Patents

Literature

59results about How to "Improve surface aesthetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

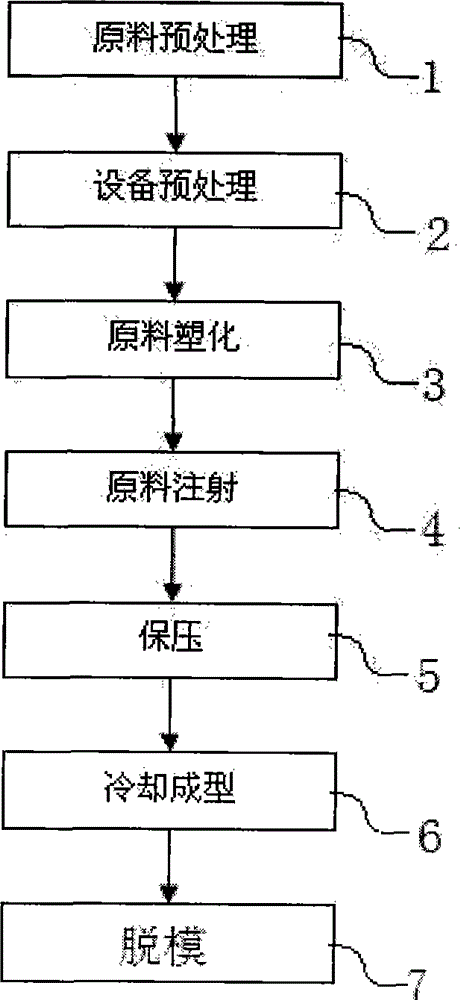

Cover plate injection molding technology of ABS (Acrylonitrile Butadiene Styrene) plastic washing machine

ActiveCN102407589AThe process steps are simpleEasy to implementDomestic articlesEngineeringPre treatment

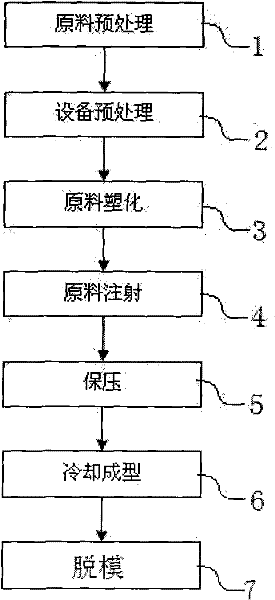

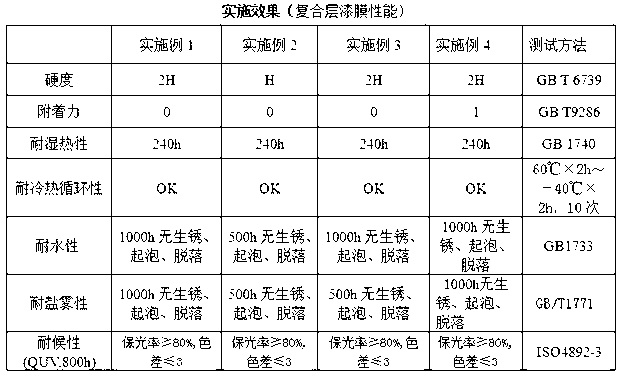

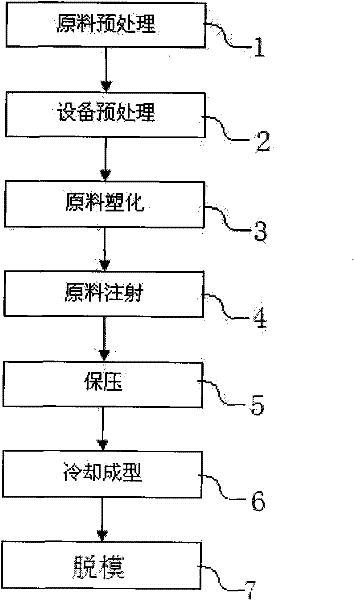

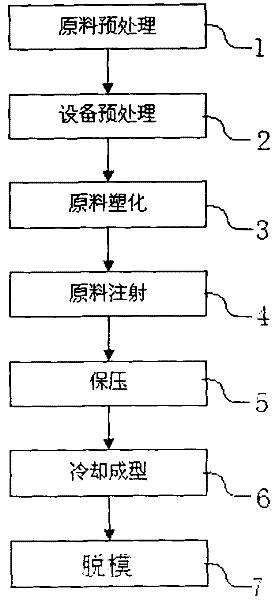

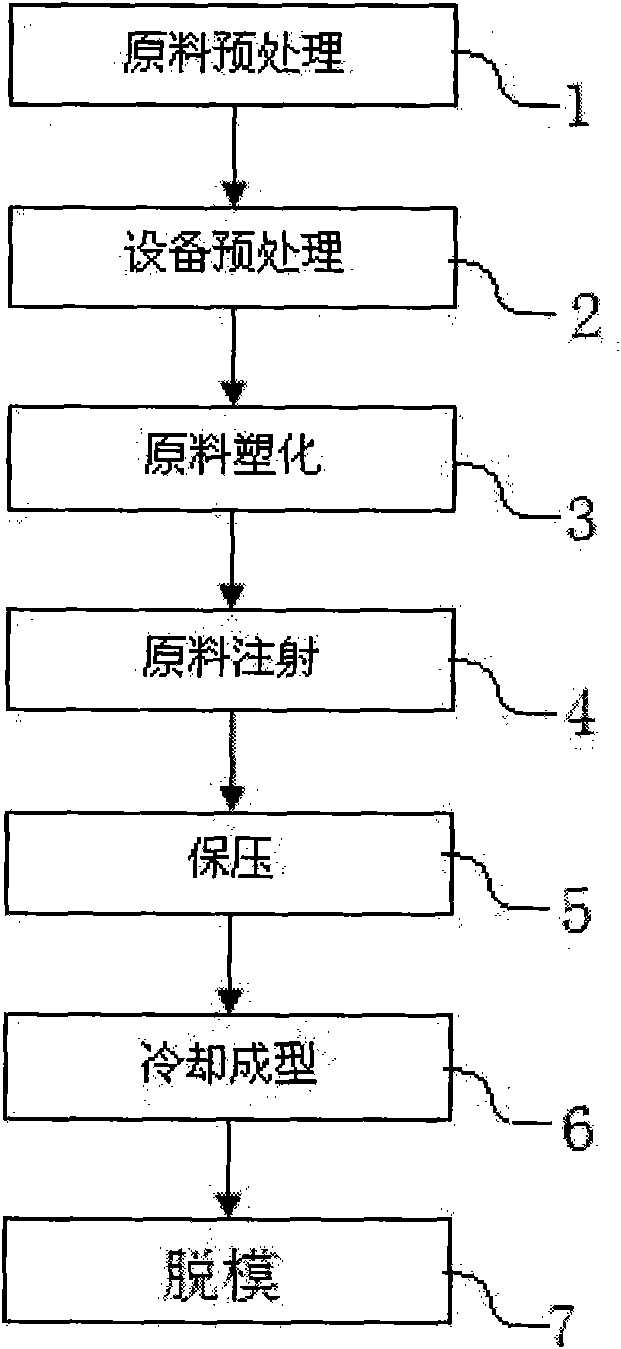

The invention discloses a cover plate injection molding technology of ABS (Acrylonitrile Butadiene Styrene) plastic washing machine, which comprises the following steps of: (1) preprocessing raw materials; (2) preprocessing an injection molding system and an injection molding mould; (3) plasticizing; (4) injecting; (5) maintaining pressure; (6) cooling and forming; and (7) demolding. The technology has simple implementation steps, effectively reduces forming cycle and production cost and effectively improves quality of finished product by corresponding technological conditions.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

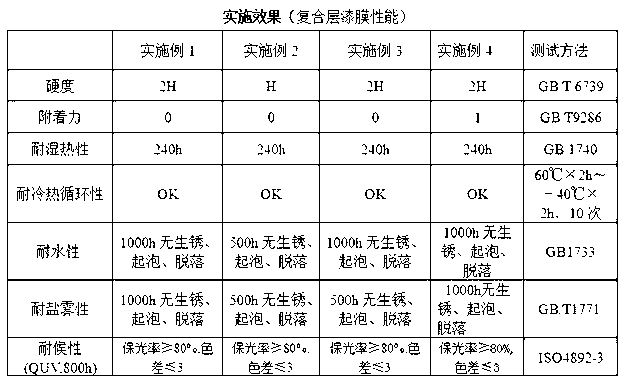

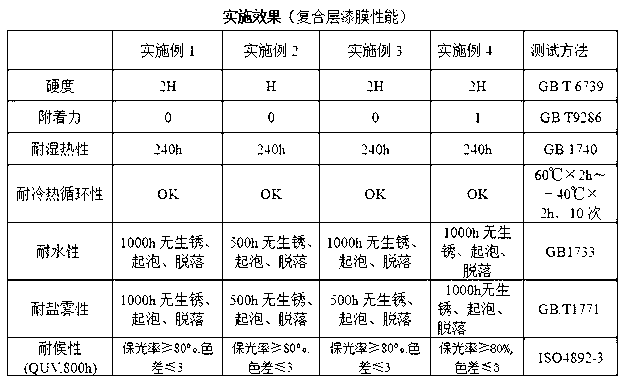

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Injection molding technology for acrylonitrile butadiene styrene (ABS) plastic air conditioner shell

ActiveCN102407588AThe process steps are simpleEasy to implementCoatingsEngineeringInjection molding process

The invention discloses an injection molding technology for an acrylonitrile butadiene styrene (ABS) plastic air conditioner shell, and the technology comprises the following steps of: (1) pretreating raw materials; (2) pretreating an injection molding system and an injection molding mould; (3) plasticizing; (4) injecting; (5) maintaining the pressure; (6) molding by cooling; and (7) demoulding. The injection molding technology is simple in implementation steps, and can be used for effectively reducing the molding period and the production cost, and effectively improving the quality of finished products by virtue of the corresponding technological condition.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Coating process applying water-based paint to metal parts of engineering machinery

InactiveCN102974522AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyEngineering

The invention discloses a coating process applying water-based paint to metal parts of engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery enables the water-based paint to be correctly used for the coating of the metal parts of the engineering machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and physical and chemical performance coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

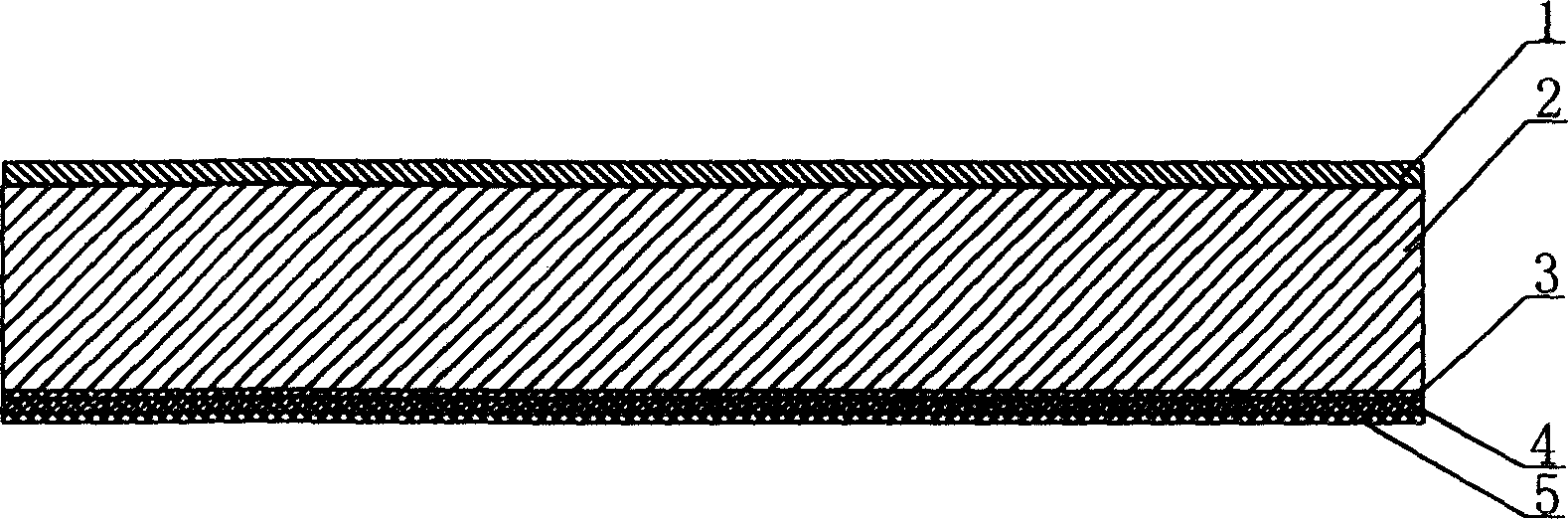

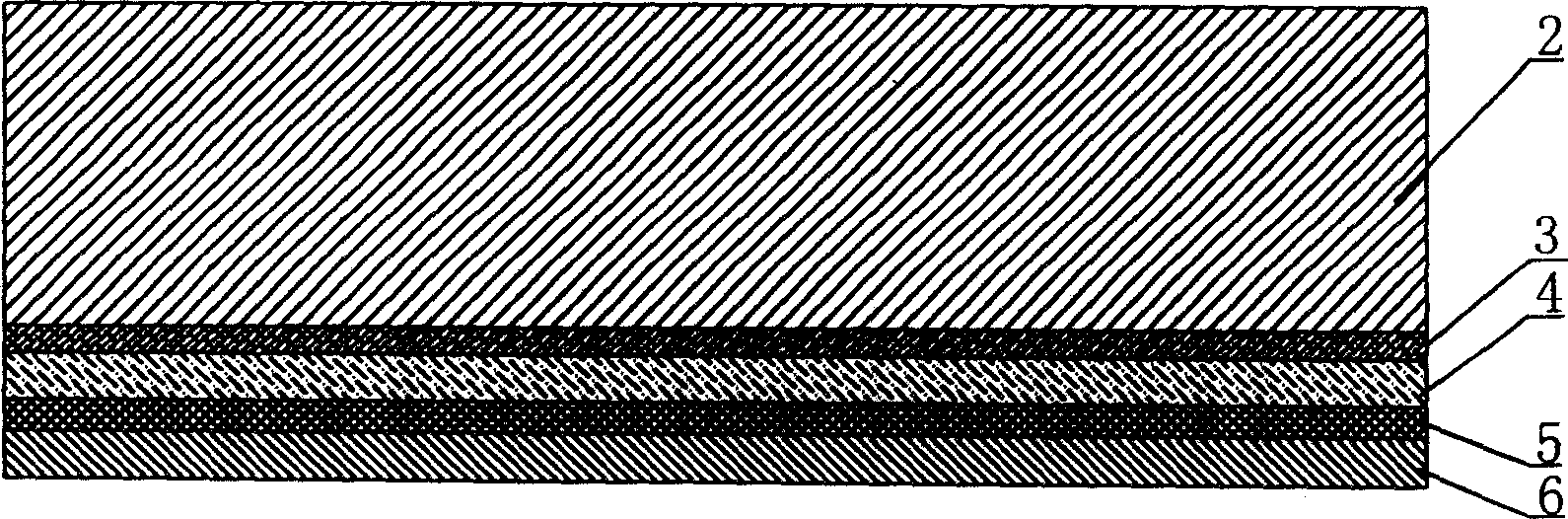

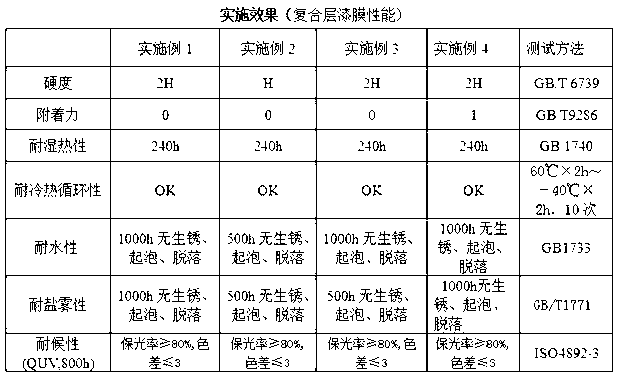

Coloured clad armor plate composite material and adhesive used thereon

InactiveCN1730519AAdhesion has no effectAdhesion effectPolyureas/polyurethane adhesivesMetal layered productsPolyesterPolyurethane adhesive

