Wind generator tower and lifting method thereof

A technology for wind turbines and towers, which is applied to the field of combined towers and their lifting, can solve the problems of inability to lift wind turbines, high costs, increased costs, etc., and achieves reduced installation costs, low labor intensity, and easy portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

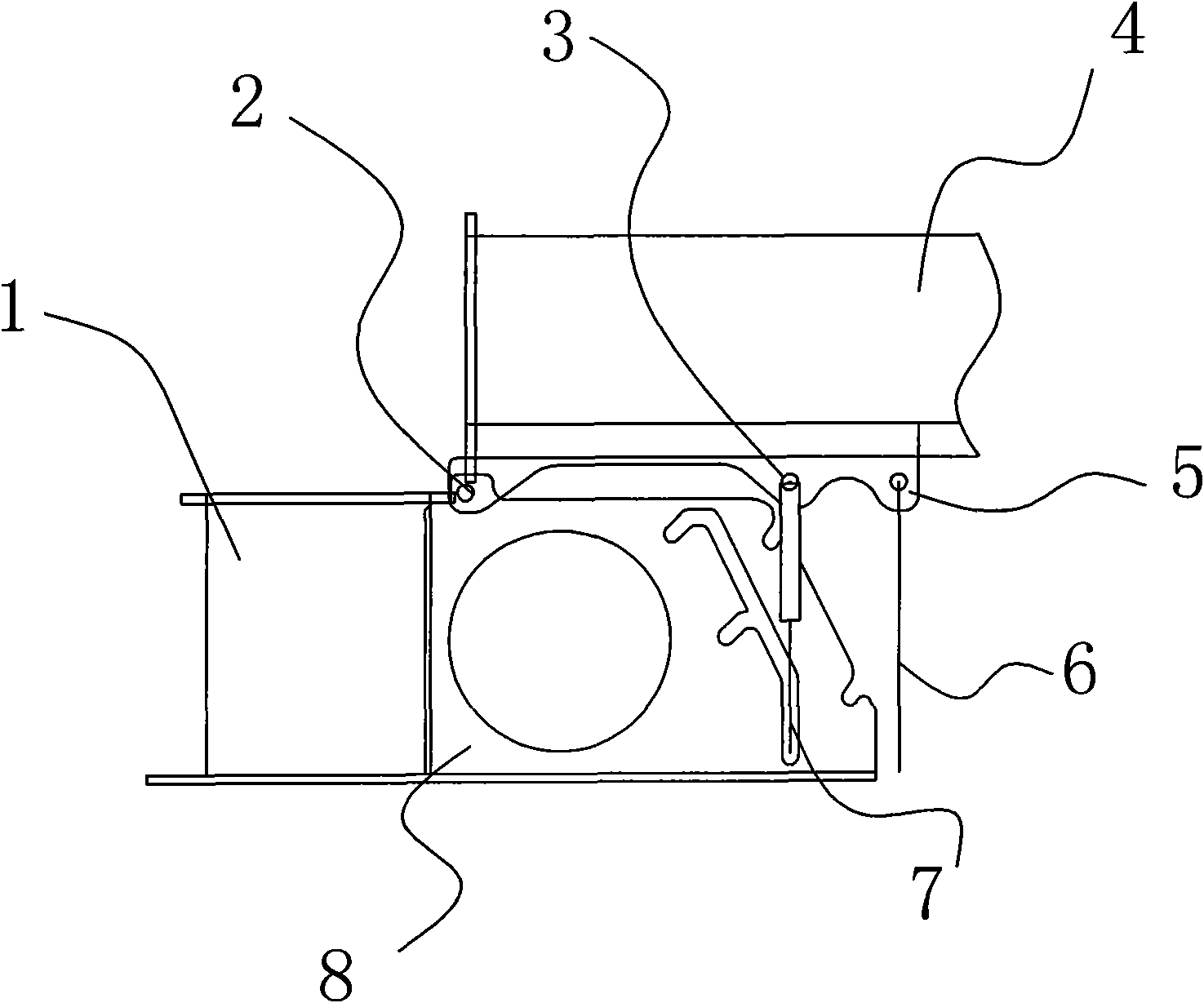

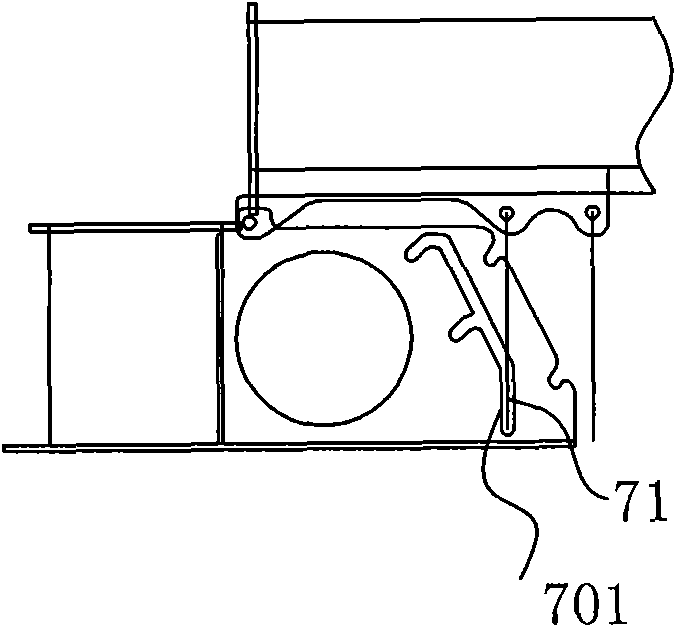

[0020] The wind power generator tower of the present invention is as figure 1 As shown, it includes a base 1 fixed on the ground, a tower 4 hinged with the base 1, the tower 4 is hinged with the base 1 through the hinge shaft 2, and the tower 4 can be leveled to an upright state relative to the base 1 