Patents

Literature

60results about How to "Fine pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound for Photoacid Generator, Resist Composition Using the Same, and Pattern-Forming Method

ActiveUS20100035185A1Stable structureImprove solubilityOrganic chemistryOrganic compound preparationResistOrganic group

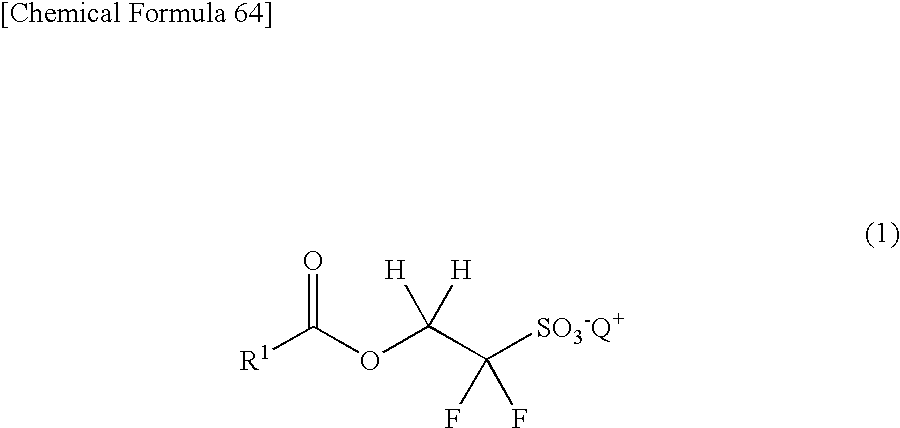

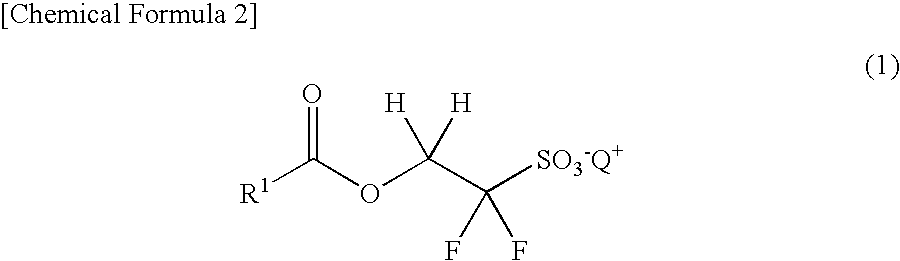

A sulfonic acid onium salt represented by the following formula (1) can be used as a superior radiosensitive acid generator for resist compositions. It is possible to form a good pattern by using a resist composition containing this sulfonic acid onium salt.In formula (1), R1 represents a monovalent organic group, and Q+ represents a sulfonium cation or iodonium cation.

Owner:CENT GLASS CO LTD

Fabric graft modified full-fixation printing method

InactiveCN101403185AReduced charge repulsionReduce processing burdenDyeing processVegetal fibresSodium bicarbonateWorking fluid

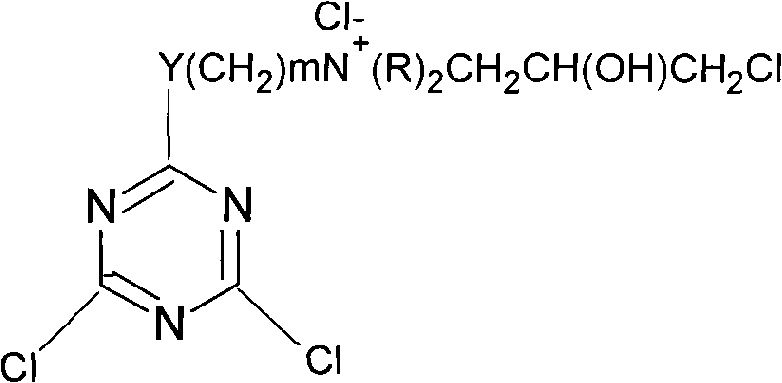

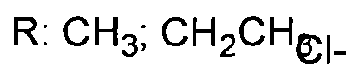

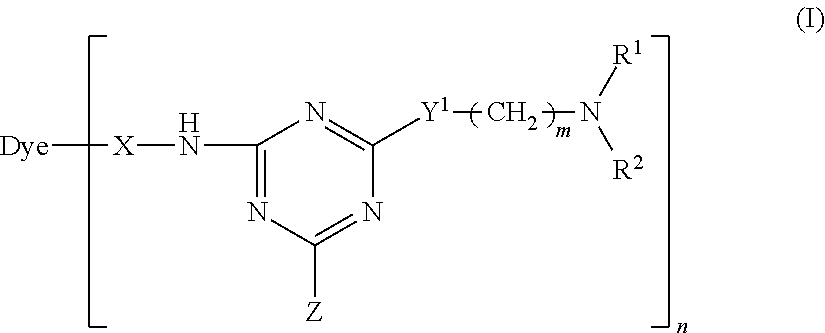

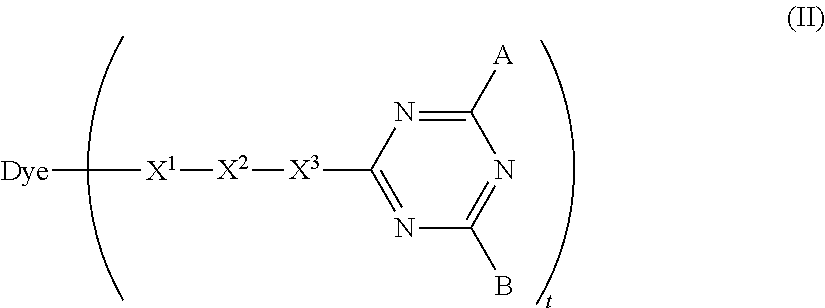

The invention relates to a whole fixation printing method for the graft modification of textiles, and aims at providing the whole fixation printing method that can promote the dye fixation rate from 70 percent to 80 percent to more than 90 percent to 98 percent. The technical proposal is as follows: 1) the pretreatment of a textile, the textile is treated according to the processes of desizing, boiling, smelting and bleaching; 2) the preparation of the graft modification working fluid, the working fluid comprises 0.1 percent to 10 percent of cationic graft agent, 0.1 percent to 20 percent of alkali agent and 0 percent to 1 percent of penetrating agent, and the rest is water; 3) the treatment of the graft modification, the pretreated textile is put into a dyeing machine, and the graft modification working fluid is added; or the pretreated textile is padded with the graft modification working fluid in a padder; the printing formula of the invention comprises 50 grams of protoplasm, 2 grams to 5 grams of urea, 0.5 gram to 8 grams of dye, 1 gram to 2.5 grams of sodium bicarbonate and 0.5 gram to 1.5 grams of reserve salt, and the rest amount of water in every 100 grams according to weight; and 4) the printing technology, the printing is carried out according to the conventional technology. The whole fixation printing method for the graft modification of the textiles is used in the whole fixation printing.