The invention provides a colored coating and steel plate composite material, wherein steel plate with a coated layer is used as the base plate, the surface of the coating layer is covered by composite polyester film, a polyurethane adhesive layer is arranged between the two materials, the thickness of the coated steel plate is 0.1-2.5mm, the thickness of the polyester film is 10-50um, the thickness of the adhesive layer is 3-30um. The invention also provides the process for preparing the polyurethane adhesive.

Owner:NANTONG GAOMENG NEW MATERIAL

Coating process applying water-based paint to forklift metal parts

InactiveCN102974521AGood lookingGood decorative effectAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringManufacturing engineering

The invention discloses a coating process applying water-based paint to forklift metal parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of a critical component of a forklift. The water-based paint is enabled to be correctly used for coating of the critical component of the forklift, and the coating process applying the water-based paint to the forklift metal parts not only solves harm and potential safety hazards brought about by a traditional coating process to the forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Surface treatment method for stainless steel pipe

InactiveCN1967039AImprove surface aestheticsAccelerated corrosionAbrasion apparatusSolid state diffusion coatingWaxPre treatment

The surface treatment for stainless steel tube adopts mechanical polishing and grinding pretreatment to make the original surface even and smooth, with shot-blast to make the treatment surface taking on sub light, through drying and high temperature waxing to make the surface more erosion resistant. It is advanced in performance, with good effect.

