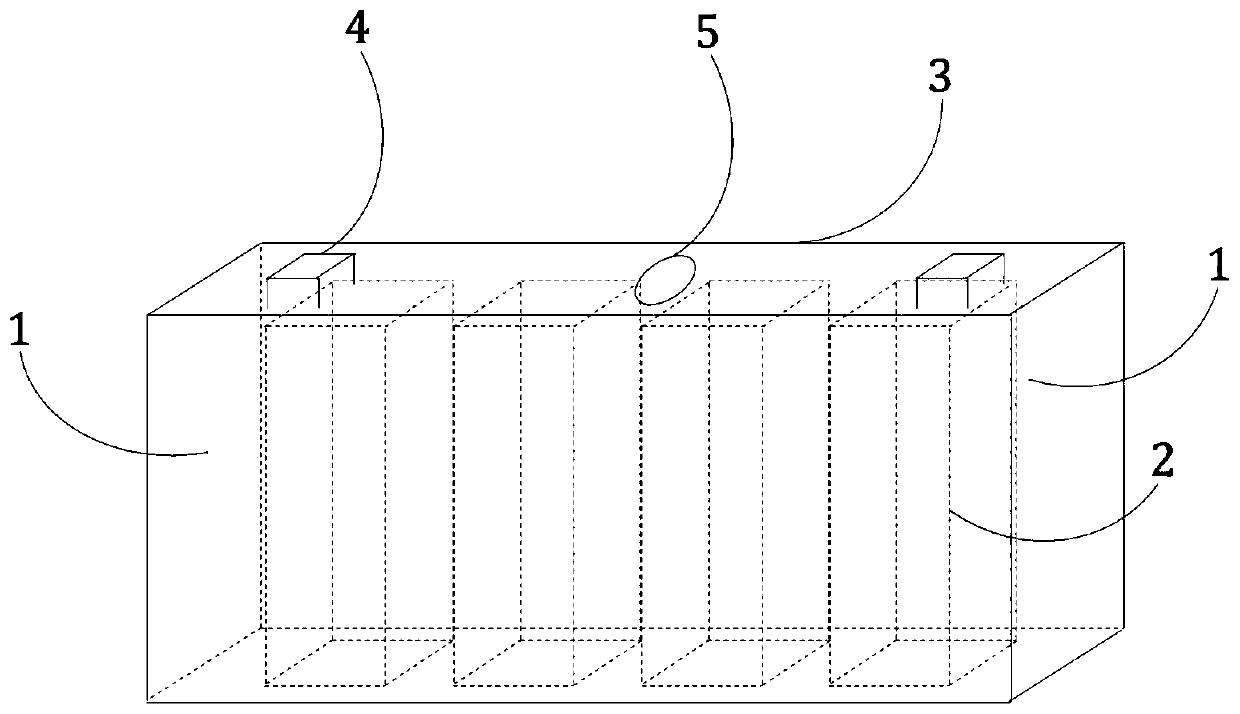

Lithium ion battery efficient liquid injection device and battery liquid injection method thereof

PendingCN112350037AImprove injection efficiencySolve the bulgeSecondary cellsCell component detailsPhysicsElectric machinery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery efficient liquid injection device which comprises a base, a vacuum standing boxfixed to the left side of the base, a right side fixing support, a liquid injection frame fixed to the support, a liquid injection clamp arranged below the liquid injection frame, a battery cell arranged in the liquid injection clamp, and a stroke motor fixed to the liquid injection frame through a template. A liquid injection head fixing base is arranged on the stroke motor, a rotating screw rodmoving up and down is arranged in the center of the liquid injection frame, and two movable fixing rods are arranged on the liquid injection frame on the two sides of the rotating screw rod. The problems that large battery liquid injection is difficult and large battery bulging and electrolyte spraying are caused by liquid injection can be effectively solved, and remote battery carrying is avoided due to the integrated design of the liquid injection device and the vacuumizing device; the liquid injection clamps of the battery cells of different specifications can be replaced by controlling the rotary screw rod according to the size of the battery; and the relative position between the lithium battery cell and the liquid injection clamp can be adjusted by controlling the stroke motor according to the number of batteries, multiple batteries can be injected at a time, and the liquid injection efficiency is improved.