Owner:ZHEJIANG JIAXIN SILK

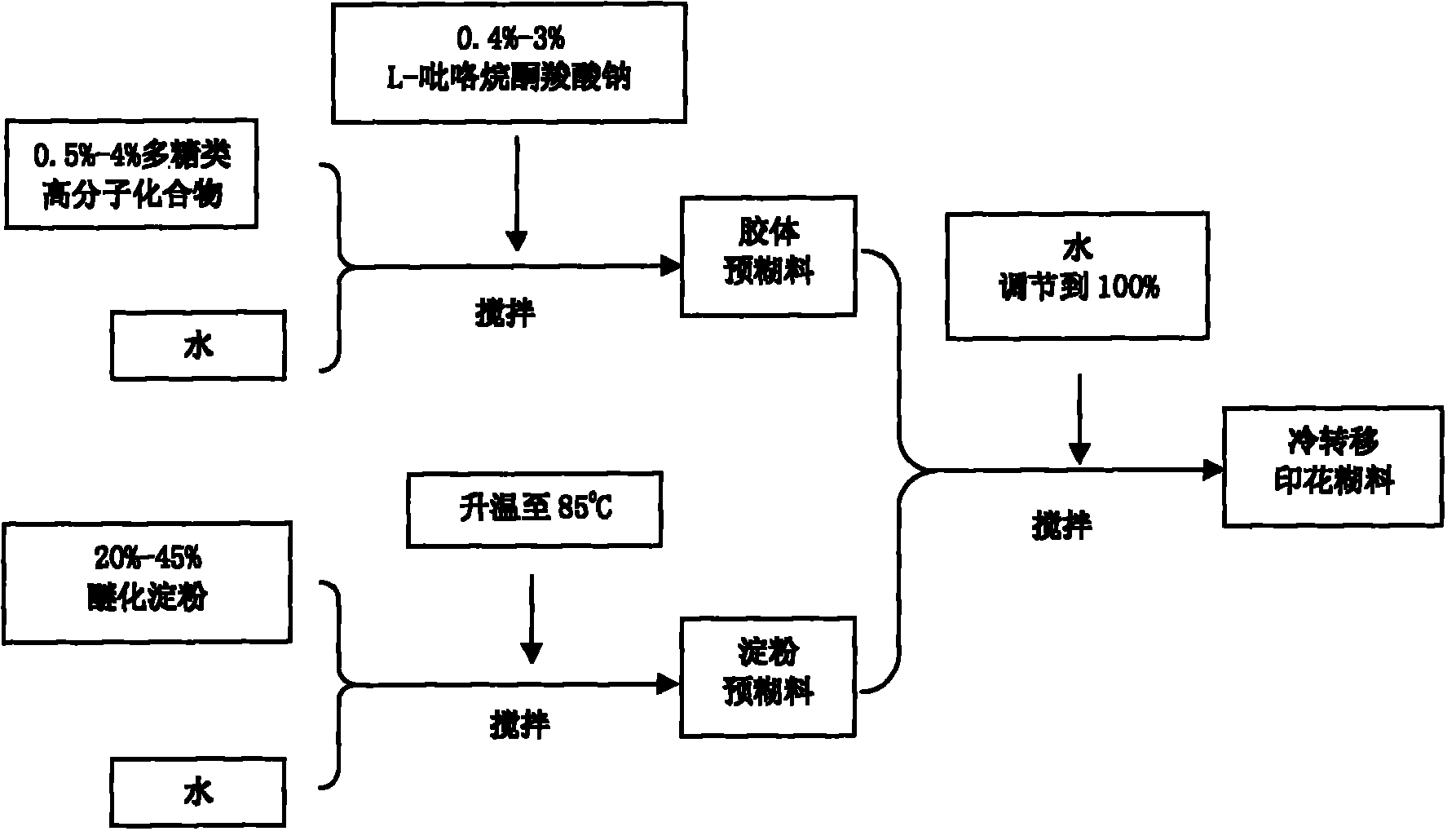

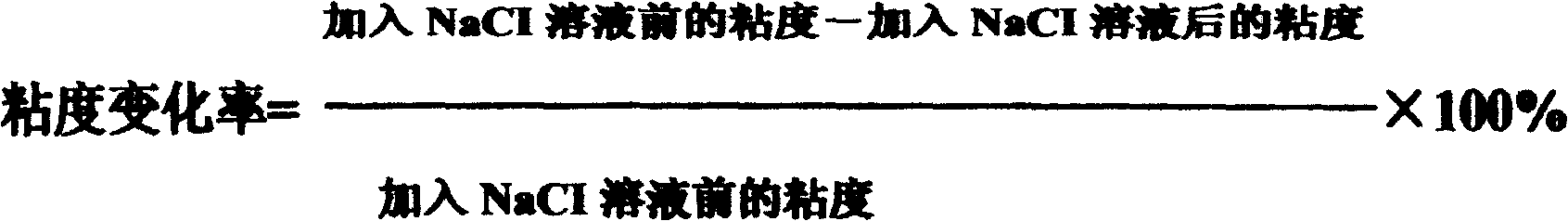

Cold-transfer printing thickener, printing paste thereof and preparation method thereof

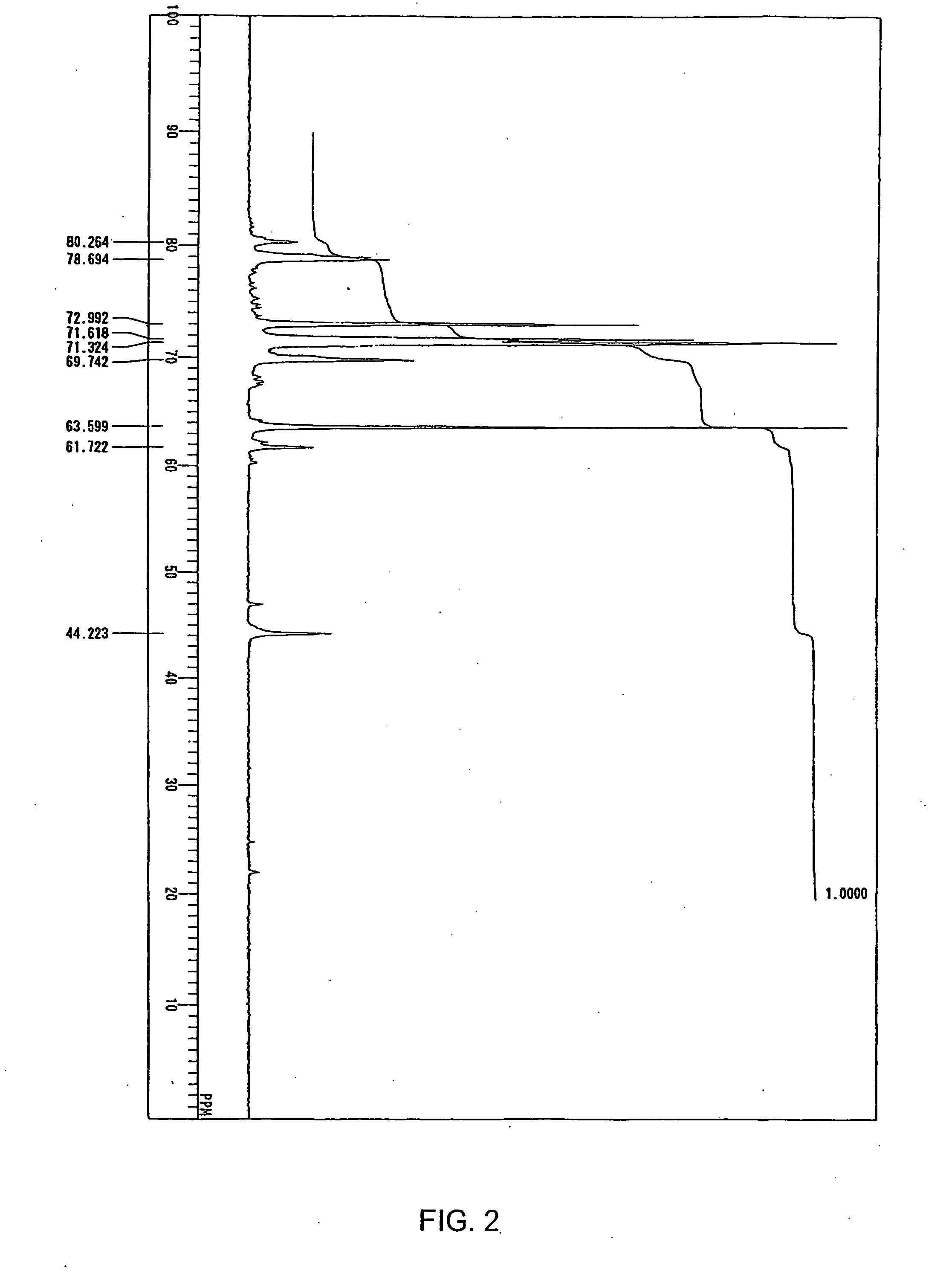

ActiveCN101892602ANo decrease in viscosityStable physical propertiesTransfer printing processInksTextile printerSODIUM PYRROLIDONE CARBOXYLATE

