Patents

Literature

68results about How to "Reduce penetration depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

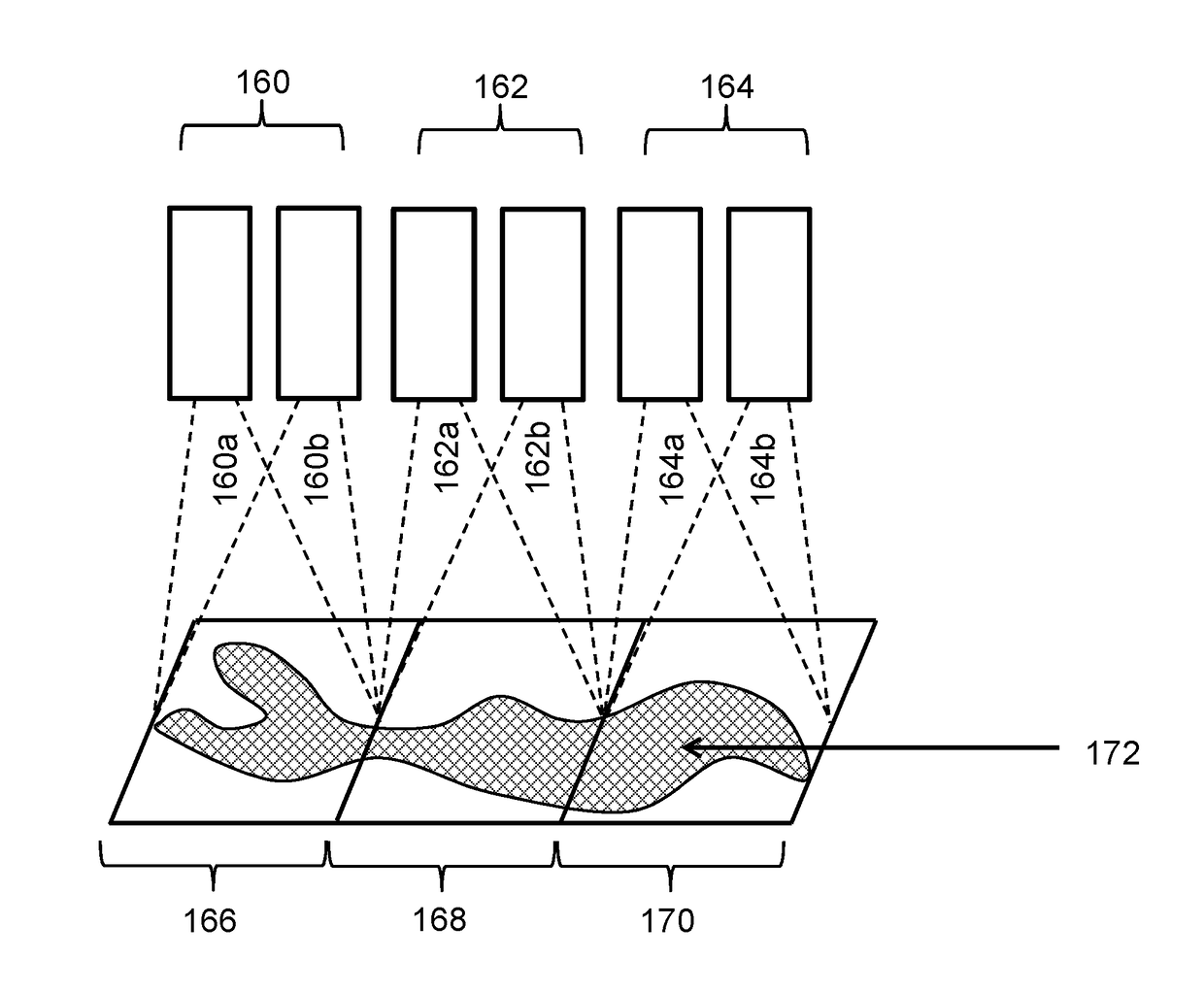

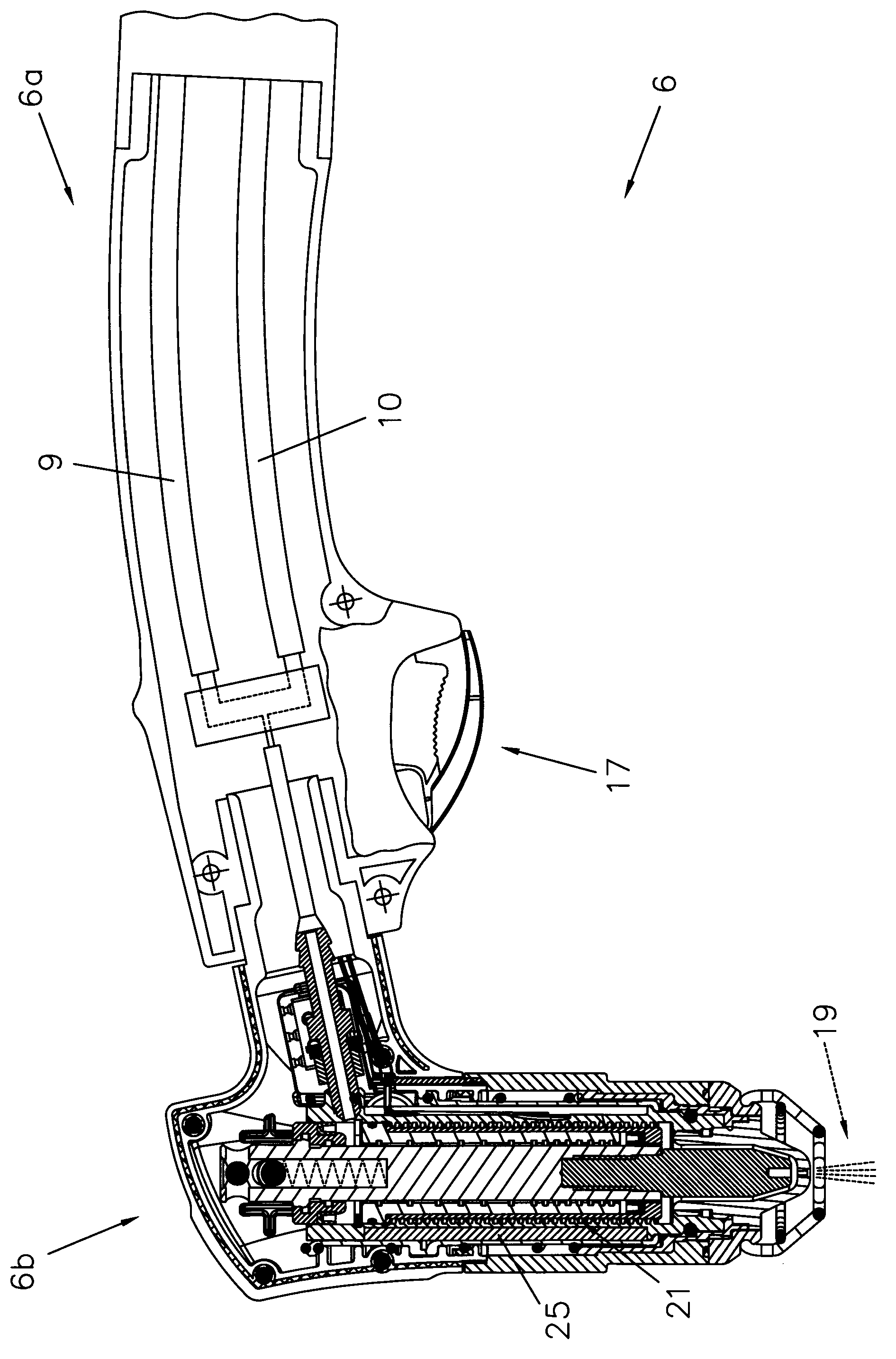

Method for radiation treatment

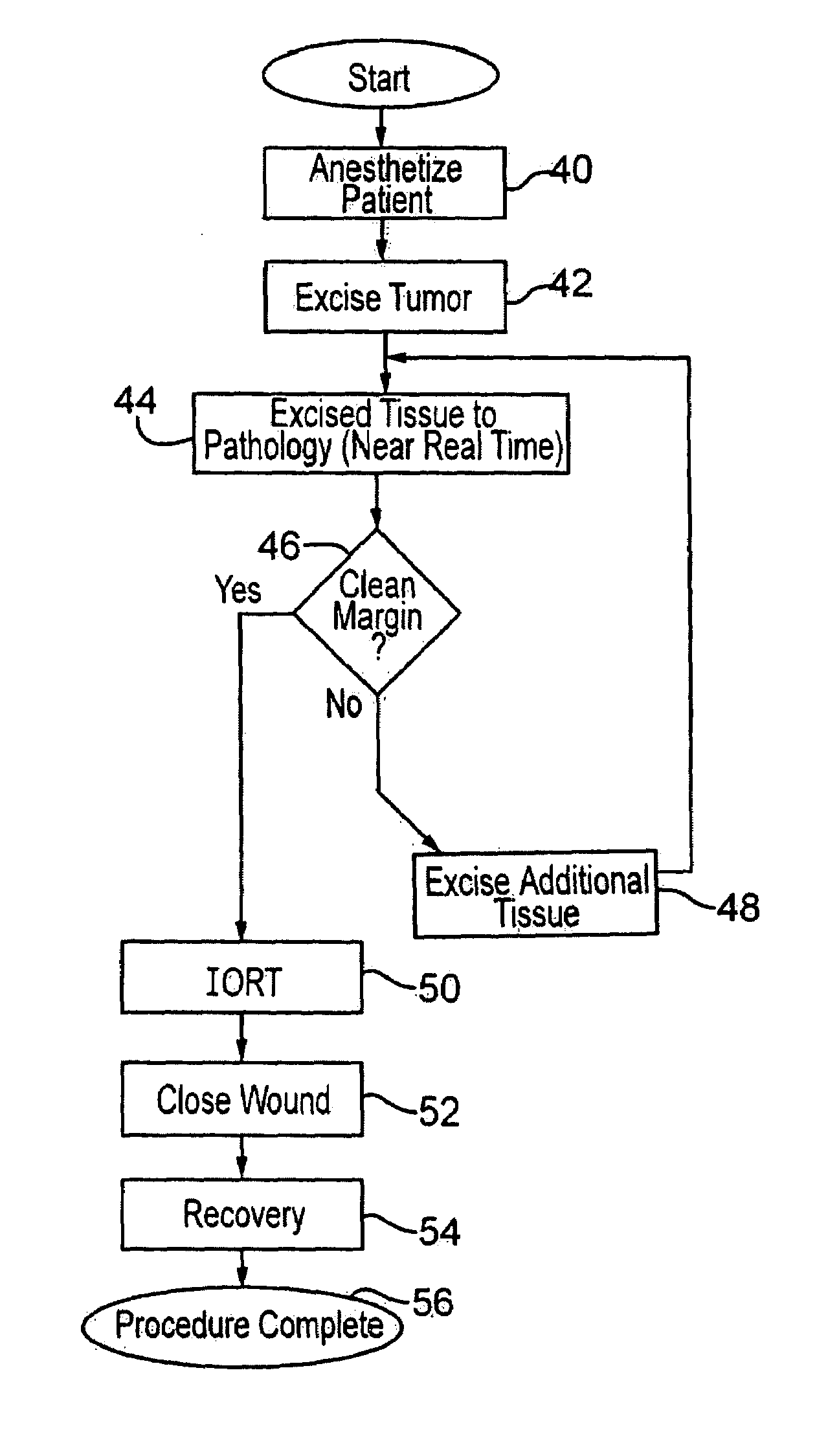

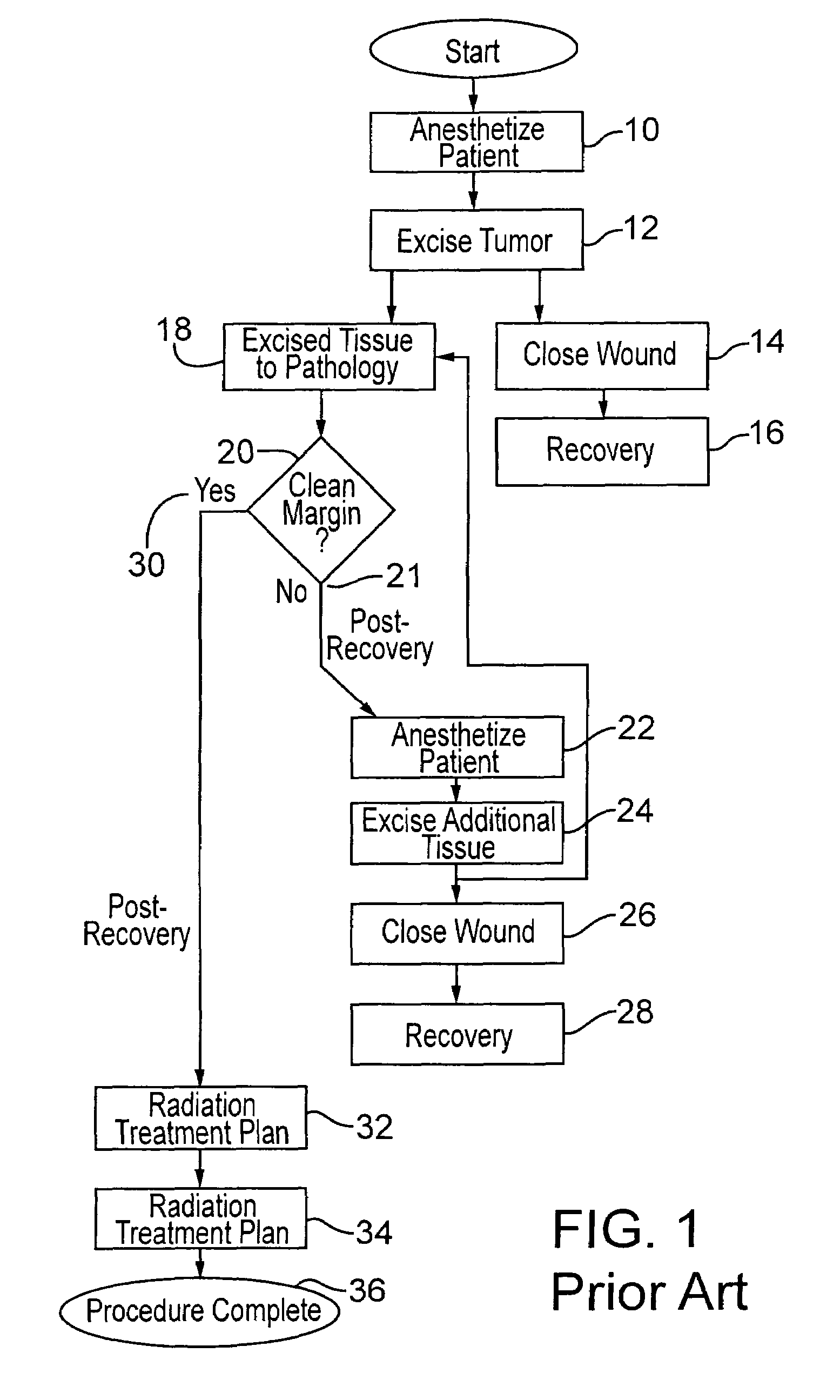

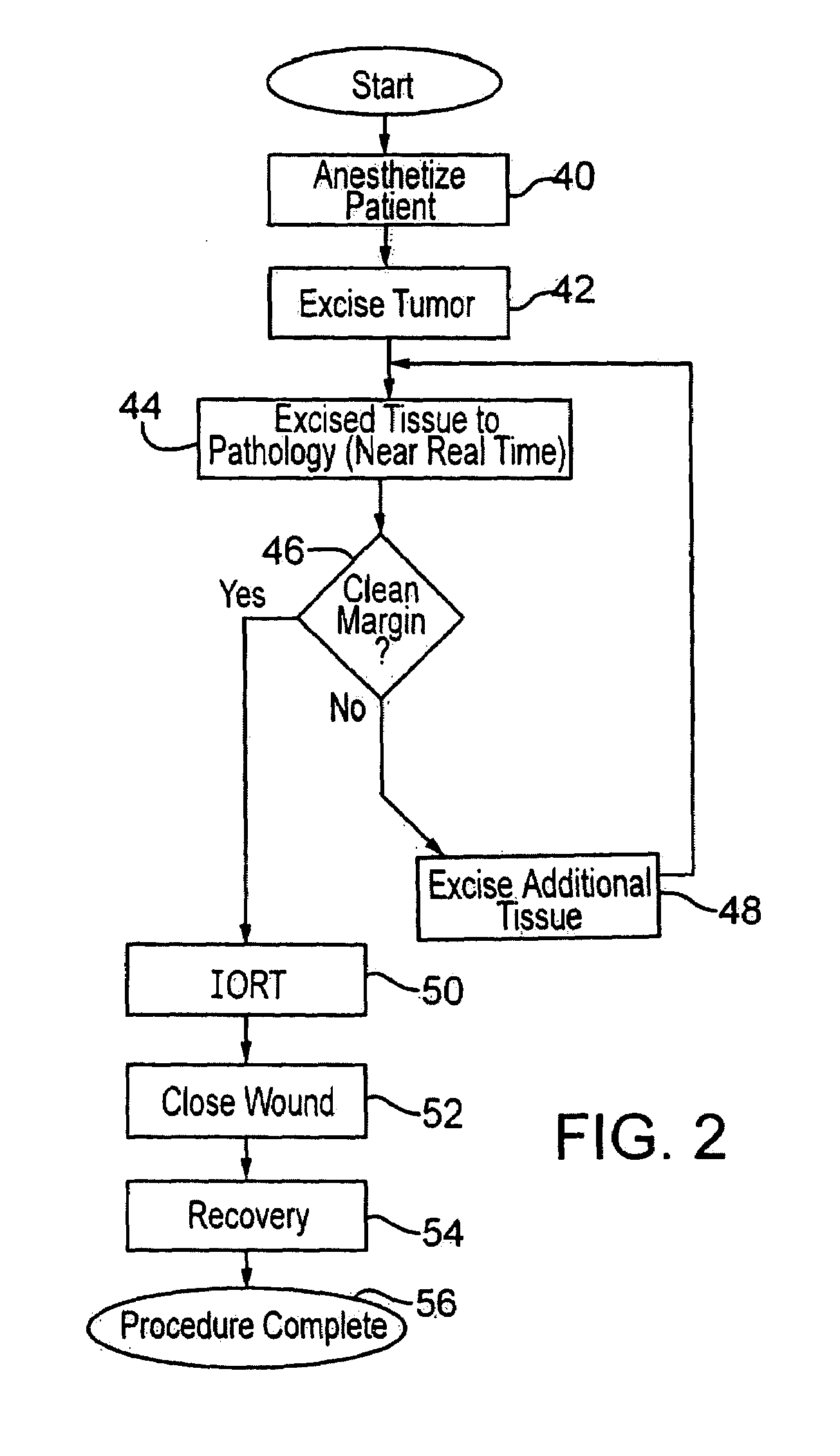

InactiveUS7322929B2Reduce penetration depthEnsure correct executionX-ray/gamma-ray/particle-irradiation therapyTumor removalRadical radiotherapy

Breast cancer patients are treated intraoperatively with radiation shortly after excision of a tumor. Pathology of the tissue is determined with a nearly instantaneous method, further excision is performed if needed, and the patient, still anesthetized and preferably unmoved, is then treated with radiation therapy. In a preferred embodiment an applicator is inserted into the excision cavity, the cavity is three-dimensionally mapped using radiation sources and a sensor, a radiation treatment plan is developed using a radiation prescription and the determined shape and location of the cavity, and the treatment plan is executed, all while the patient remains under anesthesia.