Owner:江西安驰新能源科技有限公司

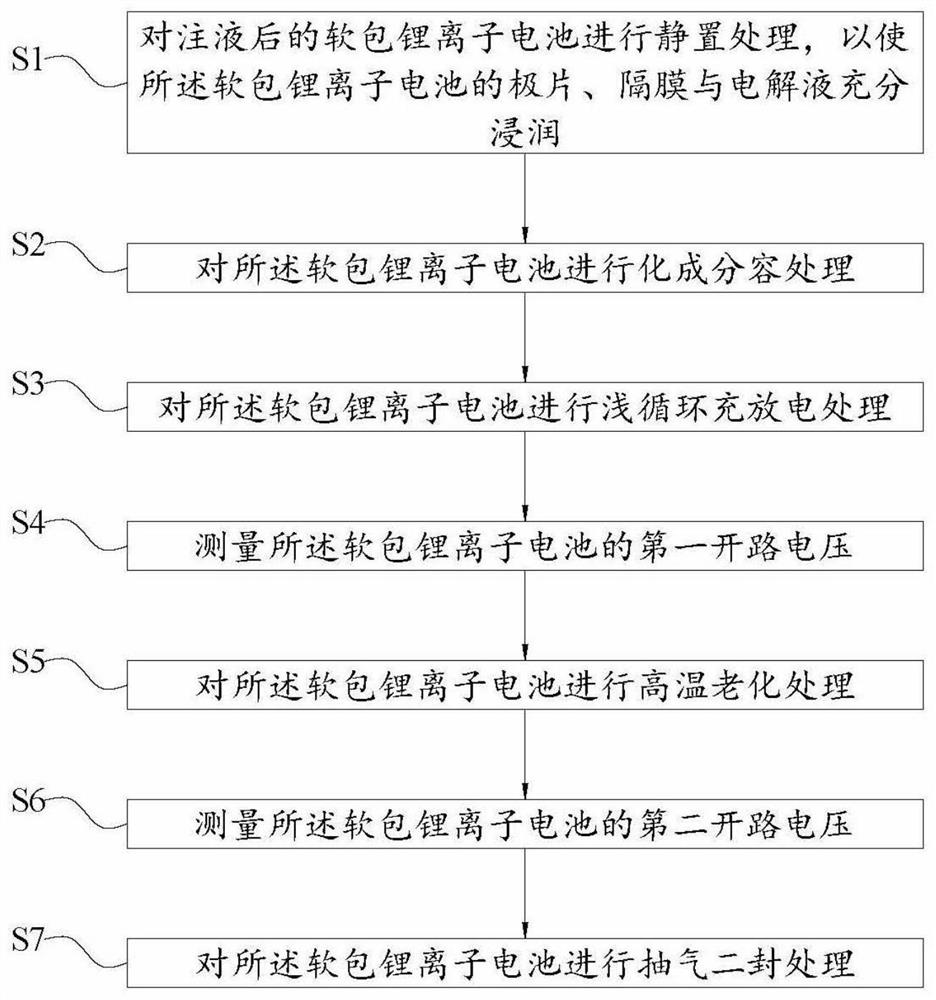

Method for reducing gas production bumps of soft package lithium ion battery and soft package lithium ion battery

PendingCN113764743ASolve the bulgeFinal product manufactureSecondary cells charging/dischargingPhysical chemistryEngineering

The invention discloses a method for reducing gas generation bumps of a soft package lithium ion battery and the soft package lithium ion battery, and the method comprises the following steps: S1, carrying out standing treatment on the soft package lithium ion battery after liquid injection, so that a pole piece, a diaphragm and an electrolyte of the soft package lithium ion battery are fully infiltrated; S2, performing formation and capacity grading treatment on the soft package lithium ion battery; S3, carrying out shallow cycle charging and discharging treatment on the soft package lithium ion battery; S4, measuring a first open-circuit voltage of the soft package lithium ion battery; S5, performing high-temperature aging treatment on the soft package lithium ion battery; S6, measuring a second open-circuit voltage of the soft package lithium ion battery; S7, performing air exhaust and secondary sealing treatment on the soft package lithium ion battery. The method can effectively solve the problem that in a traditional method, air extraction and sealing are carried out immediately after a formation stage, and a subsequent capacity grading stage, a shallow cycle charging and discharging stage, a high-temperature aging stage and other stages are neglected, so that the soft package lithium ion battery swells due to gas production.