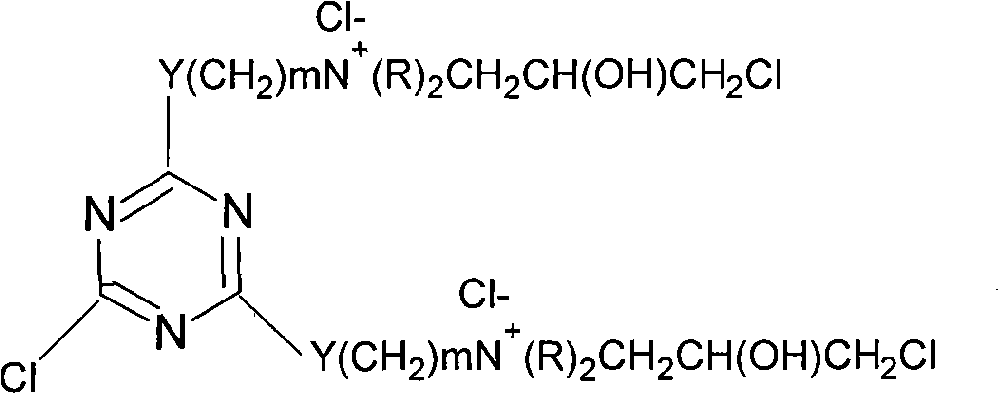

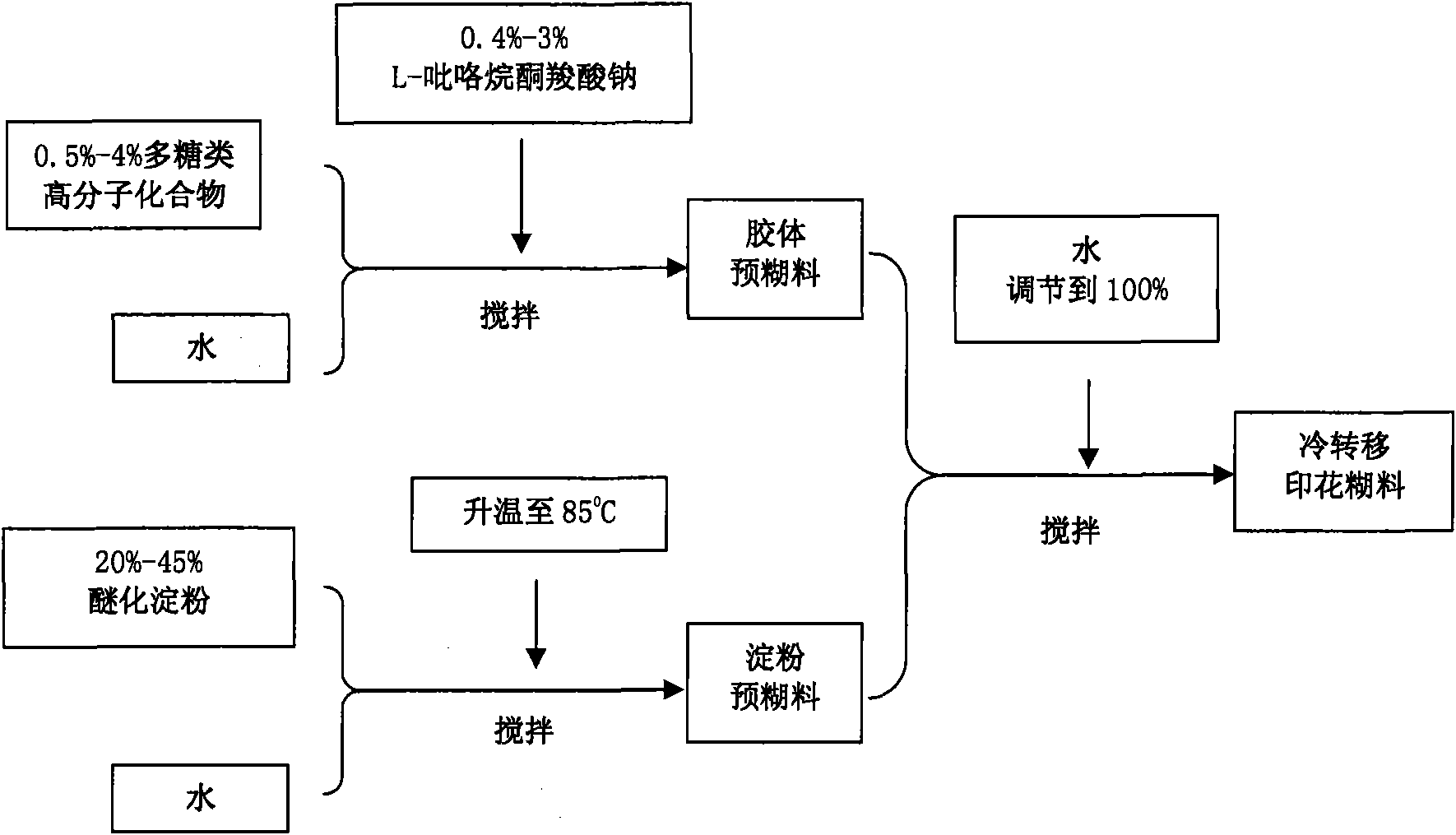

The invention relates to cold-transfer printing thickener, printing paste thereof and a preparation method thereof, in particularly to cold-transfer printing paste comprising the following components: polysaccharide macromolecular compounds, L-PCA-Sodium (L-pyrrolidone carboxylic acid-sodium), etherified starch and water. The invention further relates to printing paste comprising the following components: reactive dye, defoaming agent, leveling agent, pH value stabilizer, water and printing thickener, which is selected from any one of the printing thickeners in the claims 1 to 6. Moreover, the invention further relates to the printing thickener and a method for preparing the printing paste. The cold-transfer printing thickener and the printing paste prepared from the cold-transfer printing thickener in the invention are suitable for the production process of cold-transfer printing; and owing to the stable physical properties, the printing thickener leads to no reduction in viscosity when in use.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Porcelain polished tile and production method thereof

The invention discloses a porcelain polished tile and a production method of the porcelain polished tile. The production method comprises the steps of: (1) preparing a porcelain polished tile blank body powder material by a conventional method; (2) preparing a porcelain polished tile slurry; (3) preparing a porcelain polished tile blank body; (4) drying; (5) applying the slurry; (6) drying and sintering; (7) edging and polishing; and (8) sorting, packaging and warehousing. The porcelain polished tile and the production method have the beneficial effect of solving the technical problems of higher requirements of the traditional porcelain polished tile on a material and more waste, and provides a more environment-friendly and economic production method of the porcelain polished tile.

Owner:HANGZHOU NABEL CERAMIC +2

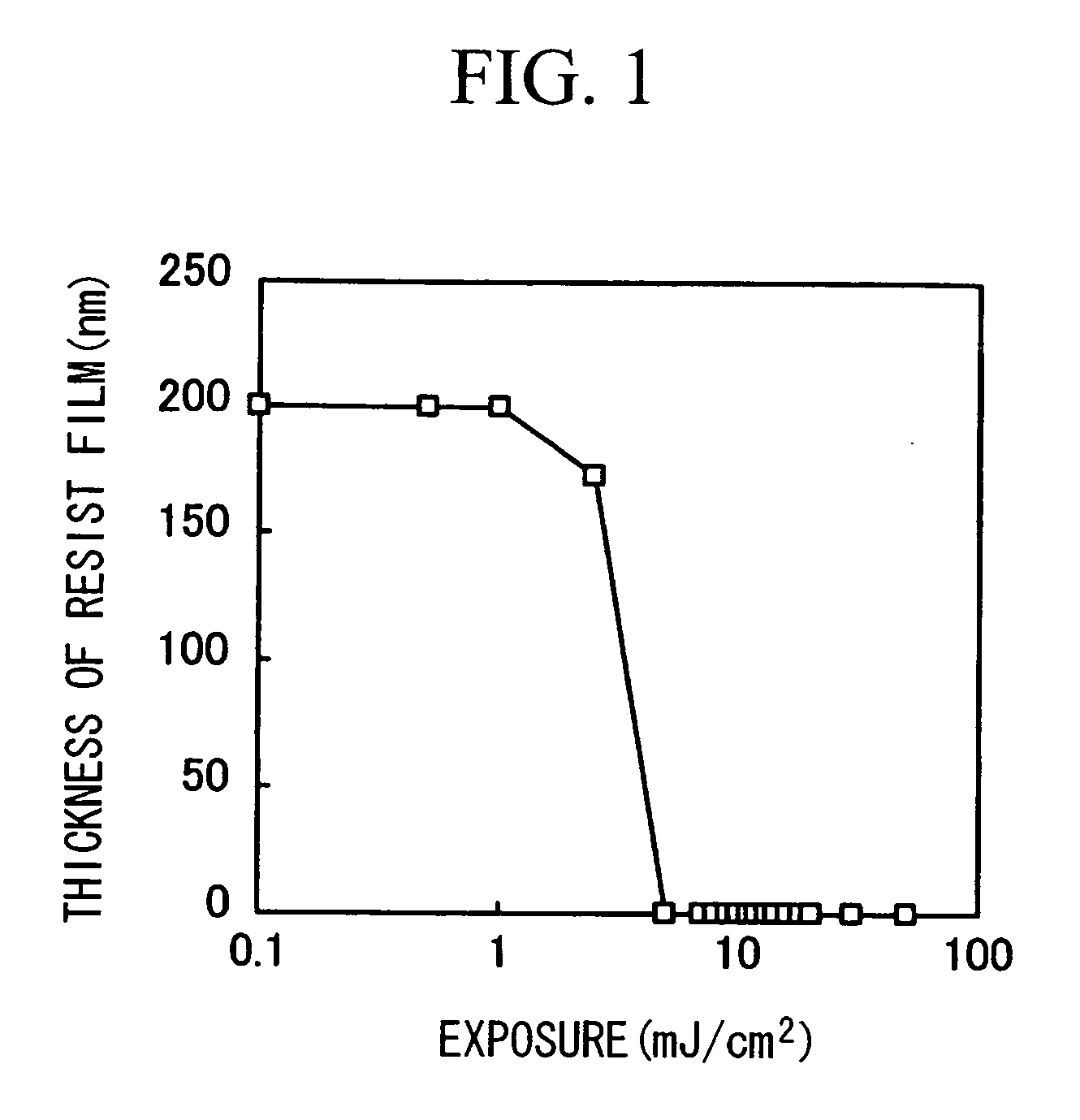

Polymer Compound, Photoresist Composition Including the Polymer Compound, and Resist Pattern Formation Method

