Treatment and recovery equipment for medical cotton

A technology for recycling equipment and receiving belts, applied in the direction of grain processing, cleaning methods and utensils, cleaning methods using liquids, etc., capable of solving problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

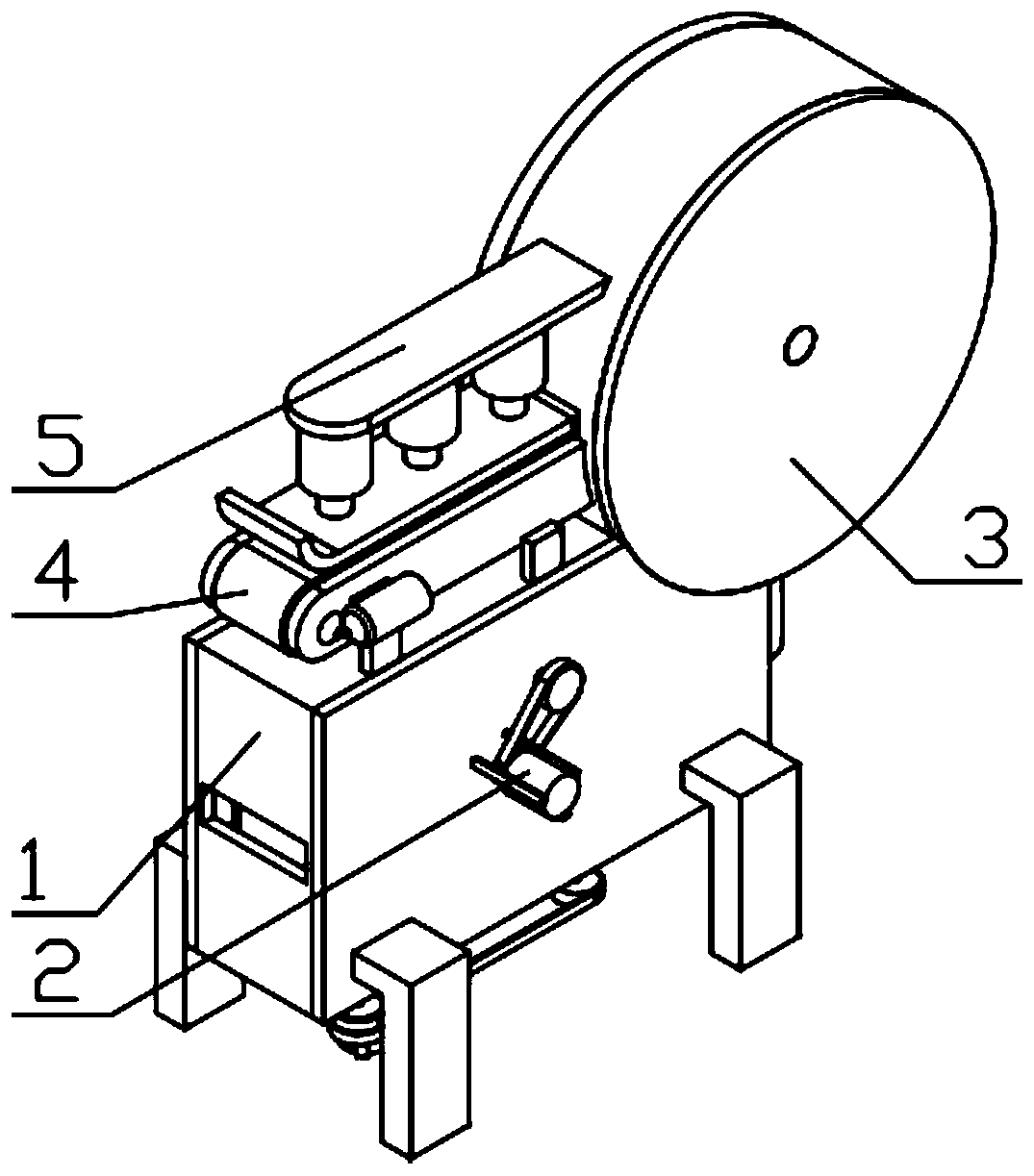

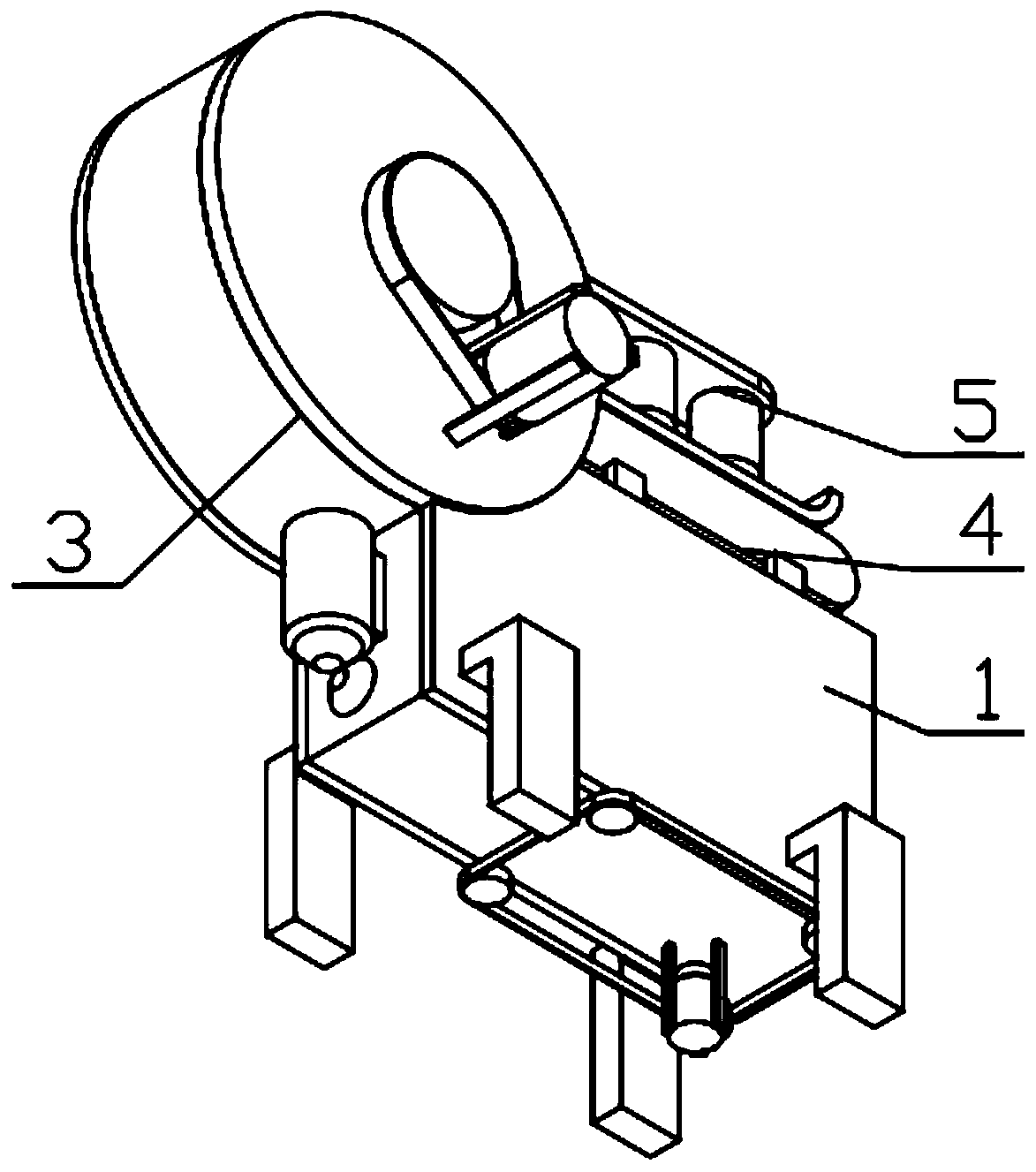

[0036] Combine below figure 1 , 2 . More specifically, it is a treatment and recovery equipment for medical cotton, including a cleaning device 1, a pressurized water discharge device 2, a crushing device 3, a feeding device 4, and an extrusion fitting device 5. After being crushed by the cleaning device 1, the The cotton is disinfected and cleaned and the cotton is raised, the water pressure discharge device discharges the cleaned cotton, the crushing device 3 cuts the cotton into pieces and then crushes it, and the feeding device 4 continuously feeds the cotton forward and squeezes it. The cooperating device 5 cooperates with the feeding device 4 to press the cotton into strips and advance the sliver, etc. It is characterized in that: the pressurized water discharge device 2 is installed inside the cleaning device 1, and the crushing device 3 is installed and fixed on the cleaning device 1, the feeding device 4 is installed and fixed on the cleaning device 1, and the extru...

