Tile-like wooden floor and preparation method thereof

A wood and ceramic tile technology, used in coatings, buildings, building structures, etc., can solve the problems of rough surface, high water absorption, many pores, etc., to improve surface wear resistance and aesthetics, and enhance antistatic performance. , the effect of improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] Correspondingly, the present invention also discloses a preparation method of the above-mentioned hydrophobic coating, which includes:

[0091] (1) Mix 5-10 parts by volume of inorganic nano powder dispersion, 85-90 parts by volume of polyurethane acrylate dispersion and 3-5 parts by volume of silane coupling agent to obtain modified polyurethane acrylate dispersion body;

[0092] Specifically, the inorganic nano-powder is first subjected to plasma fluorination treatment, then the treated inorganic nano-powder is mixed with the dispersion liquid, and stirred at 40-50° C. for 15-30 min to obtain the inorganic nano-powder dispersion liquid; Then mix the inorganic nano-powder dispersion liquid with the polyurethane acrylate dispersion and the silane coupling agent evenly to obtain the product.

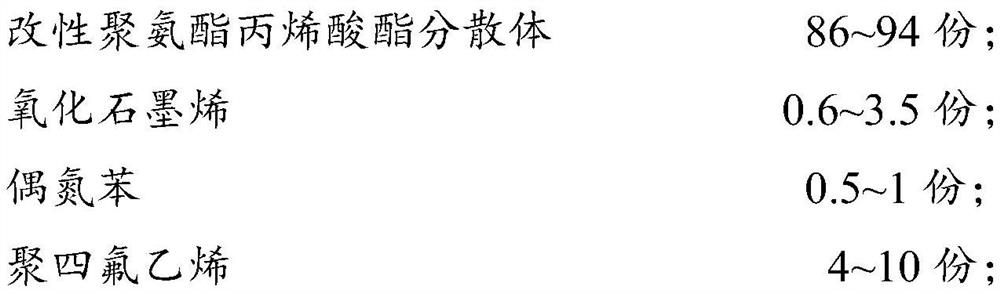

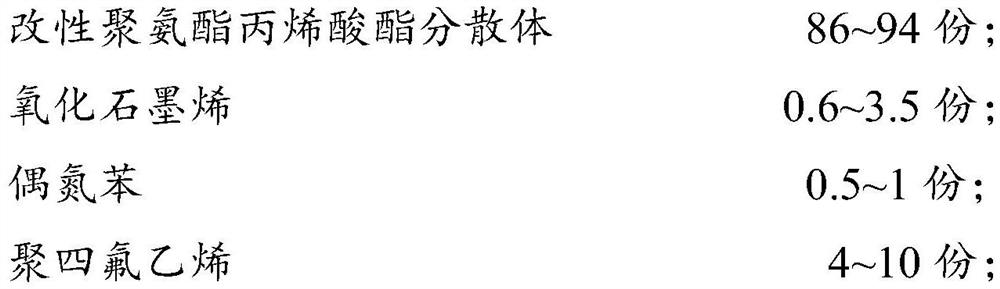

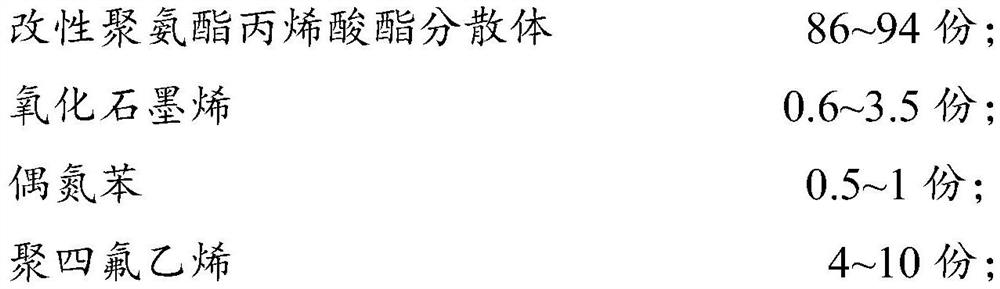

[0093] (2) Add 0.6 to 3.5 parts by weight of graphene oxide, 0.5 to 1 parts by weight of azobenzene and 4 to 10 parts of polytetrafluoroethylene successively in the modified polyu...

Embodiment 1

[0113] This embodiment provides a tile-like wooden floor, which includes a wooden substrate, an inkjet pattern layer arranged on the front of the wooden substrate, and a moisture-proof coating arranged on the back of the wooden substrate.

[0114] Among them, the wooden base material is 7 layers of eucalyptus veneers, which are symmetrically distributed, vertically interlaced vertically and horizontally, and then hot-pressed; an adhesive is arranged between adjacent eucalyptus veneers; the adhesive includes the following components by weight: 2 parts of magnesium oxide, 7 parts of phenolic resin, 90 parts of MDI resin adhesive, 1 part of nano titanium dioxide.

[0115] The moisture-proof coating is made of moisture-proof paint. Moisture-proof coatings include the following components by volume:

[0116] 82 parts of polyurethane dispersion;

[0117] 9 parts of paraffin emulsion;

[0118] 9 parts of nano titanium dioxide dispersion liquid;

[0119] Among them, the type of po...

Embodiment 2

[0129] This embodiment provides a tile-like wooden floor, which includes a wooden substrate, a hole-filling layer arranged on the front of the wooden substrate, a hydrophobic coating, an inkjet pattern layer and a wear-resistant coating, and a layer arranged on the back of the wooden substrate Moisture-resistant coating and sound insulation.

[0130] (1) Among them, the wooden base material is 7 layers of eucalyptus veneers, which are symmetrically distributed, vertically interlaced, vertically and horizontally assembled, and then hot-pressed; adhesives are arranged between adjacent eucalyptus veneers; the adhesives include the following components in parts by weight: Composition: 2 parts of activated magnesium oxide, 7 parts of phenolic resin, 90 parts of MDI resin adhesive, 1 part of nano titanium dioxide.

[0131] (2) Among them, the hole-filling layer is made of hole-filling paint, and the hole-filling paint is epoxy mastic produced by Guizhou Zhuonengda Building Materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com