Lithium ion battery

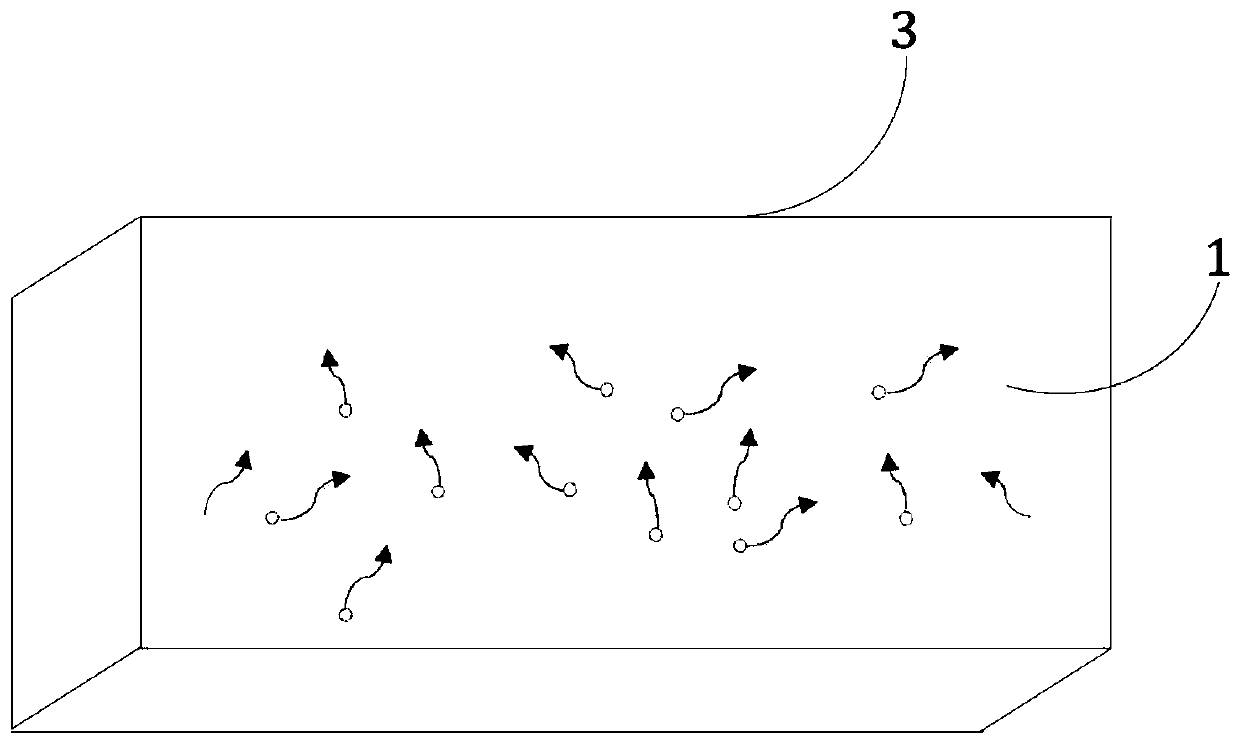

A lithium-ion battery and molecular sieve technology, which is applied in secondary batteries, secondary battery gas removal, secondary battery repair/maintenance, etc., can solve the problem of increased cost of lithium-ion batteries, which have not yet entered industrial application, and the application of ternary cathode materials Problems such as unclear prospects can achieve the effect of improving cycle life, improving safety performance, and solving battery bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