Owner:张明亮

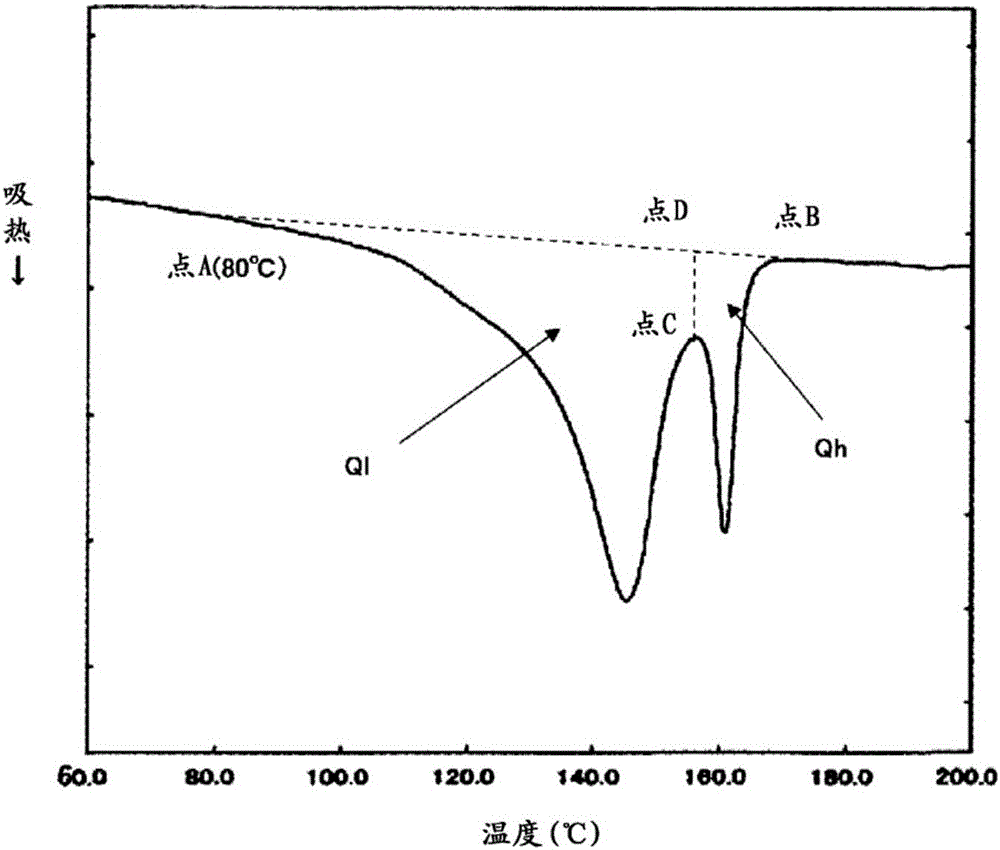

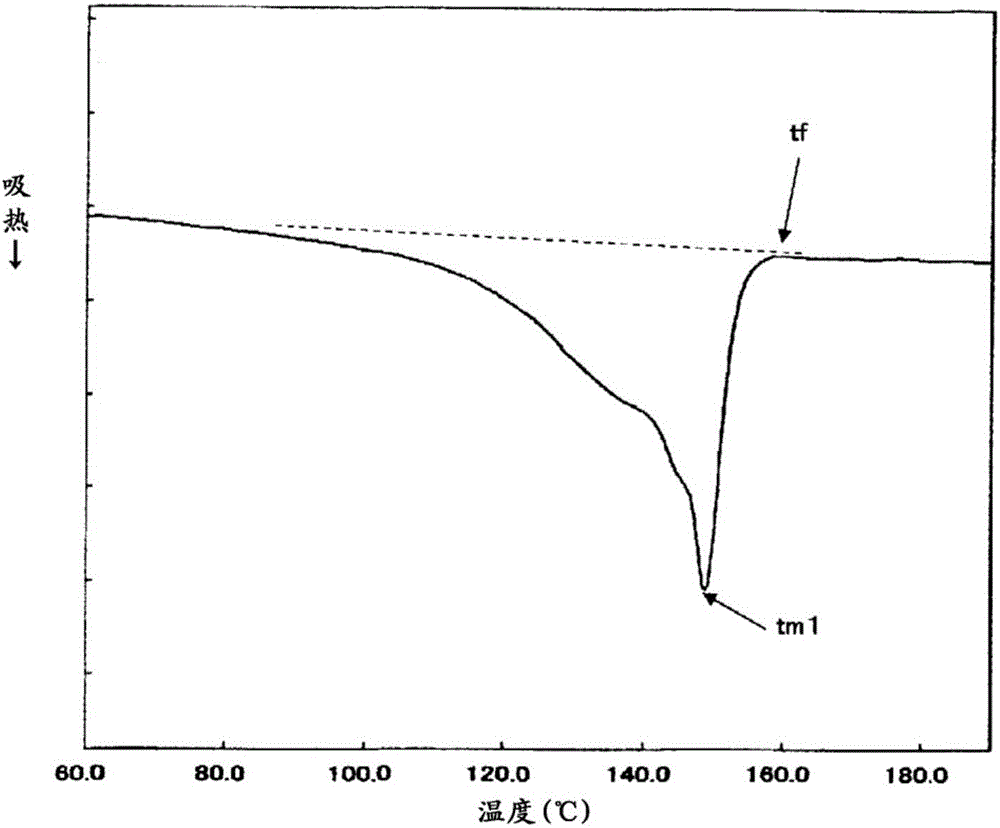

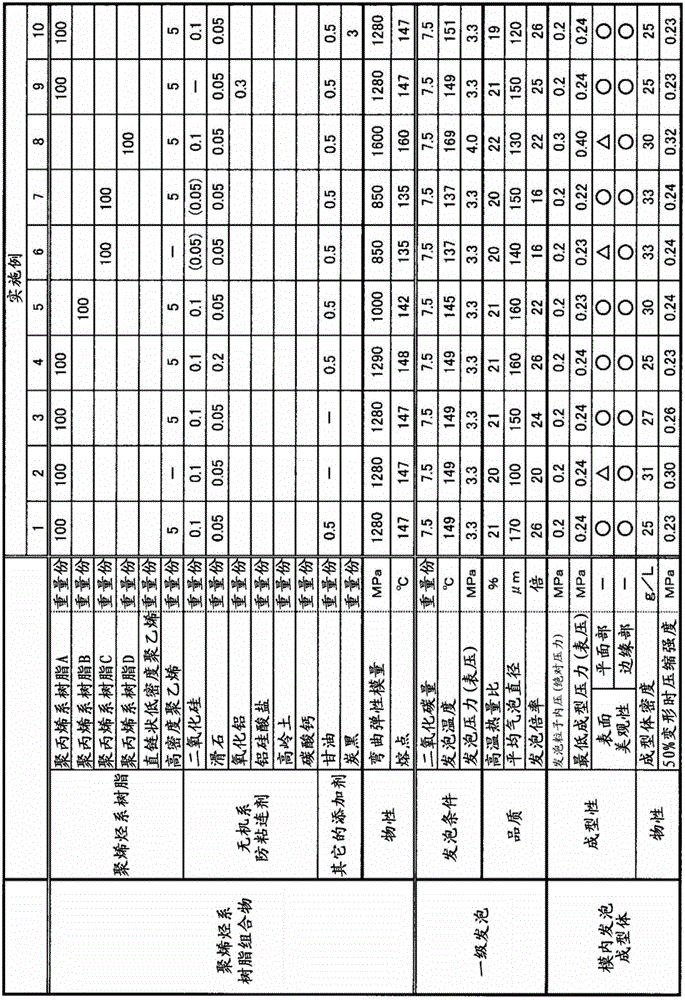

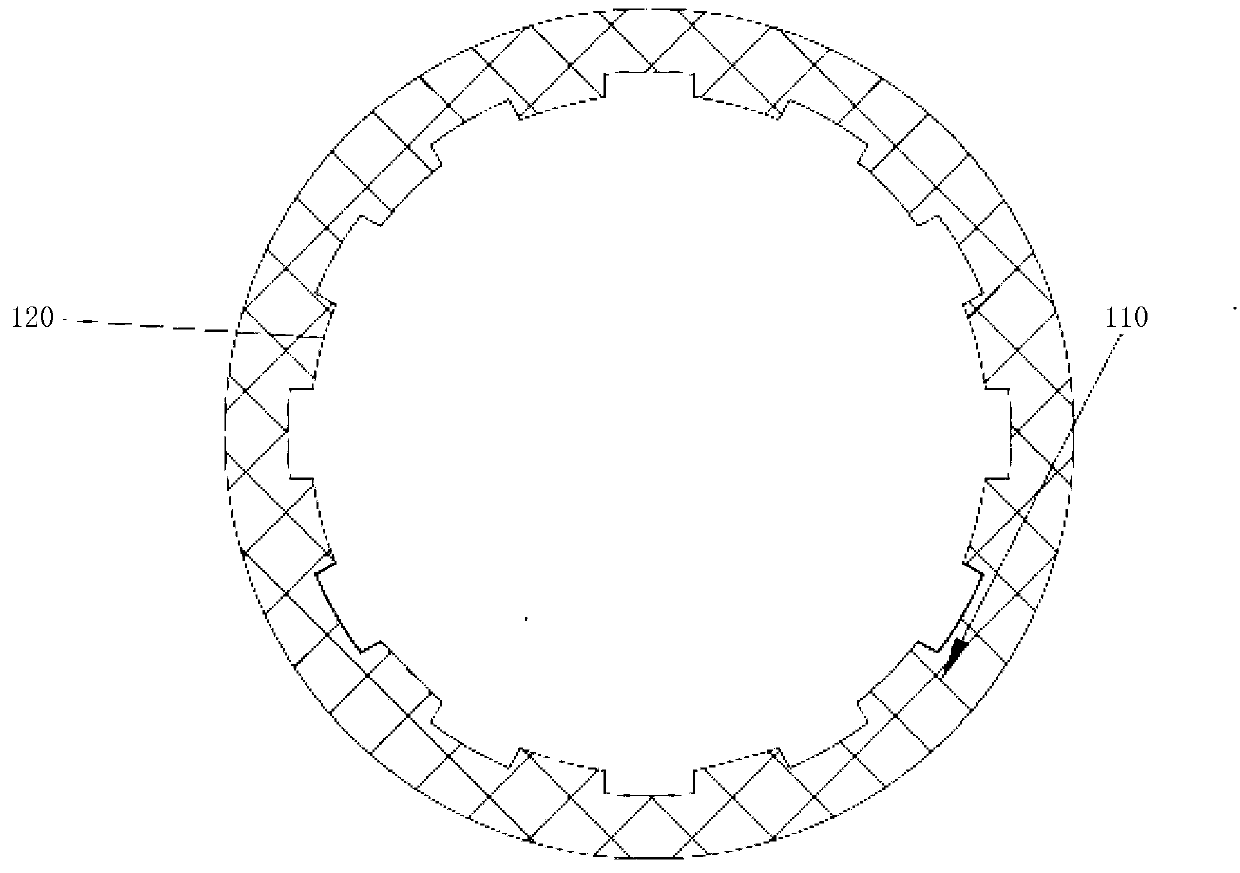

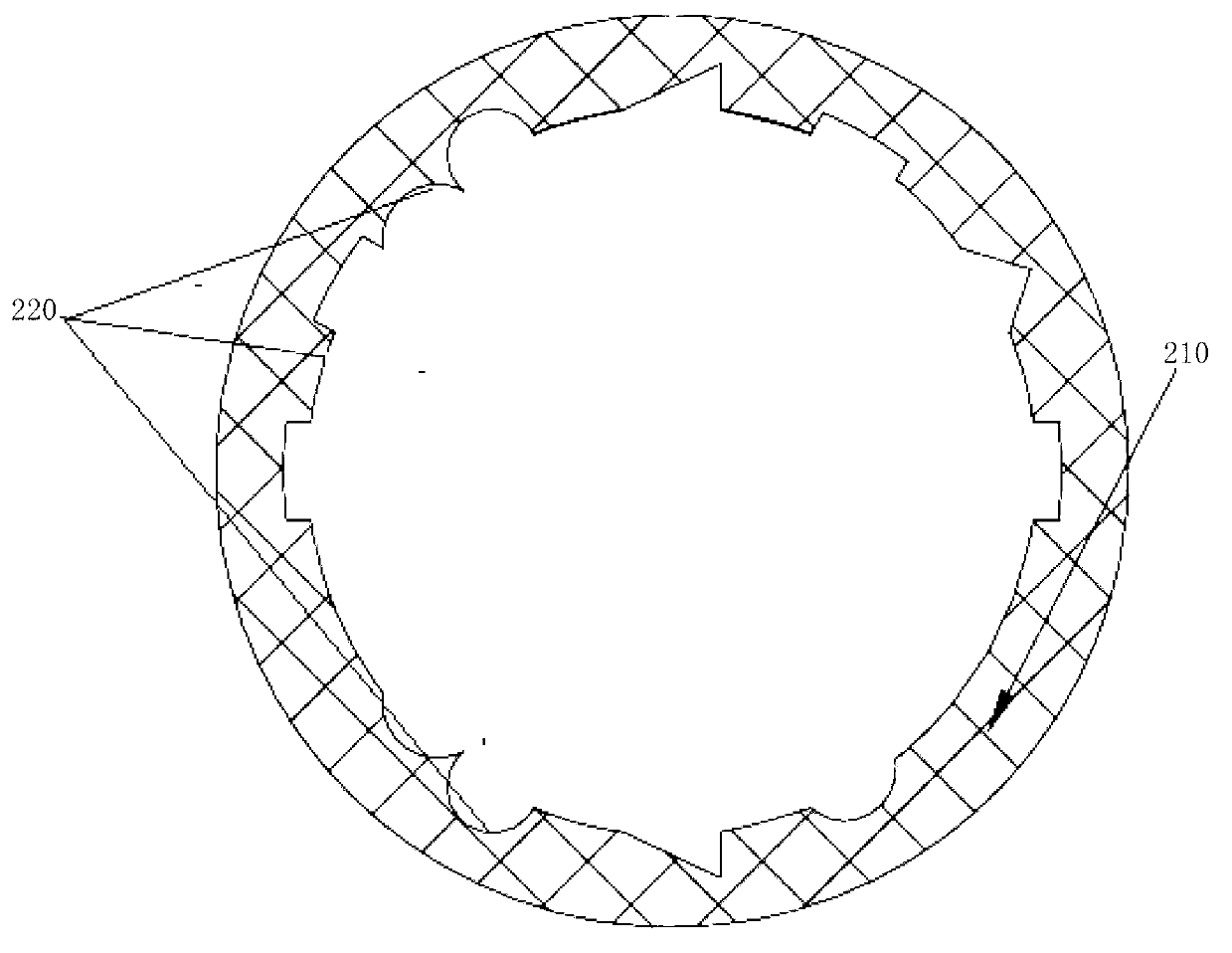

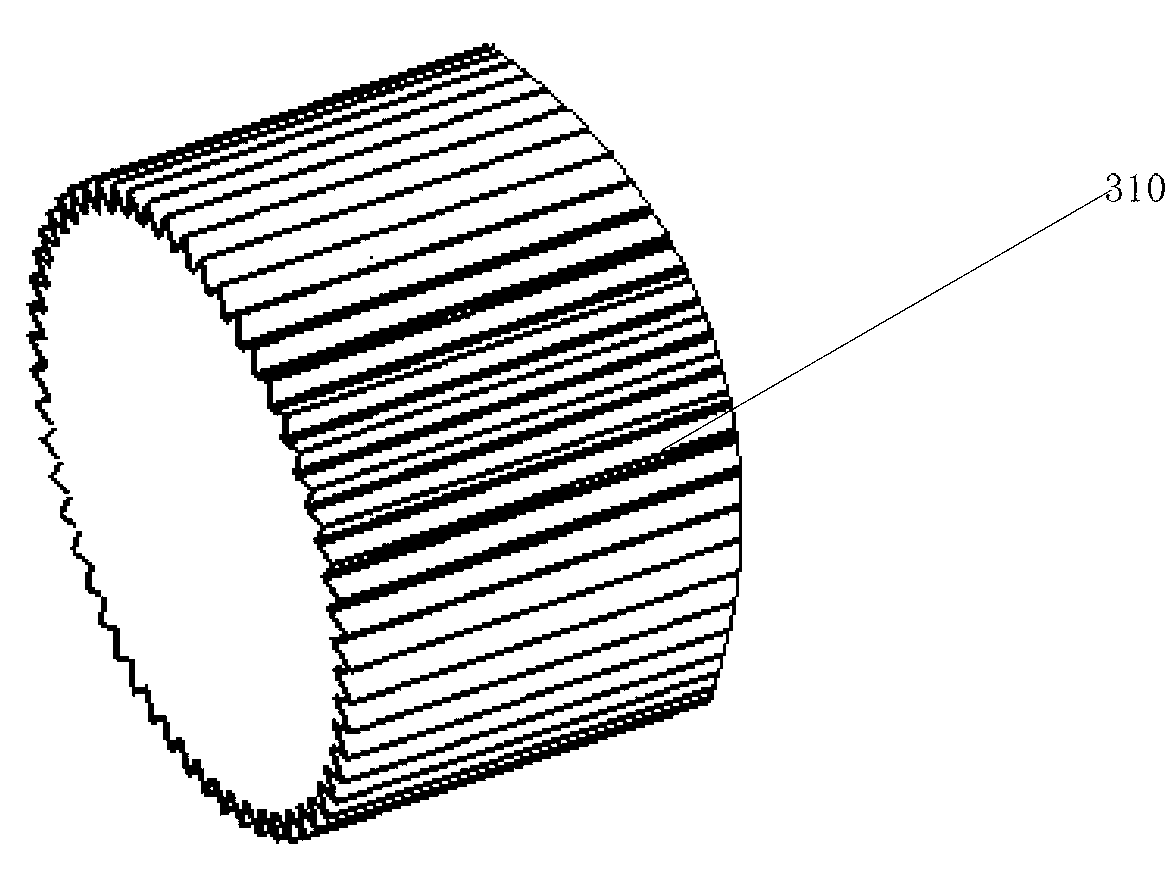

Polyolefin resin foam particles, and polyolefin resin in-mold expansion molded article

The purpose of the present invention is to produce: polyolefin resin foam particles each of which has a large cell diameter in spite of a fact that the particles are produced using a polyolefin resin having an inorganic anti-blocking agent added thereto such as a polyolefin resin for films; and a polyolefin resin in-mold expansion molded article which comprises the polyolefin resin foam particles and has excellent beauty of the surface thereof. Provided are polyolefin resin foam particles which can be produced by expanding polyolefin resin particles each comprising a polyolefin resin composition and which have an average cell diameter of 100 to 400 [mu]m inclusive, wherein the polyolefin resin composition contains at least two types of inorganic anti-blocking agents in the total amount of 0.03 to 2 parts by weight inclusive relative to 100 parts by weight of a polyolefin resin.

Owner:KANEKA CORP

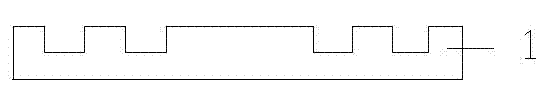

Heat shrink tube and manufacturing method of the same

InactiveCN103138222ATo achieve the effect of exhaust compressionResolve Surface WrinklesCable fittingsEngineeringHeat-shrink tubing

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

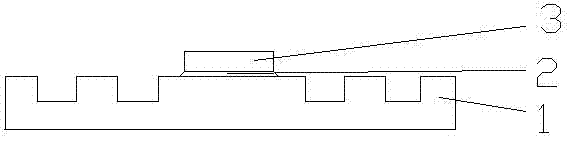

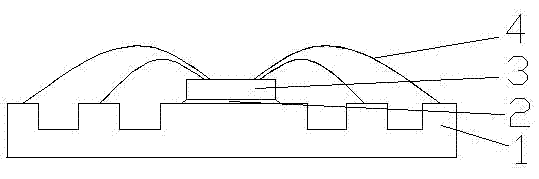

AAQFN package part using electroplating process and manufacture process thereof

InactiveCN103094235AEliminate reflow soldering processReduce consumptionElectrolytic coatingsSemiconductor/solid-state device detailsSolder maskSolder ball

The invention discloses an AAQFN package part using an electroplating process and a manufacture process thereof. The package part is mainly composed of a copper lead framework, adhesive tape glue, a chip, a bonding wire, a plastic package material, a solder mask layer and a solder ball. The copper lead is etched to be adhered with the chip through the adhesive tape glue, the chip is connected with a pin of the copper lead framework through the bonding line and plastically packed by the plastic package materials, the solder mask layer is filled in a pin gap etched at the bottom of the copper lead framework, and the solder ball is electroplated on the pin. The manufacture process mainly comprises the following steps of semi etching a copper framework, thinning a wafer, scratching a wafer, bonding the chip, press soldering, plastically packing, framing, etching at the back, brushing the solder mask layer at the back, electroplating the solder ball and cutting. The manufacture process saves package cost and improves electric performance and product reliability.

Owner:HUATIAN TECH XIAN

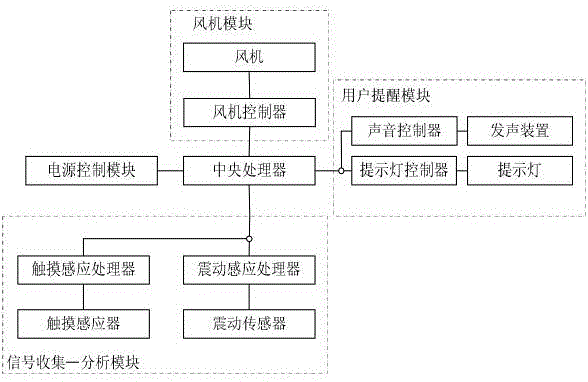

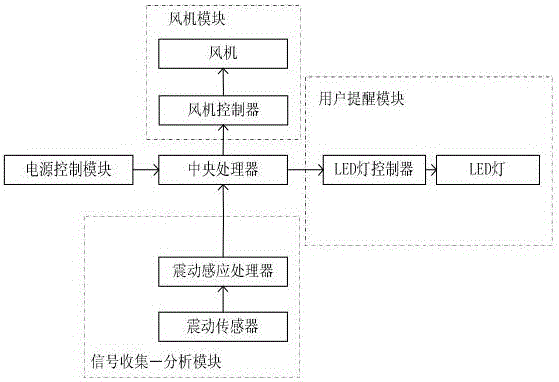

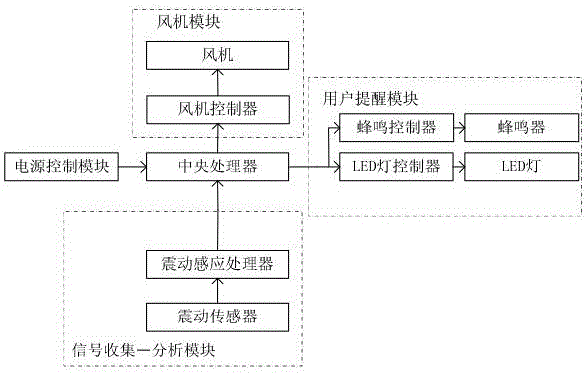

Vehicle-mounted air cleaner control system, control method and vehicle-mounted air cleaner with control system

ActiveCN106739968AImprove practicalityEasy to understandAir-treating devicesSignalling/lighting devicesControl systemAir cleaning

The invention relates to a vehicle-mounted air cleaner control system, a control method and a vehicle-mounted air cleaner with the control system, and belongs to the field of vehicle-mounted air cleaning. The vehicle-mounted air cleaner control system comprises a circuit control module, a signal collection and analysis module, a central processing unit, a fan module and a user reminder module. By controlling the system with the specific control method, the vehicle-mounted air cleaner can be automatically switched on or switched off according to the motion state of a vehicle; on-off conditions are optimized, so that the control method is user-friendlier, and the user experience is better. The invention further discloses the vehicle-mounted air cleaner adopting the control system and the control method. The rationalization and user-friendliness of the vehicle-mounted air cleaner are guaranteed; besides, the vehicle-mounted air cleaner is ingenious in design, and elegant and attractive in appearance design.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