Owner:XOFT INC

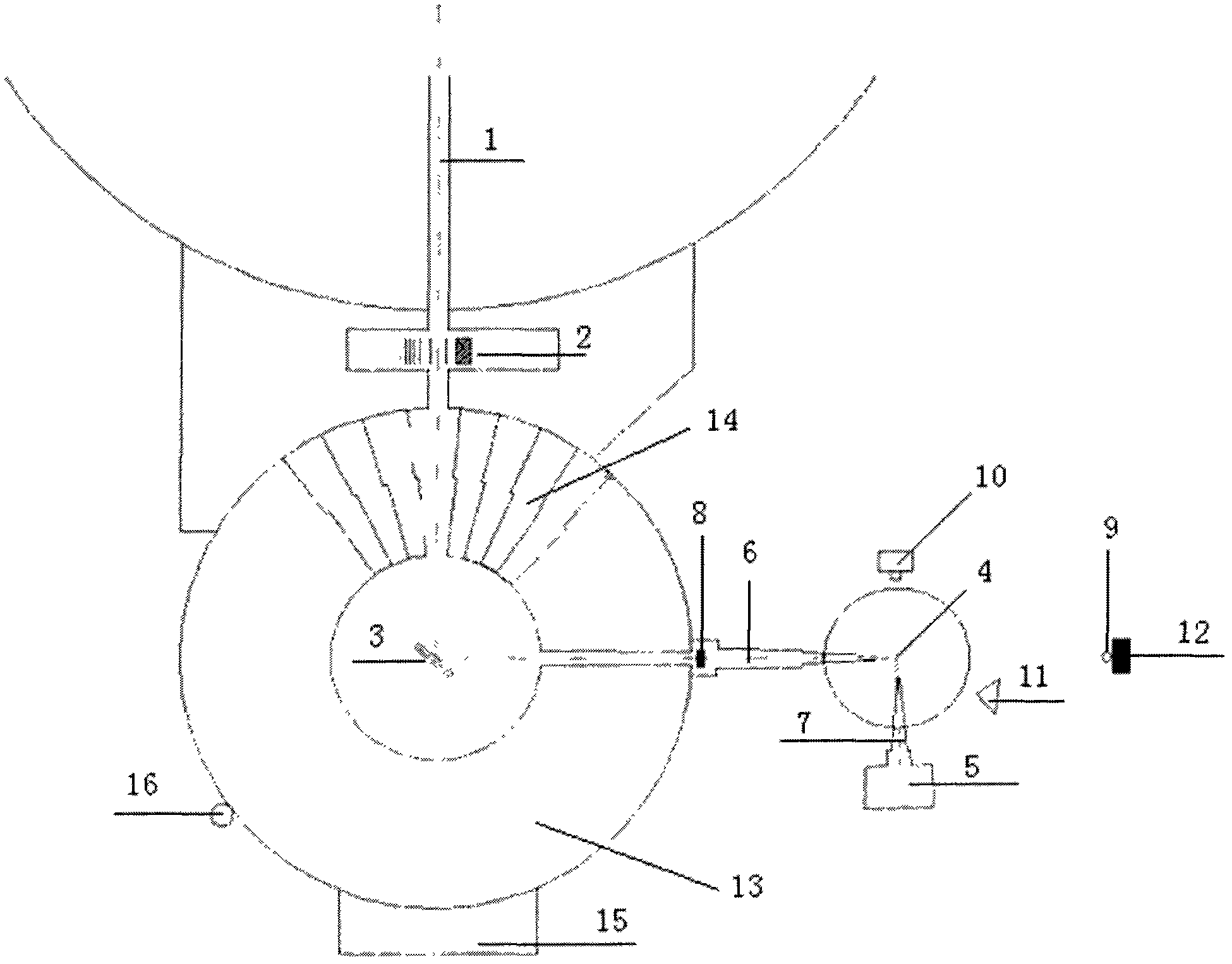

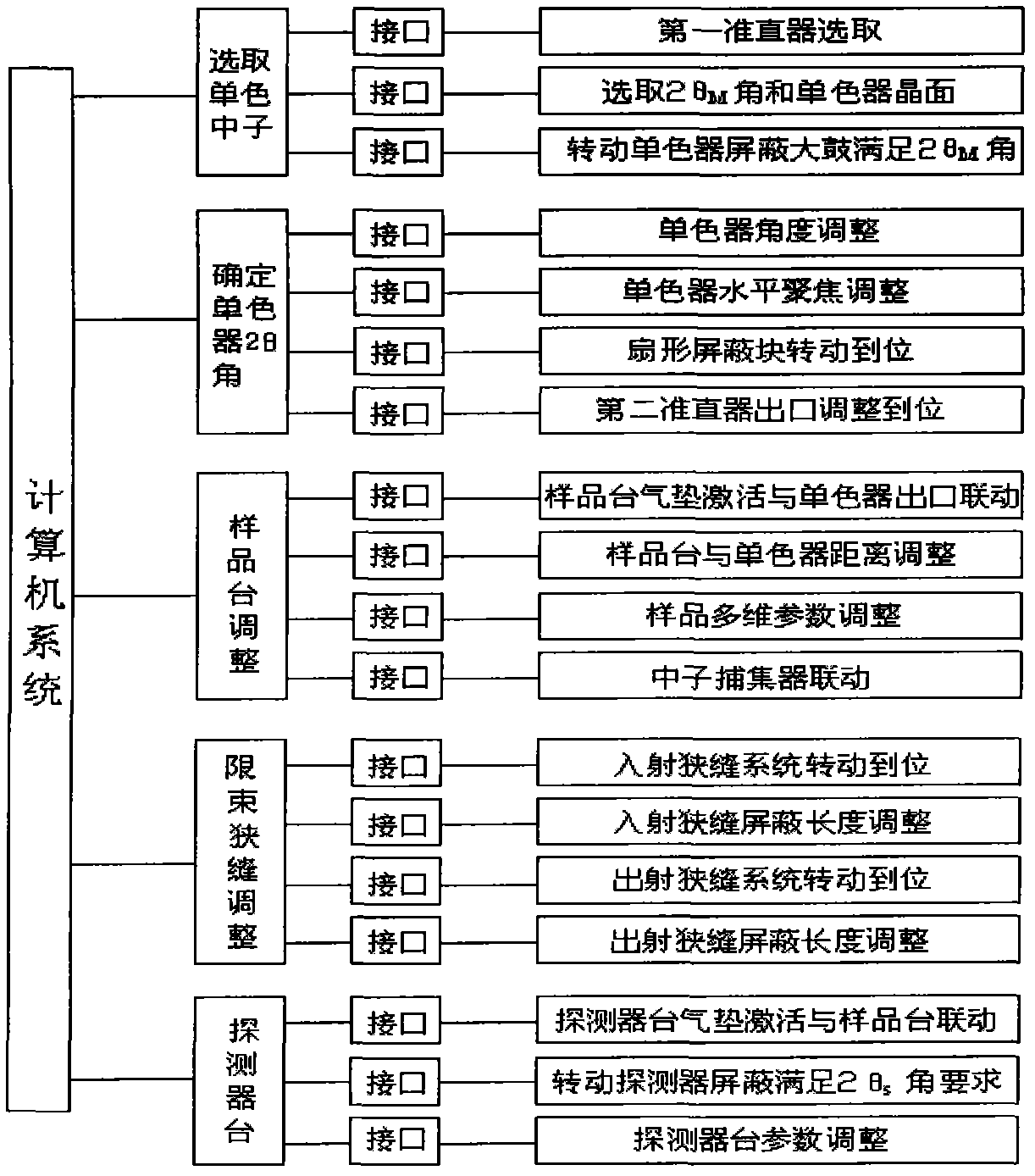

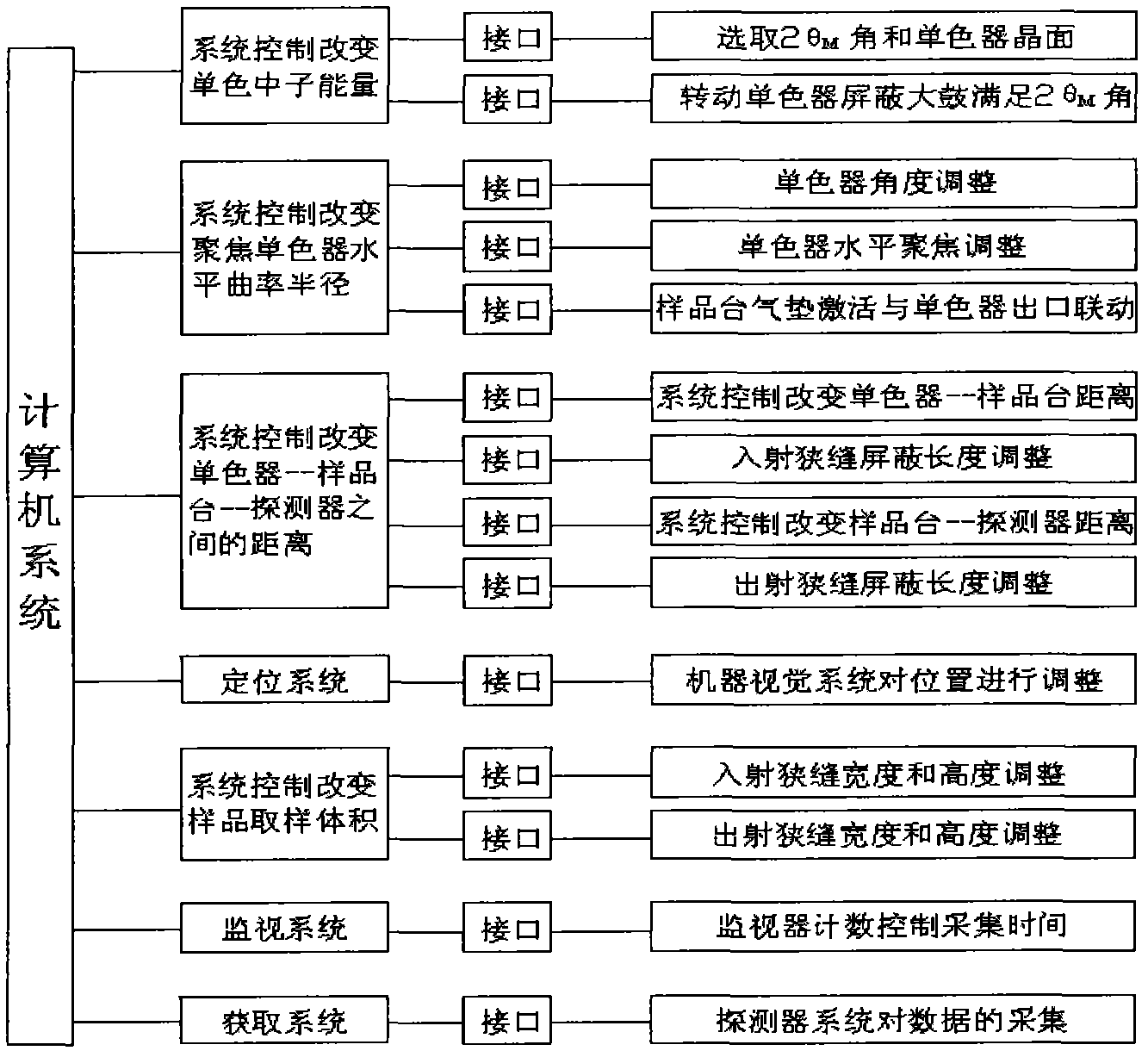

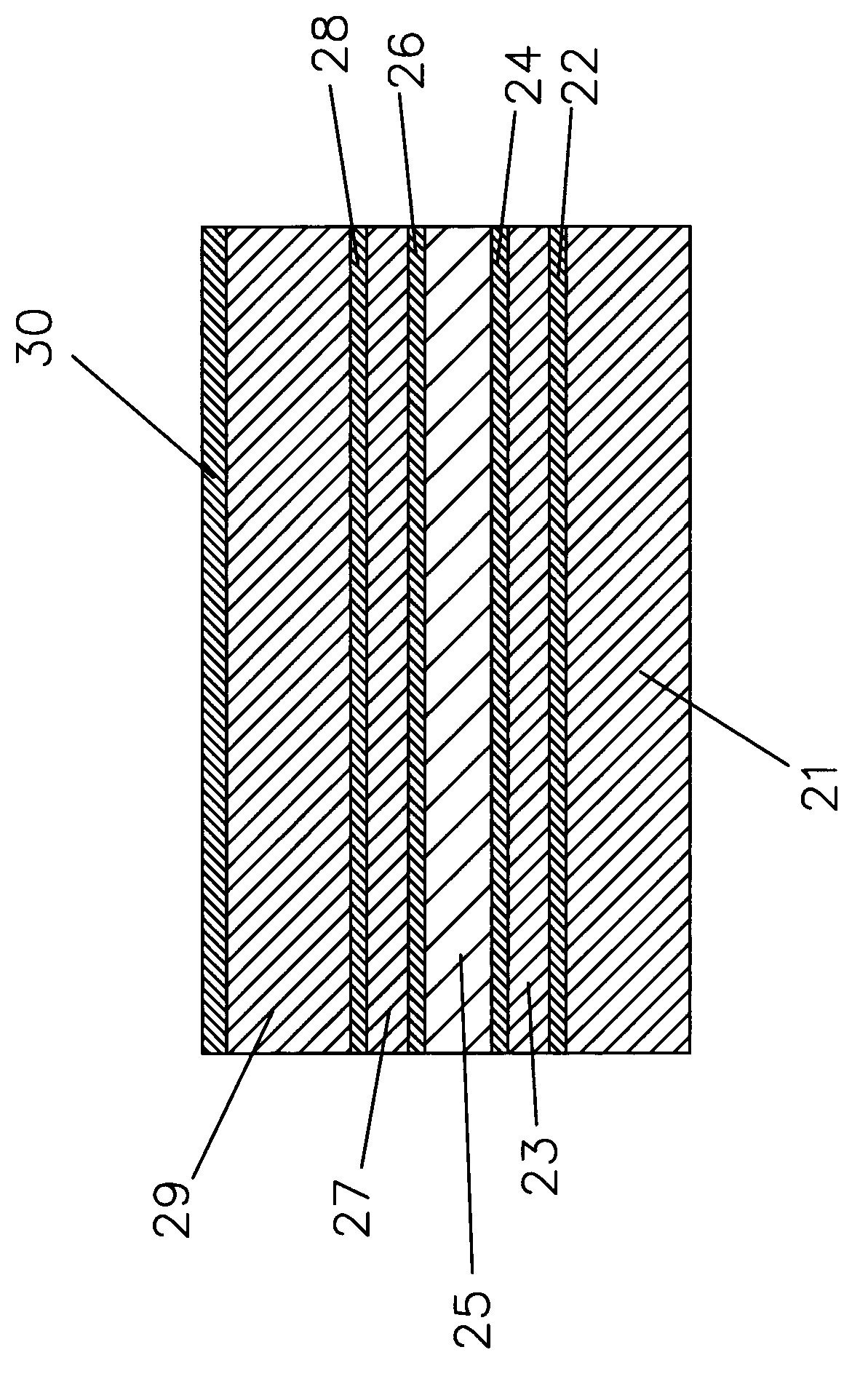

Neutron diffraction residual stress determination device and method

ActiveCN102435623AReduce absorptionNo need to overcome Coulomb barrierMaterial analysis using radiation diffractionX-rayNeutron diffraction

The invention discloses a neutron diffraction residual stress determination device and a method. The device is characterized by using the reactor neutron source, carrying out monochromatization by a monochromator to obtain a required monochromatic neutron beam at a certain wavelength, and using the neutron beam to detect the residual stress. According to the invention, because the neutrons are uncharged, and when the neutrons interact with substance, the neutrons have no effect with extranuclear electons, charge Coulombian force obstacle has no need to overcome, thus low energy neutrons can enter in atoms; the neutron absorption of great majority of materials is low, thus the penetration depth of incoming neutron beam is deep. Simultaneously by collimator and slit collimation, the limitedneutron beam has high space resolution ratio, a three-dimensional lossless and deep stress test of a test piece is realized by translation of three directions which are vertical to each other and rotation around testing central point, and the defect that an X-ray and a synchrotron radiation residual stress determination device can only losslessly determine the residual stress of the crystal material surface and subsurface is overcome.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

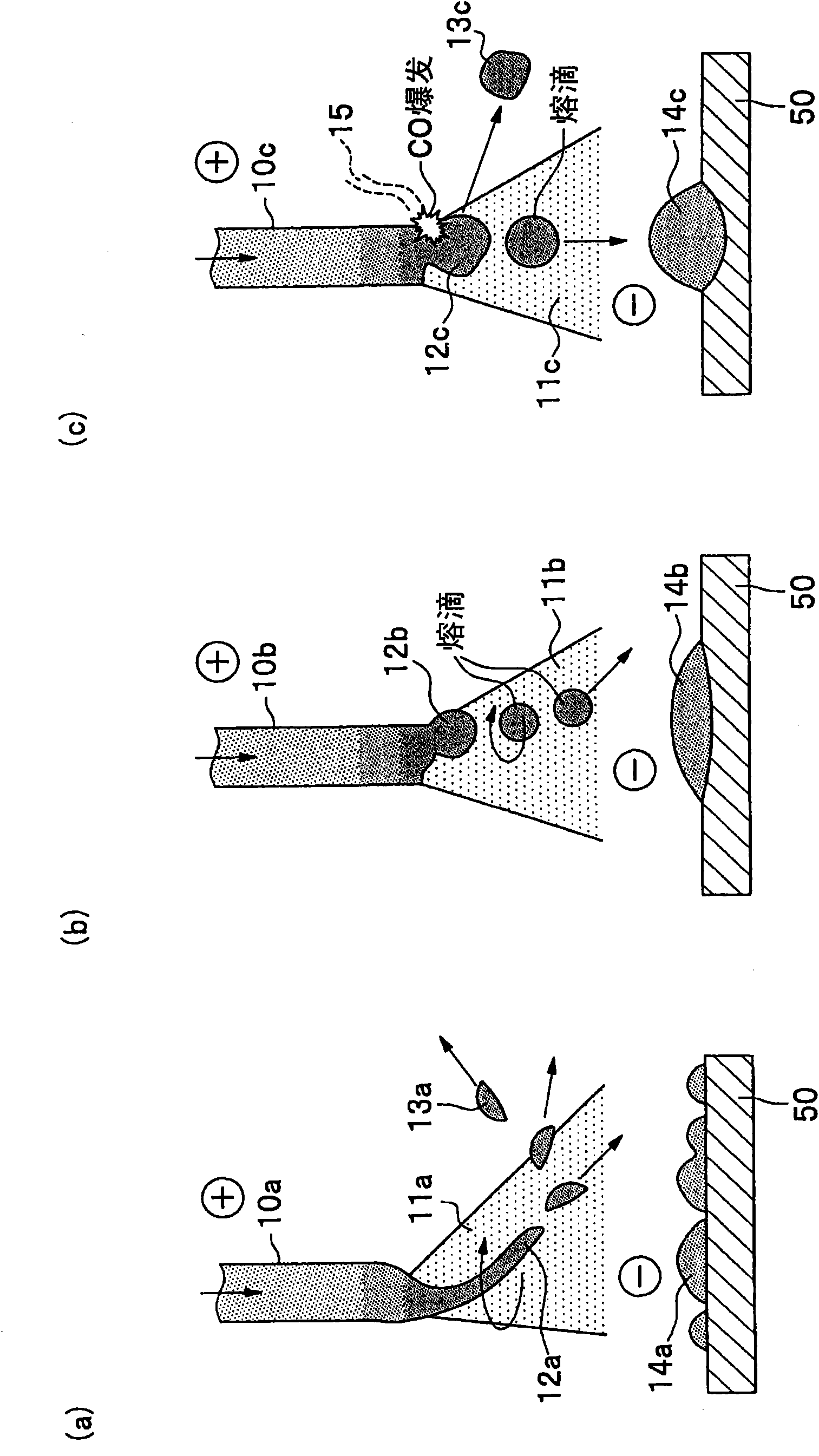

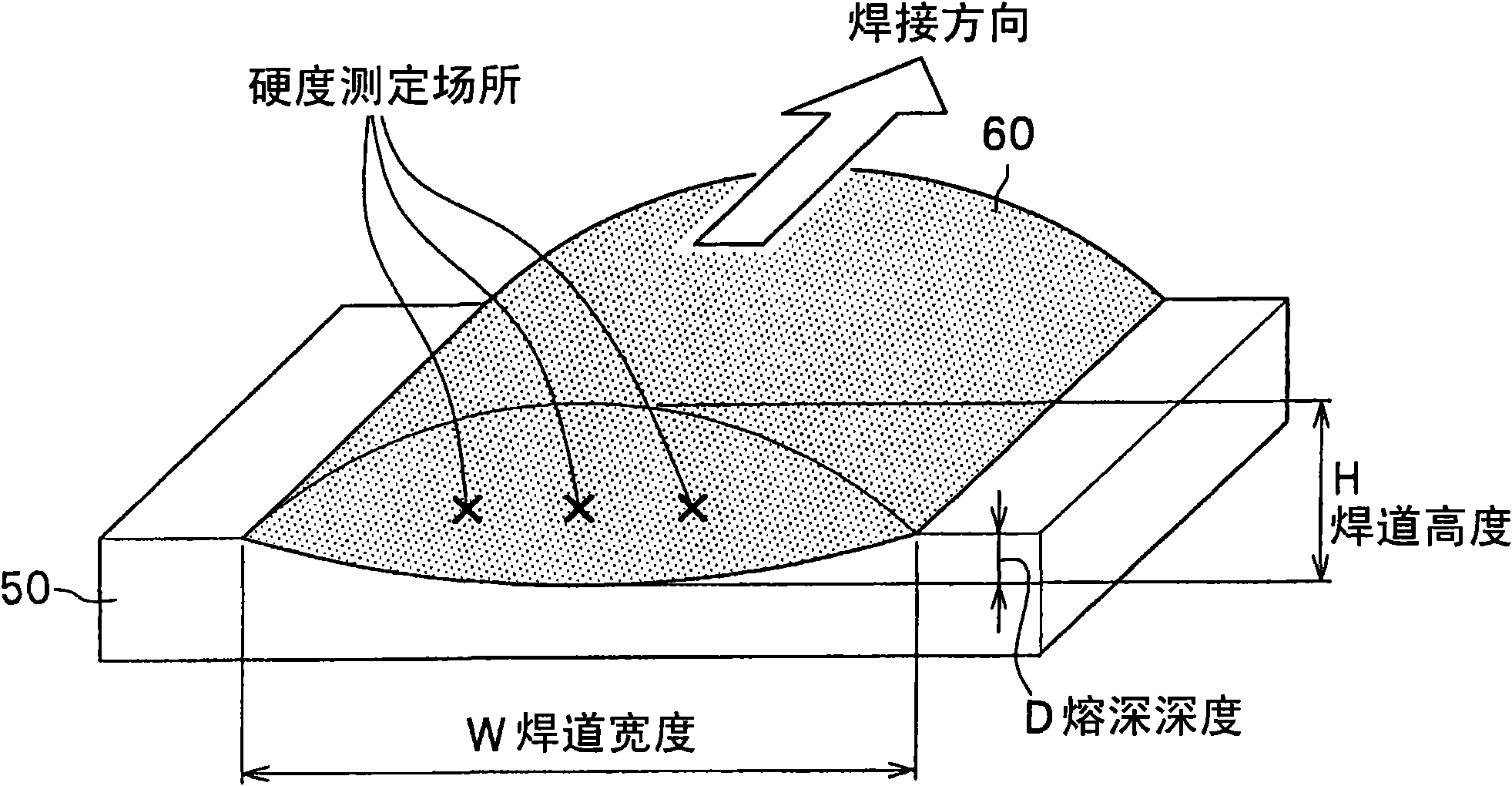

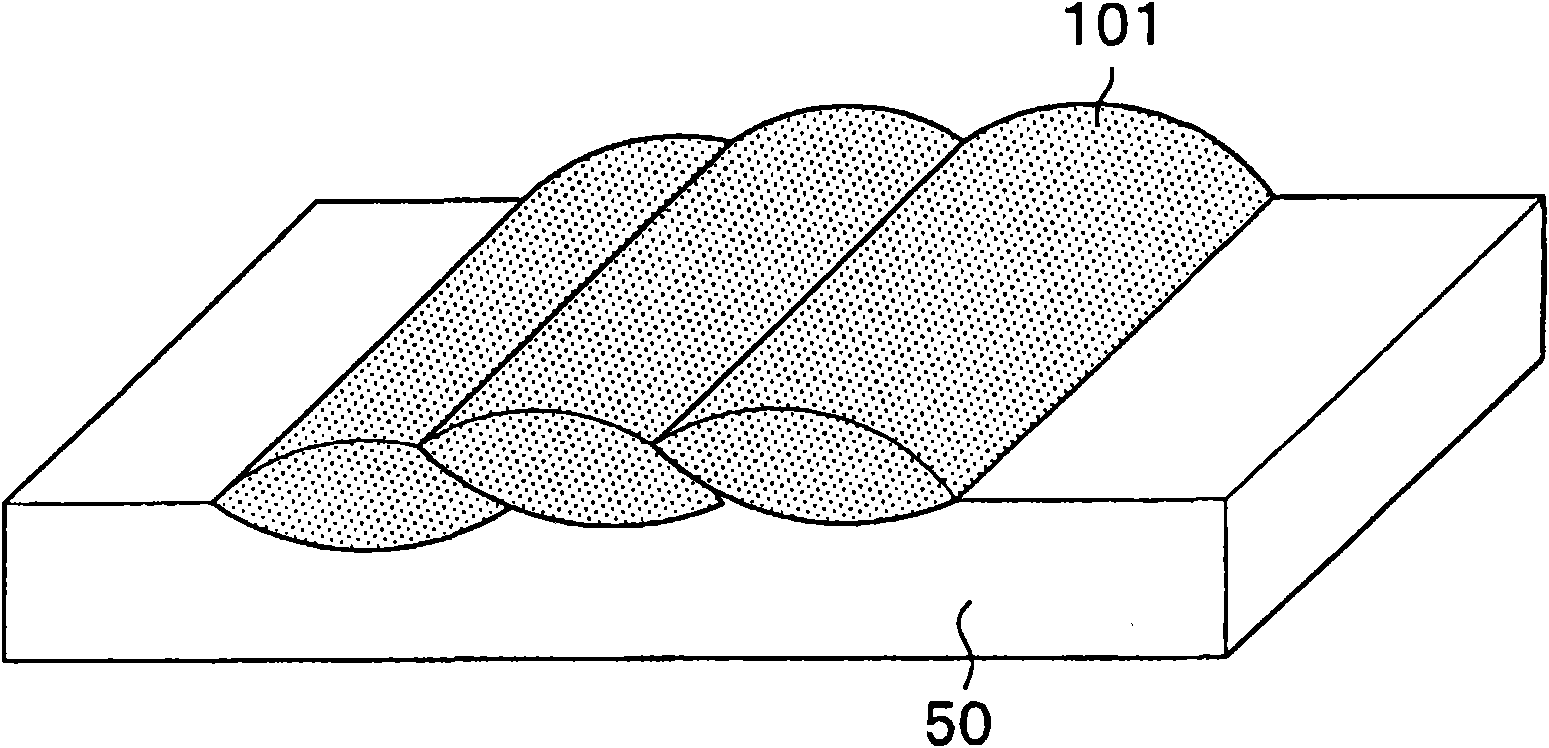

Hardfacing MIG-arc welding wire and hardfacing MIG-arc welding process

InactiveCN102059476AFlat shapeFull hardnessArc welding apparatusWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A wire is adopted to hardfacing MIG-arc welding using a pure argon gas as a shielding gas. The wire is a flux-cored wire prepared through drawing a steel hoop or steel pipe as a sheath in which a flux is filled. The flux contains, based on the total mass of the wire, C: 0.12 to 5.00 percent by mass, Si: 0.50 to 3.00 percent by mass, Mn: 0.30 to 20.00 percent by mass, P: 0.050 percent by mass or less, S: 0.050 percent by mass or less, and at least one of TiO2, ZrO2, and Al2O3 (TiO2+ZrO2+Al2O3) in a total content of 0.10 to 1.20 percent by mass and has a total content of silicon and manganese (Si+Mn) of 1.20 percent by mass or more. The wire has a ratio of the total mass of the flux to the mass of the wire of 5 to 30 percent by mass.

Owner:KOBE STEEL LTD

Porcelain polished tile and production method thereof

The invention discloses a porcelain polished tile and a production method of the porcelain polished tile. The production method comprises the steps of: (1) preparing a porcelain polished tile blank body powder material by a conventional method; (2) preparing a porcelain polished tile slurry; (3) preparing a porcelain polished tile blank body; (4) drying; (5) applying the slurry; (6) drying and sintering; (7) edging and polishing; and (8) sorting, packaging and warehousing. The porcelain polished tile and the production method have the beneficial effect of solving the technical problems of higher requirements of the traditional porcelain polished tile on a material and more waste, and provides a more environment-friendly and economic production method of the porcelain polished tile.