ActiveUS20080166655A1Good resist pattern shapeExquisite patternOrganic chemistryOrganic compound preparationPolymer scienceHalogen

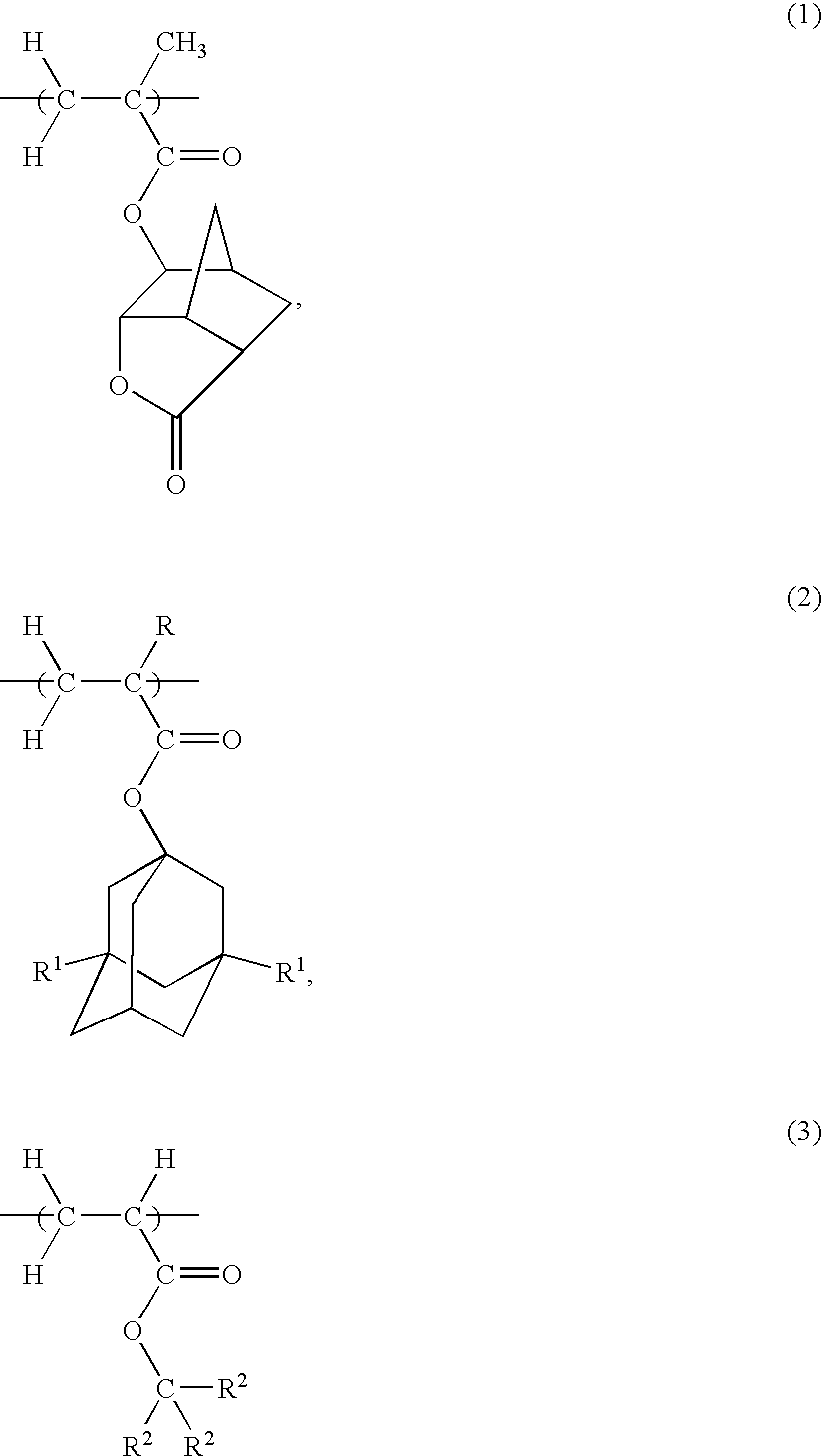

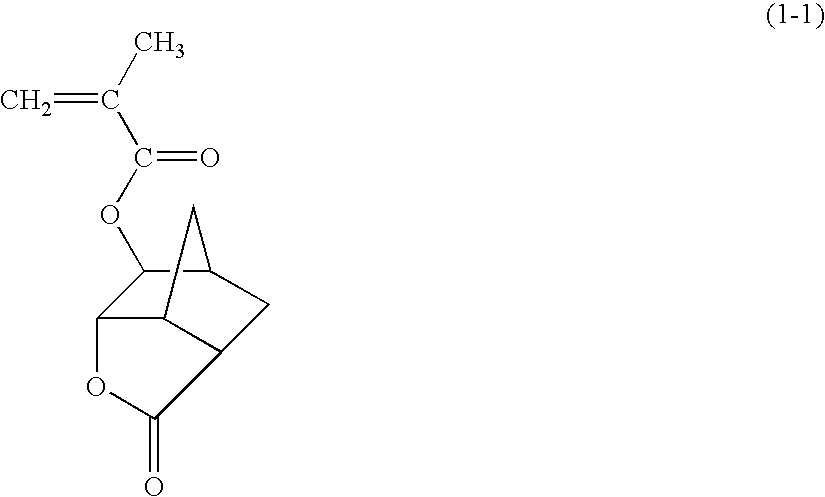

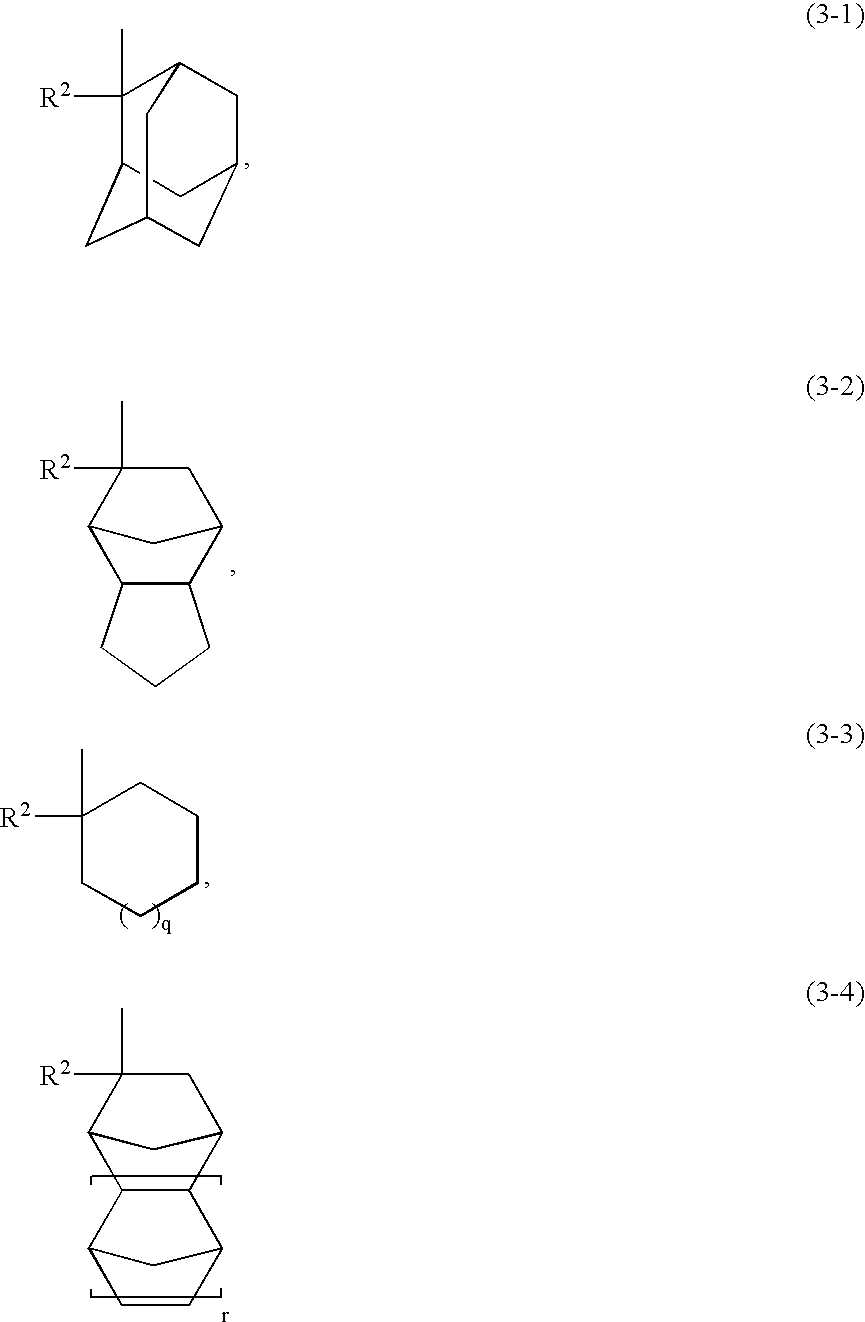

The present invention provides a polymer compound which can constitute a photoresist composition which is capable of having an excellent resolution, forming a fine pattern with a good rectangularity, obtaining favorable resist characteristics even when acid strength of a acid generated from an acid generator is weak, and having favorable sensitivity; a photoresist composition including the polymer compound; and a resist pattern formation method using the photoresist composition. The photoresist composition and the resist pattern formation method use the polymer compound including an alkali soluble group (i), wherein the alkali soluble group (i) is at least one substituent group selected from an alcoholic hydroxyl group, a carboxyl group, or a phenolic hydroxyl group, and the substituent group is protected by an acid dissociable, dissolution inhibiting group (ii) represented by a general formula (1):—CH2—OCH2nR1 (1)(wherein R1 represents a cycloaliphatic group which contains no more than 20 carbon atoms and may contain an oxygen atom, a nitrogen atom, a sulfur atom, or a halogen atom, and n represents 0 or an integer of 1 to 5.).