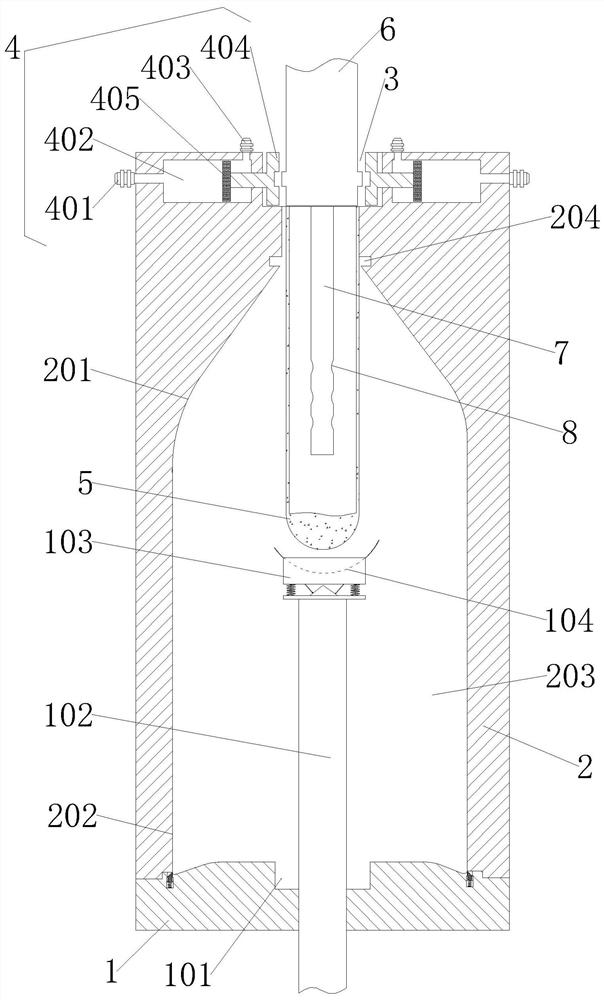

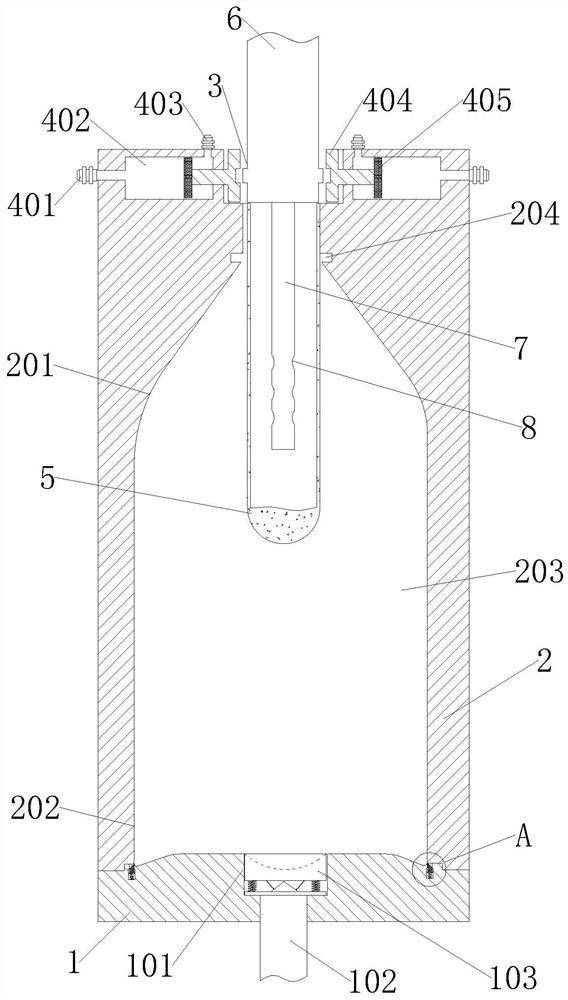

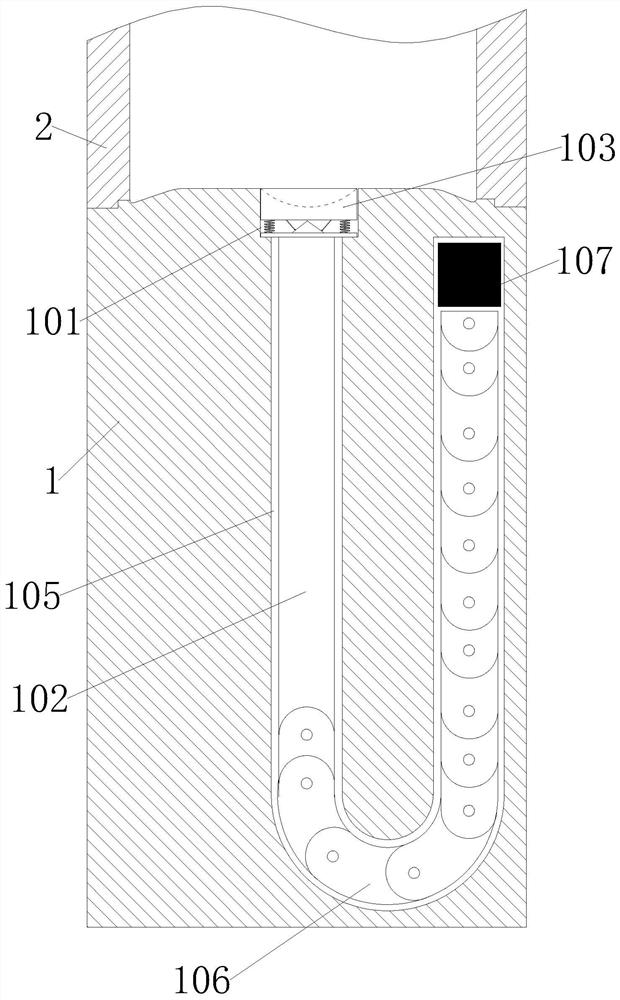

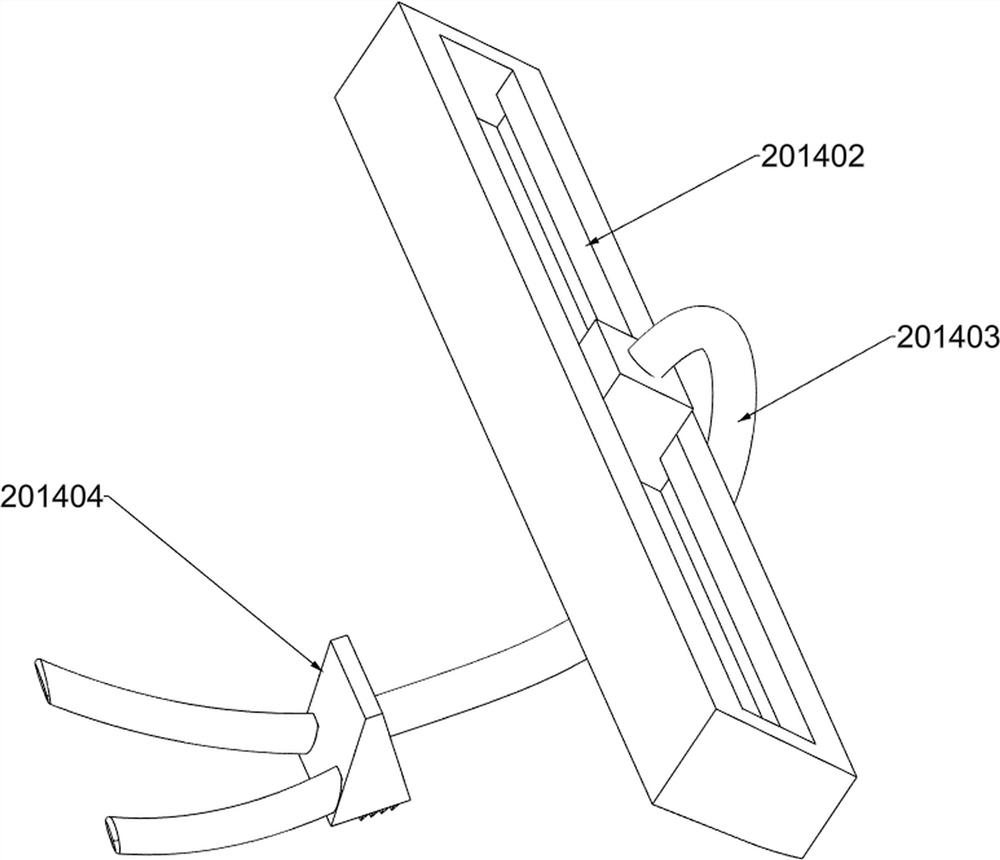

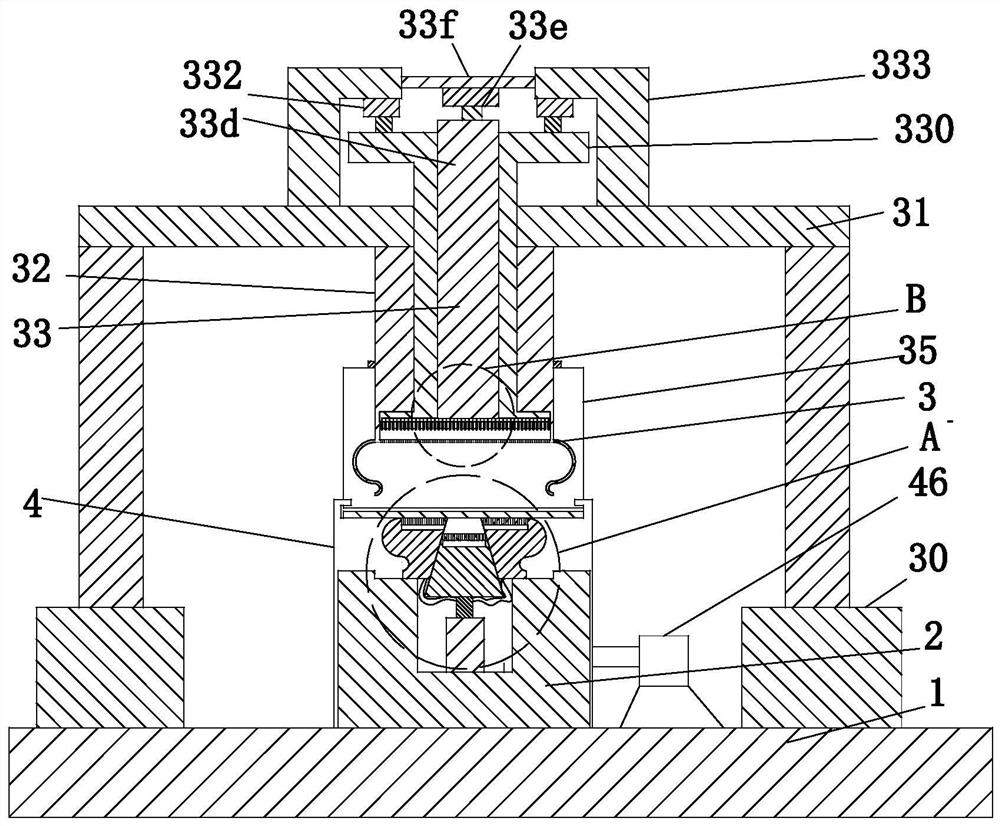

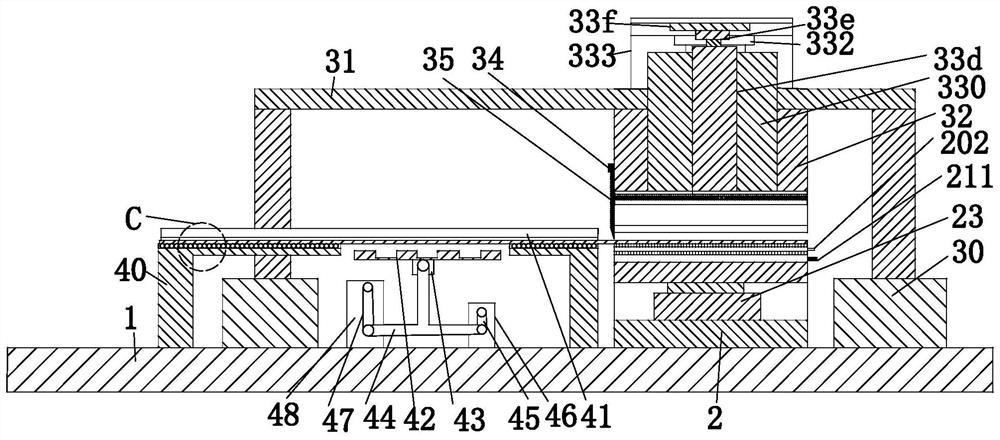

Plastic bottle blow forming mold

The invention provides a plastic bottle blow forming mold and relates to the technical field of blow molding. The plastic bottle blow forming mold is used for blow forming of tubular bottle performs with bottoms. The plastic bottle blow forming mold comprises a lower mold, an upper mold and a liquid blow molding device. The middle portion of the top end of the upper mold is provided with a moldingcavity penetrating through the bottom end of the upper mold. The lower mold is arranged at the bottom end of the upper mold. The lower mold seals the bottom end of the molding cavity of the upper mold. According to the plastic bottle blow forming mold, an annular clamping groove is formed in the position, located at a neck ring, of the top end of the upper mold; the inner wall of the clamping groove is equidistantly provided with pneumatic clamping assemblies; the liquid blow molding device is clamped and fixed through the pneumatic clamping assemblies; movable clamping jaws clamp and hold the liquid blow molding device in the clamping groove, so that the liquid blow molding device is firm and reliable in installation and high in airtightness. The plastic bottle blow forming mold conductsclamping and fixing on the liquid blow molding device through the pneumatic clamping assemblies and has the advantages of being flexible in operation, high in loosening and clamping efficiency, largein clamping force and the like.

Owner:合肥新胜塑料科技有限公司

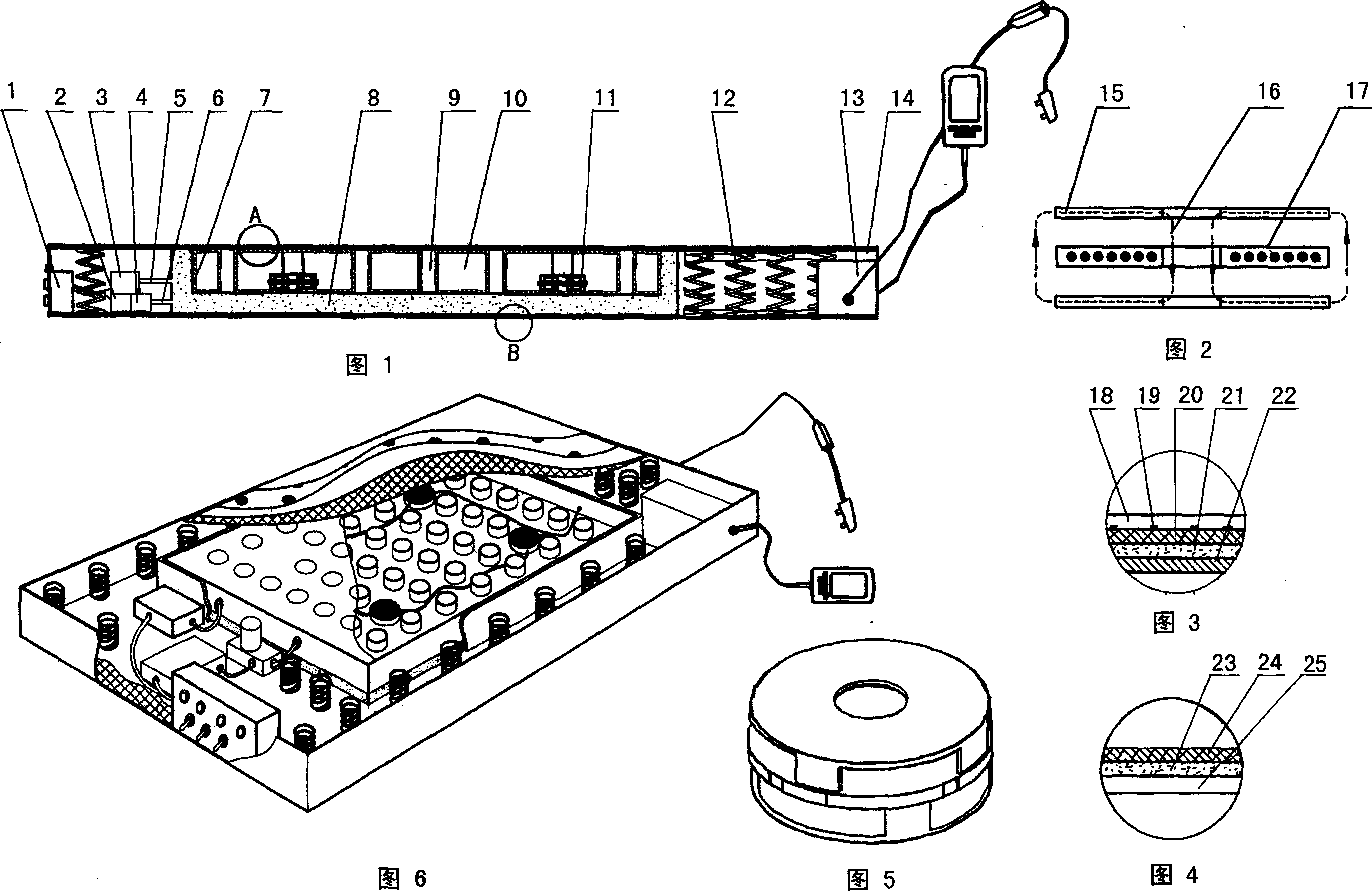

Moisture health insole

InactiveCN1907179ASmall footprintService life is not affectedStuffed mattressesSpring mattressesMagnetic heatingFiber