specific Embodiment approach 2

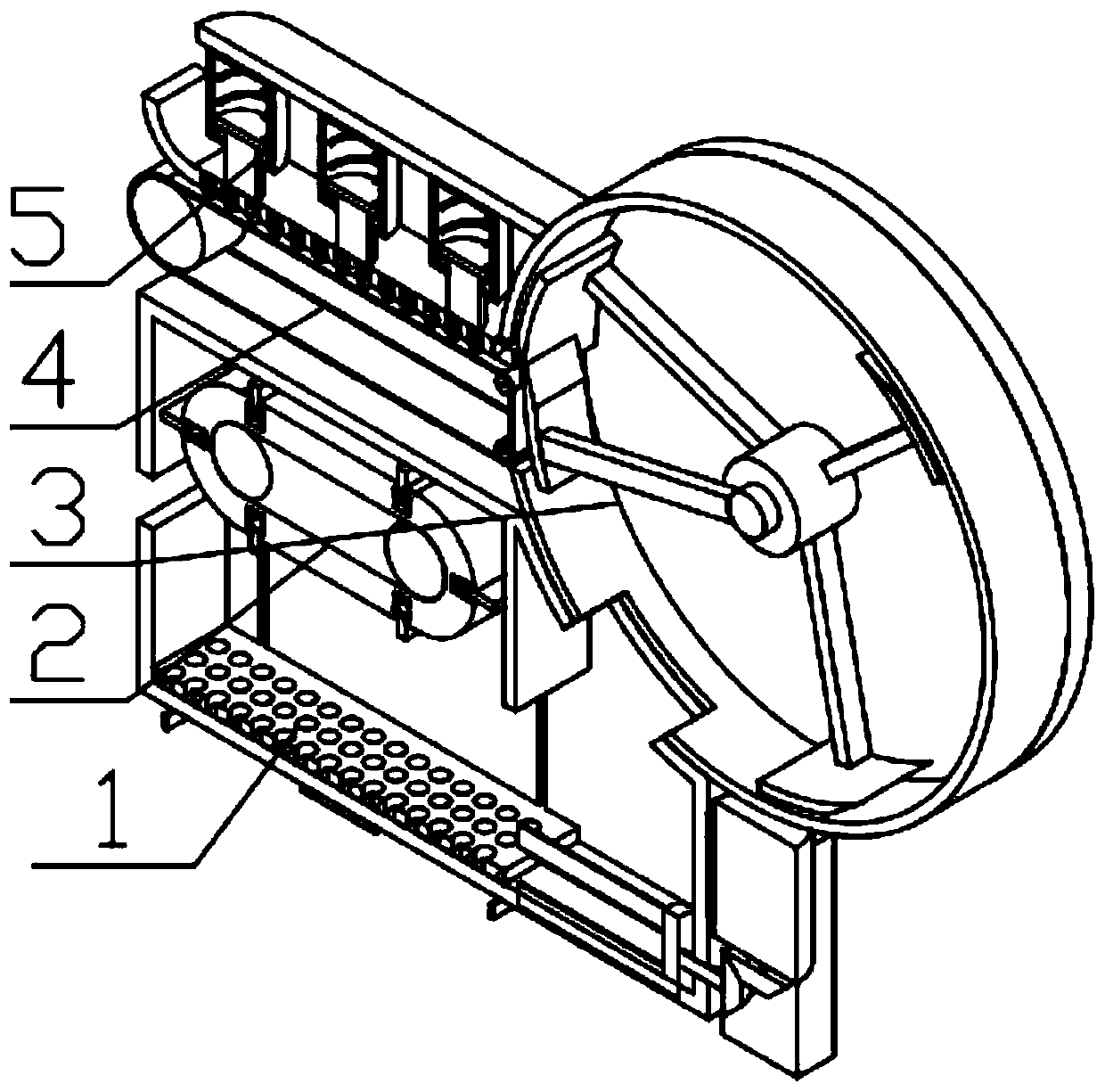

[0038] Combine below figure 1 , 2 . The cleaning device 1 described above includes a cleaning box 1-1, a material inlet 1-2, a material outlet 1-3, a baffle plate 1-4, a sealing plate at both ends 1-5, a strip groove 1-6, a rotating thread Shaft 1-7, receiving pulley 1-8, transmission belt 1-9, motor bracket 1-10, motor 1-11, output pulley 1-12, transmission belt one 1-13, receiving pulley one 1-14 , sieve plate 1-15, threaded ring 1-16, motor one 1-17, bevel gear 1-18, rotating shaft 1-19, bevel gear one 1-20, rotating disk 1-21, stirring rod 1-22, The supporting legs 1-23, the cotton enters from the feed port 1-2 of the cleaning device 1, the material blocking plate 1-4 prevents the cotton from falling directly on the sieve plate 1-15, and then the motor 1-17 drives the bevel gear 1-18 Rotate, the bevel gear 1-18 drives the bevel gear 1-20 to rotate, the bevel gear 1-20 drives the rotating shaft 1-19 to rotate, the rotating shaft 1-19 drives the rotating disc 1-21 to rota...

specific Embodiment approach 3

[0040] Combine below figure 1 , 2 . Said pressurized water discharge device 2 comprises motor frame two 2-1, motor two 2-2, output pulley two 2-3, transmission belt two 2-4, rotating shaft two 2-5, receiving pulley two 2-6 , Rotating shaft three 2-7, transmission wheel 2-8, thick transmission track 2-9, trapezoidal groove 2-10, spring 2-11, sliding strip 2-12, pusher plate 2-13, sieve plate 1 -15 makes the pusher plate 2-13 move inward, and the pusher plate 2-13 drives the sliding strip plate 2-12 to move the compression spring 2-11 in the trapezoidal groove 2-10, and when the cleaning and disinfecting solution is discharged, the motor 1 -11 reversely moves a certain distance and then stops to make the moving strip 2-12 and the pushing plate 2-13 push out under the action of the spring 2-11, and then the motor 2-2 drives the output pulley 2-3 Rotate, the output pulley 2-3 drives the receiving pulley 2-6 to rotate through the transmission belt 2-4, the receiving pulley 2-6 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com