through the lifting device 7 The movement of the base 1 towards the side of the tower 4 is provided with a receiving frame 8, and the tower 4 is hinged with a strut 6 through the strut hinge pin 5 near the hinge point, and the tower 4 below the strut 6 is also equipped with The connecting ear 3 of the lifting device 7 is hingedly connected; the lower end of the supporting frame 8 corresponding to the pole 6 is provided with a supporting groove group 60 , and the corresponding action end of the lifting device 7 is provided with a receiving groove group 70 .

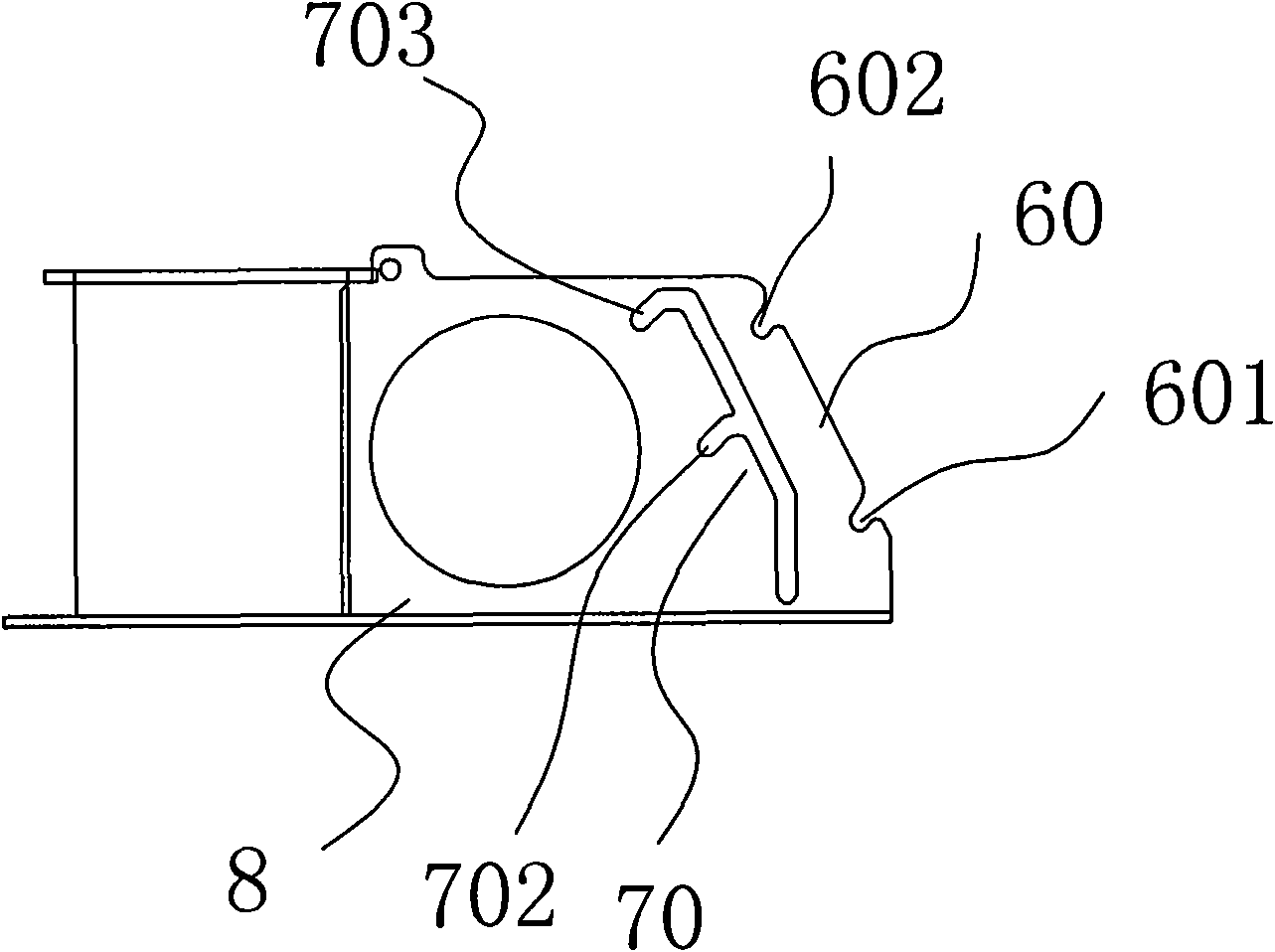

[0021] Such as figure 2 As shown, the receiving groove group 70 on the receiving frame 8 on one side of the base 1 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com