The invention discloses a hydrosphere hygienic mattress, which contains hollow sealed bag, wherein several column holes are set on the upper and lower surface of bag, whose lateral wall contains vent pipe, water pipe; the insulating layer is loaded on the lateral and bottom of bag; the magnetic heating element is set in the bag, which loads bag accessory; the bag and bag accessory are set in the base, whose residual space contains spring; the upper surface of base possesses PVC pull net, felt layer, fiber cotton insulating layer and surface layer from inwards to outwards sequently; the lower surface of base concludes metal pull net, felt layer, bottom layer, surface layer in connection with bottom layer from inwards to outwards sequently.

Owner:孙兴国

3D painting, method for preparing same and construction process

The invention provides a 3D painting, a method for preparing the same and a construction process. The 3D painting comprises the following components in percentage by weight: 70.0 to 75.0 percent of hydroxy acrylic acid resin, 0.2 to 0.3 percent of polyacrylate solution, 1.0 to 2.0 percent of adhesive force promoter, 5.0 to 10.0 percent of toluene, 6.0 to 10.0 percent of butyl acetate, 5.0 to 10.0percent of trimethylbenzene, 0 to 1.0 percent of metal complex dyestuff, 0 to 1.5 percent of butyl glycol ether, 0 to 1.0 percent of cyclohexanone and 0.5 to 2.0 percent of pearlescent pigment. The 3D painting has good comprehensive properties, can provide the vivid 3D effect for the decoration surface, enhance the surface beauty, improve decorative property and bring people new visual experience, and is widely applied to the surface decoration of indoor and outdoor decoration and furniture, handicraft articles and the like; moreover, the 3D painting also has the advantages of simple preparation method, simple construction process, easy operation and good effect.

Owner:三河亮克威泽工业涂料有限公司

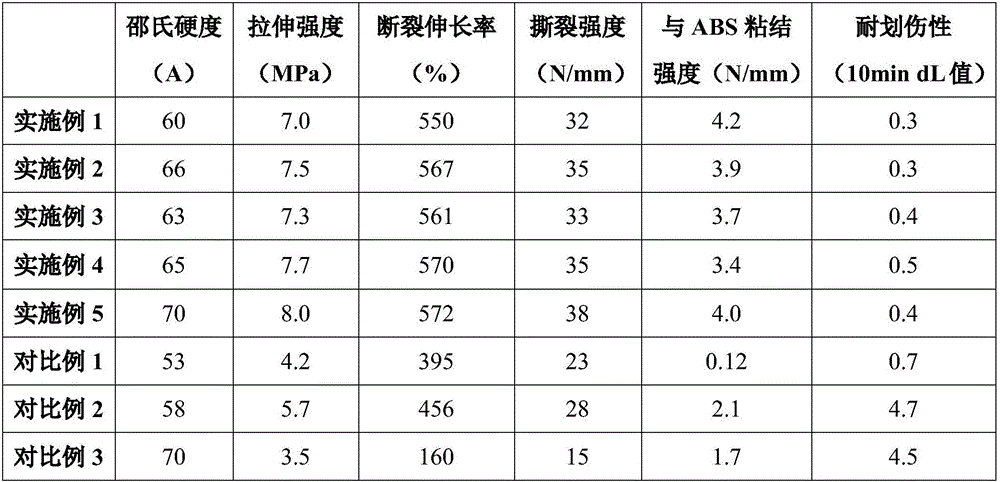

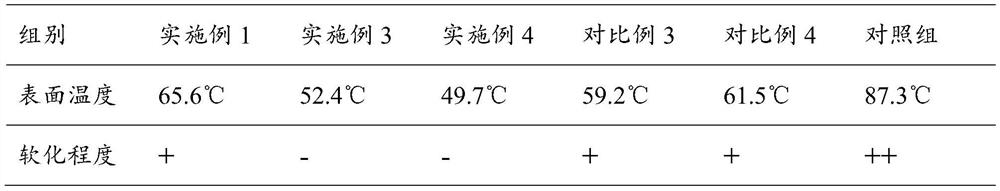

Surface scratch-resistant TPV composition capable of achieving secondary coating forming with ABS base material and preparation method thereof

InactiveCN106519635AImproved surface wear resistance and scratch resistanceIncrease surface aesthetics and service lifeIonomerAging resistance

The invention discloses a surface scratch-resistant TPV composition capable of achieving secondary coating forming with an ABS base material and a preparation method thereof. The TPV composition comprises the raw materials of 31%-63% of TPV, 25%-40% of thermoplastic polyester elastomer, 5%-8% of compatilizer, 2%-6% of ethylene-vinyl acetate copolymer and 5%-15% of ethylene-acrylic acid ionomer. The preparation method includes the following steps that (1) the thermoplastic polyester elastomer is dried; and (2) the thermoplastic polyester elastomer, the TPV, the compatilizer, the ethylene-vinyl acetate copolymer and the ethylene-acrylic acid ionomer are evenly mixed in proportion and then the mixture is placed into a parallel co-rotating twin-screw extruder for melt extrusion and pelleting. The surface scratch-resistant TPV composition disclosed by the invention not only has the heat resistance, ageing resistance and low compression permanent deformation of TPV materials but also has the excellent scratch resistance, and the TPV composition can achieve secondary coating with polar resin ABS. The preparation method is simple, the production process is easy to operate, and the surface scratch-resistant TPV composition can be widely used as an ABS secondary coating material with high requirements on the coating surface.

Owner:广东省石油化工研究院

Carbon fiber composite material for high-temperature environment and preparation thereof

PendingCN112409787AAvoid problems with poor mixing uniformityThe problem of poor mixing uniformity is overcomeSynthetic resin layered productsResin-Based CompositeBoron nitride

The invention relates to an enhanced heat-resistant carbon fiber composite material and a product thereof. The enhanced heat-resistant carbon fiber composite material is prepared from the following raw materials: a composite resin base material prepared from a first composite resin composition, a second composite resin composition and an auxiliary agent 1; and a graphene nanosheet selected from nitride particles of silicon nitride or boron nitride; and a corresponding auxiliary agent 2. The carbon fiber composite material prepared by the preparation method of the invention not only has excellent mechanical properties, but also has the advantages of excellent heat resistance, heat insulation, processing formability and the like, and is particularly suitable for manufacturing heat insulationdevices in a high-temperature heat radiation environment.

Owner:NANJING XIAOZHUANG UNIV

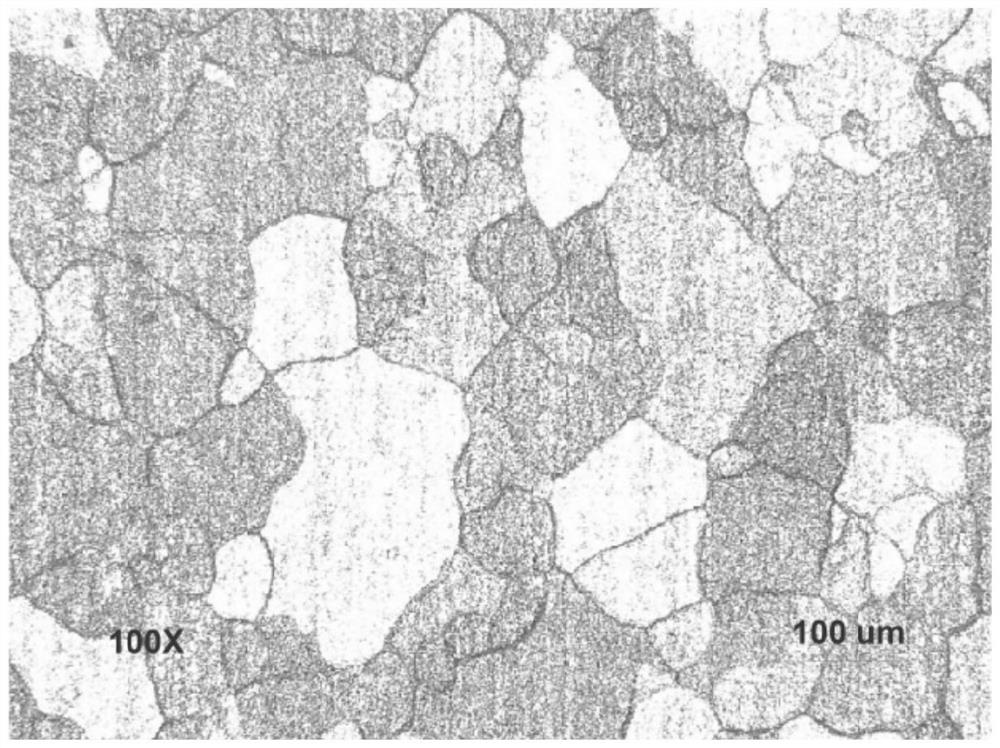

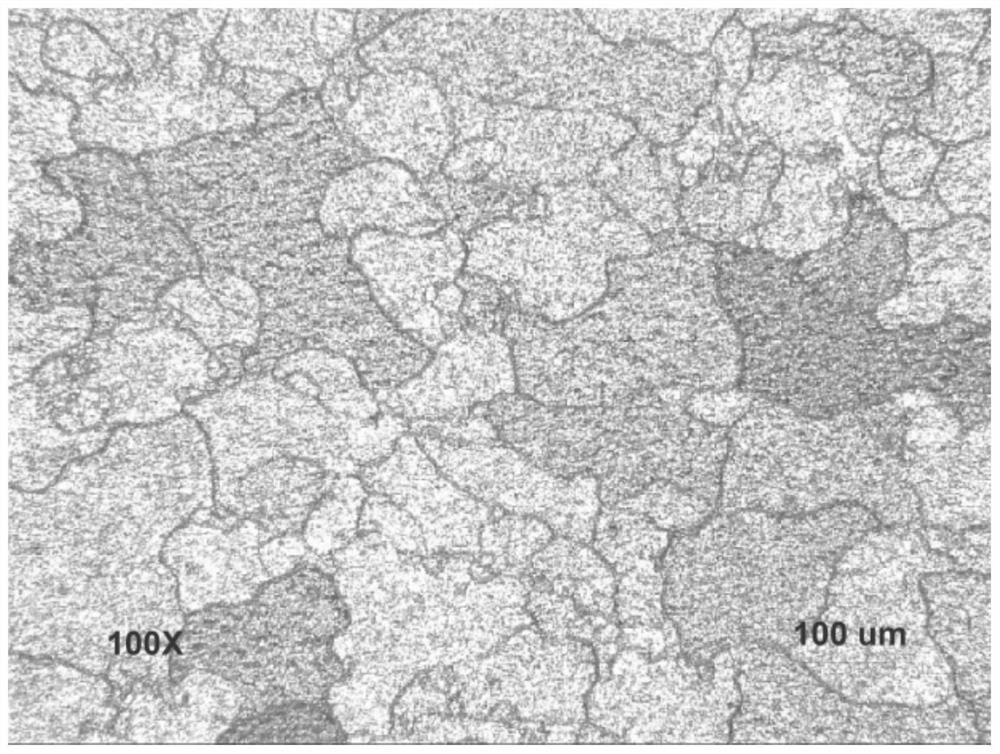

Extrusion die and aluminum alloy profile extrusion method

The invention provides an extrusion die and an aluminum alloy profile extrusion method. The extrusion die comprises a body and an extrusion channel, wherein the extrusion channel is arranged in the body, runs through the body and comprises a flow guide groove, a conical groove and a working belt which are connected in sequence, and the flow guide groove, the conical groove and the working belt are the same in section shape. According to an aluminum alloy profile, because the ingredient proportion, the extrusion process parameters and the extrusion die are adjusted, so that the hardness is larger than or equal to HB95, and coarse grains on the surface layer and the section are less than or equal to 94 microns.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