Owner:DONGGUAN CHUANGMING BATTERY TECH

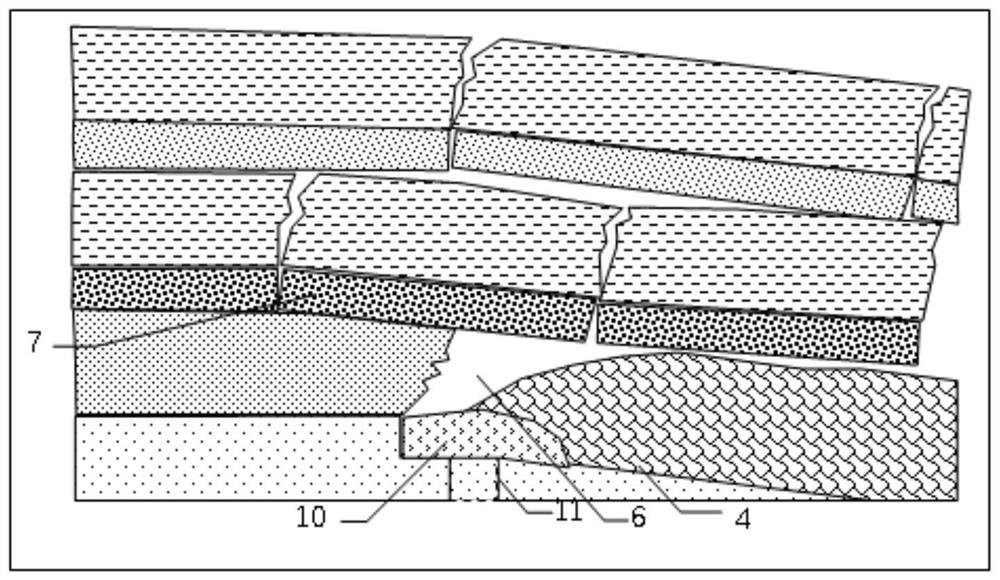

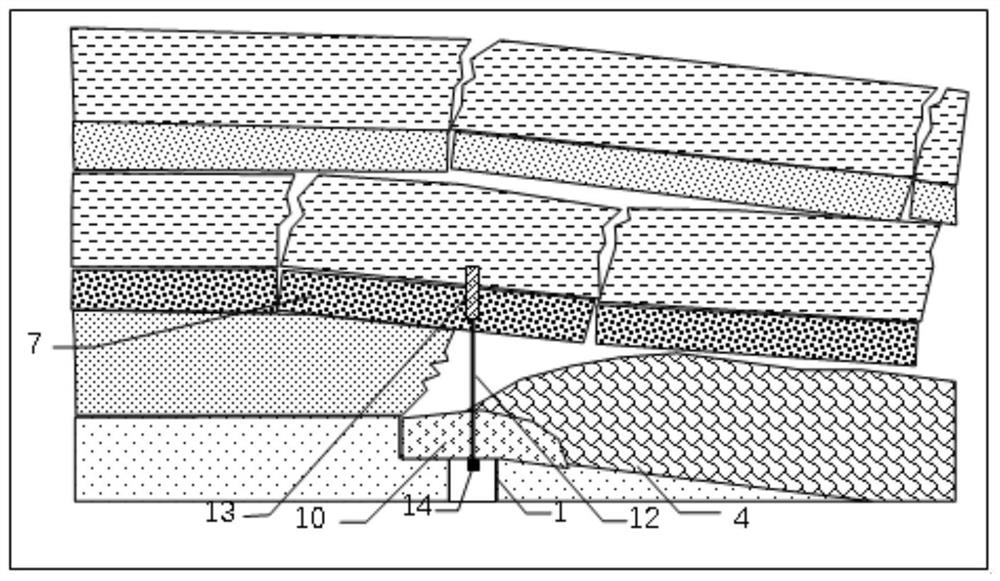

Method for maintaining broken roof of negative coal pillar roadway by grouting reinforcement anchor rod suspension

ActiveCN114000902AResolve the breakSolve artificial false top bulgeUnderground chambersTunnel liningArchitectural engineeringCoal pillar

