Multifunctional control system of screed of spreader

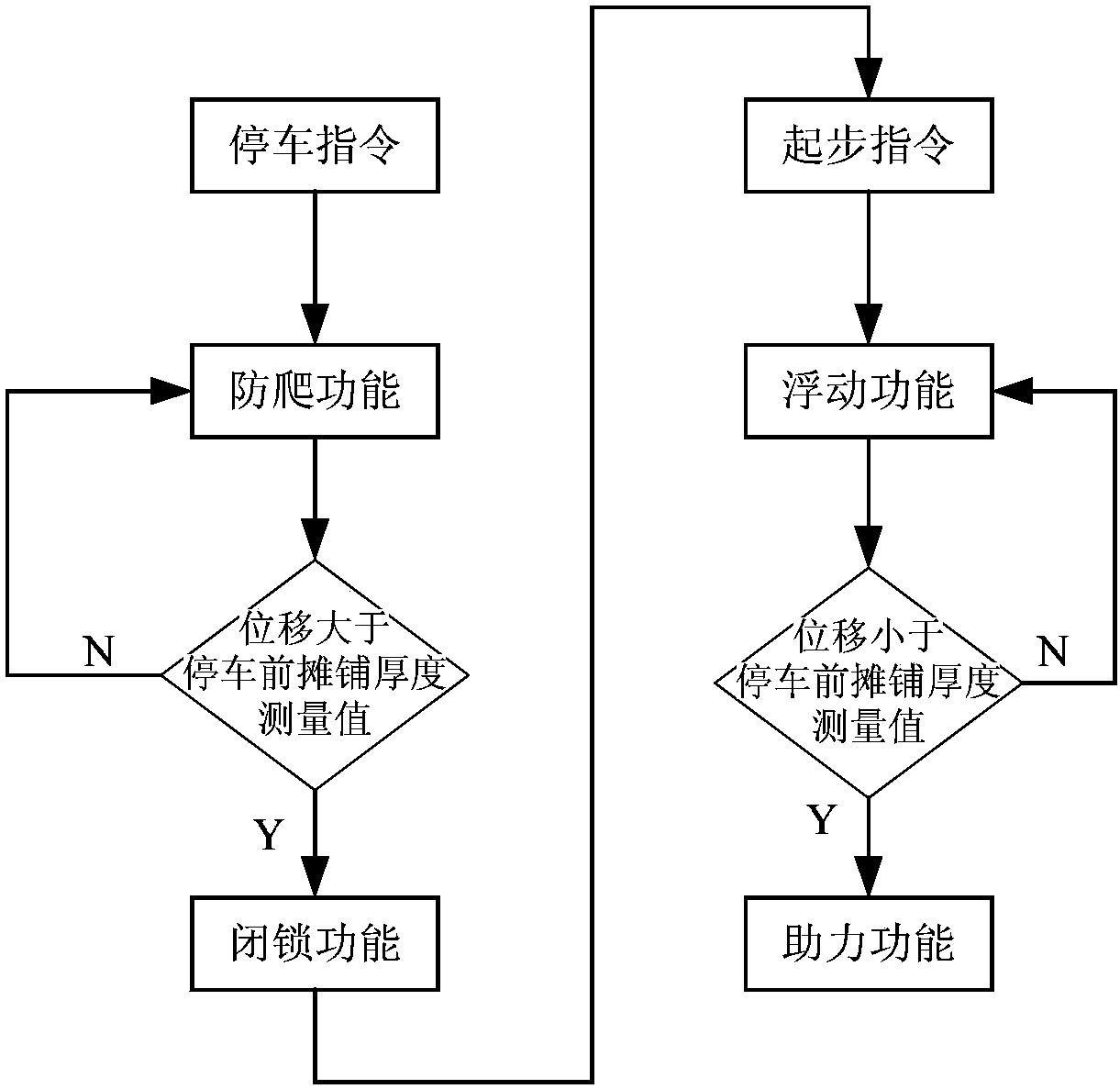

A control system and machine screed technology, which is applied to fluid pressure actuation system components, mechanical equipment, roads, etc., can solve the problem that the screed cannot enter complete floating, and achieve the effect of solving road bumps or indentations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