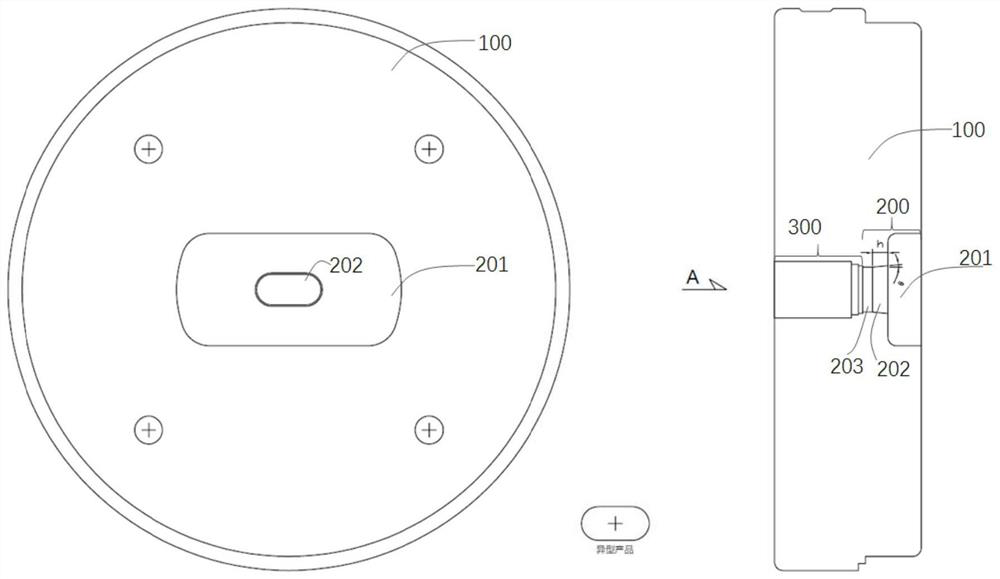

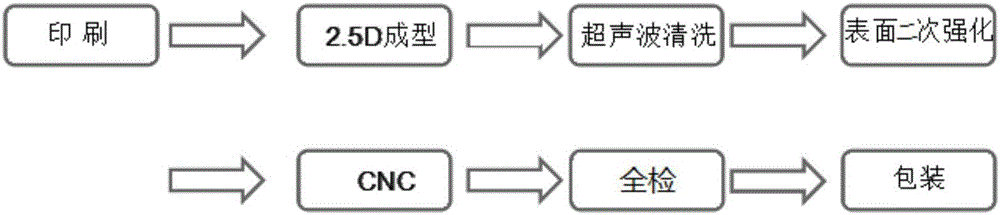

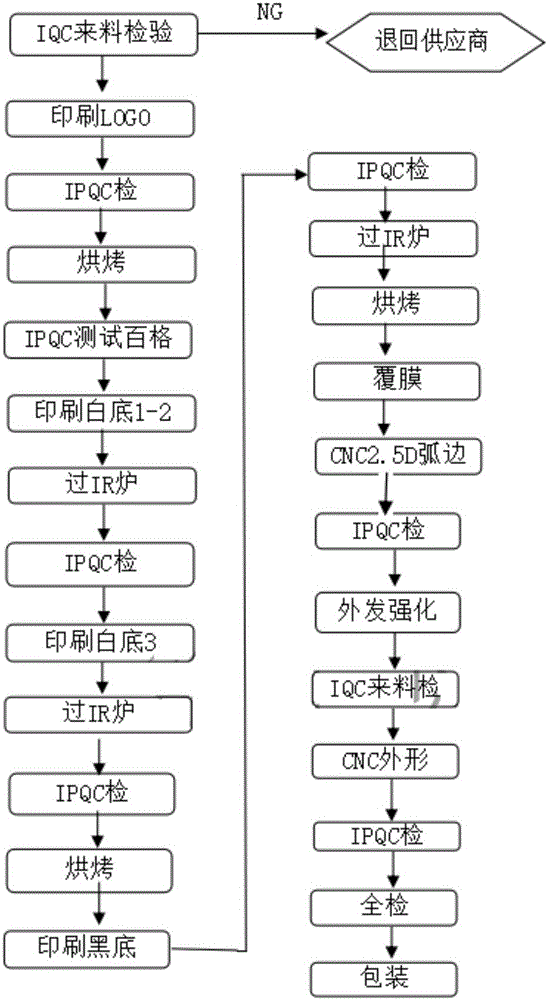

Processing method of 2.5D mobile phone front and rear covers

ActiveCN106559527ALow costReduce processing difficultyTelephone set constructionsSocial benefitsMegasonic cleaning

The present invention discloses a processing method of 2.5D mobile phone front and rear covers. The method comprises the following steps: the step 1: cutting; the step 2: printing; the step 3: 2.5D molding; the step 4: ultrasonic cleaning; the step 5: surface secondary reinforcement; the step 6: CNC; the step 7: lamination; and the step 8: complete inspection and package. The processing method of 2.5D mobile phone front and rear covers is simple in technology steps, the 2.5D can become the mainstream direction in the mobile phone industry in the next 3-5 years, the 2.5D composite board is lower in processing difficulty, more stable in the manufacture procedure and much lower in cost than the 2.5D glass, the 2.5D composite board can be more dazzling in color than the 2.5D glass to allow the customers to be more satisfied, the 2.5D composite board is better in resistance to fall than the glass so as to greatly solve the after cost of the terminal caused by a broken screen, and the 2.5D mobile phone battery cover can realize industrial production and can bring good economic and social benefits for the enterprises.

Owner:SHENZHEN ATES SCI & TECH CO LTD

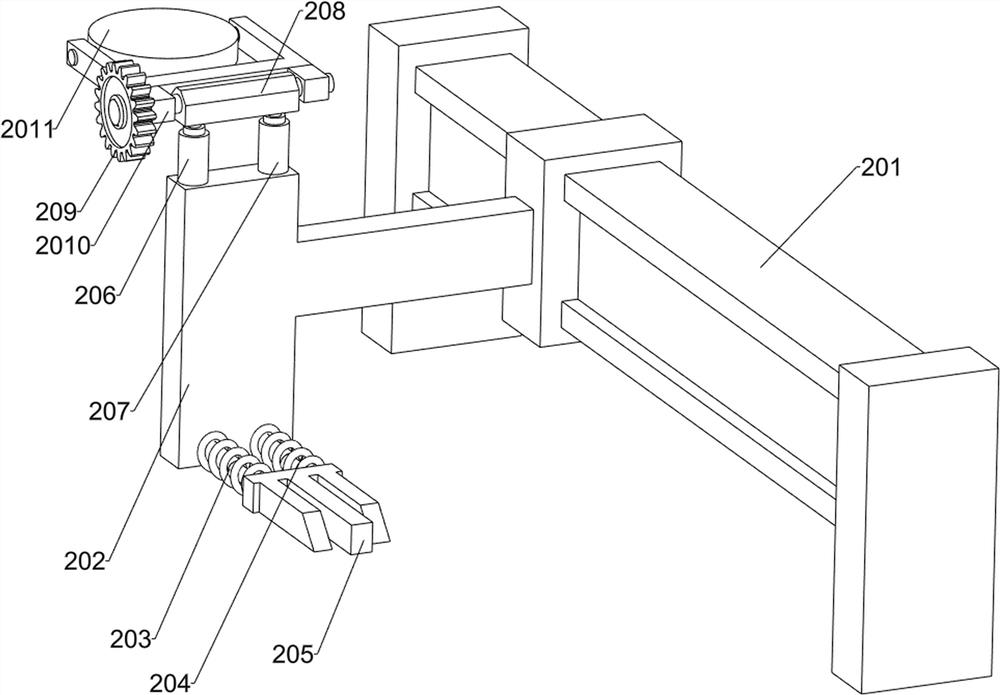

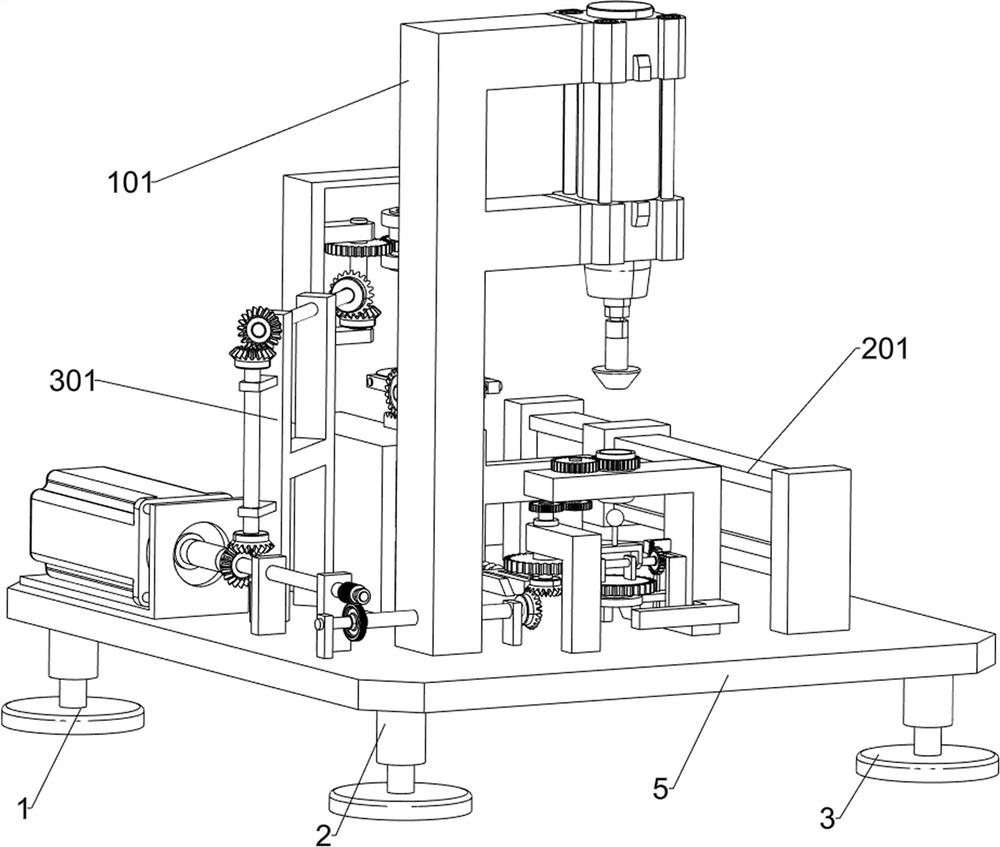

Production detection equipment for metal accessory eyelet buttons

ActiveCN113787412AImprove surface aestheticsAvoid scratchesMeasurement devicesGrinding drivesElectric machineMechanical engineering

The invention relates to the field of metal accessories, in particular to production detection equipment for metal accessory eyelet buttons. The technical problem is how to provide the production detection equipment for the metal accessory eyelet buttons. According to the technical scheme, the production detection equipment for the metal accessory eyelet buttons comprises a bottom plate, a power motor and the like; and the power motor is mounted on the left rear side above the bottom plate. According to the equipment, length detection is carried out on the metal eyelet buttons, the surfaces of the overlong metal eyelet buttons are ground, end face extrusion is carried out on the metal eyelet buttons with the lengths exceeding the rated length, the lower end faces of the metal eyelet buttons are in bent arc shapes, workers are prevented from being scratched by the bottom in the follow-up installation process, finally, the inner ring faces and the outer ring faces of the eyelet buttons are cleaned, residual fine ground scrap particles are removed, and the surface attractiveness of the eyelet buttons is improved.

Owner:江苏仕爵科技有限公司

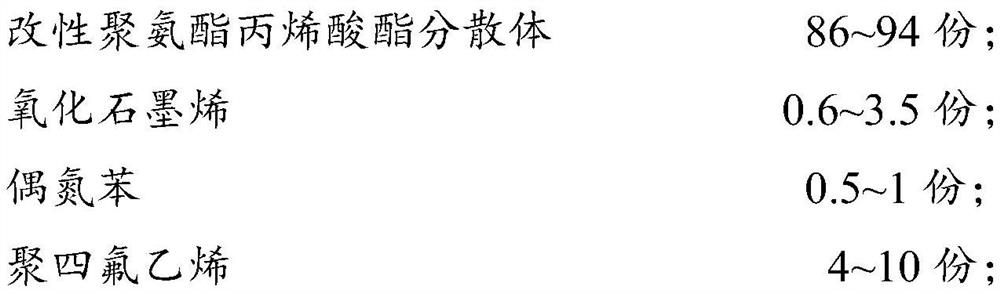

Tile-like wooden floor and preparation method thereof

InactiveCN112778896AEasy to usePlay a role in isolating moisturePolyurea/polyurethane coatingsFlooring insulationsParaffin waxPolyurethane dispersion

The invention discloses a tile-like wooden floor. The tile-like wooden floor comprises a wooden base material, an ink-jet pattern layer is arranged on the front face of the wooden base material, and a moisture-proof layer is arranged on the back face of the wooden base material; and the moisture-proof layer is prepared from a moisture-proof coating, the moisture-proof coating comprises the following components: a polyurethane dispersion, a paraffin emulsion and a nano titanium dioxide dispersion liquid, the nano titanium dioxide dispersion liquid is obtained by dispersing nano titanium dioxide into a dispersion system, the mass fraction of the nano titanium dioxide is 10-15%, and the dispersion system comprises organosilane, water and a solvent. The moisture-proof layer can play a role in isolating moisture and preventing mildew, so that the wood base material is prevented from being rotted, and the decorative pattern is prevented from being influenced.

Owner:广东大自然家居科技研究有限公司

Injection molding process for polyphenylene oxide (PPO) plastic air conditioner shell

The invention discloses an injection molding process for a polyphenylene oxide (PPO) plastic air conditioner shell. The process comprises the following steps of: (1) pretreating a raw material; (2) pretreating an injection molding system and an injection mold; (3) plasticizing; (4) injecting; (5) keeping pressure; (6) cooling for molding; and (7) demolding. The process is simple in implementation steps, the molding cycle is effectively shortened, and production cost is effectively reduced; meanwhile, the quality of a finished product prepared by the process is effectively improved through corresponding process conditions.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