Owner:TOKYO OHKA KOGYO CO LTD

Photosensitive coloring composition, color filter, method for producing color filter, organic el liquid crystal display device, and color filter forming kit

ActiveUS20160139505A1Good solvent resistanceSimple structurePhotosensitive materialsPhotomechanical coating apparatusDouble bondColor filter array

Provided is a photosensitive coloring composition of the present invention including a polymerization initiator (a) with an absorption coefficient at 365 nm in methanol of 1.0×103 mL / gcm or more, a polymerization initiator (b) with an absorption coefficient at 365 nm in methanol of 1.0×102 mL / gcm or less and an absorption coefficient at 254 nm in methanol of 1.0×103 mL / gcm or more, a compound (c) which has an unsaturated double bond, an alkali-soluble resin (d), and a coloring material (e), in which, in the total solid content of the photosensitive coloring composition, the content of the polymerization initiator (a) is 1.5 mass % to 10 mass % and the content of the polymerization initiator (b) is 1.5 mass % to 7.5 mass %.

Owner:FUJIFILM CORP

Cloisonne product and preparation method thereof

InactiveCN103241052AWith traditional artistic senseFine patternDecorative surface effectsCopperMetallurgy

The invention provides a cloisonne product and a preparation method thereof. The cloisonne product comprises cloisonne and a ceramic fitting, wherein the cloisonne comprises copper body ware and one or more red copper fittings, the base body of the ceramic fitting is provided with at least one groove, the red copper fitting fixes the ceramic fitting on the cloisonne in an embedding manner through the groove in the base body of the ceramic fitting, and thus, the obtained cloisonne product has traditional artistic sense, elaborate patterns and unique shape.

Owner:林戈

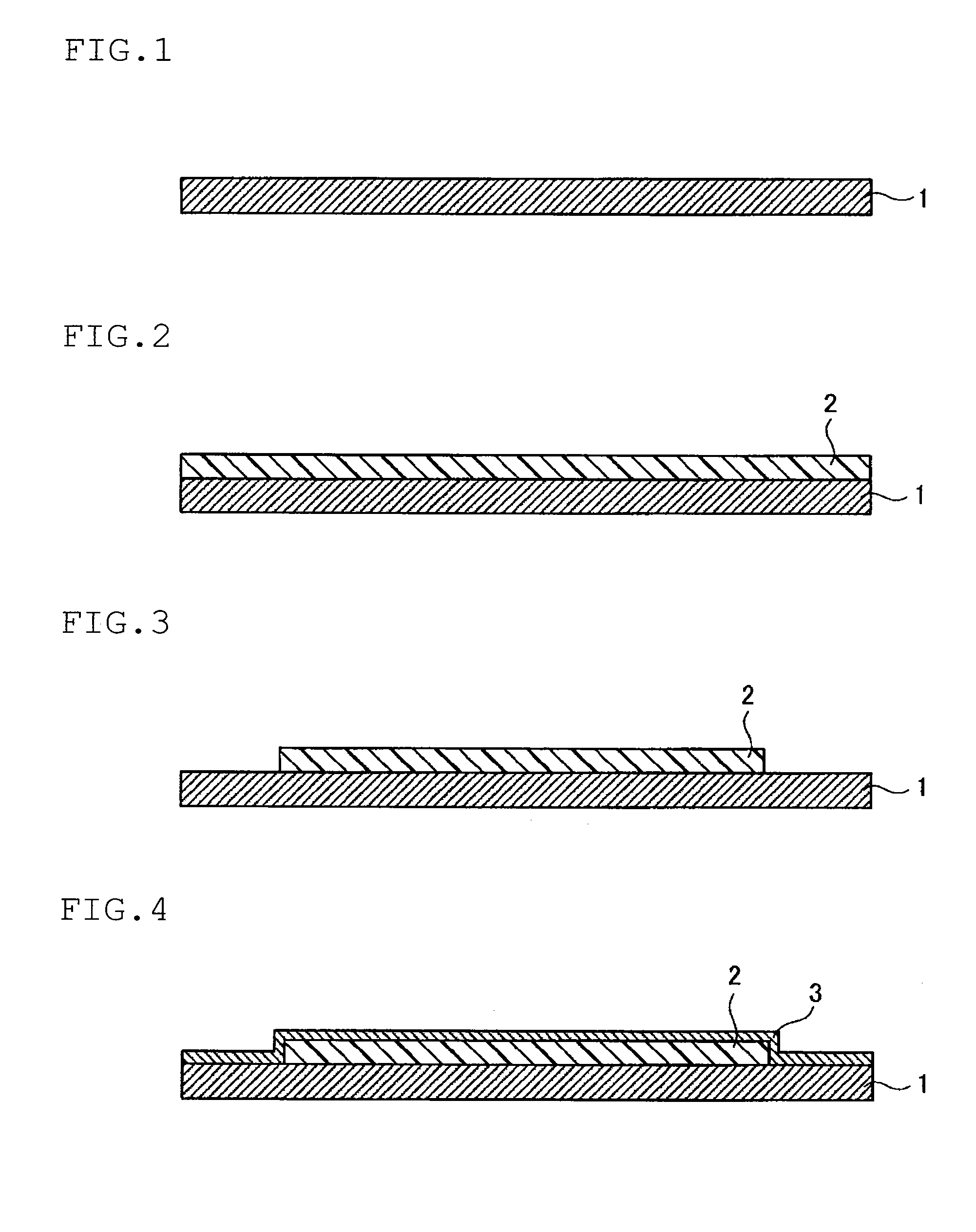

Process for formation of pattern of polyhydroxyalkanoate

InactiveUS20050196521A1Fine patternEfficiently conductedBacteriaPretreated surfacesEnzymePolyhydroxyalkanoates

A process for forming a fine pattern comprised of a polyhydroxyalkanoate on a substrate is provided. The process comprises steps of applying a polyhydroxyalkanoate-synthesizing enzyme and a 3-hydroxyacyl CoA to coexist in an intended pattern on a substrate, and polymerizing the 3-hydroxyalkanoate by action of the enzyme to form the polyhydroxyalkanoate in a pattern on the substrate. In particular, the fine pattern can be formed by an inkjet system.

