Fluoroplastic full-lining cutting ball valve

A technology for cutting off ball valves and fluoroplastics, which is applied in the direction of cocks, valve details, and valve devices including cut-off devices, which can solve problems such as short service life, easy rupture of the diaphragm, and easy damage of the diaphragm, and achieve strong corrosion resistance and guarantee The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

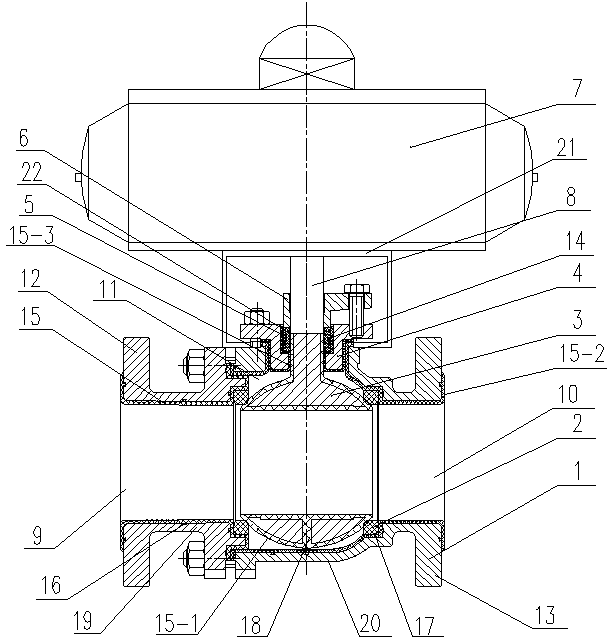

[0014] Such as figure 1 As shown, the fluoroplastic full-lined cut-off ball valve includes a valve body 1, a valve cover 4, a valve stem 8, and a valve ball 3. The valve body 1 is provided with an inlet 9, an outlet 10, and an upper connecting port 11, and the inlets and outlets 9 and 10 are respectively The inlet and outlet flanges 12 and 13 are connected, the valve cover 4 is fixed at the upper connection port of the valve body 1 by bolts and nuts, the valve stem 8 is fixed through the valve cover 4, and a stuffing box is set between the valve stem 8 and the valve cover 4 5. The packing seal 14 formed by the packing 22 and the packing gland 6; the valve ball 3 is arranged in the valve body 1, the valve stem 8 and the valve ball 3 are integrally arranged by casting, and the inner wall of the valve body 1 is fully lined with a fluorine plastic layer 15. The inner and outer surfaces of the ball 3 and the valve stem 8 arranged in the valve body 1 are respectively provided with fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com