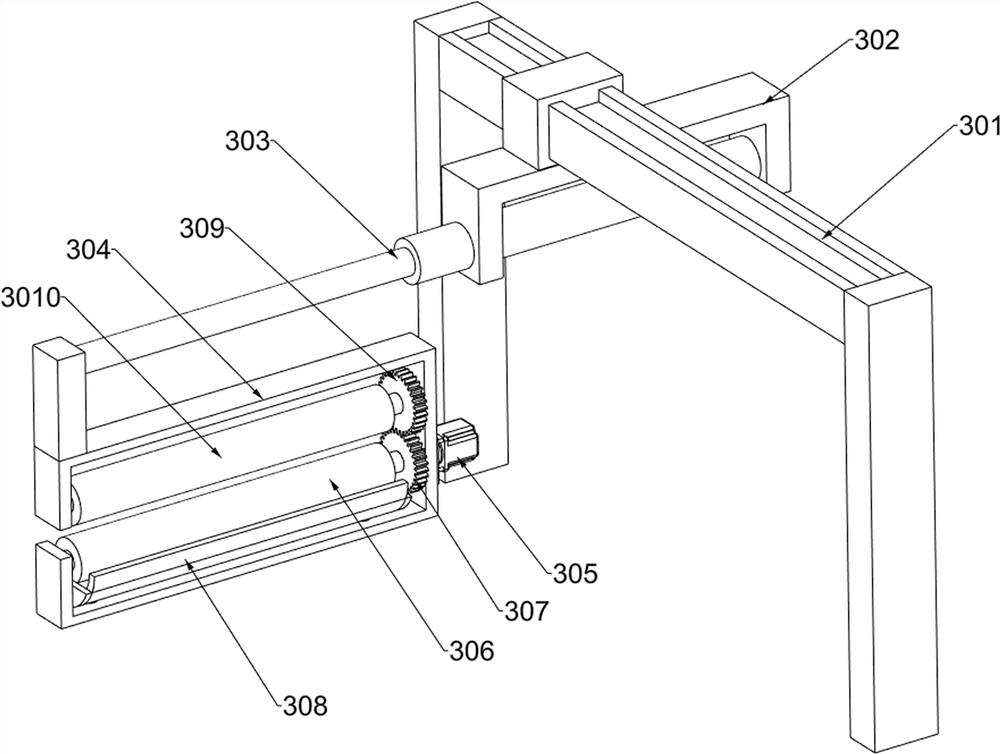

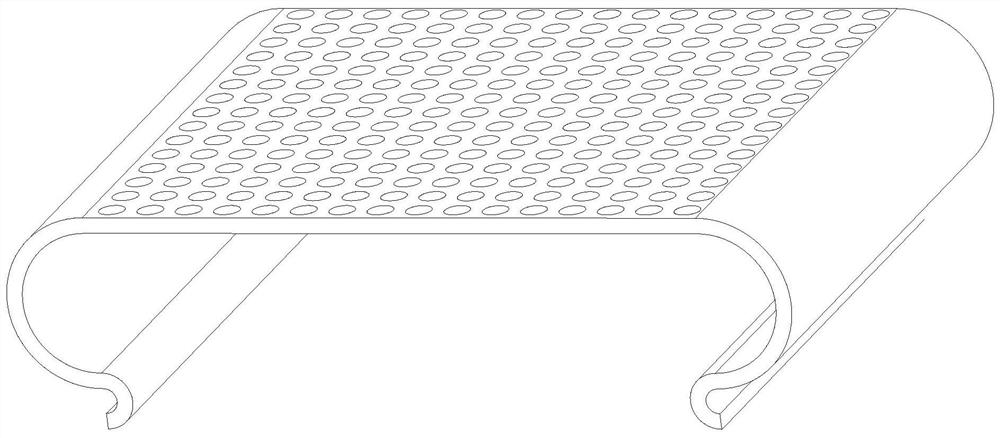

Cotton cloth gluing equipment for surface flattening treatment

ActiveCN113649234ASolve the problem that inclusions cannot flow normallySolve the problem of not flowing normallyMechanical cleaningLiquid surface applicatorsPolyesterPolymer science

The invention relates to the field of cotton cloth dip dyeing subsequent treatment, in particular to cotton cloth gluing equipment for surface flattening treatment. The cotton cloth gluing equipment for surface flattening treatment is provided. According to the technical scheme, the cotton cloth gluing equipment for surface flattening treatment comprises a bottom frame, a bottom plate and the like; and the bottom plate is installed above the bottom frame. According to the cotton cloth gluing equipment for surface flattening treatment, subsequent surface strengthening of polyester-mixed cotton cloth is achieved, a traditional method that gluing is conducted firstly and then removing is conducted is abandoned, the surface of the polyester-mixed cotton cloth is firstly subjected to fluff and cotton ball removing, and meanwhile, in the cotton ball removing process, fluff discharged from cotton balls is protected against being brought up, so that the surface quality of the polyester-mixed cotton cloth is not affected; and finally, glue liquid on the surface of the polyester-mixed cotton cloth is subjected to flattening treatment, the problem that the glue liquid cannot flow normally when the fluff is mixed with the glue liquid is solved, thus the surface attractiveness of the polyester-mixed cotton cloth is enhanced, and the quality of the polyester-mixed cotton cloth is improved.

Owner:长兴钦氏纺织有限公司

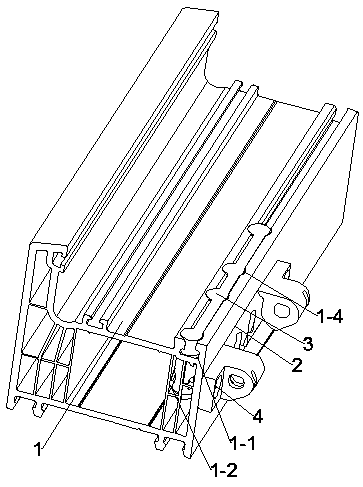

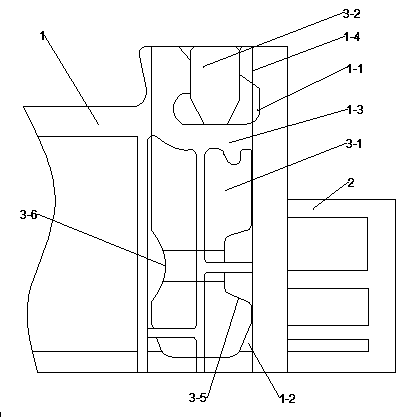

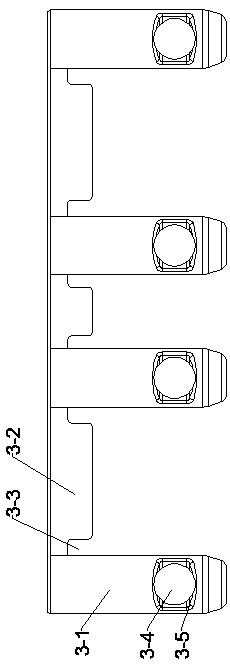

Door and window profile mechanism with hinge fixing reinforcing piece and mounting method thereof

PendingCN108915496AHigh strengthReduce the chance of saggingWindow/door framesWing framesSash windowEngineering

Owner:河南科饶恩门窗有限公司

Injection molding technology for acrylonitrile butadiene styrene (ABS) plastic air conditioner shell

ActiveCN102407588BThe process steps are simpleEasy to implementCoatingsEngineeringInjection molding process

The invention discloses an injection molding technology for an acrylonitrile butadiene styrene (ABS) plastic air conditioner shell, and the technology comprises the following steps of: (1) pretreating raw materials; (2) pretreating an injection molding system and an injection molding mould; (3) plasticizing; (4) injecting; (5) maintaining the pressure; (6) molding by cooling; and (7) demoulding. The injection molding technology is simple in implementation steps, and can be used for effectively reducing the molding period and the production cost, and effectively improving the quality of finished products by virtue of the corresponding technological condition.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

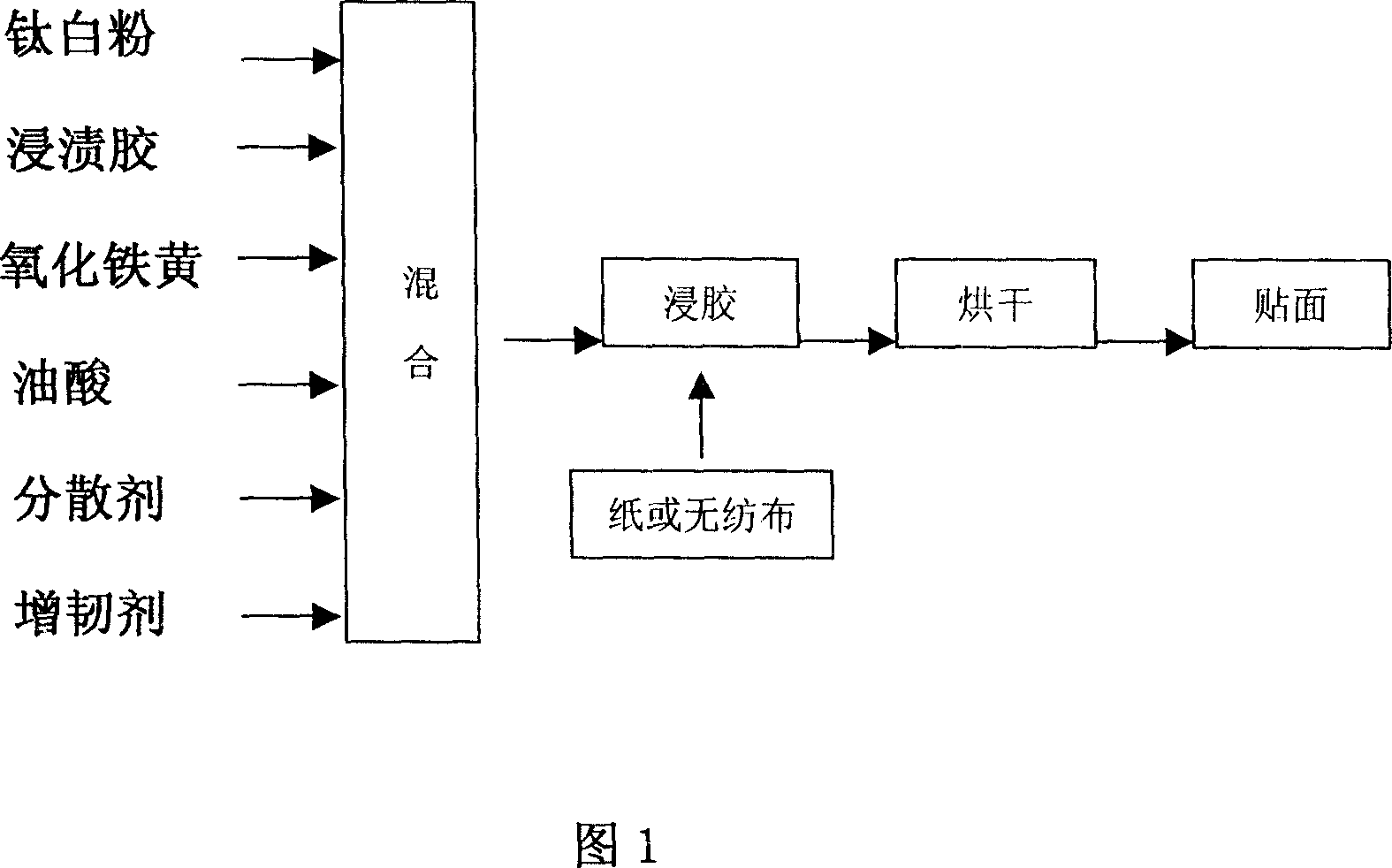

Glue used for floor veneer film immersion and construction method thereof

InactiveCN101100590ASolve the color transition puzzleAvoid the problem of too much color contrast affecting the appearanceAldehyde/ketone condensation polymer adhesivesPolymer scienceTitanium

A glue formula for dip faced paper and faced film and its use for wooden floor faced film are disclosed. The glue consists of dip phenolic glue 80-120 proportion, titanium pigment 15-25 proportion, oleic acid 0.7-1.4 proportion, iron oxide yellow 1-2 proportion, dispersant 1-2 proportion and toughening agent 0.2-0.5 proportion. It has light-yellow color, good appearance and protecting function.