Owner:CANON KK

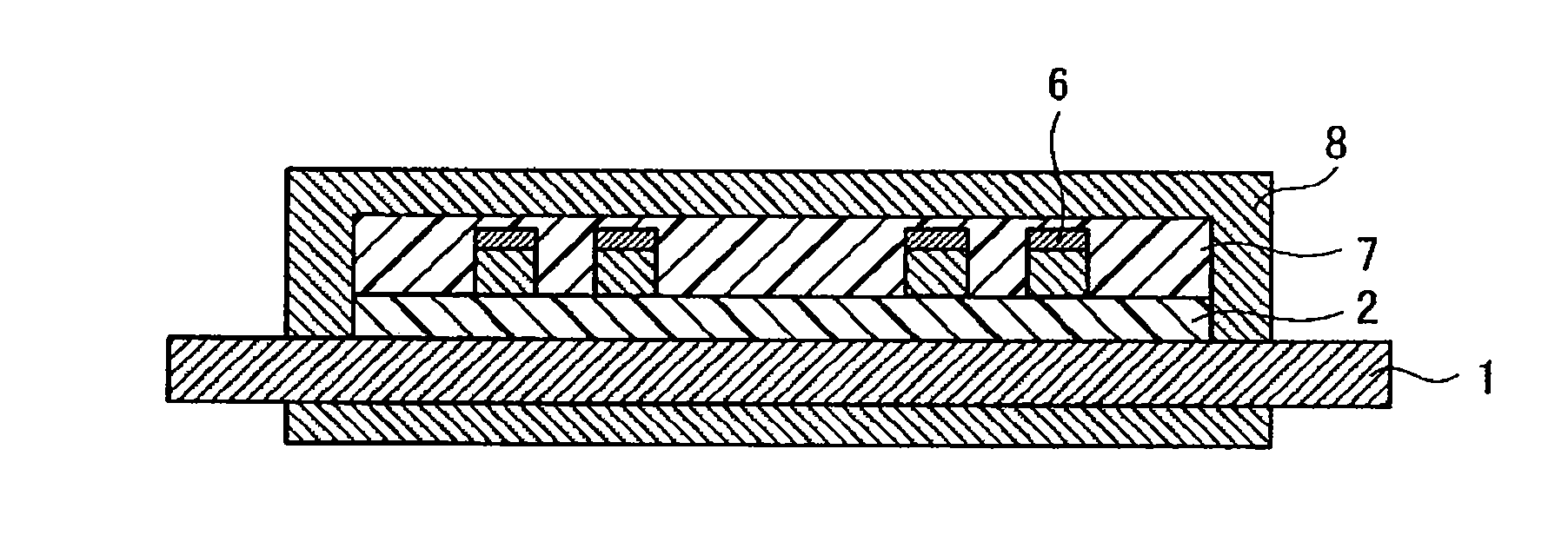

Photosensitive resin composition and circuit formation substrate using the same

ActiveUS20100260983A1Exquisite patternHigh sensitivityPhotosensitive materialsLayered productsStructural unitPolymer chemistry

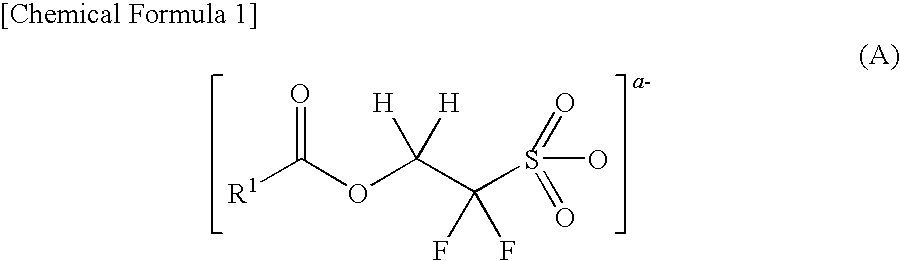

A photosensitive resin composition for an interlayer insulating film or a protective film of a substrate for circuit formation, which includes a polymer (a) having a structural unit shown by the formula (A) and a compound (b) which generates a radical when irradiated with active rays and has a structure shown by the following formula (B).

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

Silicon Compound, Condensation Product, Resist Compostion and Pattern Formation Method

InactiveUS20130137037A1Increase acidityImprove insulation performanceSilicon organic compoundsPhotosensitive materialsHigh energyOxygen

A silicon compound according to the present invention is represented by the general formula (1). This silicon compound can be easily synthesized by using a hydrolysable silicon compound such as alkoxysilane and has, in its molecule, a hydrolysable group e.g. alkoxy group and a photoacid generating group capable of being dissociated to generate an acid by irradiation with a high-energy ray.R1nAmSiB4-(n+m) (1)where R1 is each independently a hydrogen atom, a C1-C20 straight or C3-C20 branched or cyclic hydrocarbon group; a carbon atom of the hydrocarbon group may be replaced by an oxygen atom; and the hydrocarbon group may contain a fluorine atom; A is an acid decomposable group; B is a hydrolysable group; n is an integer of 0 to 2; m is an integer of 1 to 3; and n+m is an integer of 1 to 3.