Owner:HANGZHOU NABEL CERAMIC +2

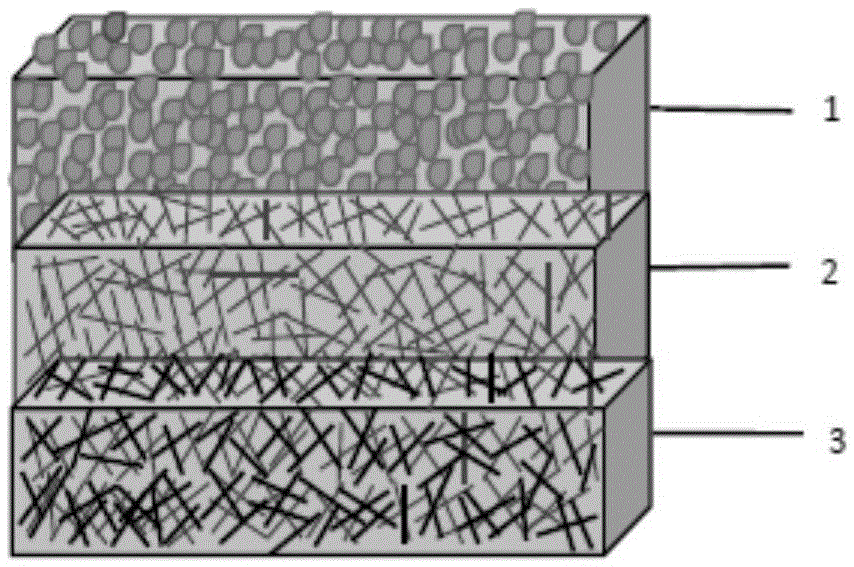

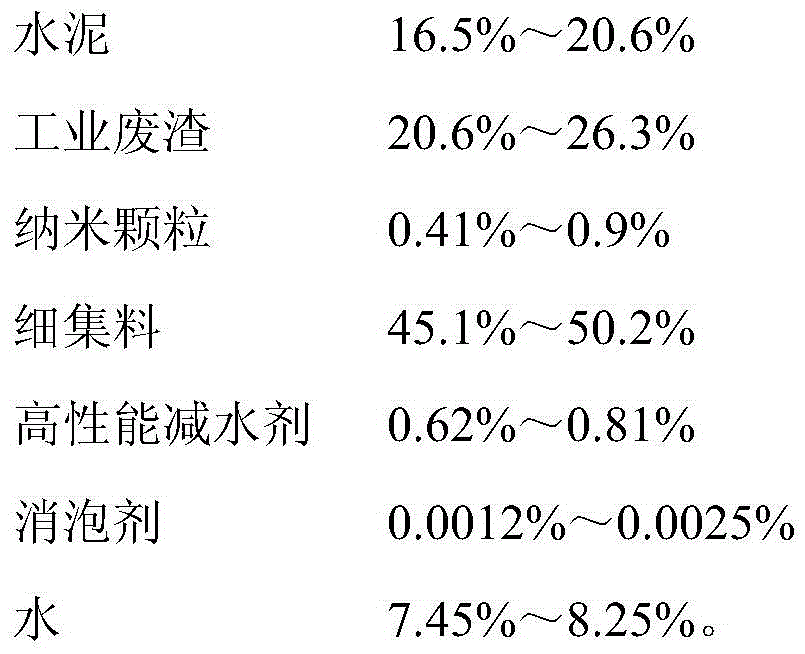

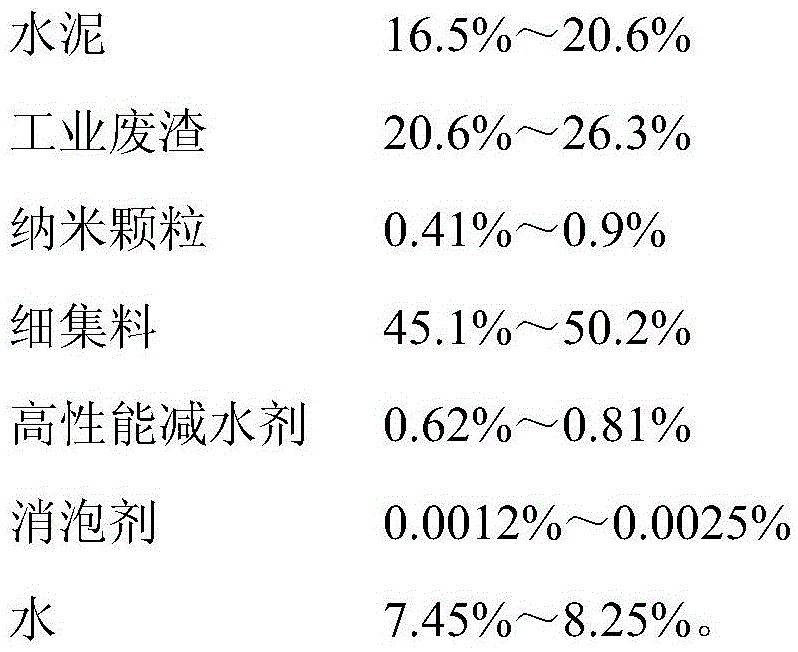

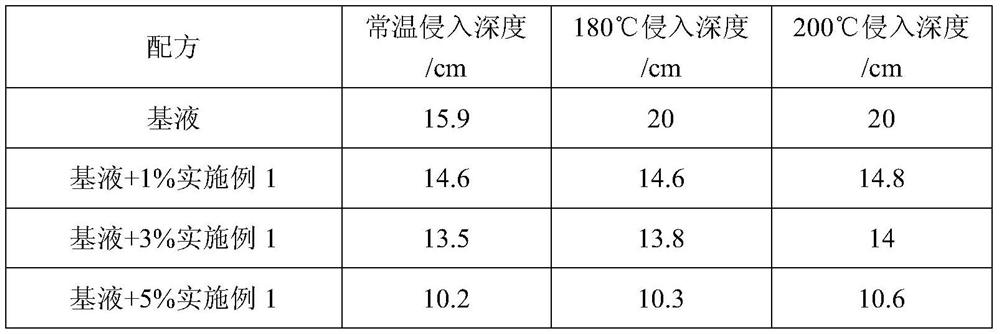

Anti-penetration and anti-explosion cement-based protective engineering material and preparation method thereof

ActiveCN105622018AWide variety of sourcesConducive to ecological sustainable developmentCrack resistanceCoupling

The invention discloses an anti-penetration and anti-explosion cement-based protective engineering material and a preparation method thereof. The protective engineering material is of a three-layer gradient structure made from very-high-performance mortar of the same proportioning ratio, a bottom layer is made from hybrid-fiber reinforced very-high-performance cement-based composite material, a middle layer is made from large-mixing-quantity steel-fiber reinforced very-high-performance cement-based composite material, a top layer is made from very-high-performance mortar-grouted high-strength coarse aggregate concrete, and the interfacial adhesivity is good. The very-high-performance mortar is prepared from cement, industrial residues, nanomaterials, fine aggregates, an antifoamer, a high-performance water reducing agent and water. According to the protective engineering material disclosed by the invention, hybrid fibers of the bottom layer can be used for improving the toughness and impact wave absorbing action of the structure and can also be used for improving crack resistance and high-temperature resistance; large-mixing-quantity steel fibers of the middle layer can be used for keeping the integrity of the structure and preventing bursting; high-strength coarse aggregates are added into the top layer, so that the penetration depth can be reduced, and the aim of anti-penetration and anti-explosion coupling action is achieved.

Owner:NANJING UNIV OF SCI & TECH

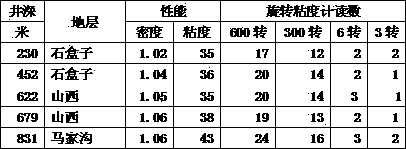

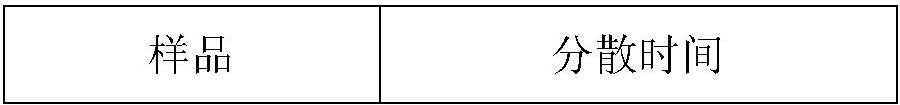

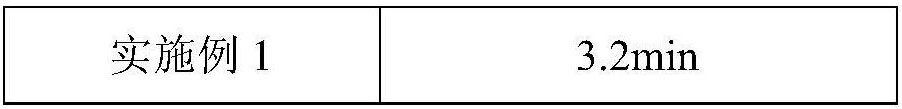

Film formation drilling fluid applicable to coal-bed gas well and preparation method thereof

InactiveCN103525383AImprove blockageReduce leakageDrilling compositionPhysical chemistryFilm-forming agent

The invention discloses a film formation drilling fluid applicable to a coal-bed gas well and a preparation method thereof. The film formation drilling fluid comprises the following components in percentage by mass: 0.1-0.3% of tackifying agent, 2.0-5.0% of film forming agent, 0.1-0.3% of coated flocculant, 0.2-5.0% of blocking agent, 1.0-10.0% of plugging agent, 0.05-0.2% of alkalinity regulator and the balance of water. By adopting the film formation drilling fluid disclosed by the invention, a low-permeability blocking layer can be quickly formed at the coal pore throat so as to prevent the fluid or solid phase from entering the coal bed, effectively prevent and slow down fluid loss and prevent the easily-hydrated substances in the coal cleat and crack from expanding, dispersing and polluting the reservoir stratum.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

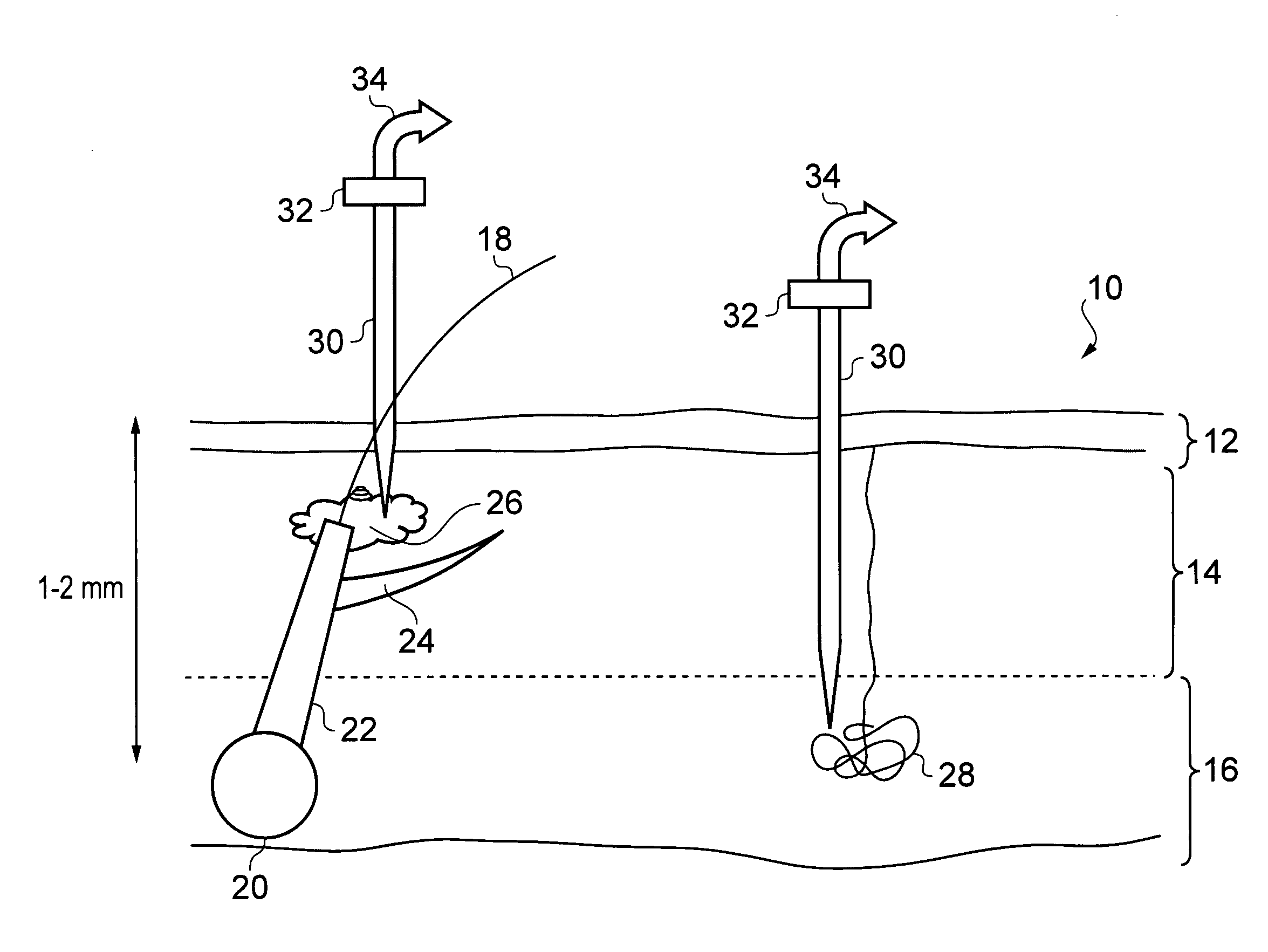

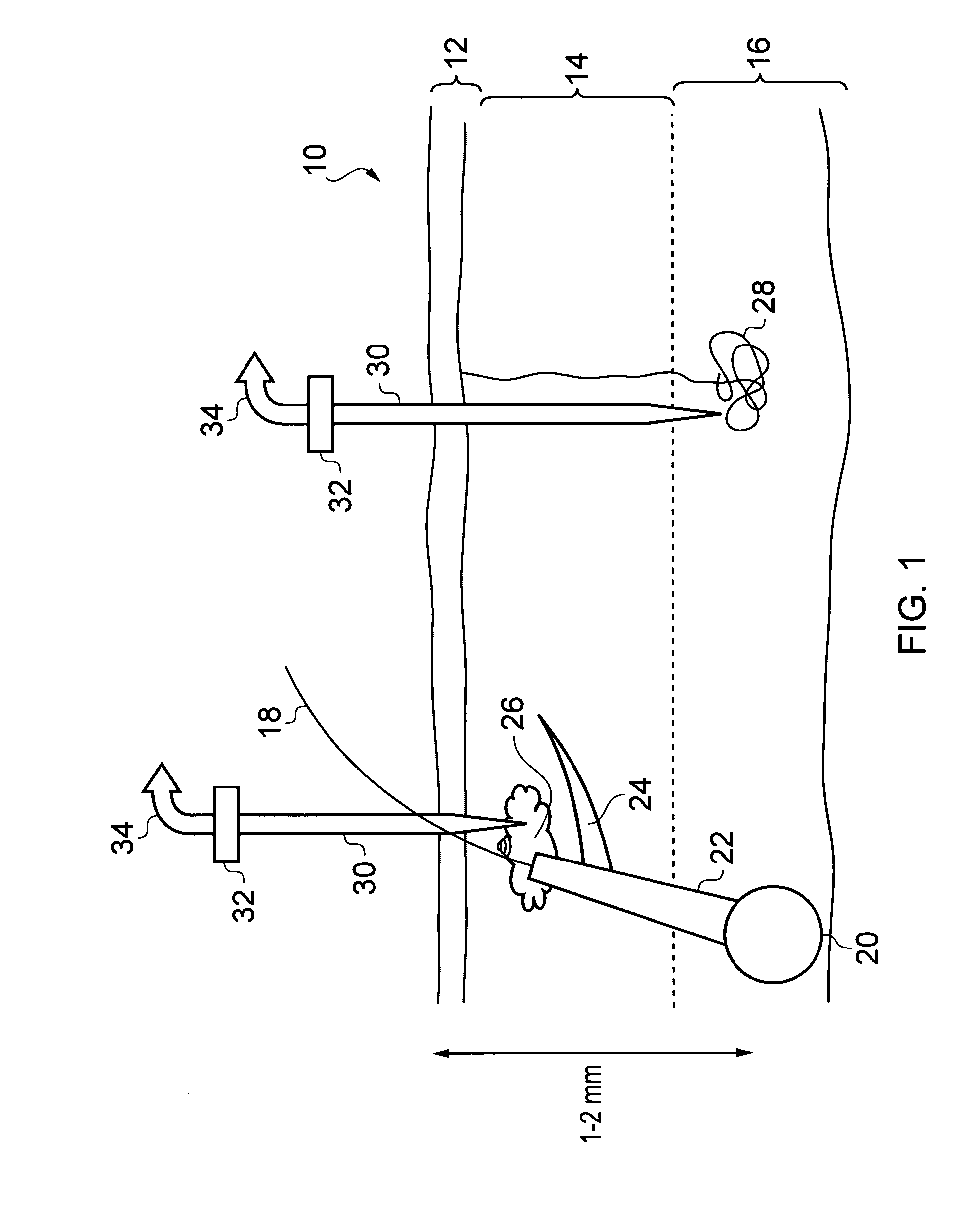

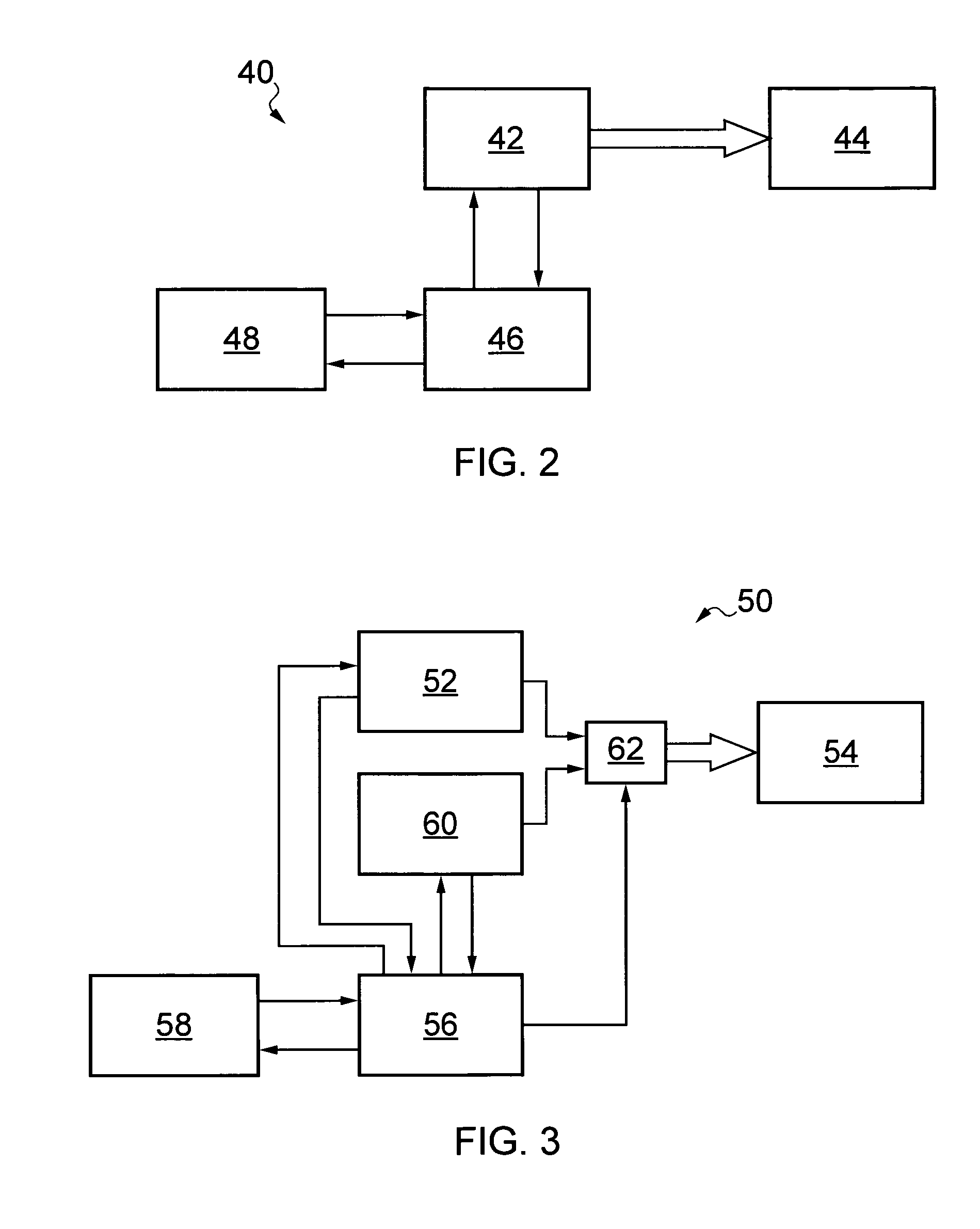

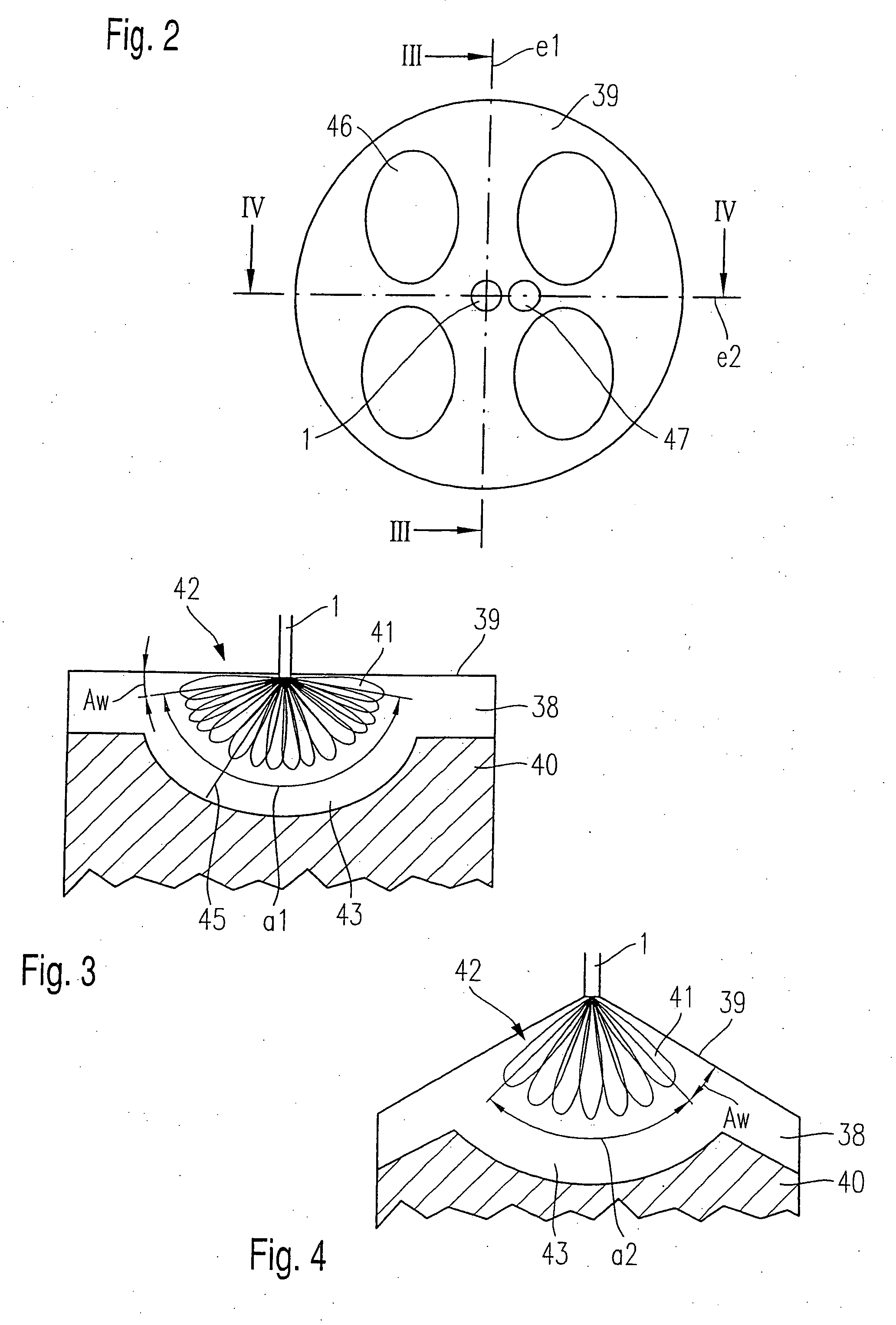

Apparatus for localised invasive skin treatment using electromagnetic radiation

InactiveUS20120035688A1Precision therapyMinimally invasiveElectrotherapySurgical needlesSkin treatmentsSkin surface

Skin tissue measurement / treatment apparatus (40) for controllably delivering electromagnetic radiation having a frequency of 10 GHz or more directly to a localised region of skin tissue via a monopole antenna (44) adapted to penetrate the skin surface. One embodiment includes an applicator (152) having a plurality of independently controllable monopole antennas (158) protruding therefrom for selective treatment / measurement of an area of skin. Treatment may be activated based on the complex impedance of tissue in the localised region calculated by determined the magnitude and phase of reflected power relative to a reference signal. The power level of the generated electromagnetic radiation may be adaptively controlled based on the detection of net power delivered to the skin tissue.