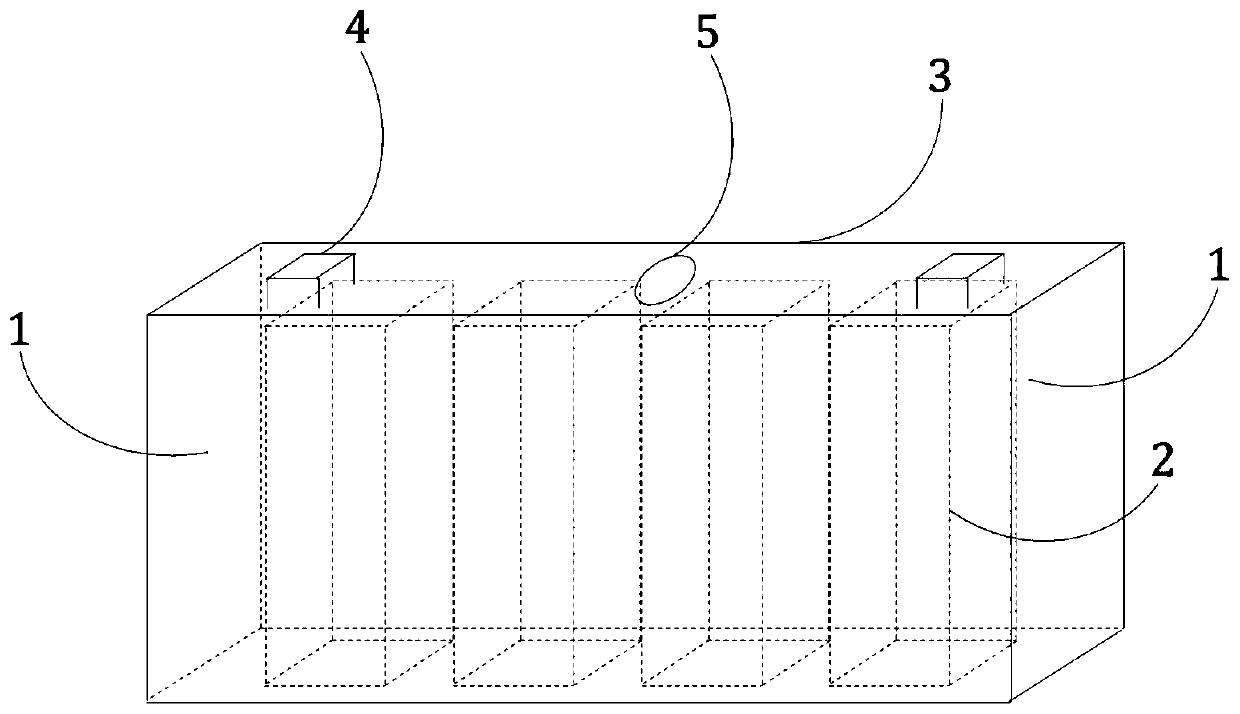

[0056] The lithium-ion battery is a square battery, which consists of an electrode group, an aluminum case, a gas capture structural unit, a cover plate, tabs, and an explosion-proof valve. The pole group adopts the lamination or winding process to assemble the positive pole piece, negative pole piece and diaphragm in an orderly manner. The active material of the positive pole piece is nickel-cobalt lithium manganese oxide NCM811, the negative pole piece uses graphite as the active material, and the battery capacity is ~122A·h. The gas-trapping structural unit is composed of metal-organic framework (porous) materials and molecular sieve nanoparticles.

[0057] The gas trapping structural unit is prepared by the following process:

[0058] 1mmol of H 2 BTTA(2,5-di(1H-1,2,4-triazol-1-yl)terephthalic acid) ligand and 1mmol Cu(NO 3 ) 2 ·3H 2 O was reacted in a hydrothermal reactor for 48 h, cooled to room temperature and washed several times with deionized water and acetone, ...

Embodiment 2

[0065] The lithium-ion battery is a square battery, which consists of an electrode group, an aluminum case, a gas capture structural unit, a cover plate, tabs, and an explosion-proof valve. The pole group adopts the lamination or winding process to assemble the positive pole piece, negative pole piece and diaphragm in an orderly manner. The active material of the positive pole piece is nickel-cobalt lithium manganese oxide NCM811, the negative pole piece uses graphite as the active material, and the battery capacity is ~122A·h. The gas capture structural unit is composed of metal-organic framework (porous) materials, molecular sieves, cerium-zirconium solid solution, and barium oxide nanoparticles.

[0066] The gas trapping structural unit is prepared by the following process:

[0067] 1mmol of H 2 BTTA ligand and 1mmol of Cu(NO 3 ) 2 ·3H 2 O was reacted in a hydrothermal reactor for 48 h, cooled to room temperature and washed several times with deionized water and aceton...

Embodiment 3

[0076] The lithium-ion battery is a square battery, which consists of an electrode group, an aluminum case, a gas capture structural unit, a cover plate, tabs, and an explosion-proof valve. The pole group adopts the lamination or winding process to assemble the positive pole piece, negative pole piece and diaphragm in an orderly manner. The active material of the positive pole piece is nickel-cobalt lithium manganese oxide NCM811, the negative pole piece uses graphite as the active material, and the battery capacity is ~122A·h. The gas-trapping structural unit is composed of metal-organic framework (porous) material, molecular sieve, cerium-zirconium solid solution, barium oxide, and Pd-based molecular sieve nanoparticles.

[0077] The gas trapping structural unit is prepared by the following process:

[0078] 1mmol of H 2 BTTA ligand and 1mmol of Cu(NO 3 ) 2 ·3H 2 O was reacted in a hydrothermal reactor for 48 h, cooled to room temperature and washed several times with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com