Owner:范会芳

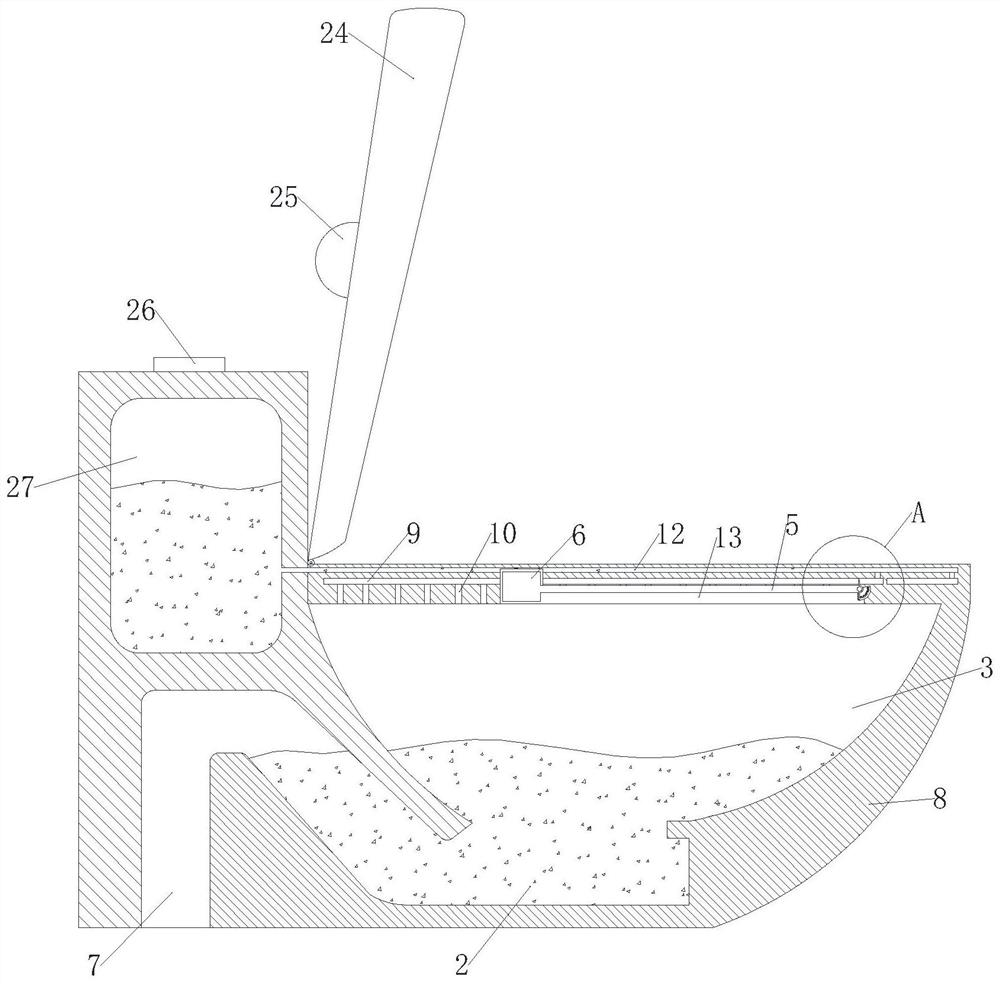

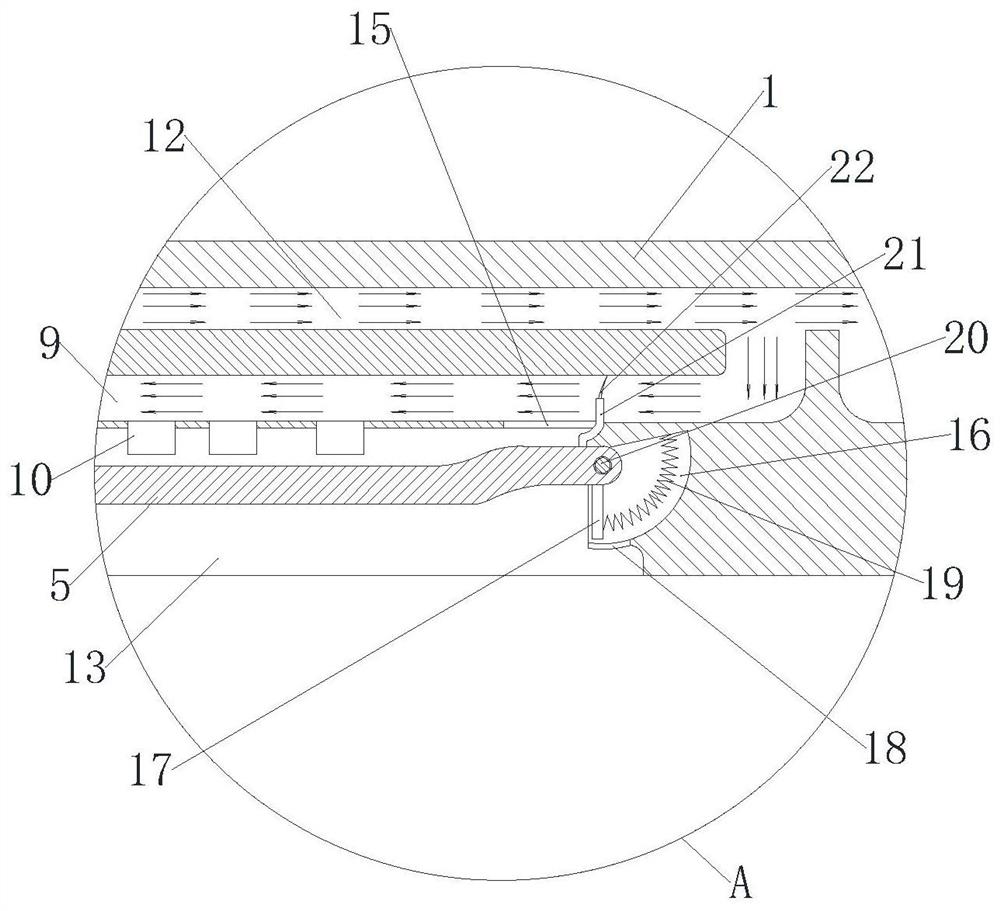

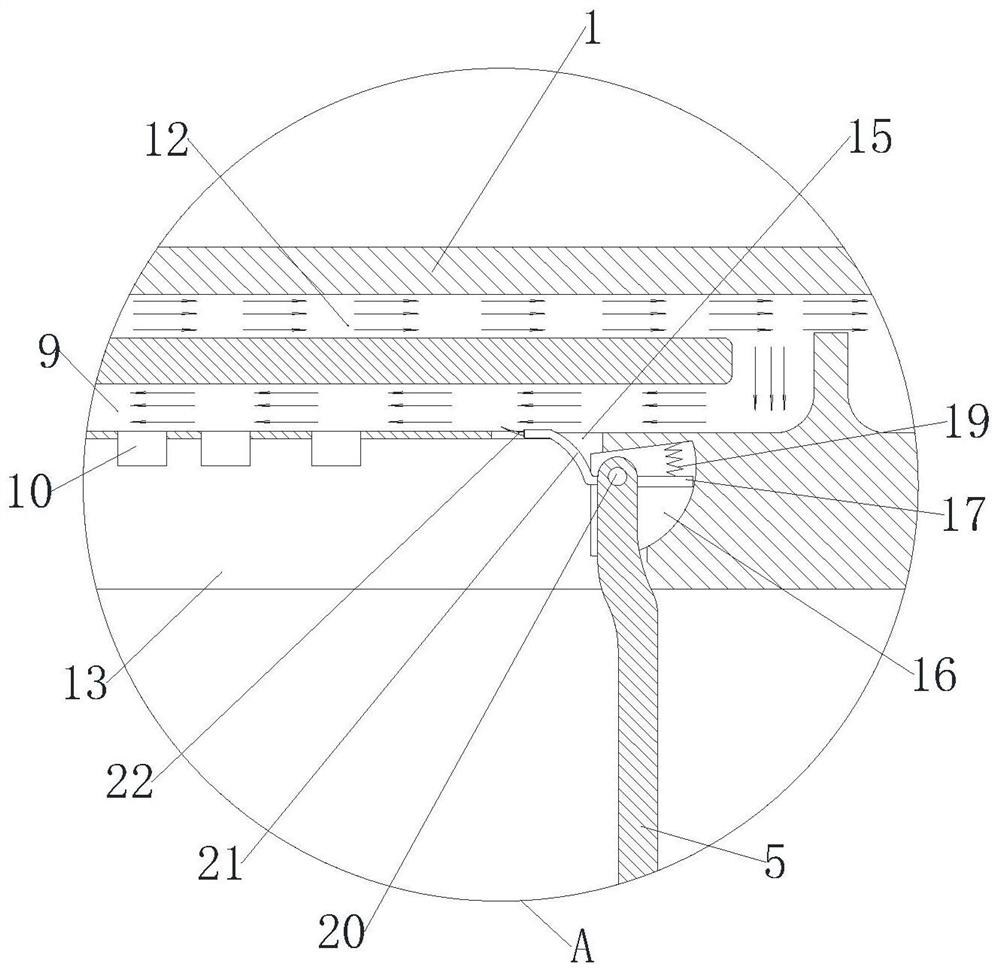

Internet-of-things smart home decontamination closestool equipment

ActiveCN112252433AEasy dischargeImprove structural aestheticsWater closetsLavatory sanitoryWater flowMechanical engineering

The invention relates to the technical field of internet-of-things smart home equipment, and provides internet-of-things smart home decontamination closestool equipment, which comprises a urinal, a blow-off pipe, a closestool body, a water discharging button and a water tank, wherein the urinal is formed in the top face of the closestool body, the water tank is arranged close to the periphery of the urinal, the water discharging button is installed at the top end of the water tank, a closestool cover is hinged to the top end, close to the bottom surface of the water tank, of the urinal, a defecation opening is formed in the bottom surface of the urinal, the defecation opening is communicated with a discharge pipe, and excrement is discharged through the discharge pipe. When water flow is sprayed to the inner wall of the urinal through water spraying openings, a cleaning and brushing rod is pushed to swing downwards at the top end of the inner wall of the urinal, excrement adhering to the inner wall of the urinal is brushed away in a reciprocating mode by a cleaning and brushing plate at the top end of the cleaning and brushing rod, and similar excrement adhering to the inner wall of the urinal is removed, thus, after the closestool is used by a person, the inner wall of the urinal is subjected to self-cleaning treatment, so that the cleanness of the closestool is improved.

Owner:缙云星暖智能科技有限公司

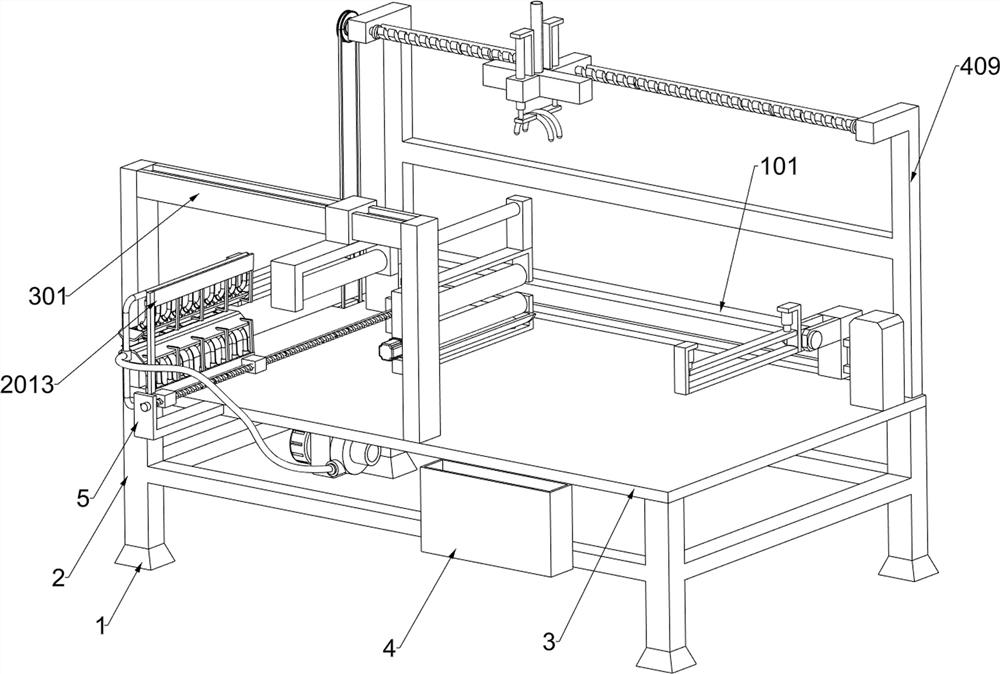

Building interior decoration alloy buckle strip stamping machining system

InactiveCN111760972AAvoid damageAvoid cumbersome workflowShaping toolsPerforating toolsStructural engineeringMachining system

The invention relates to a building interior decoration alloy buckle strip stamping machining system. The system comprises a bottom plate, a mold, a stamping device and a feeding device, wherein the bottom plate is installed on the existing working ground, the mold is arranged at the upper end of the bottom plate, the stamping device is arranged over the mold, and the feeding device is arranged behind the mold. According to the system, the mold is movable during molding processing, so that tedious working procedures caused by molding processing by adopting a composite mold during processing are avoided, and the deformation of the plate after demolding due to damage to the plate caused by difficult falling of the molded plate during demolding is avoided.

Owner:张美

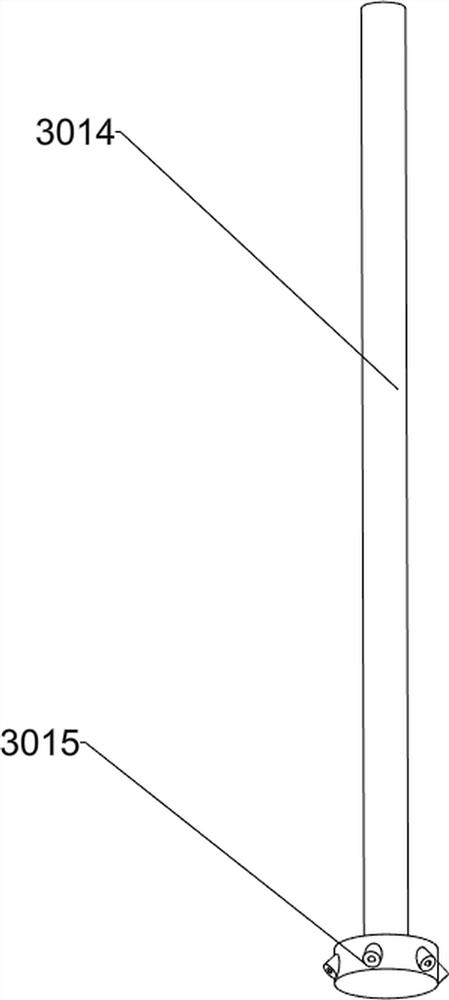

Method for carrying out chemical nickel plating on surface of stainless steel flagpole

InactiveCN108977797AImprove surface aestheticsImprove bindingLiquid/solution decomposition chemical coatingBiological activationNickel plate

The invention relates to the technical field of stainless steel flagpoles, particularly to a method for carrying out chemical nickel plating on the surface of a stainless steel flagpole. The method comprises: 1, grinding and polishing the surface of a stainless steel flagpole, and rinsing for 10-15 min with running water after the grinding; 2, removing the oxide formed on the surface of the stainless steel flagpole by using an activation solution, and carrying out water washing for 5-10 min after the activation; 3, soaking the stainless steel flagpole in a chemical nickel plating solution, carrying out chemical nickel plating treatment, and carrying out water washing for 5-10 min after the chemical nickel plating treatment; 4, carrying out passivation, wherein the obtained stainless steelflagpole is placed in a passivation solution and is subjected to passivation treatment, and water washing is performed for 10-20 min after the passivation; and 5, carrying out blow drying on the passivated stainless steel flagpole to obtain the finished product. According to the present invention, the method has characteristics of simple steps, improved work efficiency and good adhesion of the nickel plating layer, can prolong the service life of the stainless steel flagpole, and can further improve the surface beauty of the stainless steel flagpole.

Owner:成都中源红科技有限公司

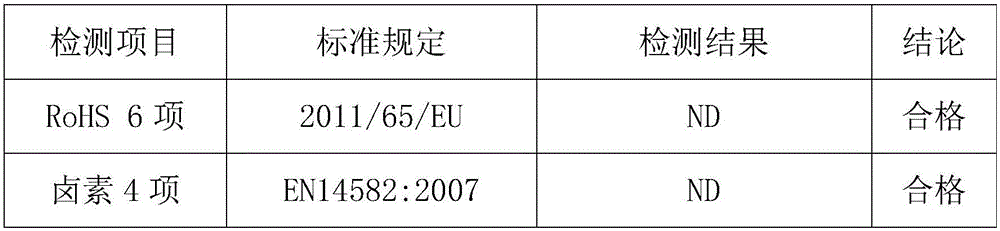

Energy-saving and environment-friendly preparation technology of control panel of washing machine

InactiveCN108515679AImprove surface aestheticsQuality improvementPretreated surfacesCoatingsInjection pressureInfrared

The invention provides an energy-saving and environment-friendly preparation technology of a control panel of a washing machine. The energy-saving and environment-friendly preparation technology comprises the following steps: (1) carrying out injection molding: preparing sol, carrying out die closing, injecting the sol, pressurizing, cooling, carrying out die opening and de-molding; after carryingout the de-molding to obtain an injection molding part; (2) carrying out paint spraying treatment: pre-treating, carrying out primary paint spraying, carrying out secondary paint spraying, carrying out primary drying, carrying out secondary drying, carrying out primary UV (Ultraviolet) curing, carrying out IR (Infrared Ray) curing, carrying out secondary UV curing, and cooling; after carrying outcooling to obtain a finished product. According to the energy-saving and environment-friendly preparation technology provided by the invention, a multi-section sol injection and injection molding method is adopted, and sol injection time and sol injection pressure are set by sections; the work is refined, raw materials can be effectively saved and the cost is reduced. All technological parametersare reasonably selected by adopting a series of technologies of paint spraying, flash drying, leveling and baking, and the steps are clear; the surface of an injection molding panel which is sprayedwith paint according to the method is smooth and bad conditions that the paint is not uniformly sprayed, the drying is not sufficient, foaming is caused and the like do not occur.

Owner:丹阳市逸帆电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com