Owner:UNIV OF WALES BANGOR

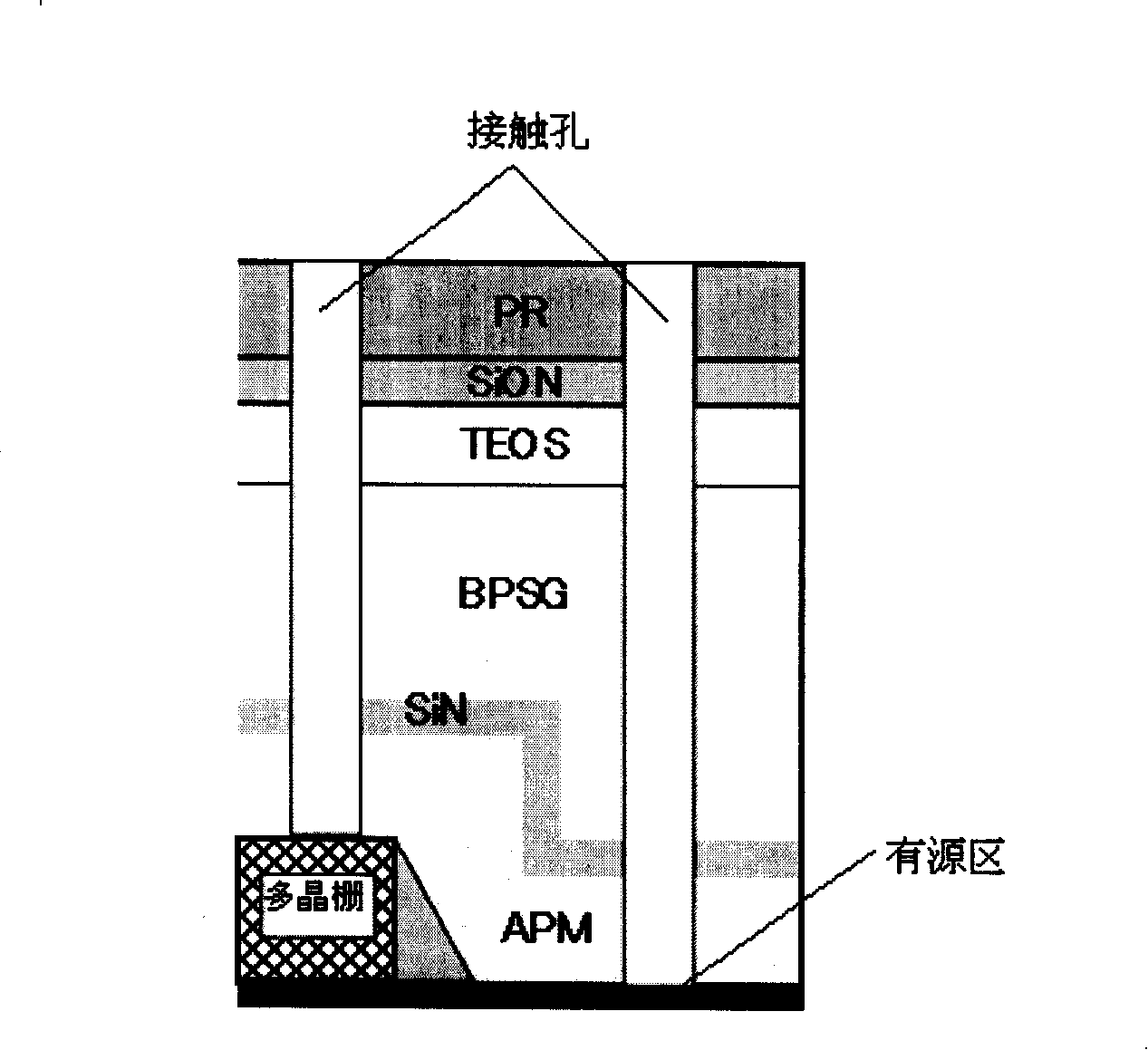

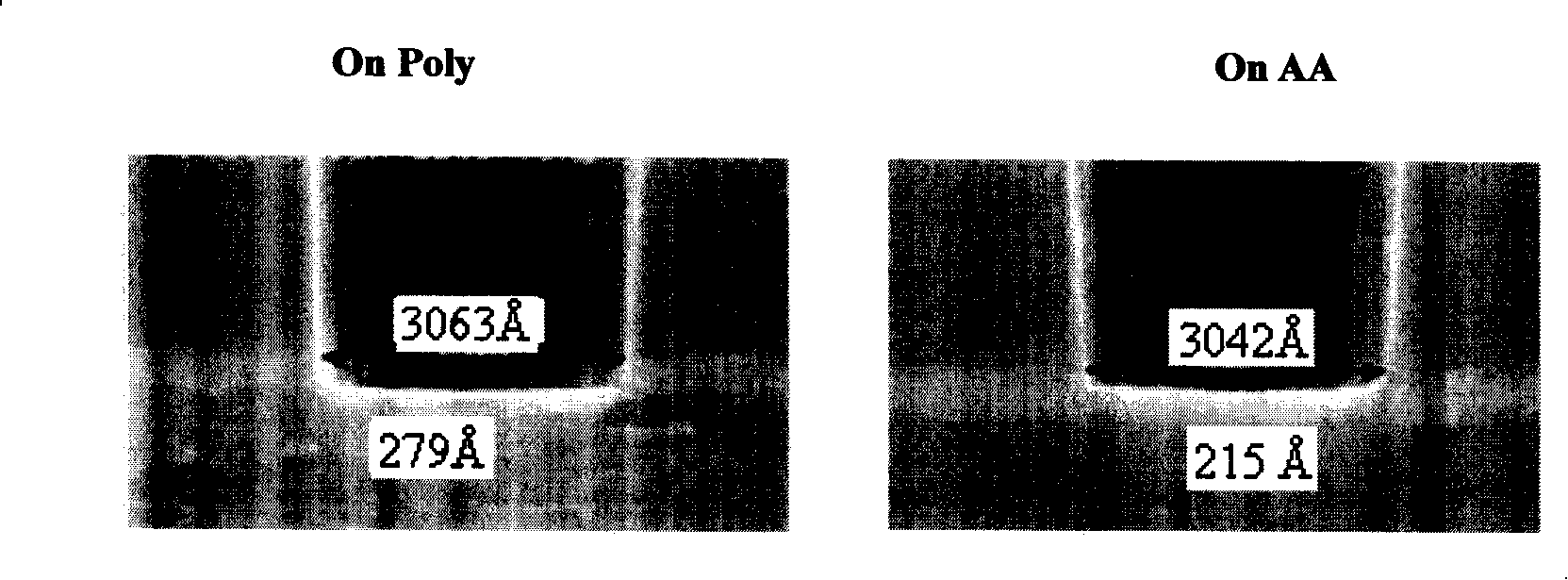

Method for etching suspending type etch blocking layer contact hole in embedded flash memory device

ActiveCN101202243AReduce lossesReduce depthSemiconductor/solid-state device manufacturingSalicideSilicon oxide

The invention discloses an etching method for contact holes of a suspended type etching barrier layer of an embedded flash memory device and comprises the following steps: the first step is the etching of top silicon oxy-nitride; the second step is the fast main etching of an oxide film; the third step is the slow main etching of the oxide film: in the step, the selectivity-ratio of silicon oxide to silicon nitride is bigger than 20:1, while the etching rate is relatively slower; the fourth step is to remove polymers which are produced in the previous three steps and are left at bottom parts of the contact holes; the fifth step is to remove the suspended type etching barrier layer of the nitride silicon; the sixth step is the etching of the oxide film at the bottom part. The invention solves the problem of excessive loss of metal contact silicide on the top part of a poly gate due to no etching barrier layer; at the same time, the invention can effectively avoid excessive etching and communication of the poly gate and an isolated edge of a shallow groove caused by deviation of exposing positions, thus the loss of electric leakage of the device can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

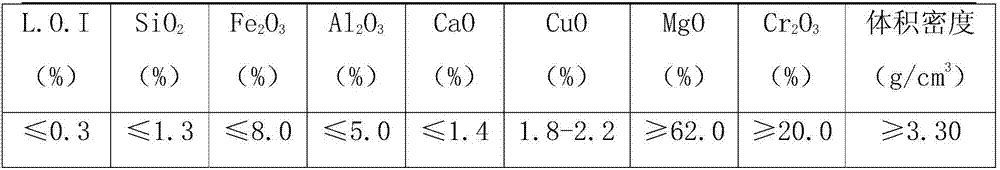

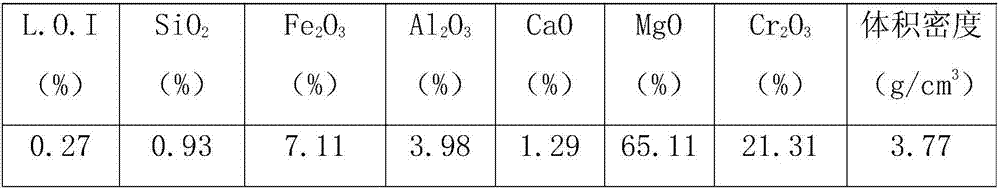

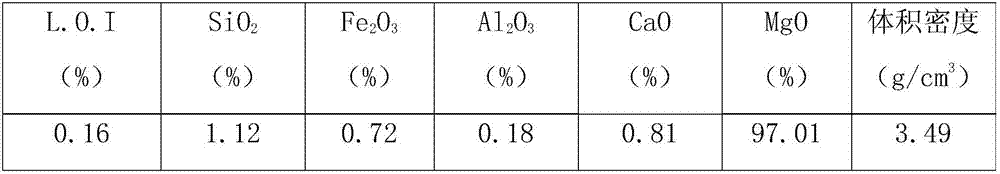

Copper composite high-performance magnesia-chrome brick and manufacturing method thereof

The invention belongs to the technical field of refractory materials, especially refractory materials for nonferrous smelting, and especially relates a copper composite high-performance magnesia-chrome brick and a manufacturing method thereof. The brick comprises 1-10 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 3-5 mm, 10-35 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 1-3 mm, 10-25 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 0.088-1 mm, 1-5 wt% of fused magnesia-chrome sands with the particle size being 3-5 mm, 1-15 wt% of fused magnesia-chrome sands with the particle size being 1-3 mm, 2-13 wt% of fused magnesia-chrome sands with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia-chrome sands with the particle size being not more than 0.088 mm, 1-5 wt% of fused magnesia with the particle size being 3-5 mm, 1-15 wt% of fused magnesia with the particle size being 1-3 mm, 2-13 wt% of fused magnesia with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia with the particle size being not more than 0.088 mm, 2-10 wt% of chromium concentrate with the particle size being not more than 0.088 mm, 1-6 wt% of a composite additive and 3-5 wt% of an (externally added) binder. Magnesia-chrome brick wastes generated by the nonferrous smelting can be fully used reasonably and effectively in the invention.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

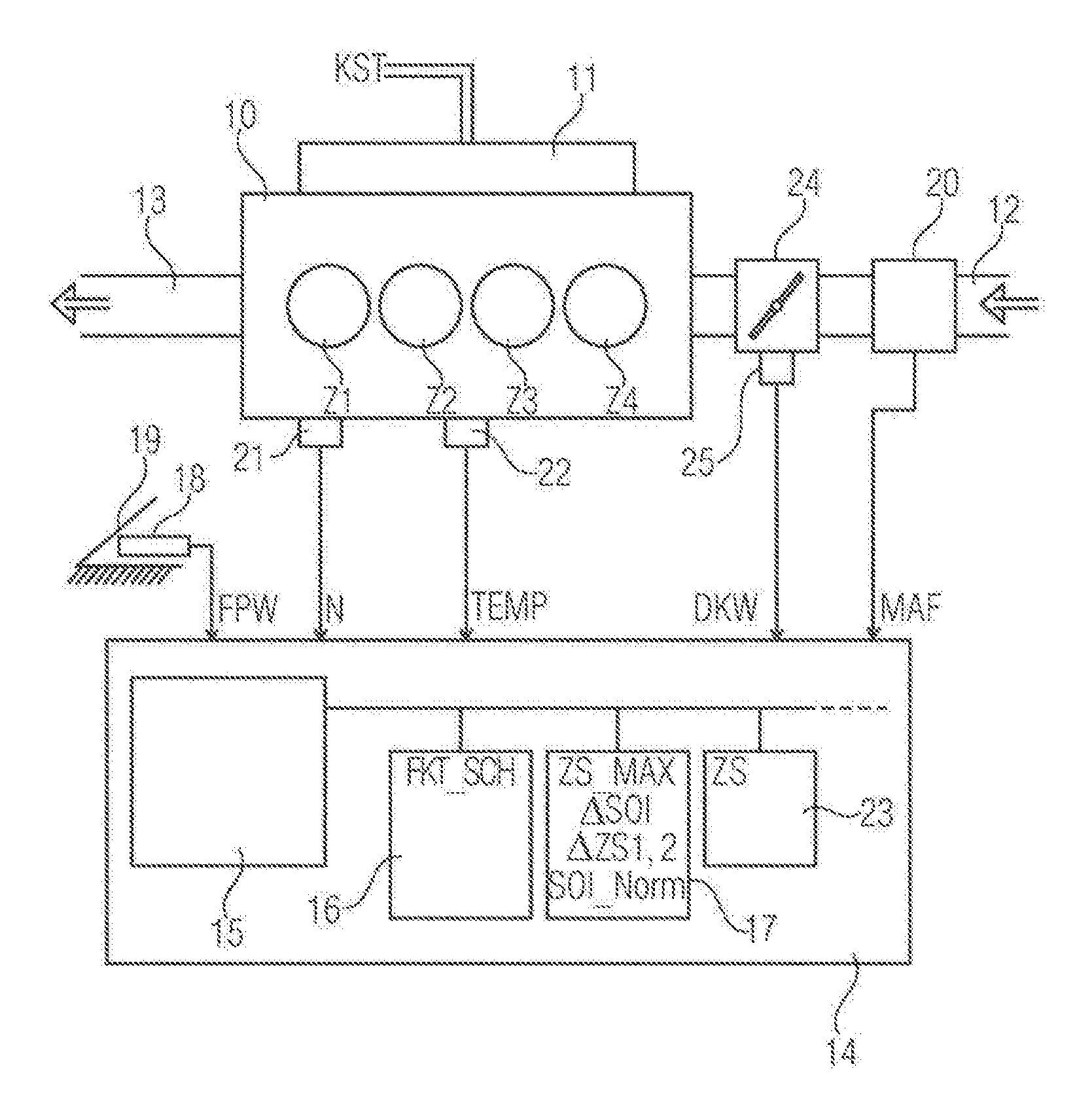

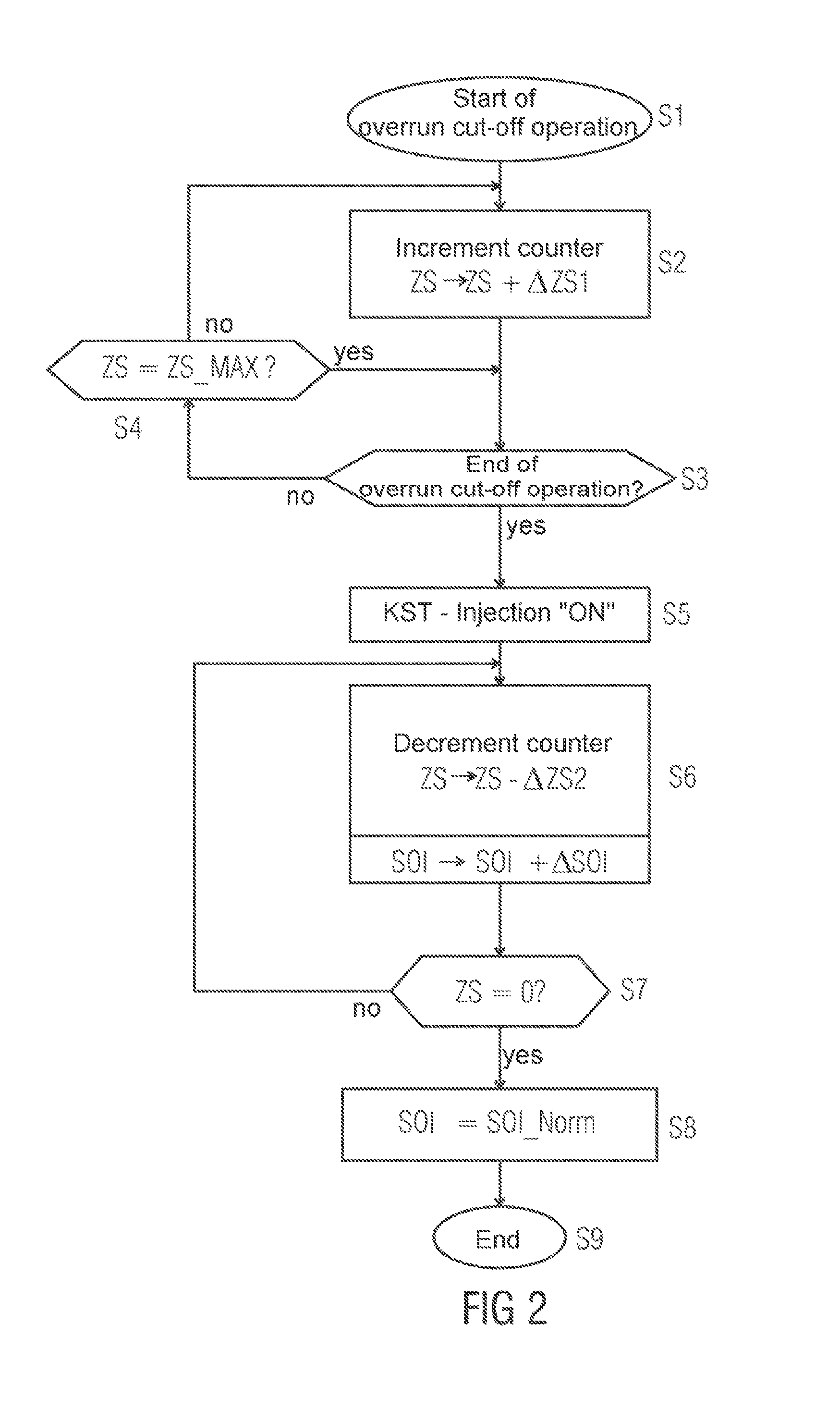

Control For Overrun Cutoff Of Internal Combustion Engine

ActiveUS20160237943A1Reduce particle emissionsReduce penetration depthElectrical controlInternal combustion piston enginesStart timeExternal combustion engine

A method for controlling an internal combustion engine operated with direct fuel injection may include, during a transition phase after the end of an overrun cut-off with resumption of fuel injection and normal operation of the internal combustion engine, shifting an injection start time (SOI) by an adaptation value (ΔSOI) in relation to an injection start time (SOI) which lies later than an injection start time (SOI_Norm) determined during normal operation of the internal combustion engine.

Owner:VITESCO TECH GERMANY GMBH

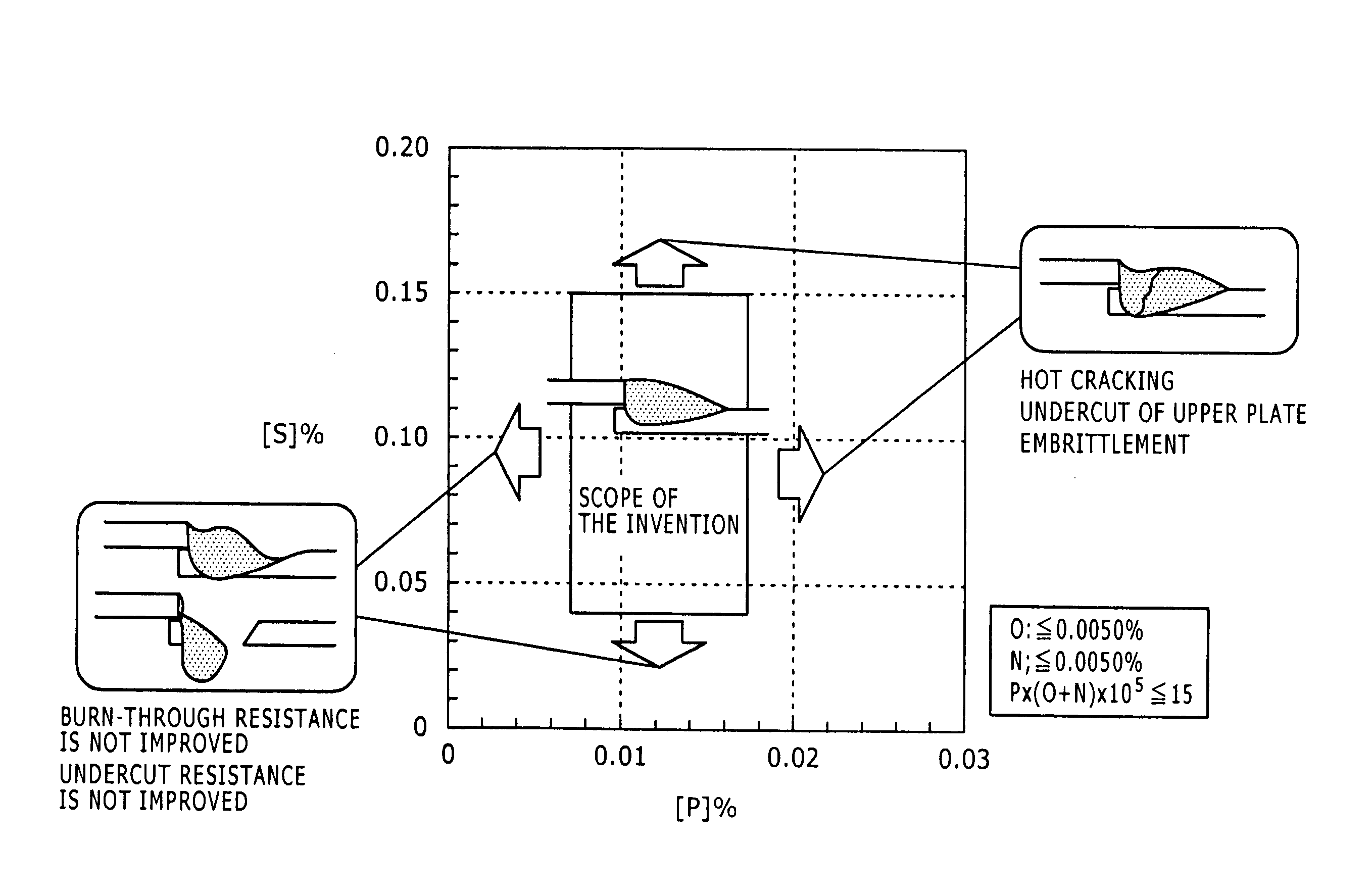

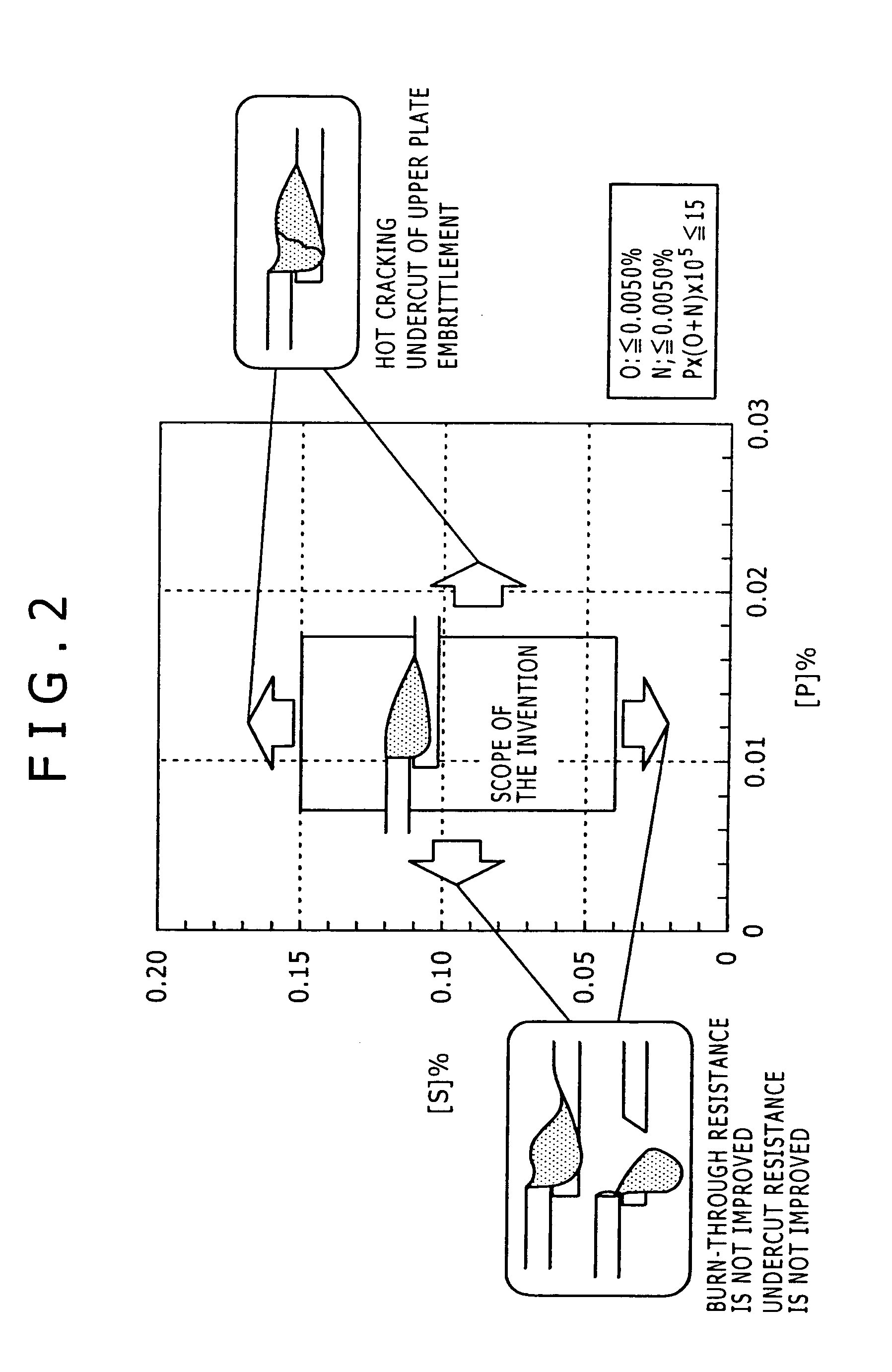

Solid wire

ActiveUS20080128399A1Reduce surface tensionLow viscosityWelding/cutting media/materialsSoldering mediaWire rodCrack resistance

A solid wire contains C of 0.020 to 0.100 mass percent, Si of 0.25 to 1.10 mass percent, Mn of 1.20 to 1.65 mass percent, P of 0.008 to 0.017 mass percent, S of 0.045 to 0.150 mass percent, O of 0.0050 mass percent or less, N of 0.0050 mass percent or less, wherein P*(O+N)*105≦15 is satisfied, and the remainder including Fe and impurities, wherein the relevant impurities contain Ti of 0.15 mass percent or less, B of 0.0050 mass percent or less, and Cr, Ni, Al, Nb, V, Zr, La and Ce of 0.20 mass percent or less respectively. According to such a configuration, a solid wire is provided, in which while increase in welding cost is controlled to the minimum, stability of wire feed, burn-through resistance, undercut resistance, and crack resistance are excellent, slag and spatter are hardly produced, hardness of weld metal is equal to or higher than that of base metal, and brittle fracture hardly occurs.