The invention provides a method for maintaining a broken roof of a negative coal pillar roadway through grouting reinforcement anchor rod suspension, and belongs to the technical field of mining. The method comprises the following steps: firstly, during upper layer mining, after an immediate roof above a layered roadway finishes collapsing, grouting reinforcement is performed on a collapsed broken top plate, so that the broken top plate of the layered roadway becomes a whole; then, after mining of an upper layered working face is finished and grouting of the broken roof of the layered roadway is completed, the layered roadway is tunneled; in the layered roadway tunneling process, a high-traction-force anchor rod is adopted to suspend the whole top plate after grouting reinforcement, so that the top plate is suspended on a lateral hard top plate; after tunneling and anchoring of the layered roadway are completed, the working face of the layered roadway is stoped, and meanwhile, a broken top plate of a next layer is treated, or an upper layer roadway of a next working face is tunneled; and operations are repeated. The method can effectively solve the problems of roof crushing and artificial roof bulging and deformation in a negative coal pillar roadway arrangement mode.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Lithium ion battery

PendingCN111430828AImprove securitySolve the bulgeSecondary cell gas removalPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery. The lithium ion battery includes a shell; a gas trapping structure unit which is arranged at the inner side of the shell and is formed by at least one adsorption active material. In the lithium ion battery, the gas trapping structure unit arranged at the inner side of the shell can spontaneously adsorb the gas generated in the battery circulation process without the additional pushing force (such as pressure, etc.), the safety performance of the battery can be effectively improved by timely removing the generated gas in the charging and discharging cycle process, the battery bulge problem is solved, and the cycle life of the battery is prolonged.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Bias ply tire bead structure and carcass tire cord fabric reverse coating forming method

InactiveCN103204035ASolve the bulgeAvoid the phenomenon of cutting the carcass cordTyresTyre beadsTire beadEngineering

The invention discloses a bias ply tire bead structure and a carcass tire cord fabric reverse coating forming method. The bias ply tire bead structure comprises a steel ring, a bead filler, a first reverse coating cord fabric layer surrounding the steel ring and the bead filler, a right coating cord fabric layer surrounding the first reverse coating cord fabric layer, and a reverse coating cord fabric layer surrounding the right coating cord fabric layer. The carcass tire cord fabric reverse coating forming method provided by the invention comprises steps of: placing the bead filler; buckling a steel ring and compacting; using a the first cord fabric cylinder for converse pressure to form the reverse coating cord fabric; completing a right coating operation by another cord fabric cylinder; and finally conducting a reverse coating by the first cord fabric cylinder to form the reverse coating cord fabric, and padding a mat bead toe pad to complete production of tire bead. The tire bead structure prepared by the carcass tire cord fabric reverse coating forming method provided by the invention can avoid cutting of the tire cord thread during repair of border break of a multi-layer tire bead opening, and can solve a problem of sidewall bulge caused by gas penetration from carcass cord thread at tire toe.

Owner:SHANDONG LINGLONG TIRE

Vacuum-resistant inner liner PTFE container and manufacturing process thereof

PendingCN109229777AConvenient sourceEasy to rule outLarge containersLinings/internal coatingsVacuum extractionWorkload

The invention discloses a vacuum-resistant inner liner PTFE container and a manufacturing process thereof and belongs to the technical field of the inner liner PTFE container. The vacuum-resistant inner liner PTFE container comprises a container steel part, a PTFE layer is arranged in the container steel part, a porous plate is arranged between the container steel part and PTFE, a plurality of vacuum balance openings are arranged on the container steel part, a temporary steel tube group is connected to the container steel part via the vacuum balance openings, and a vacuum pump is connected tothe temporary vacuum tube group; after vacuum extraction of the container steel part is completed and an electric spark test is passed successfully, the temporary vacuum tube group is removed, the container steel part is connected with a balance tube assembly through the vacuum balance openings, and the balance tube assembly includes a fluorine-lined check valve and a fluorine-lined pipe. The vacuum-resistant inner liner PTFE container is simple in structure and convenient in construction, operation of drilling a plurality of holes in advance on an outer part of the container is not needed, workloads can be reduced, effects exerted on intensity of the container steel part by pressure can be reduced, local bulging can be prevented, and the vacuum-resistant inner liner PTFE container can besafely used in high vacuum working conditions.

Owner:NANJING FUYUAN CHEM PIPELINE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com