Production detection equipment for metal accessory eyelet buttons

A technology for production inspection and accessories, which is applied in metal processing equipment, grinding/polishing equipment, control of workpiece feeding motion, etc. , to achieve the effect of improving the appearance of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

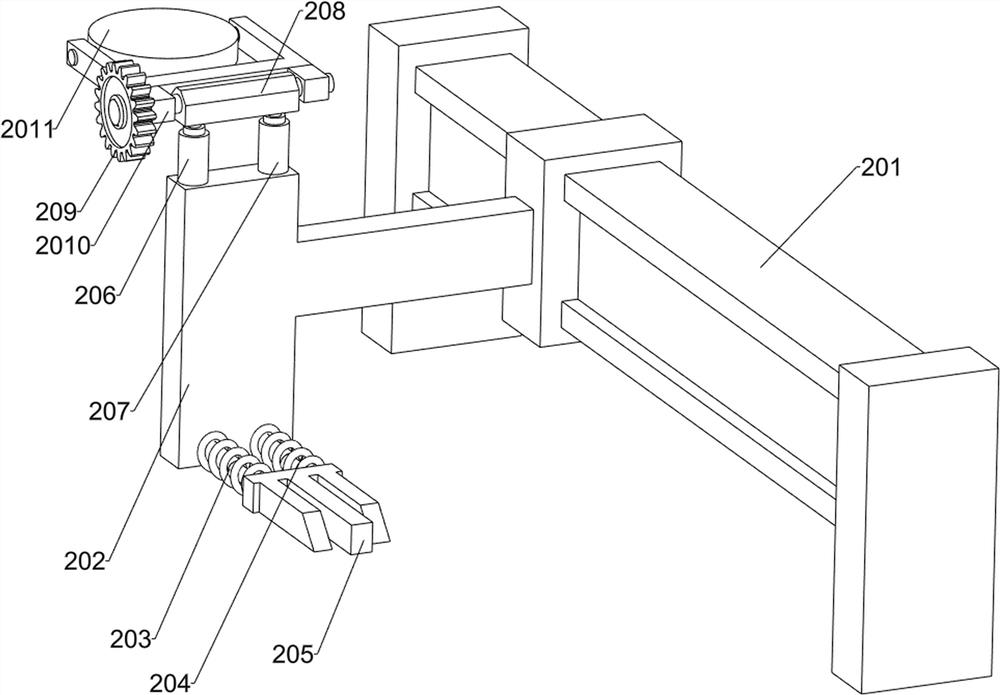

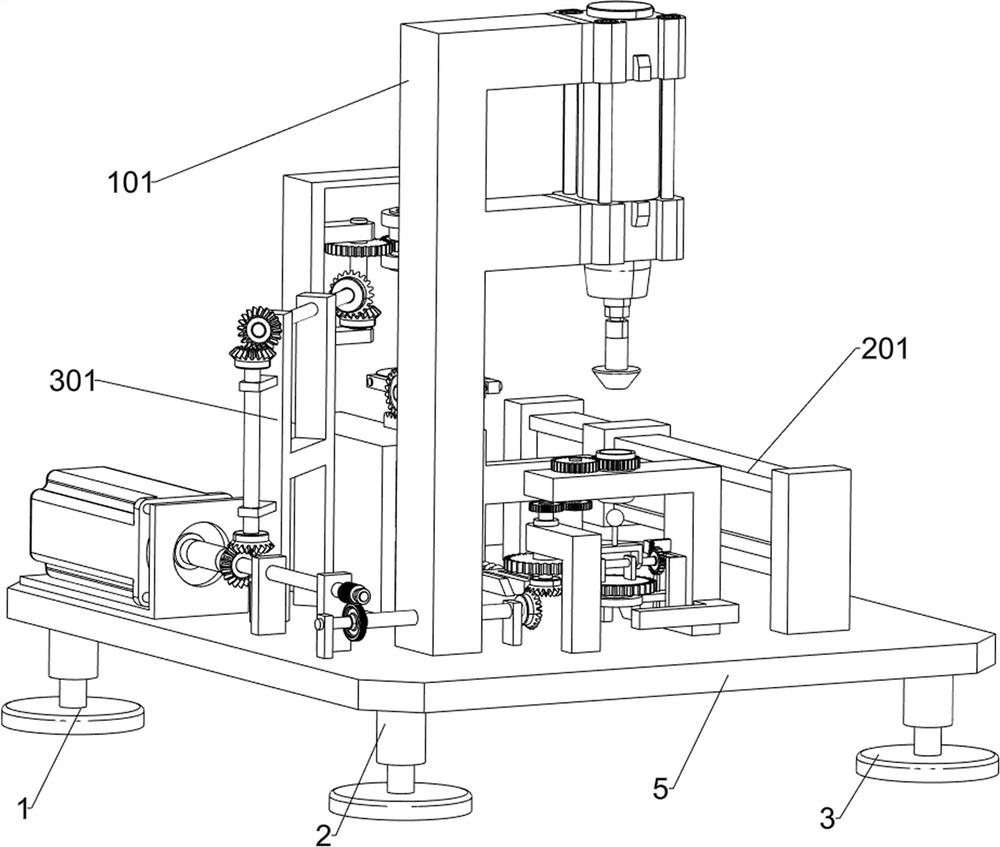

[0028] A production and testing equipment for eyelet buttons of metal fittings, according to Figure 1-3 As shown, it includes the first bottom column 1, the second bottom column 2, the third bottom column 3, the fourth bottom column 4, the bottom plate 5, the detection and grinding system, the transfer system and the debris processing system; the first bottom column 1 is installed On the lower left rear side of the base plate 5; the second base column 2 is installed on the lower left front side of the base plate 5; the third base column 3 is installed on the lower right front side of the base plate 5; the fourth base column 4 is installed on the lower right rear side of the base plate 5 side; a detection and grinding system is installed on the front side above the bottom plate 5; a transfer system is installed on the right side above the bottom plate 5; a debris treatment system is installed on the rear side above the bottom plate 5; the detection and grinding system is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com