Owner:KOBE STEEL LTD

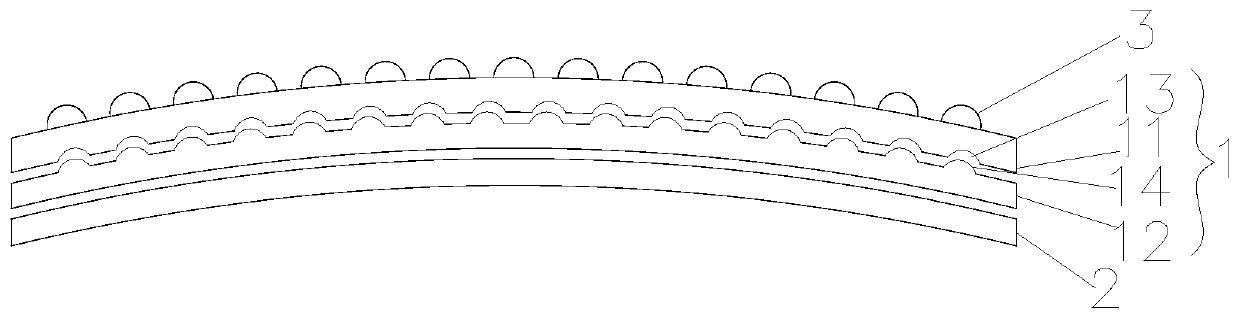

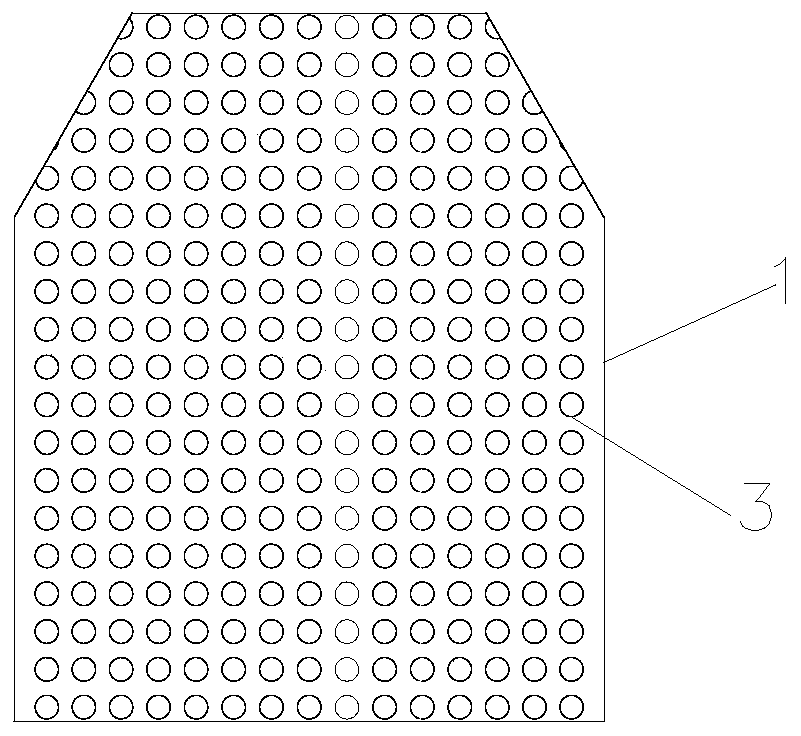

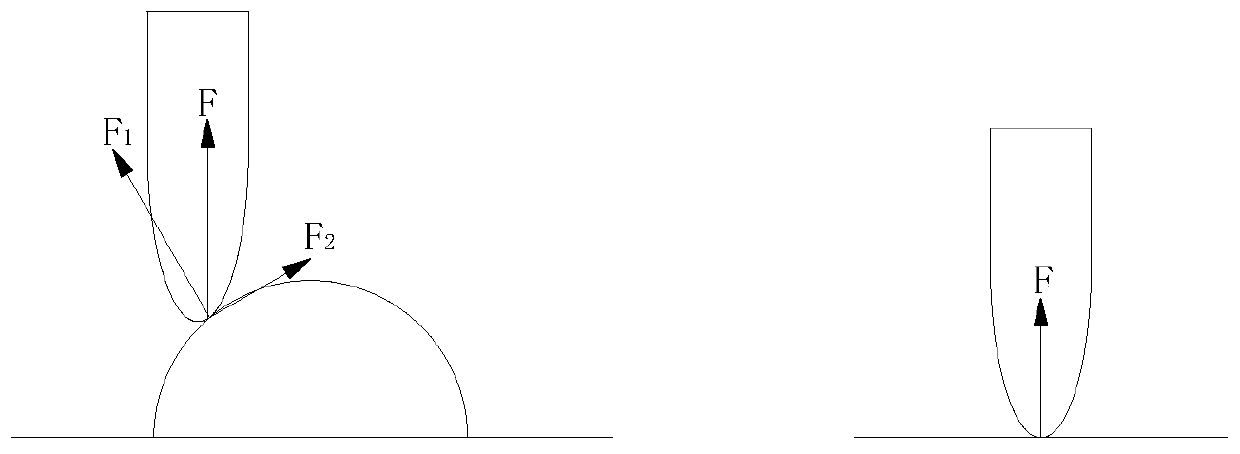

Bionic bulletproof insert plate capable of changing direction of bullet

ActiveCN111366038AReduce penetration depthReduce impact energyPersonal protection gearArmour platesFiberEngineering

The invention belongs to the technical field of protective bulletproof equipment treatment, and particularly relates to a bionic bulletproof insert plate capable of changing the direction of a bullet.The bionic bulletproof insert plate capable of changing the direction of the bullet comprises an upper board made of hard ceramics and a lower board made of high-performance fibers, wherein the upperplate and the lower plate are fixedly arranged together. A plurality of first convex hulls are arranged on the side, away from the lower plate, of the upper plate at equal intervals, the upper plateis mainly used for reducing most impact energy of the bullet, the lower plate plays a role in slowly releasing energy, and meanwhile, the form of the first convex hulls of the upper plate changes theshoot angle of the bullet shot into the bulletproof insert plate; and grooves in a first layer of the upper plate and second convex hull structures in a second layer are connected together in a clamped mode, the shoot angle of the bullet shot into the bulletproof insert plate is further changed, and the impact force of the bullet invading into the vertical direction of the insert plate is reduced,so that the upper plate of the insert plate is more beneficial to reducing the impact force and speed when the bullet collide with the bulletproof insert plate, dissipation of impact energy is facilitated, and therefore the penetration depth of the bullet on the bulletproof insert plate is reduced.

Owner:JILIN UNIV

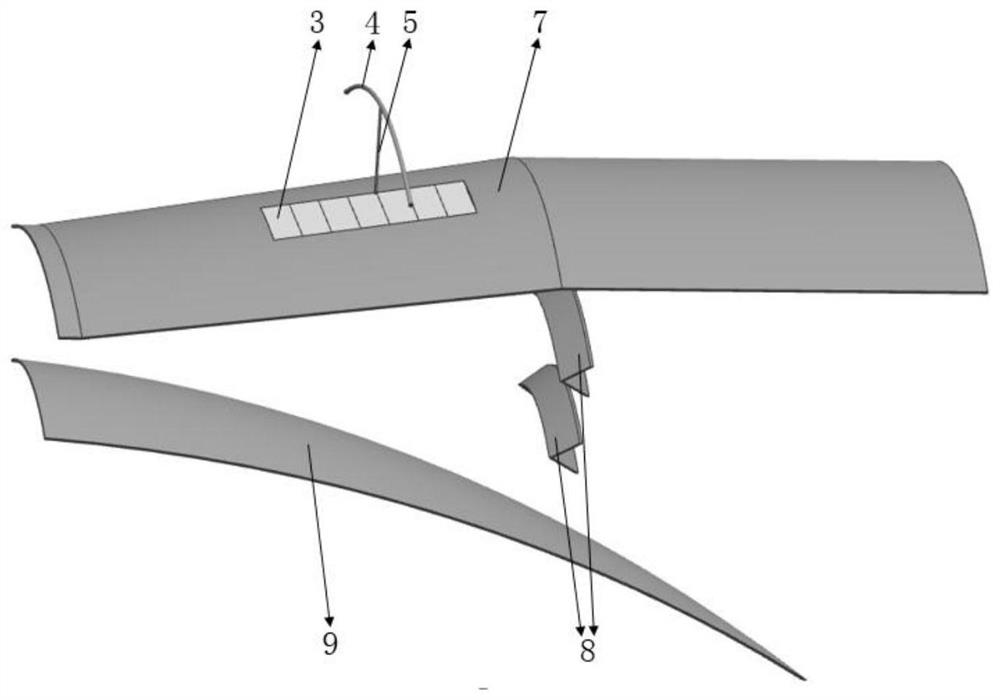

AI-regulated mixing device for inner and outer ducts of afterburner

InactiveCN113048511AImprove performanceUniform temperatureContinuous combustion chamberAviationCombustion chamber

The invention discloses an AI-regulated mixing device for inner and outer ducts of an afterburner, and belongs to the field of aero-engine afterburners. The device is characterized in that an air flow inclination angle and an air inlet amount of the outer duct are changed by changing spatial positions of mixing device blades so that an outlet temperature and speed are uniformly distributed, flow loss is reduced and infrared stealth is realized; when distribution of the outlet temperature and speed needs to be adjusted, a control terminal calculates required fuel flow according to current inlet parameters of the afterburner, then calculates space attitude angles of the mixing device blades, namely rotation angles of the mixing device blades, converts the space attitude angles into adjusting signals, and transmits the adjusting signals to a hydraulic mechanical system; and the mechanical system controls a telescopic supporting rod to move through hydraulic energy, so as to control the mixing device blades to rotate. According to the device, the distribution of the outlet temperature and speed of the afterburner are adjusted by changing the the air flow inflow inclination angle and the air inlet amount of the outer duct so that the outlet temperature and speed are uniformly distributed, the flow loss is reduced, and the infrared stealth is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

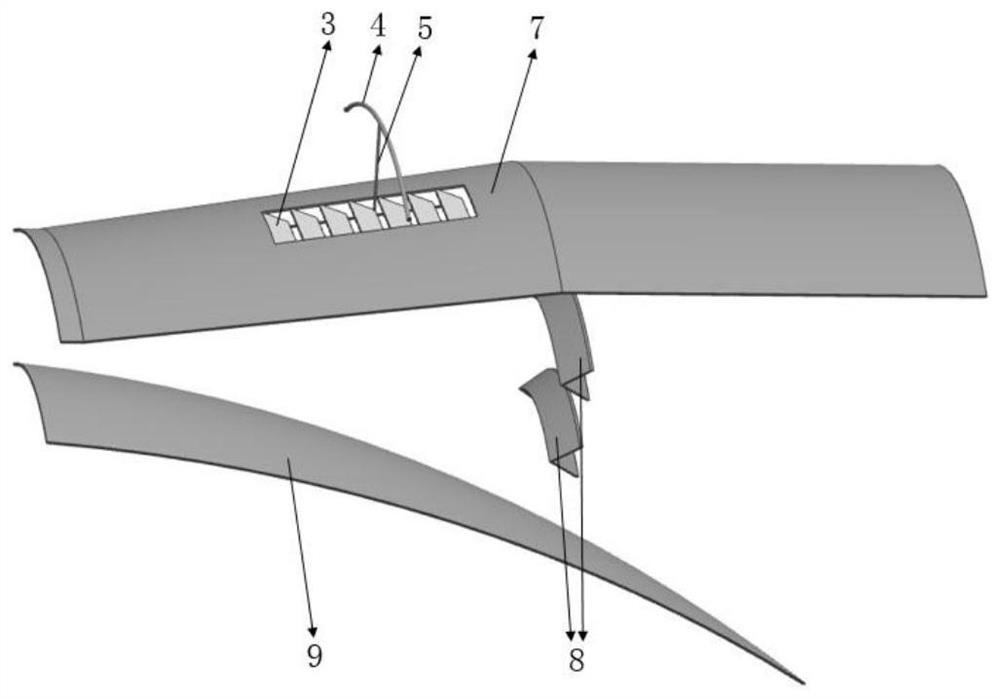

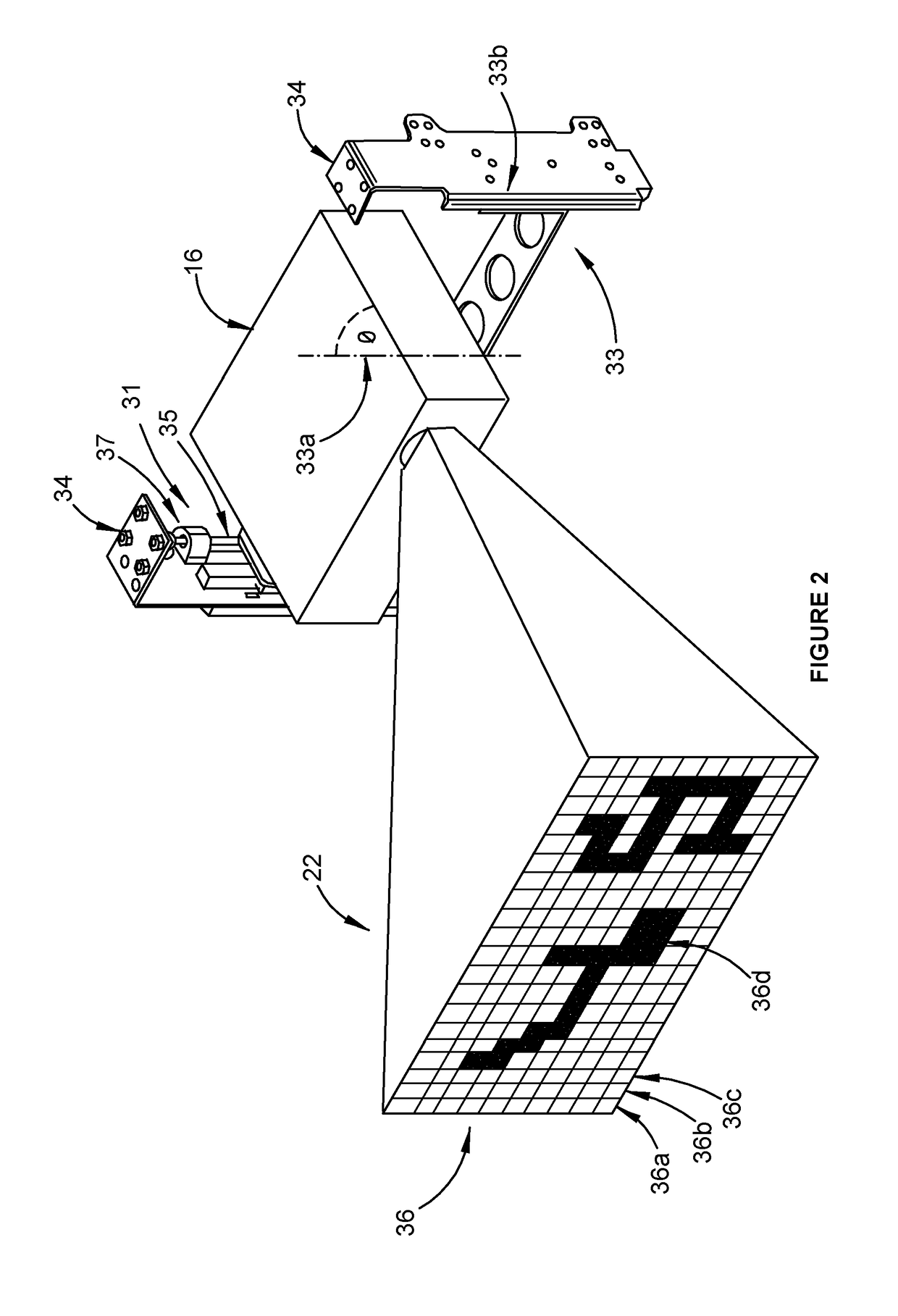

Improvements in 3D printing

InactiveUS20180056585A1High resolutionPenetration depthManufacturing heating elements3D object support structuresComputer graphics (images)Computer science

A method of 3D printing an article is described, the method comprising the steps of projecting images onto a liquid resin from a plurality of cooperating image sources; aligning the images from the first and second sources at least in a single 2D plane in the liquid resin; moving a plate relative to the 2D plane, wherein the moving is substantially continuous; and allowing the liquid resin to cure upon expose to the image in the 2D plane, thereby forming the printed article. The curing of the resin under the influence of the light emitted from the plurality of image sources can allow for a fast printing process.

Owner:GIZMO 3D PRINTERS

Non-carbonaceous brick for ultra-low carbon steel external refining steel ladle and preparation method of non-carbonaceous brick

InactiveCN107117949AImproved resistance to slag penetrationPenetration Depth DecreaseMelt-holding vesselsCarbon steelConstruction aggregate

The invention discloses a non-carbonaceous brick for an ultra-low carbon steel external refining steel ladle and a preparation method of the non-carbonaceous brick. The non-carbonaceous brick is made of aggregate, a powder material and a binding agent, wherein the aggregate is corundum of which the particle size is greater than 0.088 mm and smaller than or equal to 5 mm; the particle size of the powder material is smaller than or equal to 0.088 mm; the binding agent is a non-phosphorus binding agent consisting of organic binding agents and inorganic binding agents. The non-carbonaceous brick has the advantages that firstly, no carbon or phosphorus is used, and requirements that carbon or phosphorus is not increased to molten steel by working layer materials of a steel ladle melting tank area of low and super-low carbon steel in the external refining process, and the service life is long are met; secondly, the production efficiency of the non-carbonaceous brick is greatly improved, the production cycle is shortened, the supply capability is greatly improved, and organic combination of improvement of production efficiency and prolonging of service lives of non-carbonaceous bricks is achieved.

Owner:PUYANG REFRACTORIES GRP CO LTD

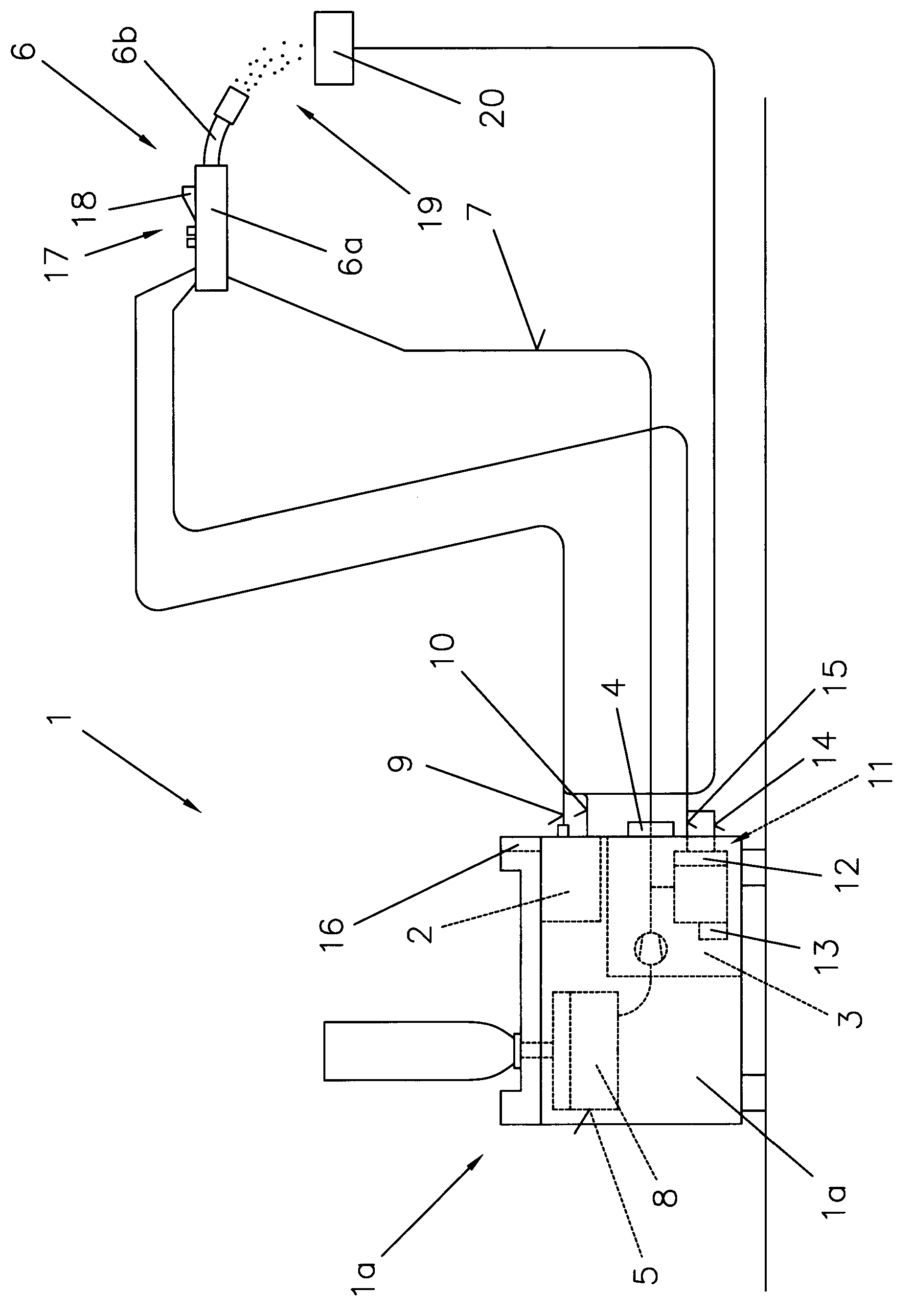

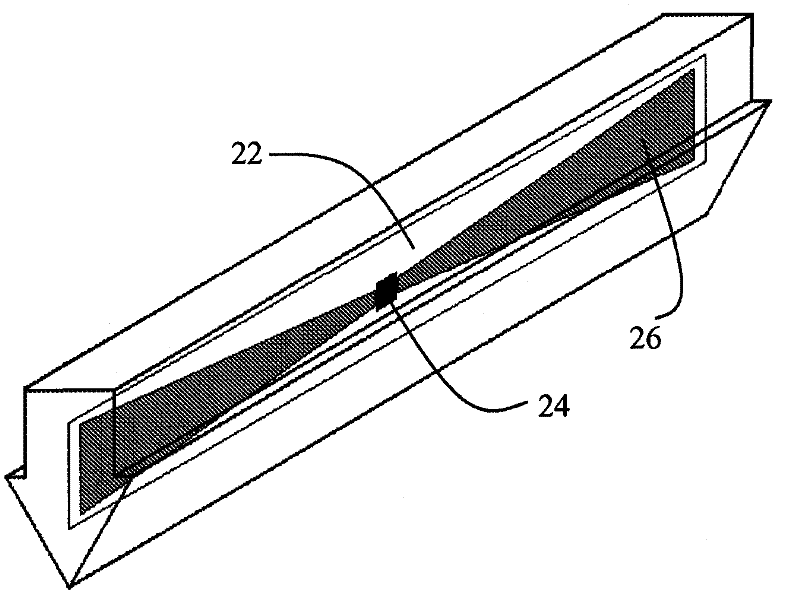

Heating element, steam cutting device, and burner of a power-enerating device

ActiveCN103262662APromote absorptionShorten the evaporation channelSteam generation heating methodsArc welding apparatusCombustorInduction heater

The invention relates to a heating element (25) for liquids to be vaporised as well as a burner (6) of a steam cutting device (1) and a burner (38) of a power-generating device, said element being designed as an induction heater (47) comprising one coil (25a). In order to improve vaporisation, the coil (25a) of the induction heater (47) is enclosed in a hybrid construction which is composed of a main part (31) with laterally extending webs (33), and which consists of an easily magnetisable material (35) and a thermally highly-conductive material, a covering element (32) consisting of nanocrystalline materials being arranged on said webs (33), and the easily magnetisable material (35) being designed to be installed on a thermally highly-conductive material (37) of a vaporiser (21).