Owner:CENT GLASS CO LTD

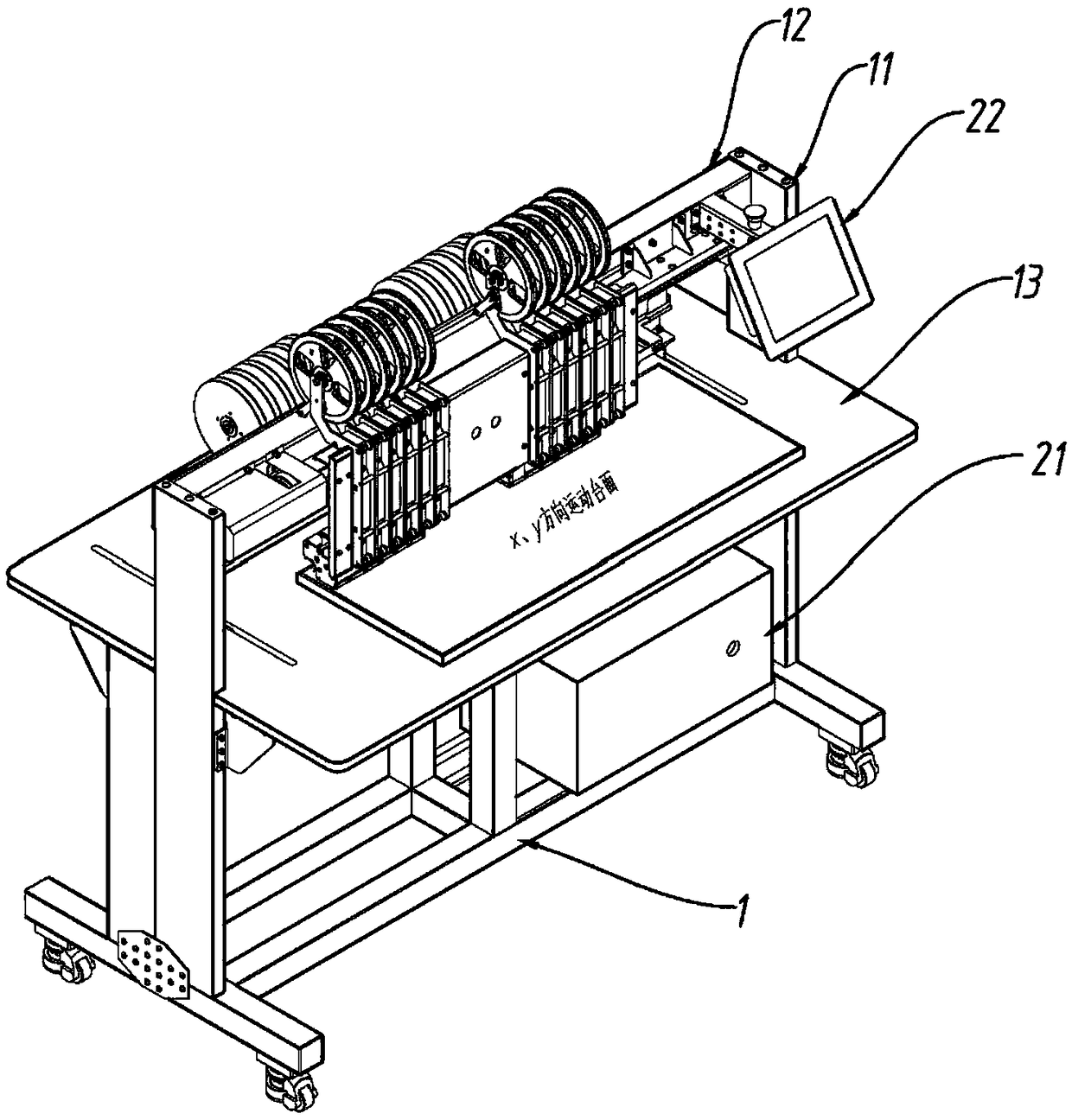

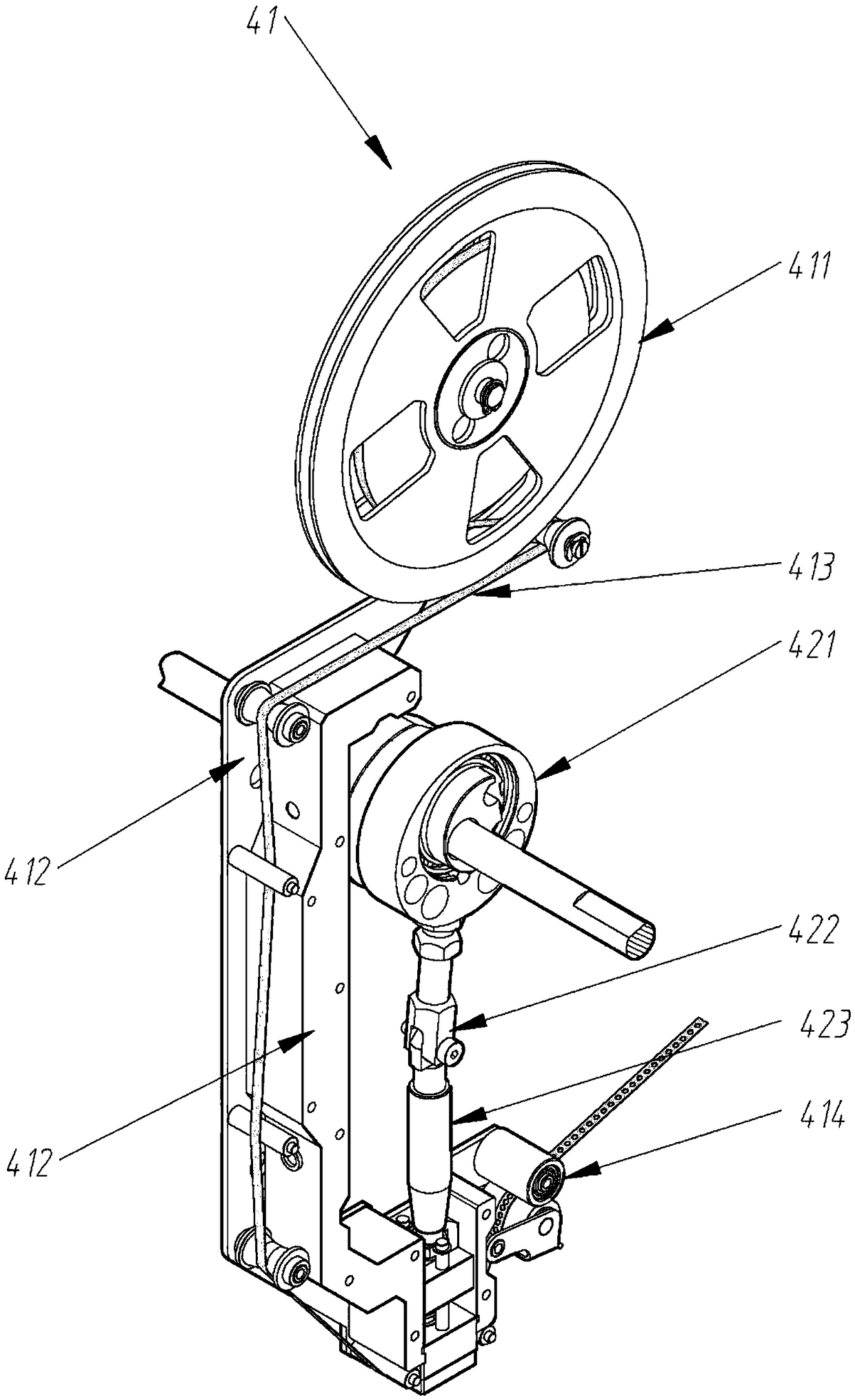

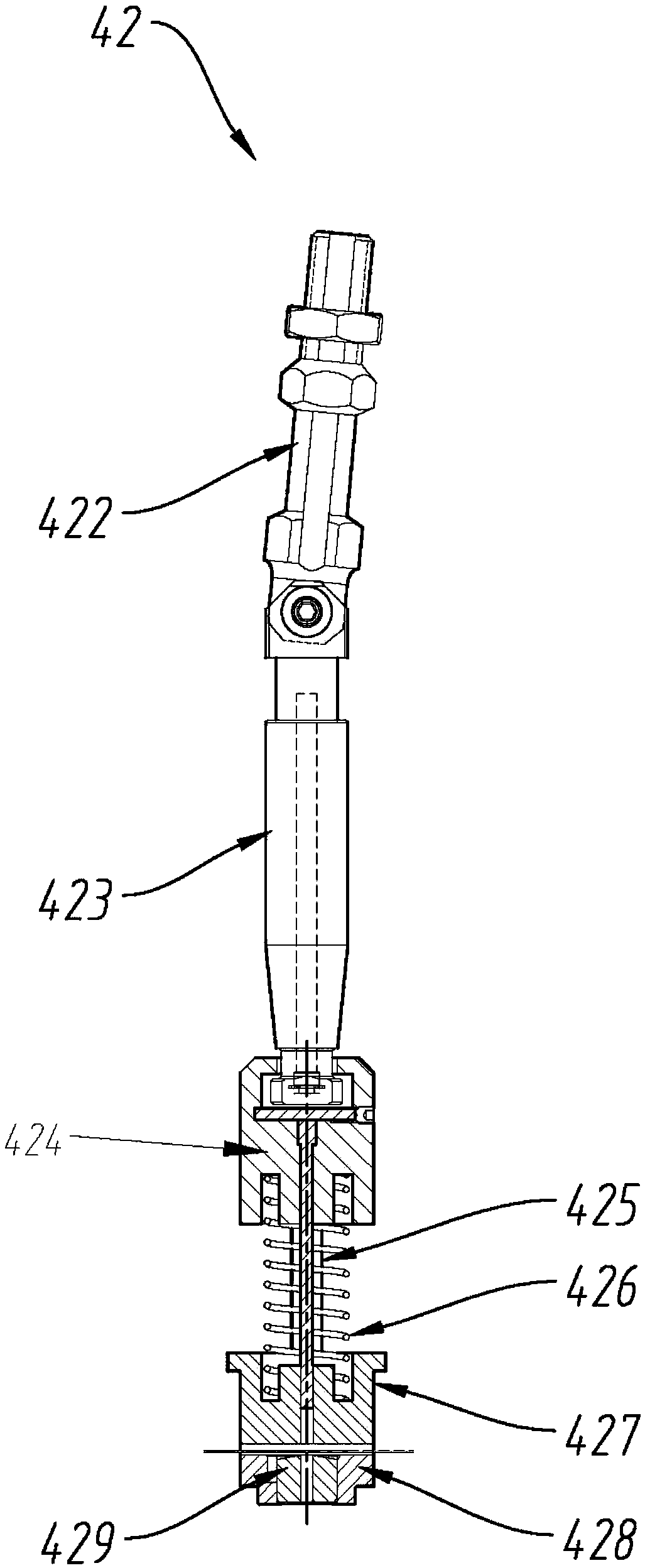

Automatic pattern arrangement machine for decorative sequins

The invention relates to mechanical punching equipment and particularly to an automatic pattern arrangement machine for decorative sequins. The automatic pattern arrangement machine comprises a stander, a control device, a color-changing driving device, a sequin punching device and a positioning device, wherein the stander is a one-table component formed by two upright pillars, a crosspiece and astable surface, and the two ends of the crosspiece are fixed at the upper ends of the two upright pillars; the color-changing driving device is mounted at one end of the crosspiece and comprises a driving motor, a screw rod, a nut, a connecting plate and a disc-control positioning device; and the driving motor is fixedly connected with the screw rod, and the screw rod is in running fit with the nut and is used for pushing the nut to move front and back. The automatic pattern arrangement machine has the advantages that no round hole is formed, so that the areas of the sequins are small, a small-sized pattern can be designed, and a belt disc can be wound with a sequin base belt; a punching mechanism can punch a transfer membrane; and the sequins have multiple shapes and smooth edges and arehigh in precision, and the pattern is fine.

Owner:上海飞豹新材料有限公司

Photosensitive resin composition and circuit formation substrate using the same

ActiveUS8304160B2Exquisite patternImproved in sensitivity and resolutionPhotosensitive materialsLayered productsStructural unitPolymer chemistry

A photosensitive resin composition for an interlayer insulating film or a protective film of a substrate for circuit formation, which includes a polymer (a) having a structural unit shown by the formula (A) and a compound (b) which generates a radical when irradiated with active rays and has a structure shown by the following formula (B).

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

Silk printed fabric and preparation method thereof

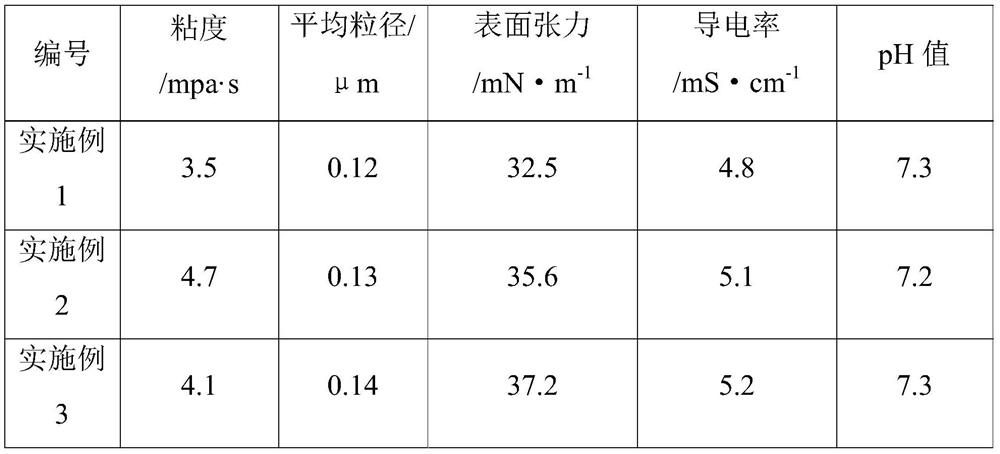

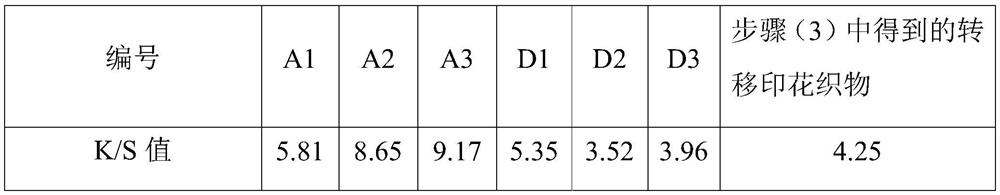

ActiveCN108660815ARealistic patternEasy to operateTransfer printing processDyeing processPre treatmentWater soluble

