Lithium ion battery efficient liquid injection device and battery liquid injection method thereof

A lithium-ion battery and liquid injection device technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of bulging, large batteries, spraying electrolyte, etc., and achieve the effect of improving liquid injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

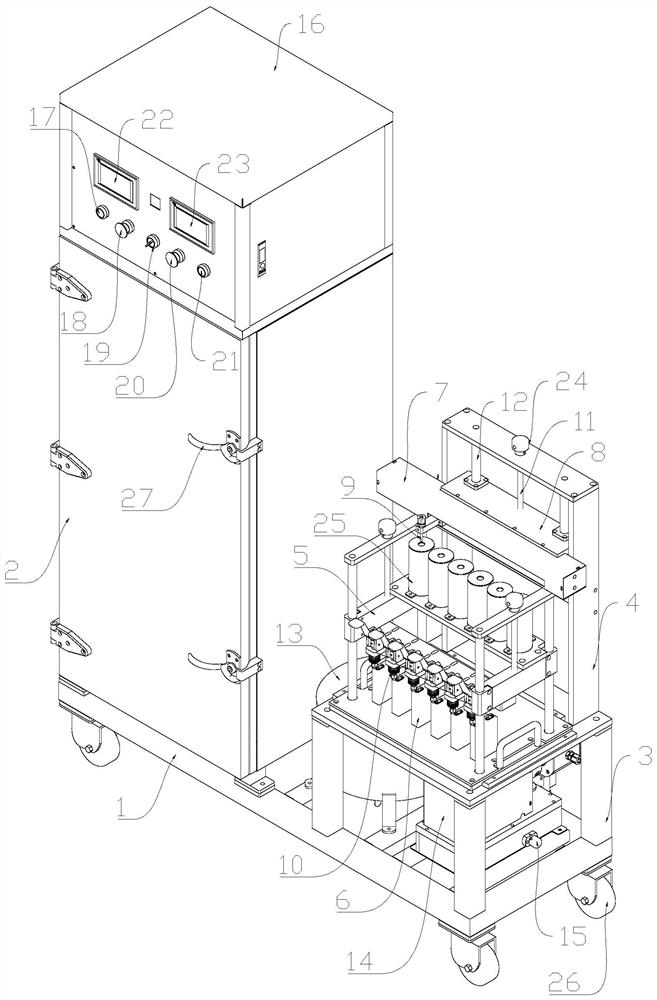

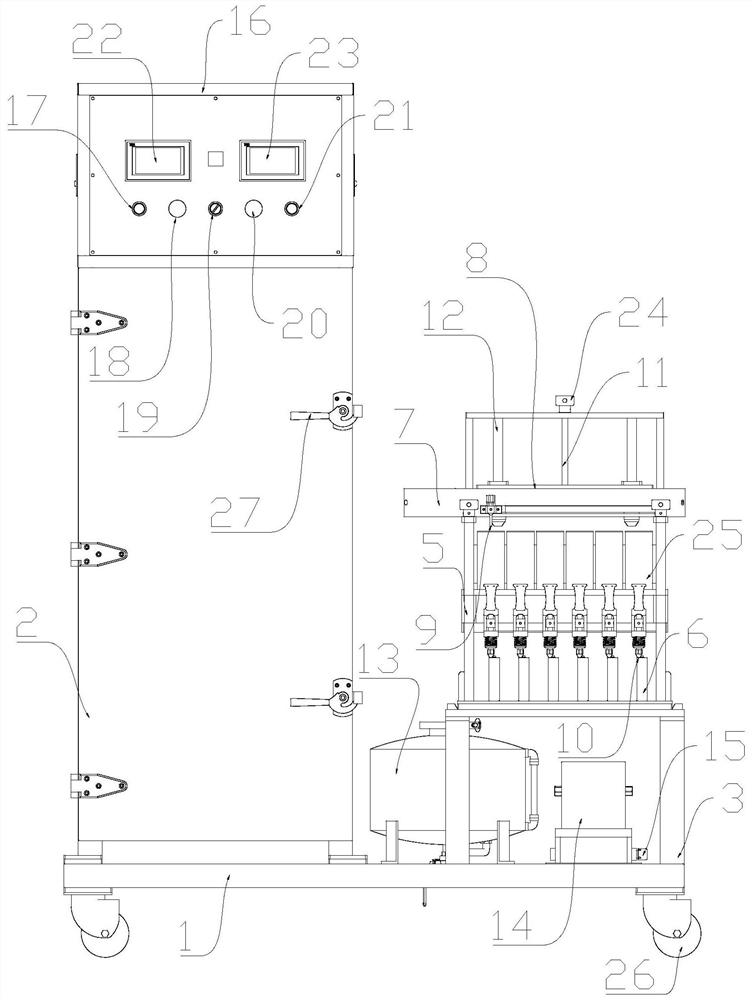

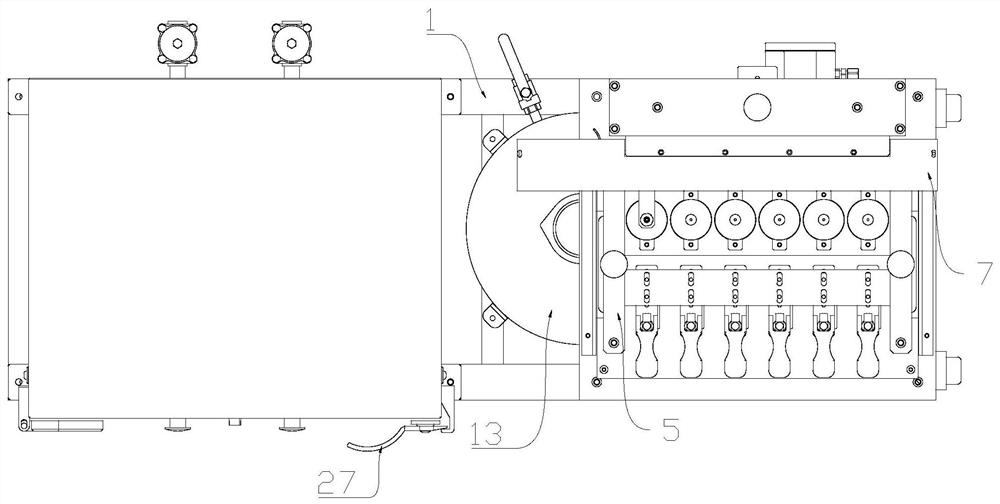

[0042]A high-efficiency liquid injection device for lithium-ion batteries, such asFigure 1-11As shown, it includes a base 1, a vacuum standing box 2 is fixedly installed on the left side of the upper surface of the base 1, a mounting bracket 3 is fixed on the right side of the upper surface of the base 1, and a liquid injection rack 4 is fixedly mounted on the bracket 3, The liquid injection fixture 5 is fixed under the liquid injection frame 4, the lithium battery cell 6 is placed in the liquid injection fixture 5, the stroke motor 7 is fixed on the liquid injection frame 4 through the template 8, and the stroke motor 7 A liquid injection head fixing seat 9 is provided on the upper part, and the stroke motor 7 is used to control the relative position of the liquid injection head 10 on the liquid injection fixture 5 and the liquid injection hole of the lithium battery cell 6; A movable rotating screw 11, two movable fixed rods 12 are provided on the liquid injection frame 4 on both ...

Embodiment 2

[0047]The liquid injection method of the lithium ion battery high-efficiency liquid injection device of embodiment 1, includes the following steps:

[0048]S1. Before liquid injection, the liquid storage tank 13 is filled with electrolyte;

[0049]S2. Put the lithium battery cell 6 into the liquid injection fixture 5, rotate the handle 24 by a wrench to control the liquid injection fixture 5 to move up and down, and control the height of the liquid injection fixture 5 according to the size of the lithium battery cell 6;

[0050]When the liquid injection hole of the lithium battery cell 6 is completely aligned with the liquid injection head 10 on the liquid injection fixture 5, the injection head fixing seat 9 is controlled by the stroke motor 7 to fix the liquid injection head 10;

[0051]S3. Turn on the power switch 19 of the control system box 16, after adjusting the liquid injection volume through the liquid injection value control display 23, turn on the liquid injection pump 14 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com