Owner:FRONIUS INTERNATIONAL GMBH

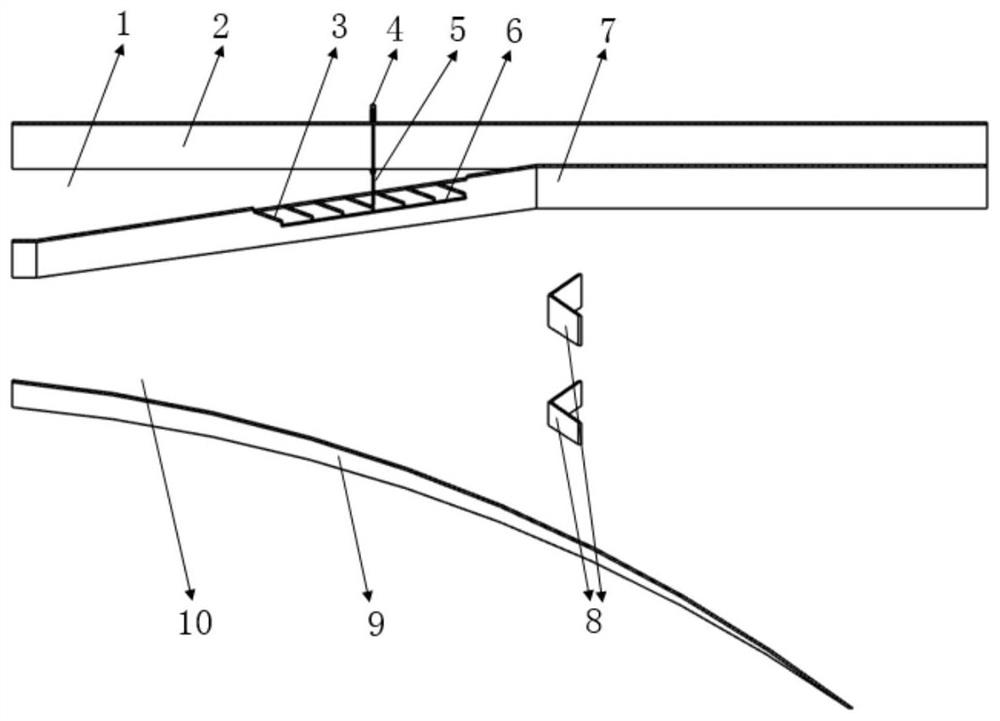

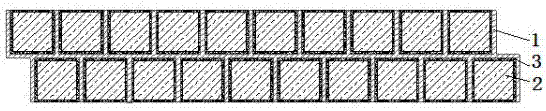

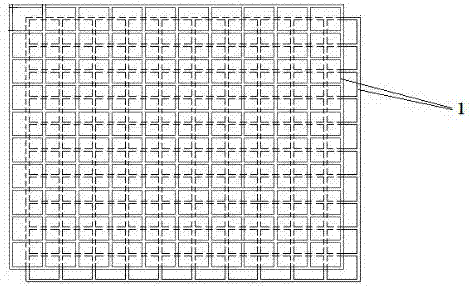

Multi-bullet-resistant light-weight bionic bulletproof flashboard and manufacturing method thereof

InactiveCN114087924AImprove the impact resistance of multiple bulletsReduce impactLayered productsReactive armourEnergy absorptionPlugboard

The invention relates to a multi-bullet-resistant light-weight bionic bulletproof flashboard and a manufacturing method thereof. The light-weight bionic bulletproof flashboard comprises a bionic main bulletproof layer, a buffer energy absorption layer and an inner layer. The bionic main bulletproof layer comprises a hard ceramic panel, the hard ceramic panel comprises a plurality of packaging ceramic units which are closely arranged in a determinant mode, and each packaging ceramic unit comprises a blocky rubber ceramic column structure and wrapping cloth wrapping the rubber ceramic column structure. The rubber ceramic column structure comprises a plurality of ceramic columns which are closely arranged in rows and columns and rubber bodies filled among the ceramic columns. The buffer energy absorption layer is stacked between the bionic main bulletproof layer and the inner layer. By referring to a biological structure, the bulletproof plugboard is designed into a rigid-flex three-layer structure, and the bionic main bulletproof layer is designed into an orderly-arranged hierarchical structure, so that the problem that an existing bulletproof plugboard is insufficient in capacity of resisting multiple bullets is effectively solved, and the bulletproof plugboard is convenient to repair and beneficial to secondary utilization.

Owner:JILIN UNIV

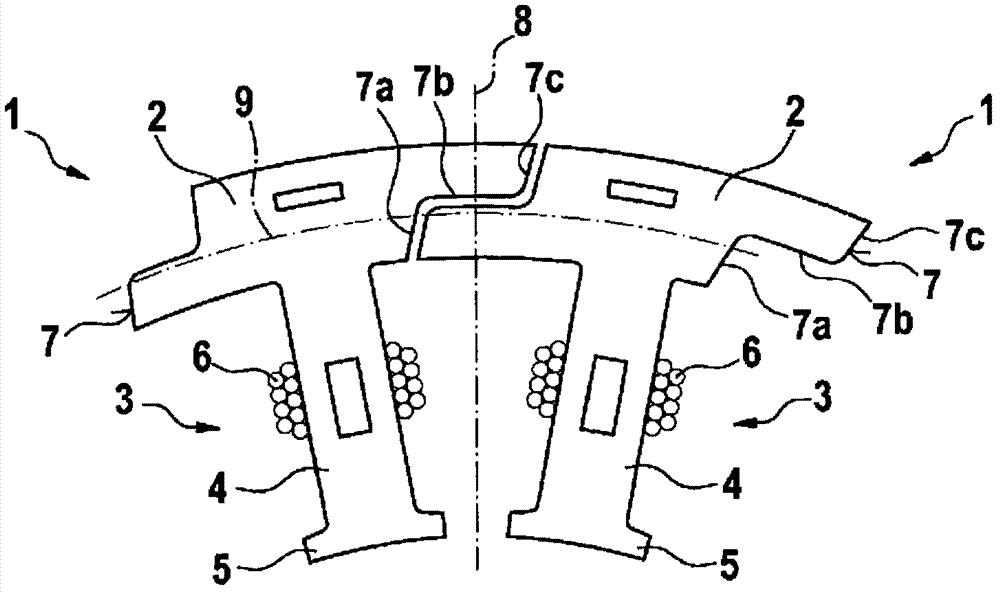

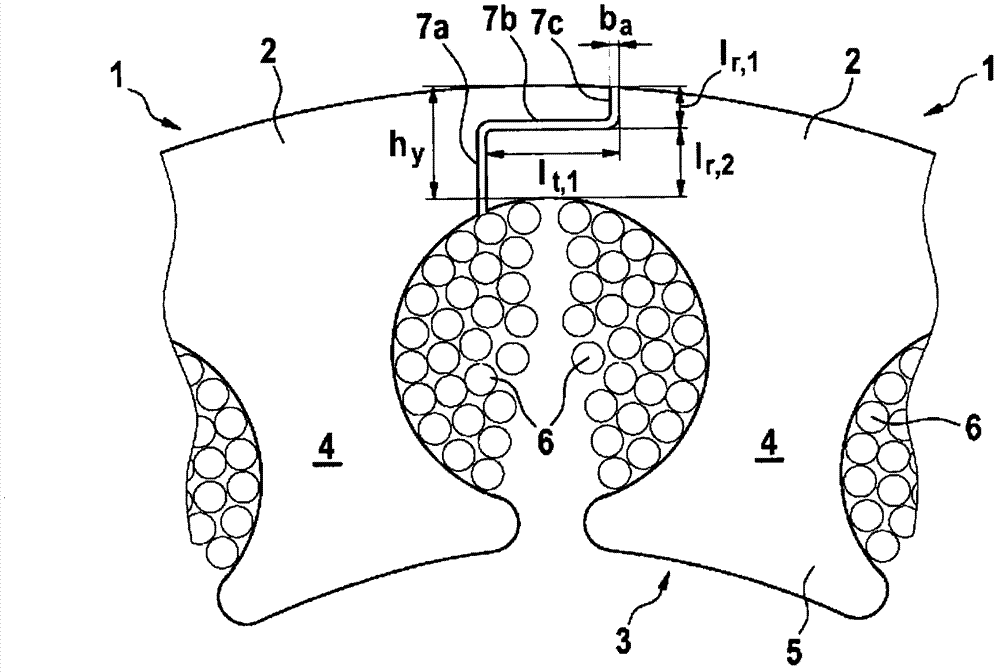

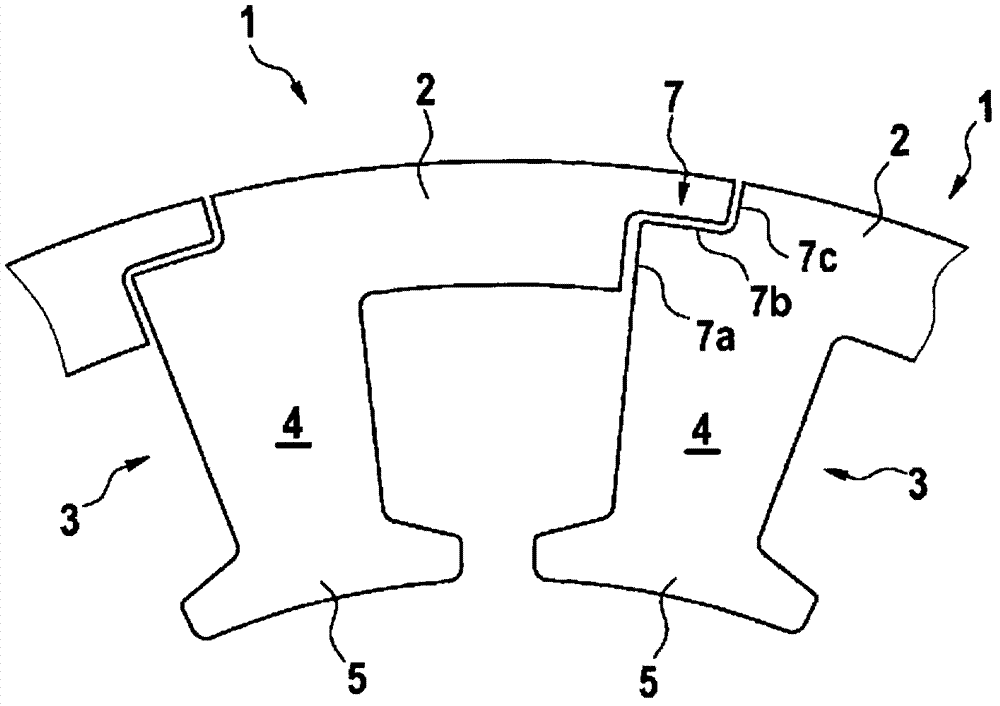

Stator in an electric motor

InactiveCN102771032AReduce lossLarge gap widthMagnetic circuit stationary partsEngineeringTooth segment

The invention relates to a stator in an electric motor comprising a plurality of teeth segments forming a stator ring. Each tooth segment comprises a yoke segment and support teeth for receiving coils carrying electric current. The peripheral front side of a yoke segment forms a contact surface with at least one straight-lined contact surface section which forms an angle in relation to the radial line.

Owner:ROBERT BOSCH GMBH

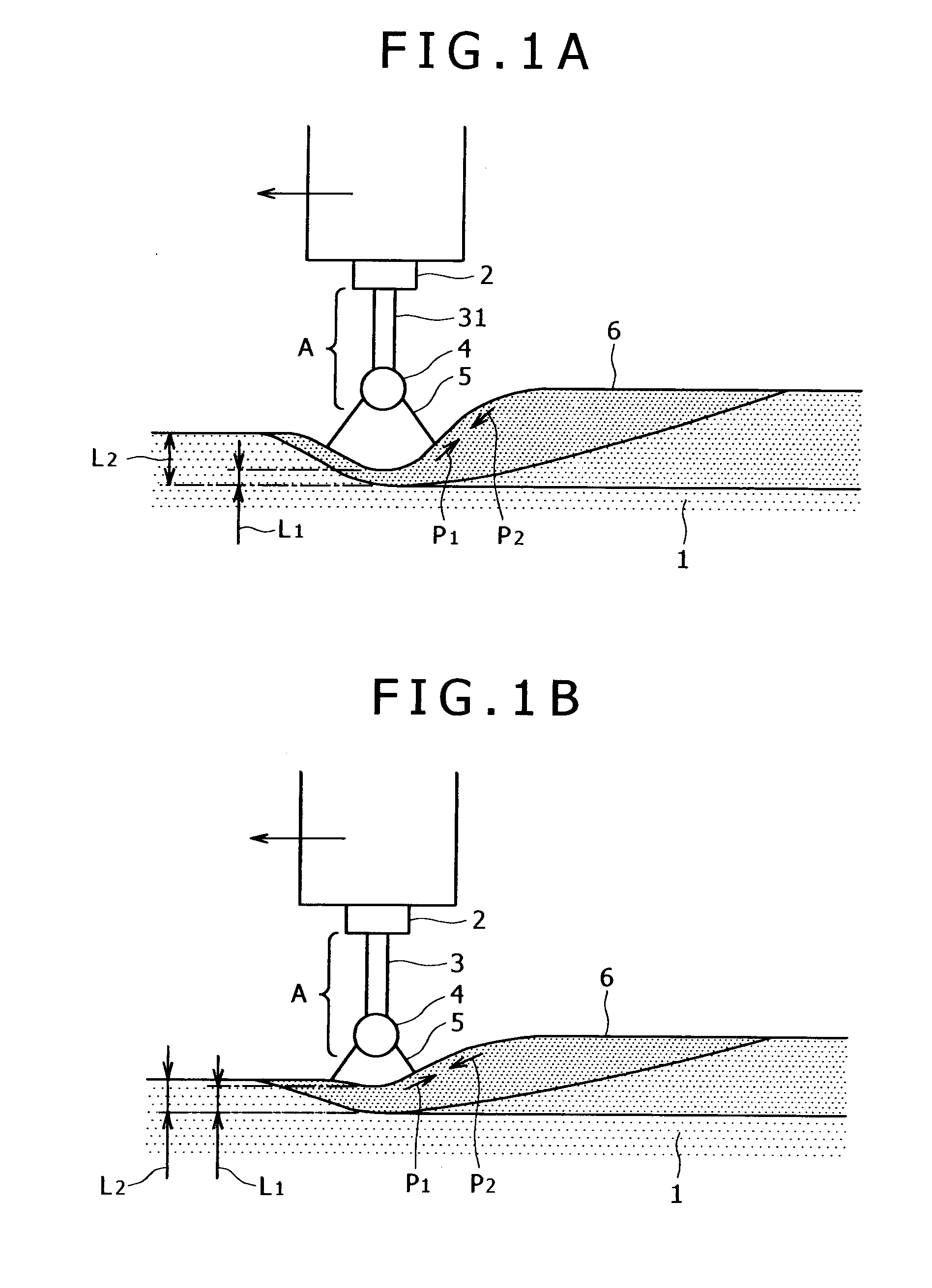

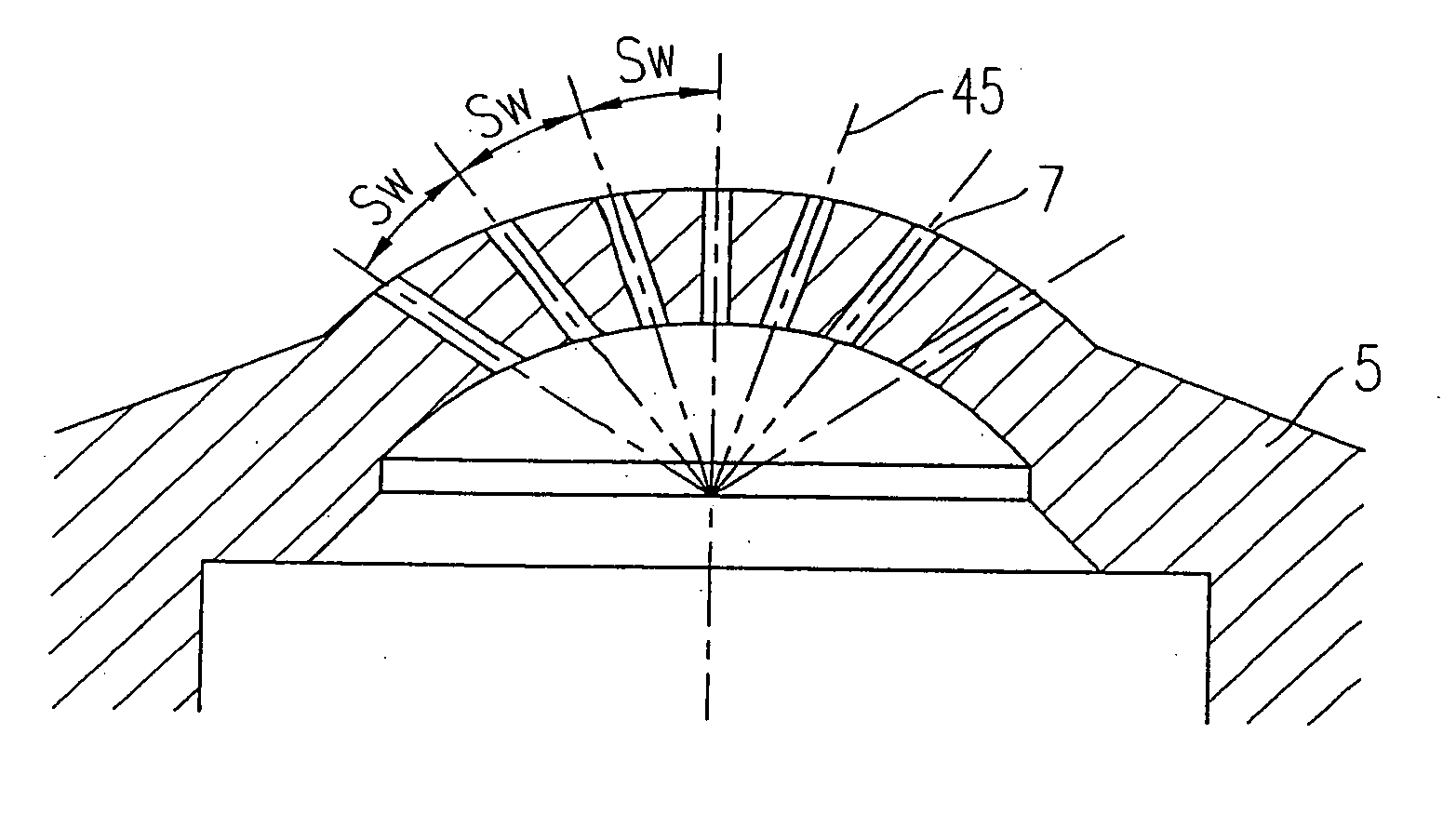

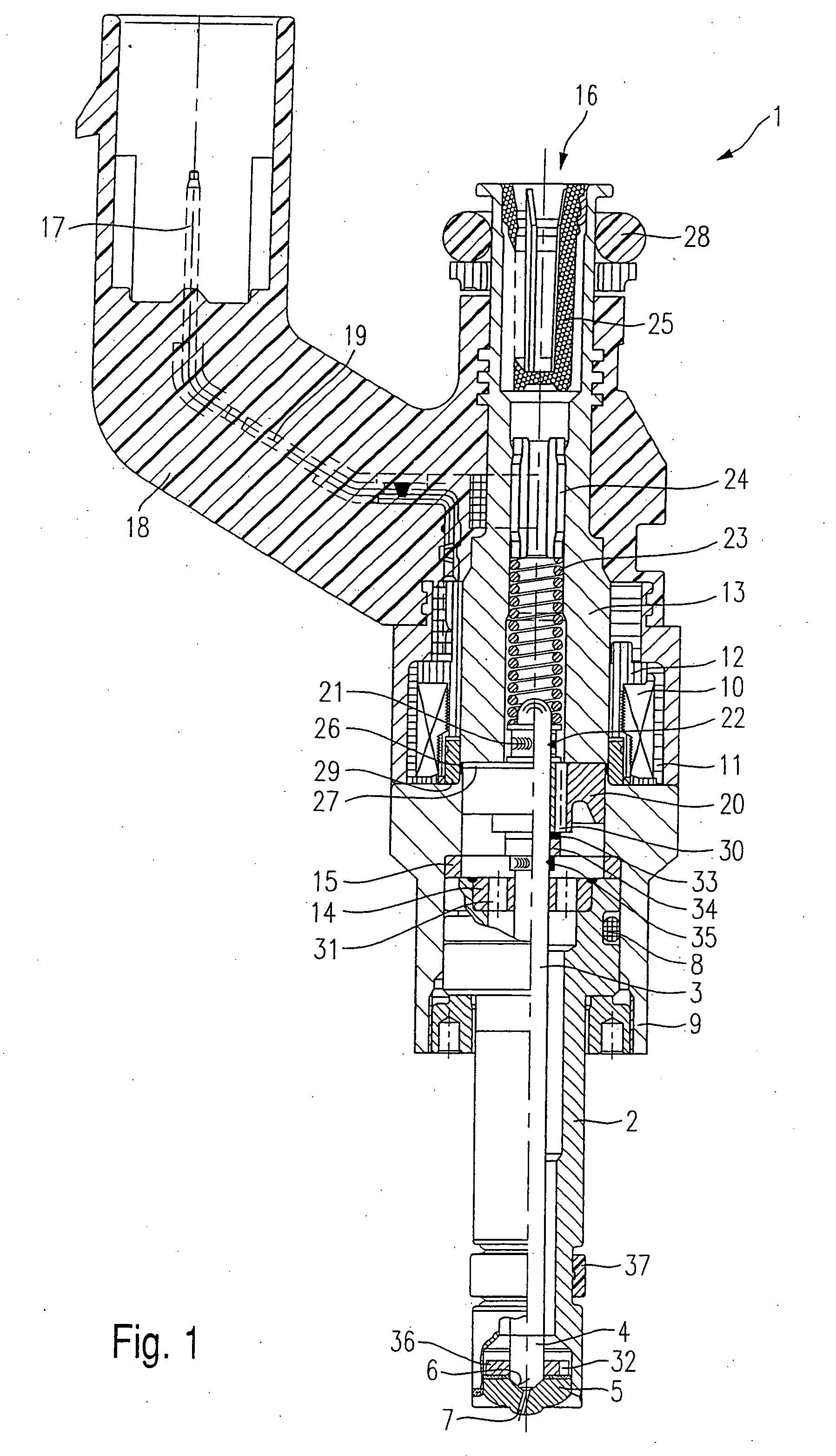

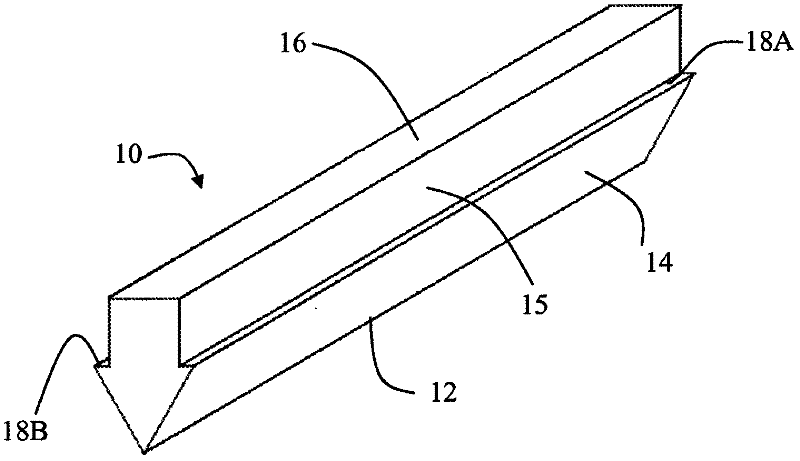

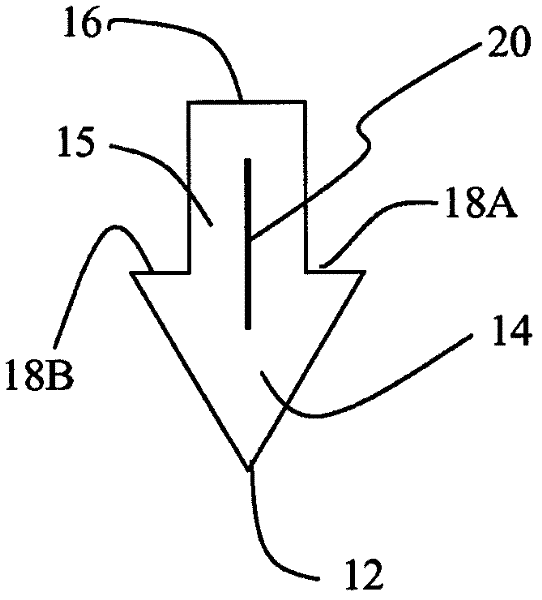

Fuel injection system

InactiveUS20090065608A1Reduce penetration depthFine surfaceAircraft navigation controlInternal combustion piston enginesCombustion chamberPiston

A fuel-injection system for direct injection of fuel into a combustion chamber through a combustion-chamber top arranged opposite a piston has a fuel injector which includes an actuable valve-closure member. The valve-closure member cooperates with a valve-seat surface to form a sealing seat. A multitude of spray-discharge orifices generates a spray cloud, each spray-discharge orifice generating a fuel jet, and the multitude of fuel jets generating the spray cloud in the combustion chamber. A first opening angle of the spray cloud in a first plane is greater than a second opening angle in a second plane extending perpendicular to the first plane.

