Ratchet wheel control mechanism of pipe washing impoundment door

A control mechanism and pipeline flushing technology, which is applied to waterway systems, water supply devices, buildings, etc., can solve the problems of controlling the storage gate, not many, and no detailed description, etc., and achieve the effect of safe and reliable operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

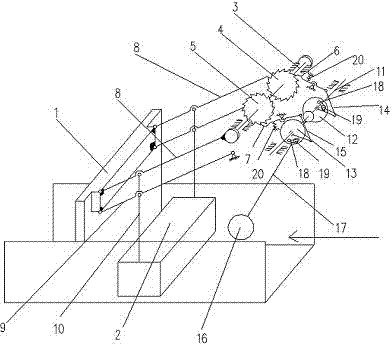

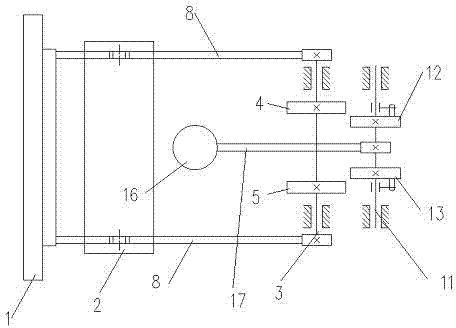

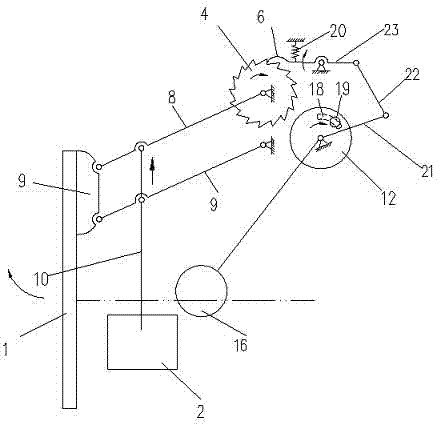

[0026] Such as Figure 1~4 As shown, a ratchet control mechanism for pipeline flushing storage door disclosed by the present invention controls the storage door through a purely mechanical ratchet control mechanism. The specific structure includes a storage door 1, a buoy 2, a water level adjustment control mechanism and a storage door control mechanism.

[0027] The shape of the storage door 1 is consistent with the cross-sectional shape of the drainage pipe, and a sealing strip is installed around it, so that the storage door is in sealing contact with the side wall of the sewage pipe to prevent leakage of the water storage.

[0028] Wherein said water level adjustment control mechanism comprises a second shaft 11, a first adjusting disc 12, a second adjusting disc 13, a first link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com