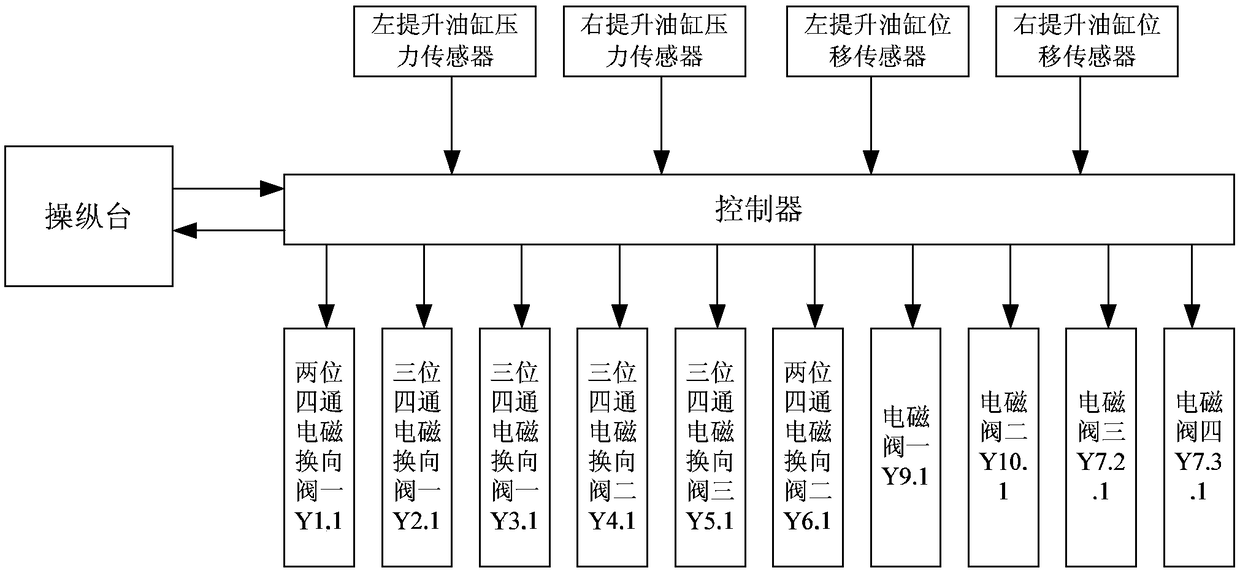

[0047] Multifunctional control system for paver screed, including hydraulic control system and electrical control system;

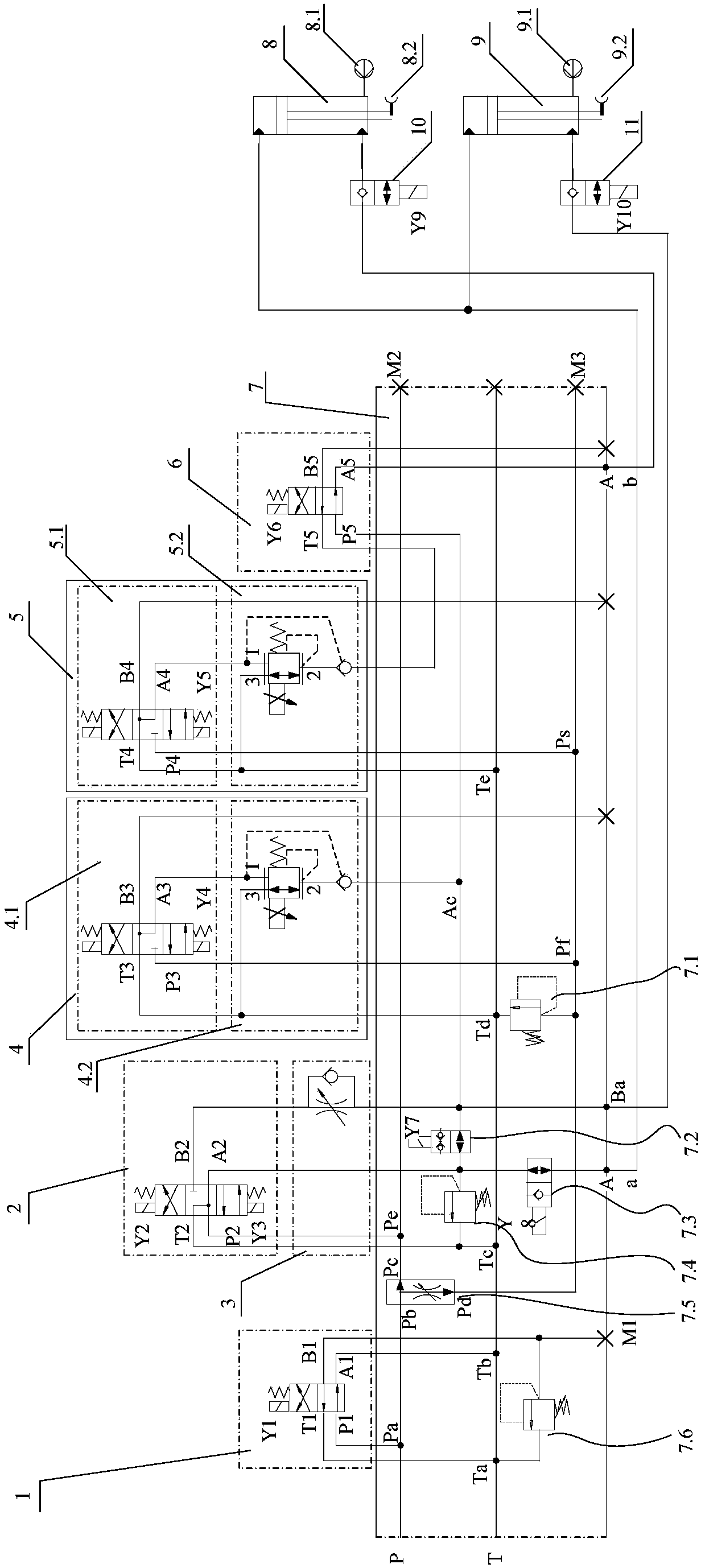

[0048] Such as figure 1 The hydraulic control system shown includes a two-position four-way electromagnetic reversing valve 1, a three-position four-way electromagnetic reversing valve 1 2, a one-way throttle valve 3, a reversing pressure reducing valve 1 4, and a reversing pressure reducing valve 2 5. Two two-position four-way electromagnetic reversing valve two 6, hydraulic valve block 7 and solenoid valve one 10 installed in the rod chamber of the left lifting cylinder 8 and solenoid valve two 11 of the rod chamber of the right lifting cylinder 9 . The hydraulic valve block 7 includes a main oil circuit P, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com