Owner:ROBERT BOSCH GMBH

Transponders, transponder kits, method of applying transponders, and products containing transponders

InactiveCN102265291AReduce penetration depthStable supportCo-operative working arrangementsForestryPondingEngineering

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT +1

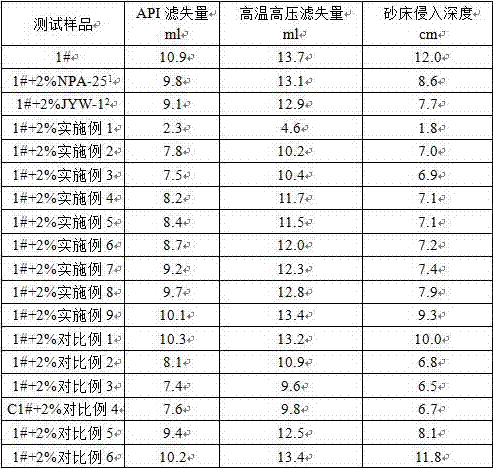

Preparation method of cationic plugging agent for drilling fluid

ActiveCN107501456AEasy accessEffective control of molecular weightDrilling compositionFiltrationEmulsion polymerization

The invention discloses a preparation method of a cationic plugging agent for a drilling fluid. The cationic plugging agent is prepared by emulsion polymerization from raw materials in parts by weight as follows: 30-90 parts of styrene, 5-75 parts of butyl acrylate and 15-75 parts of dimethyl diallyl ammonium chloride. Monomers are initiated by an initiator to be subjected to a polymerization reaction, and the cationic plugging agent with the macromolecular chain is obtained; with addition of a small quantity of the product to the drilling fluid, the filtration loss of the drilling fluid and the invasion depth in the sand bed can be effectively reduced, plugging of underground pore cracks is realized, and drilling safety is guaranteed.

Owner:XUZHOU NORMAL UNIVERSITY

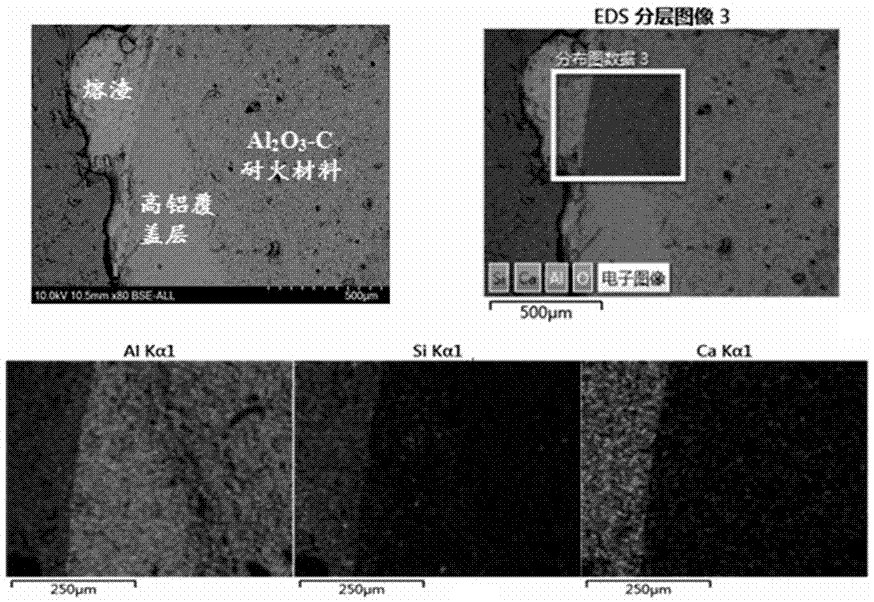

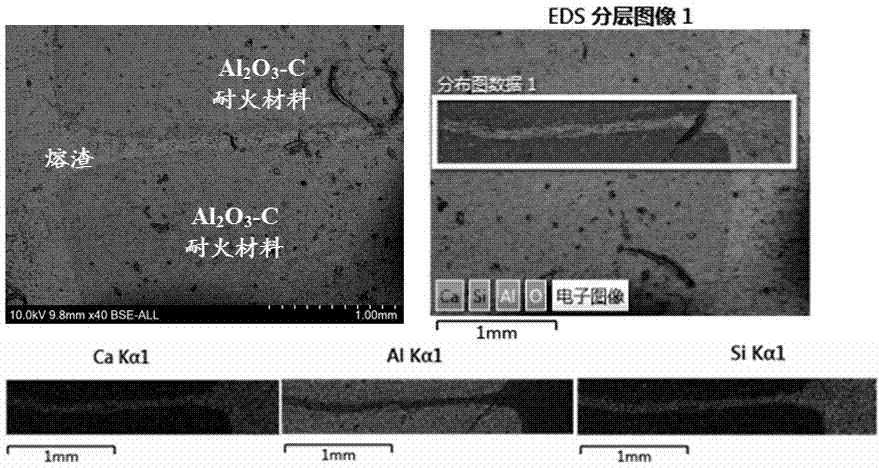

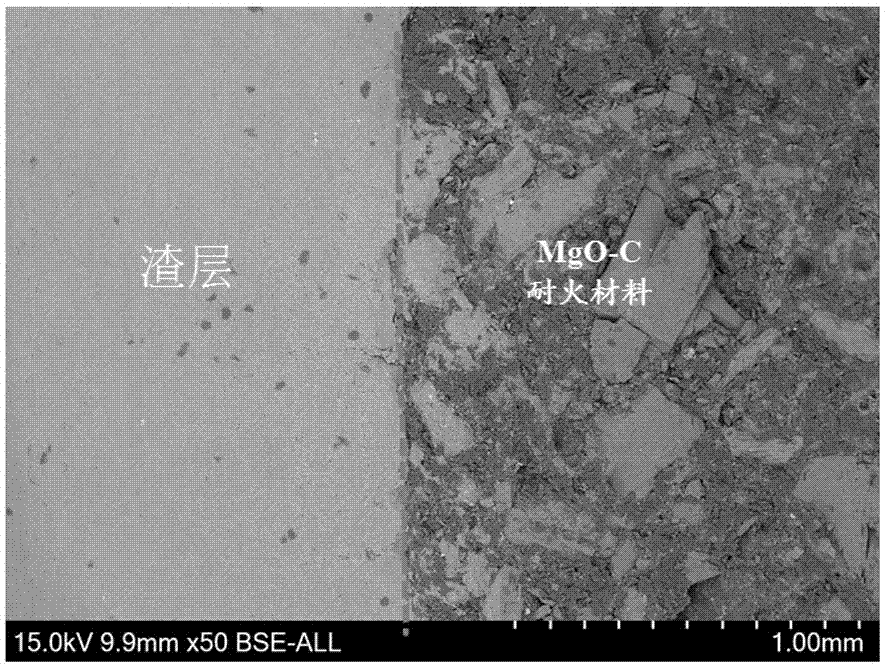

Method for preventing carbon-containing fireproof material from slag erosion

ActiveCN107253865AAchieve physical protectionReduce penetration depthMelt-holding vesselsAlkalinitySlag

The invention discloses a method for preventing carbon-containing fireproof material from slag erosion. Through providing a suitable external voltage for a slag system, the penetration depth f the slag in a fireproof material is delayed, and the physical protection of the fireproof material is realized. The method includes steps of taking aluminum oxide, silica, and calcium oxide as raw materials, and preparing to be the slag powder with alkalinity of 0.8-2.3; heating the mixed powder to 1550-1650 DEG C to melt down; after decarbonization, contacting the carbon-containing fireproof material with slag, and then connecting the fireproof material after decarbonizing treatment and the slag to both electrodes of the power source respectively; electrifying at 0-4V; realizing the protection of carbon-containing fireproof material from slag erosion. The method can effectively inhibit the physical penetration of slag in the carbon-containing fireproof material, significantly improve the slag erosion resistance of the carbon-containing fireproof material, and prolong 3-4 times of the service life of the carbon-containing fireproof material. The method is simple in operation, wide in applicable slag scale, and high in production practical value.

Owner:SUZHOU UNIV

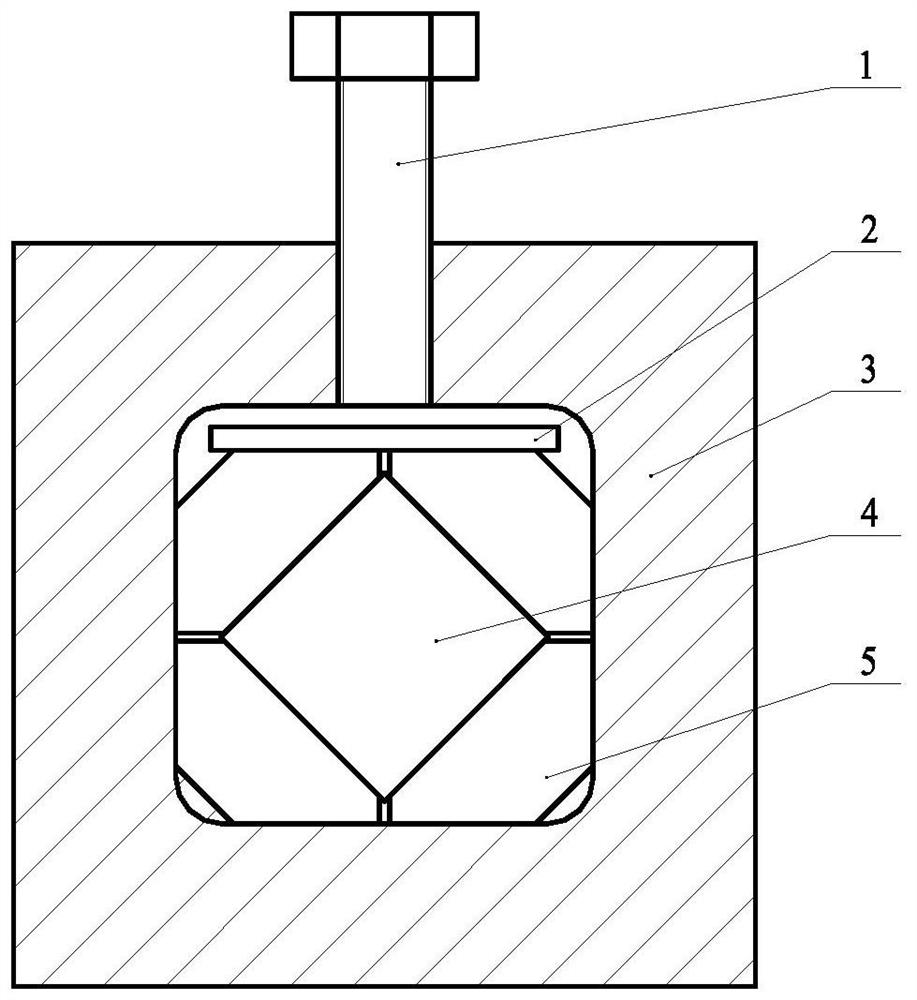

Ceramic prestress loading device and mounting method thereof

PendingCN113092247AImprove toughnessReduce penetration depthMaterial strength using tensile/compressive forcesCeramicInternal stress

The invention discloses a ceramic prestress loading device and a mounting method thereof, the ceramic prestress loading device comprises a prestress loading component, a cushion block, a constraint frame, a ceramic block and a plurality of positioning blocks, the cushion block, the ceramic block and the plurality of positioning blocks are located in the constraint frame, the ceramic block is surrounded by the plurality of positioning blocks, the prestress loading component can apply stress to the multiple positioning blocks through the cushion blocks, and the multiple positioning blocks can apply stress to the ceramic block, so that the internal stress of the ceramic block is uniformly distributed. The device is simple in structure and convenient to use, the prestress is easy to adjust, the prestress of a certain degree can be applied to the ceramic, cracks of the ceramic under the high-speed impact effect are reduced, and the penetration resistance of the ceramic armor is effectively improved.

Owner:NANJING UNIV OF SCI & TECH

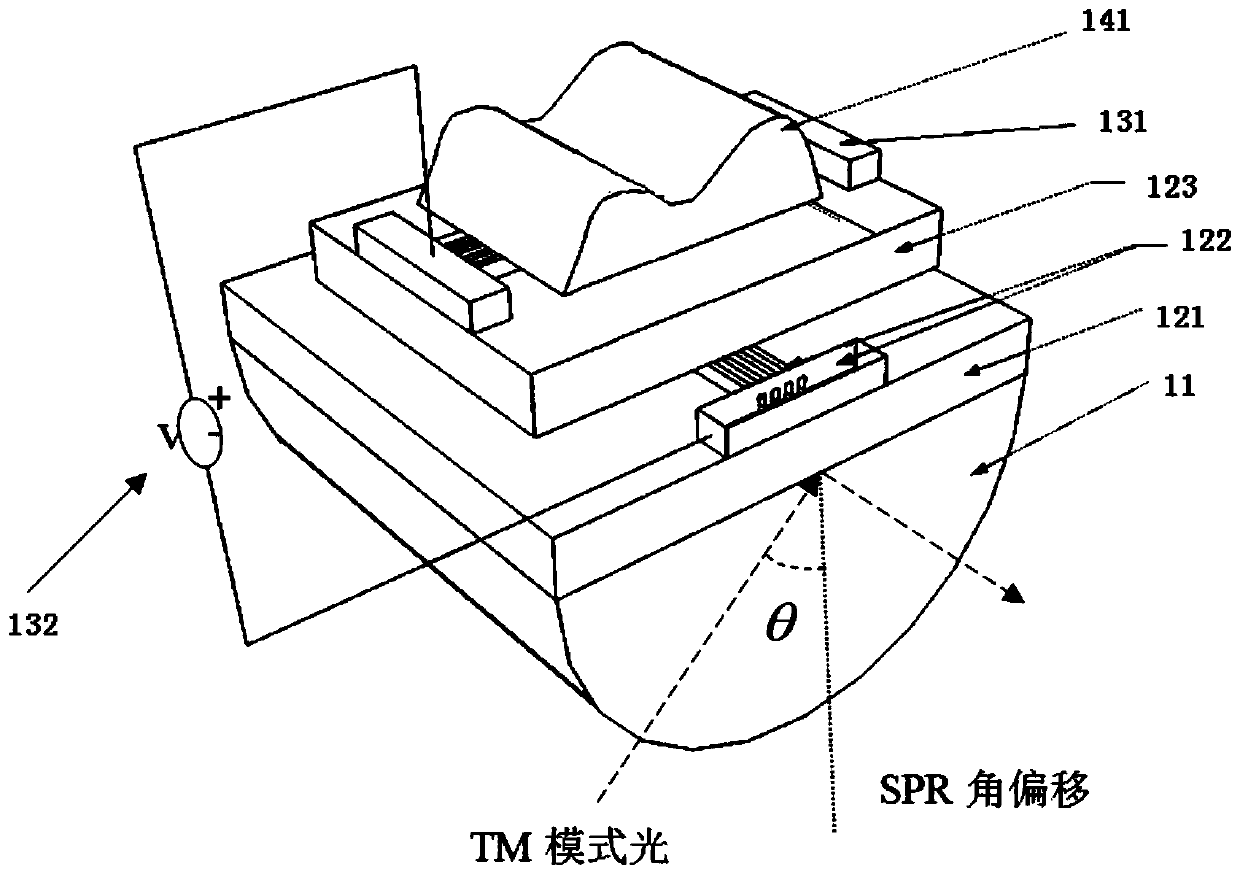

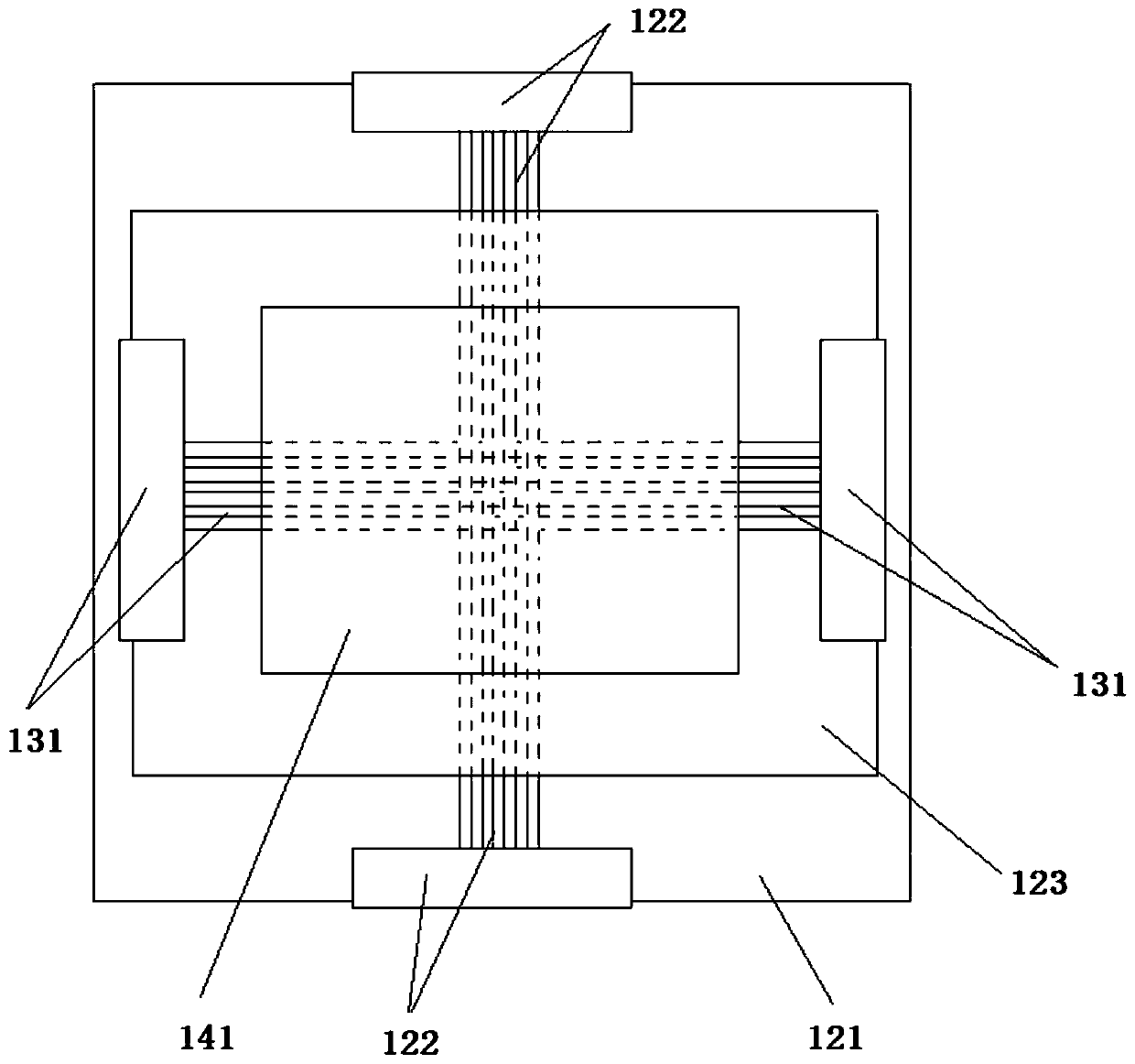

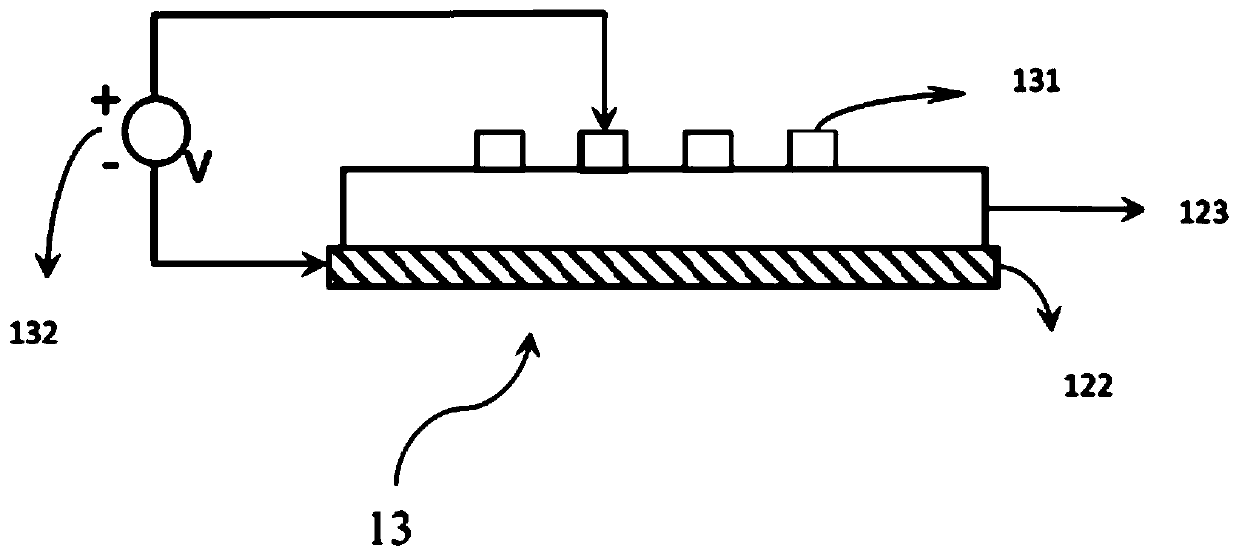

Near-infrared biosensor capable of tuning penetration depth and adopting memristor reconstruction, and method

ActiveCN110057782APenetration depth adjustableReduce penetration depthPhase-affecting property measurementsColor/spectral properties measurementsImage resolutionPrism

The invention provides a near-infrared biosensor capable of tuning the penetration depth and adopting memristor reconstruction, and a method. The sensor comprises a prism unit, a first non-conductivemedium thin film layer, a metal thin film layer, a second non-conductive medium thin film layer and a conductive medium thin film layer; the prism unit is used for generating ATR attenuation evanescent waves; the first non-conductive medium thin film layer, the metal thin film layer and the second non-conductive medium thin film layer constitute a sensing unit to achieve the basic sensing function; the metal thin film layer, the second non-conductive medium thin film layer and the conductive medium thin film layer constitute a memristor unit; and a voltage applying device is further arranged and used for applying the bias voltage to the memristor unit to achieve infrared memristor reconstruction. The invention further provides a preparation method of the sensor and the penetration depth tuning method. The penetration depth generated by the sensing unit of the biosensor is dynamically changed when the bias voltage is applied to the memristor unit, the penetration depth is tuned, and theresolution ratio of the biosensor can be obviously increased when unknown material organisms are detected.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Low-density high-temperature plugging agent as well as preparation method and application thereof

PendingCN113969148ALow densityIncreased Microfoam LifespanDrilling compositionSilane couplingPorous network

The invention relates to the technical field of leakage-proof and plugging working fluid for drilling engineering, in particular to a low-density and high-temperature plugging agent, and a preparation method and application thereof. The plugging agent comprises the following components in parts by volume: 20-40 parts of liquid glass, 5-18 parts of resin and 2-5 parts of a silane coupling agent. The preparation method comprises the following steps: converting the liquid glass into silicon dioxide gel, modifying the surface of the silicon dioxide gel by using the silane coupling agent, and combining the above with the low-density resin to form the low-density high-temperature plugging agent. A nano-porous network structure exists in particles of the protective agent, and the protective agent is light in weight and low in density which is smaller than or equal to 1.65 g / cm < 3 >; the temperature resistance is higher than or equal to 200 DEG C; inorganic rigid and organic flexible elastic plugging is achieved, and the micro-foam fluid invasion depth reduction rate before and after the plugging agent is added is larger than or equal to 65.7%; the stability of the micro-foam fluid can be improved; and the plugging agent can be applied to high-temperature leakage strata, and the plugging property and stability of low-density fluid are improved.

Owner:SINOPEC SSC +2

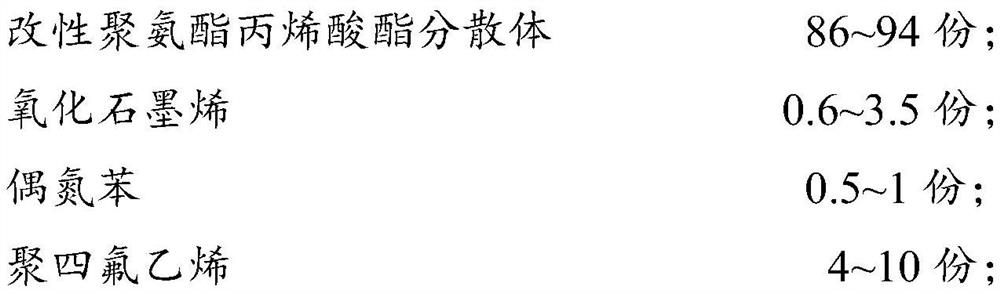

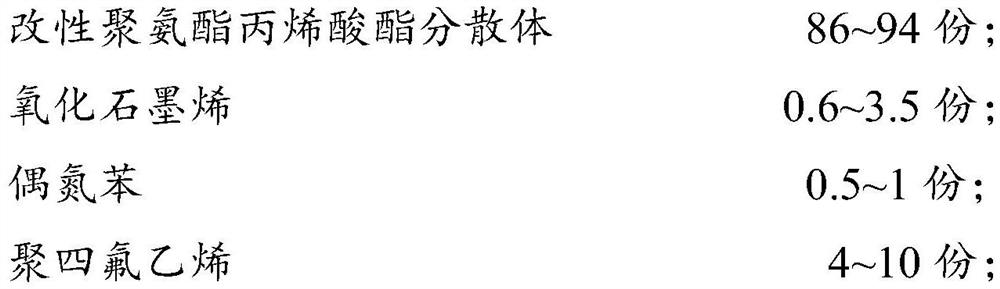

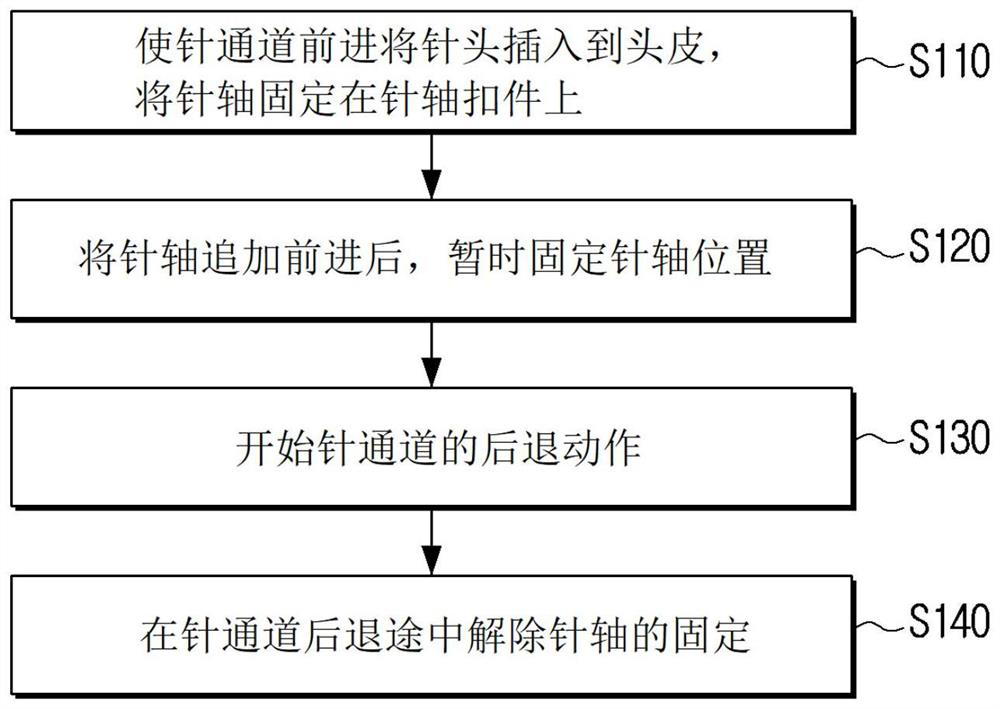

Tile-like wooden floor and preparation method thereof

InactiveCN112778896AEasy to usePlay a role in isolating moisturePolyurea/polyurethane coatingsFlooring insulationsParaffin waxPolyurethane dispersion

The invention discloses a tile-like wooden floor. The tile-like wooden floor comprises a wooden base material, an ink-jet pattern layer is arranged on the front face of the wooden base material, and a moisture-proof layer is arranged on the back face of the wooden base material; and the moisture-proof layer is prepared from a moisture-proof coating, the moisture-proof coating comprises the following components: a polyurethane dispersion, a paraffin emulsion and a nano titanium dioxide dispersion liquid, the nano titanium dioxide dispersion liquid is obtained by dispersing nano titanium dioxide into a dispersion system, the mass fraction of the nano titanium dioxide is 10-15%, and the dispersion system comprises organosilane, water and a solvent. The moisture-proof layer can play a role in isolating moisture and preventing mildew, so that the wood base material is prevented from being rotted, and the decorative pattern is prevented from being influenced.

Owner:广东大自然家居科技研究有限公司

Porcelain polished tile and production method thereof

The invention discloses a porcelain polished tile and a production method of the porcelain polished tile. The production method comprises the steps of: (1) preparing a porcelain polished tile blank body powder material by a conventional method; (2) preparing a porcelain polished tile slurry; (3) preparing a porcelain polished tile blank body; (4) drying; (5) applying the slurry; (6) drying and sintering; (7) edging and polishing; and (8) sorting, packaging and warehousing. The porcelain polished tile and the production method have the beneficial effect of solving the technical problems of higher requirements of the traditional porcelain polished tile on a material and more waste, and provides a more environment-friendly and economic production method of the porcelain polished tile.

Owner:HANGZHOU NABEL CERAMIC +2

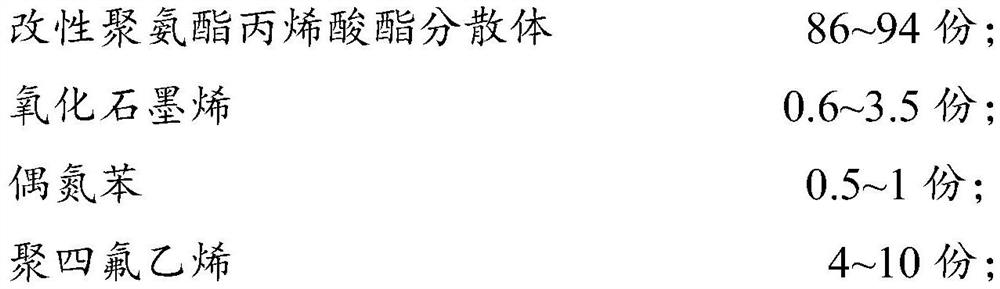

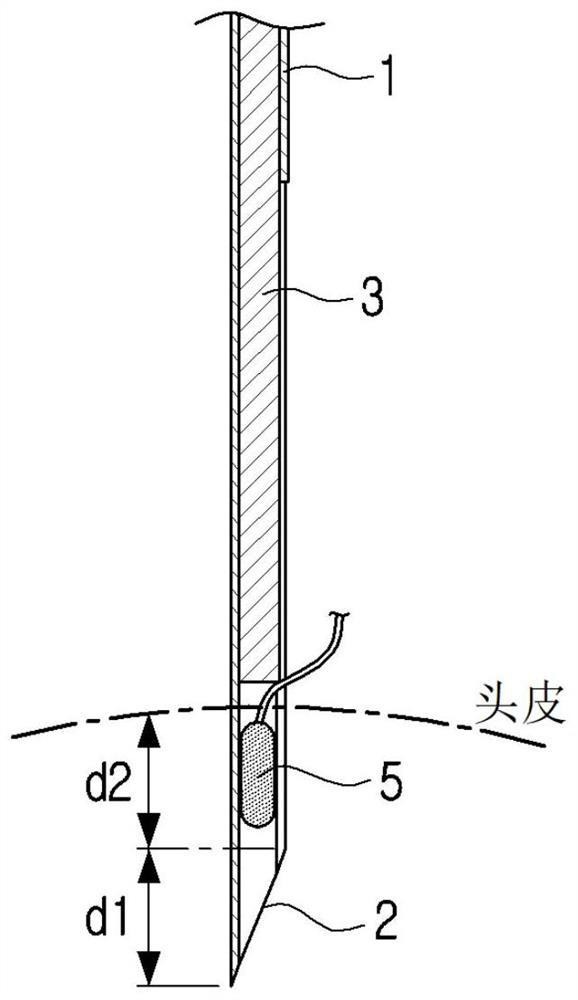

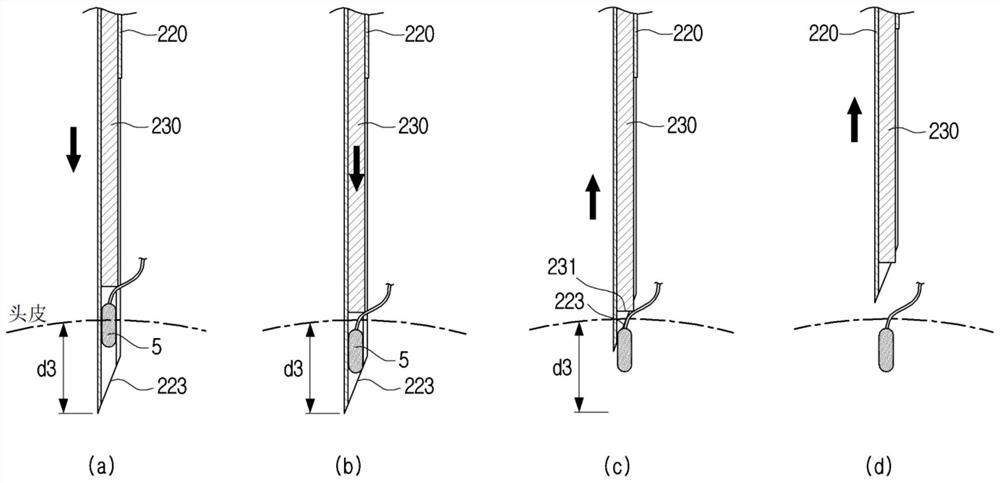

Hair transplanting device with needle shaft conveying part

PendingCN114431930AReduce penetration depthAvoid damageSkin implantsCannulasHair transplantingAnatomy

According to one embodiment, the present invention relates to a hair implant comprising: a needle channel bundle provided with a central shaft and a plurality of needle channels coupled to the outer peripheral surface of the central shaft so as to be slidable in the vertical direction; a first spring for pushing downward forward one of the plurality of needle passages; and a second spring for retracting the needle passages advancing downward to the upper side, each of the needle passages including a main body portion having a tubular inner space, a needle head coupled to the lower portion of the main body portion, and a needle shaft slidably provided in the tubular inner space.

Owner:GODAI

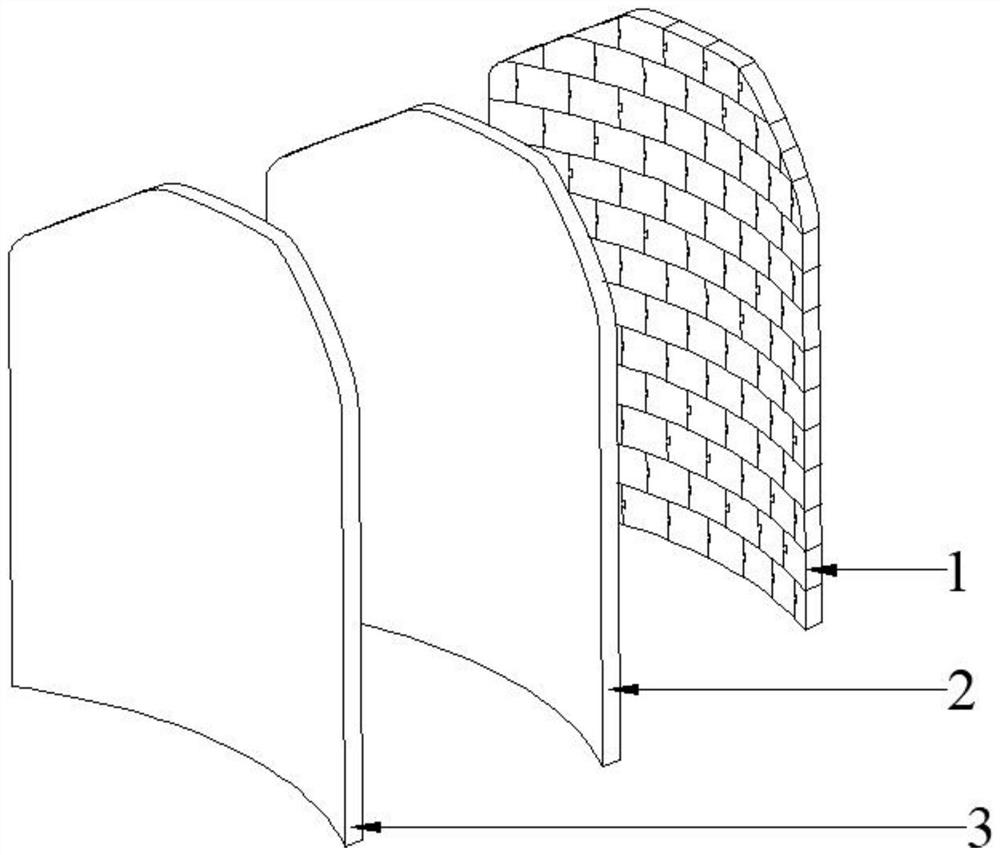

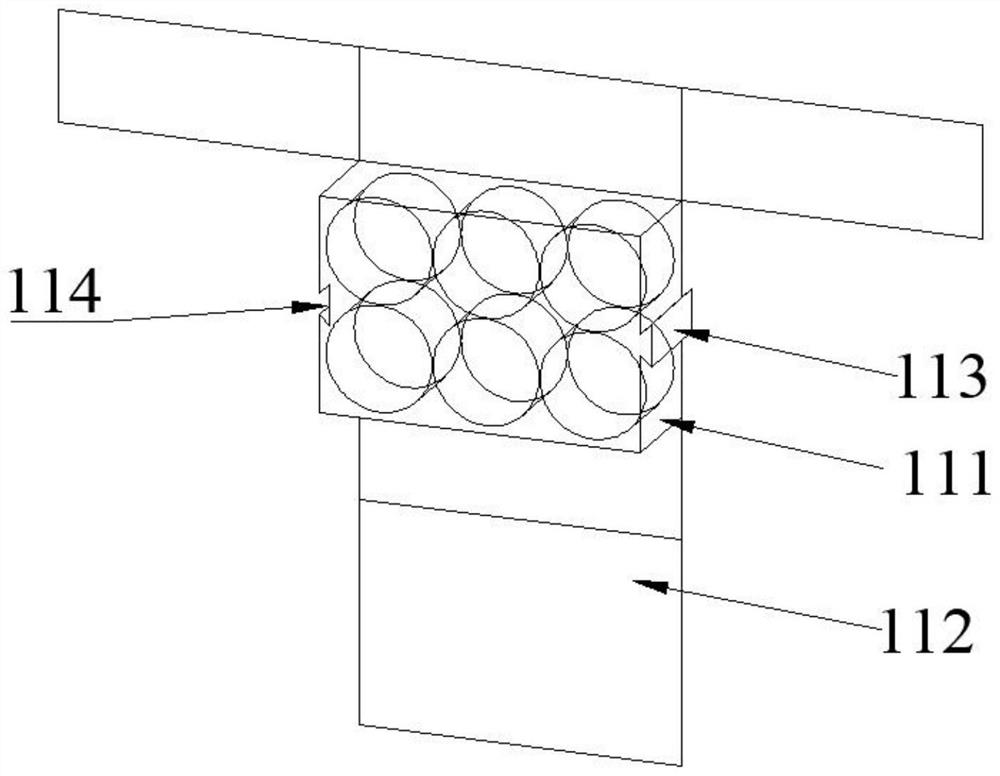

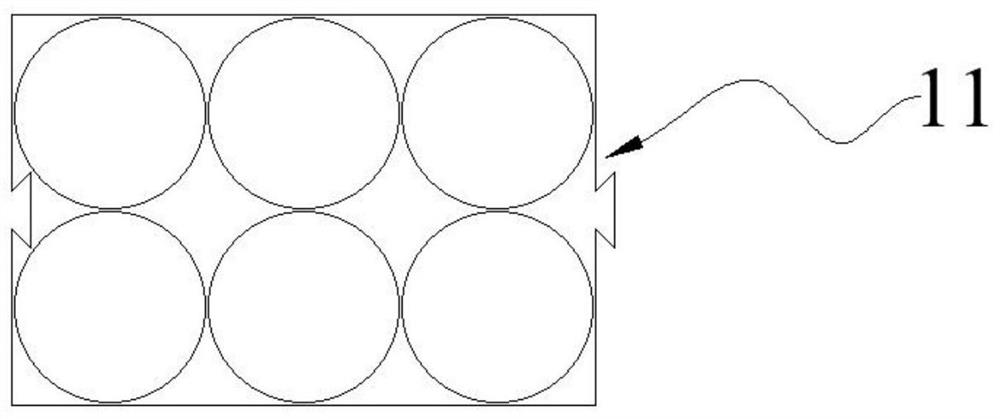

Staggered distribution plate type composite missile shielding structure

PendingCN108005453AImprove performanceEnhance penetration resistanceBuilding constructionsProtective buildings/sheltersHardnessEngineering

The invention belongs to the technical field of engineering protection and discloses a staggered distribution plate type steel-based composite missile shielding structure. The staggered distribution plate type steel-based composite missile shielding structure is of a plate type structure constituted in the mode that high-hardness core bodies are embedded into thin-wall box grid metal base bodies;a plurality of metal box grids on each layer are continuously arranged and distributed; the metal box grids on the upper layer and the lower layer are arranged and distributed in a staggered mode; thethin-wall metal box grids are overall of a vertical staggered distribution plate type structure formed by integral casting; the upper end faces of the thin-wall metal box grids on the upper layer areopen, and the lower end faces of the thin-wall metal box grids on the lower layer are open; each thin-wall metal box grid is internally provided with the corresponding high-hardness material servingas a missile-shielding structure filling core body; and the high-hardness materials and the staggered distribution metal box grids are bonded into a whole through adhesion agents to form the plate type composite structure. The staggered distribution plate type composite missile-shielding structure has the characteristics of being high in anti-impact force, good in impact toughness, excellent in performance, reliable, practical, convenient and rapid to construct, capable of resisting repeated strike, replaceable, easy to repair and the like.

Owner:UNIT 61489 OF PLA

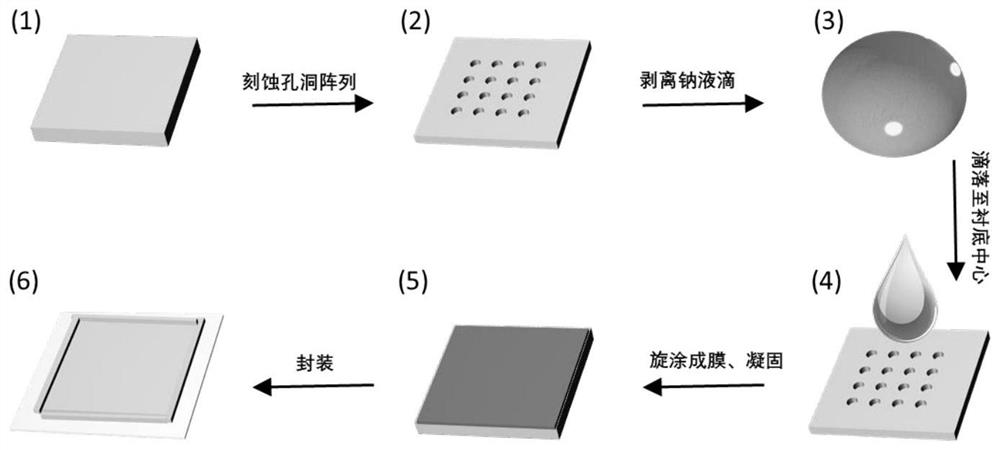

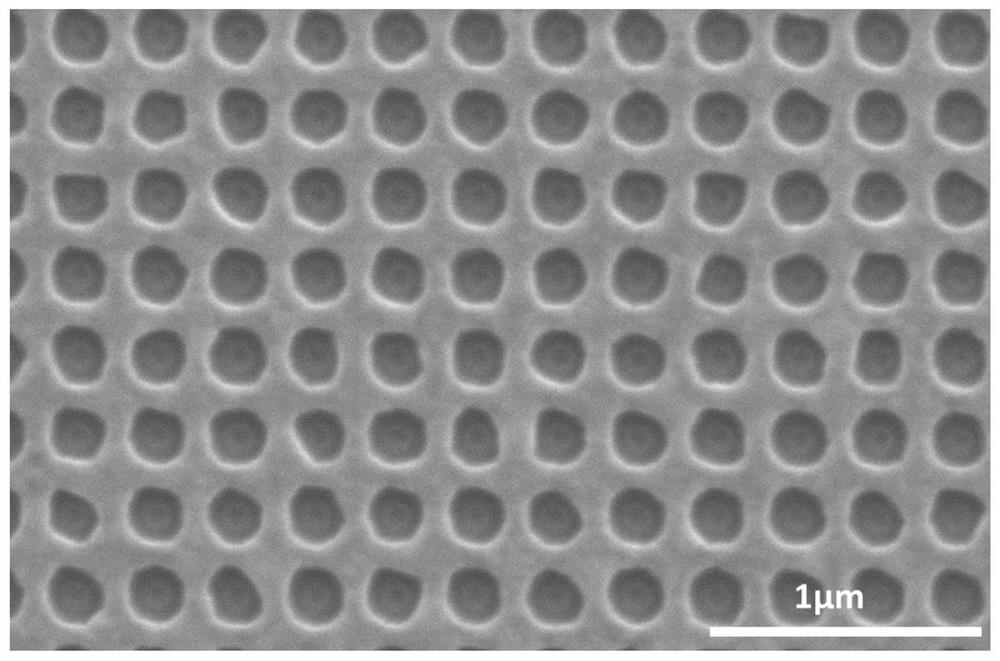

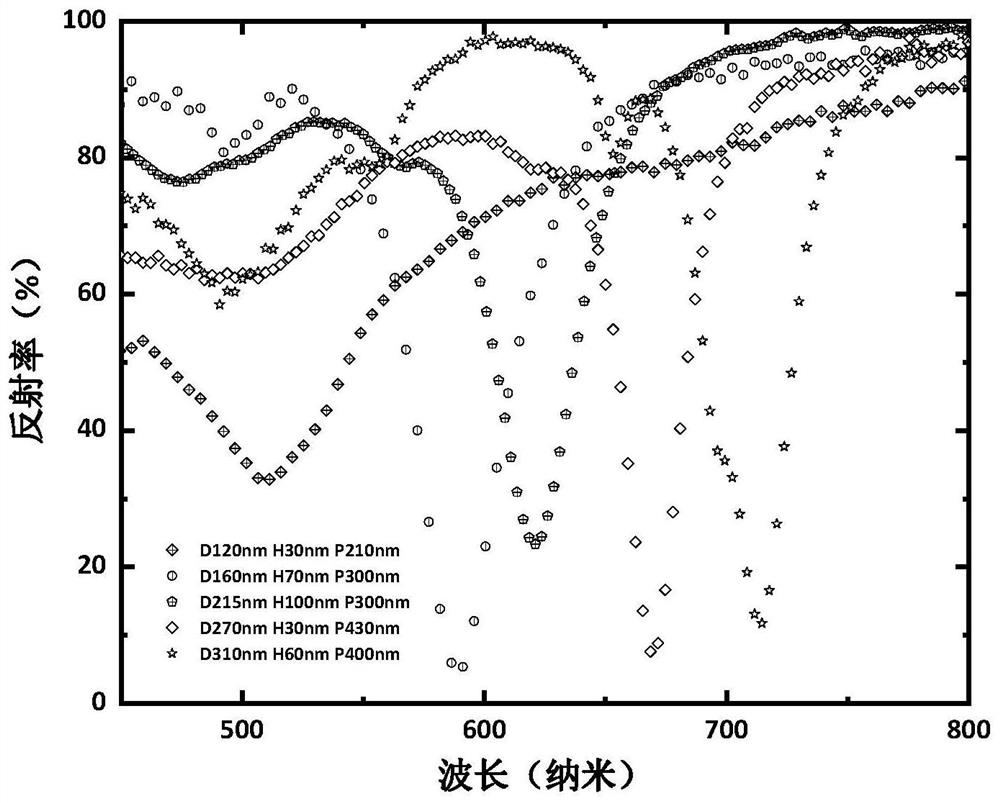

Preparation method of angle-insensitive reflective plasma structural color

PendingCN113753845AReduce penetration depthSimple designMaterial nanotechnologyDecorative surface effectsNano structuringQuartz substrate

The invention discloses a preparation method of an angle-insensitive reflective plasma structural color. The method comprises the following steps: etching a cylindrical hole array on a quartz plate; soaking in nitric acid to remove an Ag film, cleaning and drying; after calcining, carrying out ion beam etching, and sending to a glove box to obtain a spin-coated quartz substrate; placing the solid sodium block on a heating table for heating until the solid sodium block is molten into liquid sodium; stripping oxides and the like on the shell to obtain liquid sodium with metallic luster on the surface; and dripping on a quartz plate for curing, and packaging with glass to obtain the reflection-type angle-insensitive structural color device. According to the invention, a spin-coating mode is adopted, a metal micro-nano structure is constructed, and a specific reflective structural color is generated by regulating and controlling a plasmon resonance wavelength; because the metallic sodium has the characteristics of low penetration depth in the visible band, weak coupling of the adjacent micro-nano structure and the like, the reflection type structural color generated by the metallic sodium micro-nano structure has the property of angle insensitivity; the method can be applied to multiple fields of sensing, information storage and the like.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com