The invention relates to a preparation method of a silk printed fabric. The preparation method comprises the following steps of applying a macromolecular modifier to the surface of paper, and treatingat the temperature of 60 DEG C, so as to obtain the transfer printing paper, wherein the weight increasing amount of the paper is 10 to 20g / m<2>, and the macromolecular modifier is prepared from thefollowing components in percentage by mass: 0.5 to 5% of water-soluble hot melt glue, 2 to 12% of thickener, 0.5 to 3% of acid and alkaline agent, 2 to 8% of moisture absorber, and the balance of water; performing ink jetting and printing onto the transfer printing paper by active dye ink or acid dye ink, and drying, so as to obtain the transfer printing paper jetted with ink; soaking and rollingthe silk fabric, wherein the liquid entrapping rate of the fabric is 80 to 90%; laminating the transfer printing paper jetted with ink and the pretreated silk fabric in a hot press way, steaming by vapor, and washing by water, so as to obtain the silk printed fabric, wherein the permeation hot press temperature is 100 to 160 DEG C, and the hot press pressure is 3 to 6MPa. The preparation method has the advantages that the technology is simple and environmentally friendly; the color depth value of the prepared silk printed fabric is 4 to 7, the permeation rate of dye is 90% to 111%, and the color fixation rate is 79 to 90%.

Owner:SUZHOU UNIV

Acrylate emulsifying thickening agent and production process thereof

InactiveCN100418990CIncrease structural viscosityIncrease steric hindranceDyeing processPolyoxyethylene castor oilSolvent

The present invention is one kind of emulsified acrylate thickener for paint printing. It consists of acrylic acid 160-170 weight portions, vinyl benzene sulfonic acid 90-95 weight portions, 2-acrylamido-2-methypropyl sulfonic acid 18-19 weight portions, chlorotrimethylamino propyl acrylamide 22-24 weight portions, 20 % concentration ammonia water 300-320 weight portions, glyceryl dimethcrylate 2.5-3.5 weight portions, No. 200 solvent oil or aviation kerosene 100-150 weight portions, hydrogenated polyoxyethylene castor oil ether 22-28 weight portions, and ammonium persulfate 5-7 weight portions, which are reverse emulsion polymerized and mixed with linear organosilicon body in 4-6 weight portions. It has high water combining capacity, great electrolysis capacity, good handle and high color brightness.

Owner:LIAONING FIXED STAR FINE CHEM

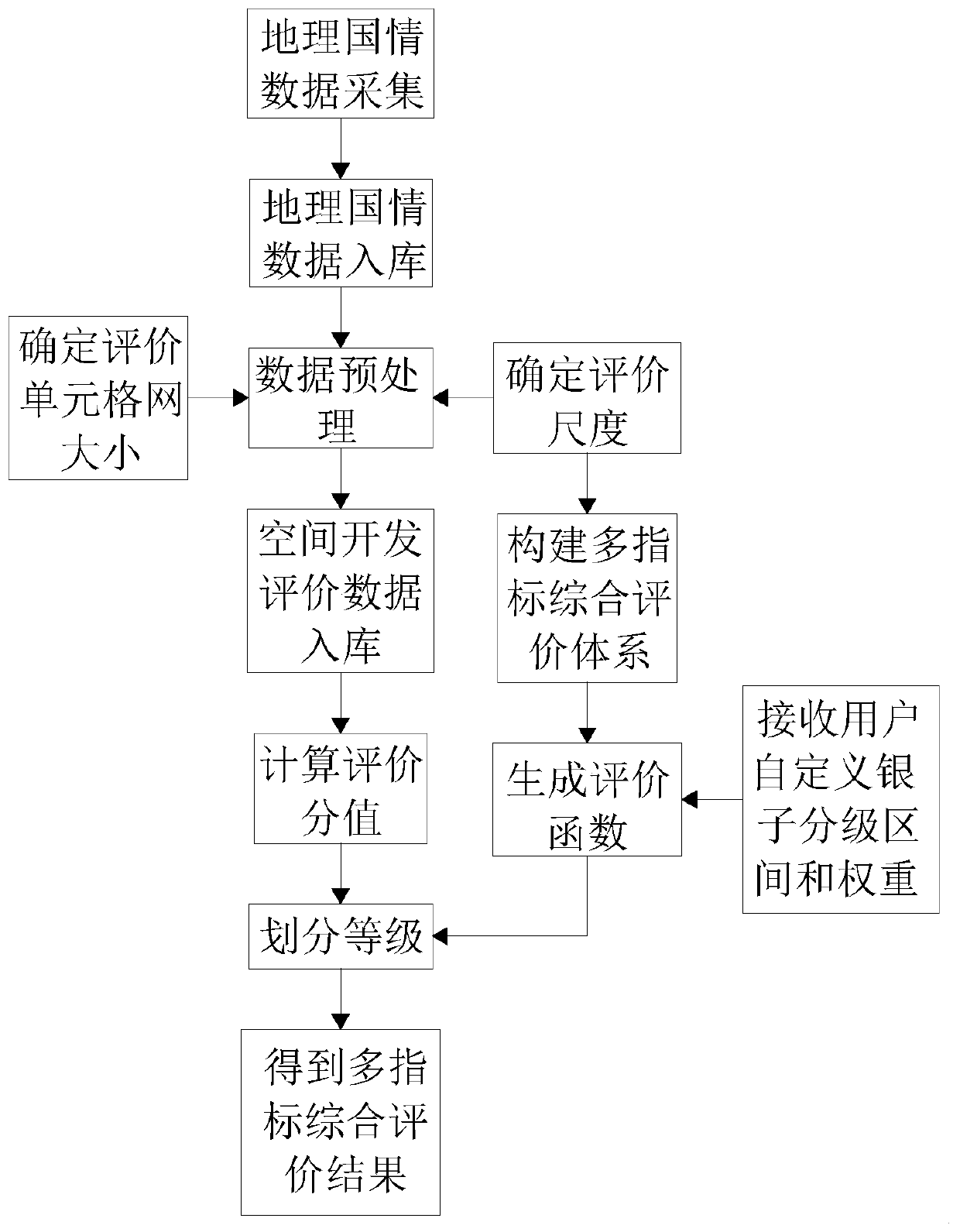

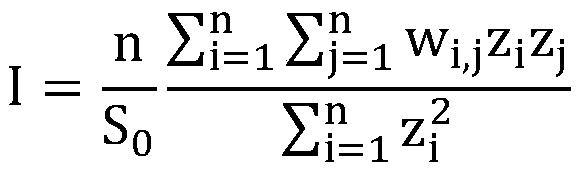

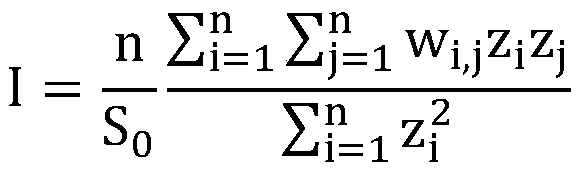

Multi-scale spatial analysis and evaluation method and system based on geographical national conditions

InactiveCN110781267AFine content divisionGuaranteed accuracyDatabase updatingGeographical information databasesIndex systemCollections data

The invention relates to the technical field of territorial space evaluation, and discloses a multi-scale space analysis and evaluation method and system based on geographic national conditions, and the method comprises the following steps: S1, carrying out the data collection according to a geographic national condition data collection standard; S2, selecting the size of a price evaluation network unit according to different evaluation requirements; S3, determining an evaluation scale according to evaluation requirements, constructing an evaluation index system, and performing data preprocessing; and S4, obtaining a single-index evaluation result through model calculation, and then obtaining a final evaluation result. According to the multi-scale spatial analysis and evaluation method andsystem based on the geographical national conditions adopt a spatial analysis and evaluation technology driven by geographic national condition data, the geographic national condition data is introduced into the field of spatial analysis and evaluation, and a long-time-sequence evaluation database is constructed by combining other basic geographic data, humanistic data and planning data, so thata comprehensive and long-time-sequence evaluation result is formed, the content division is fine, and the accuracy of the evaluation result is ensured.

Owner:江苏省基础地理信息中心

Production method of double-layer high-definition digital printing towel

ActiveCN106592276AImprove clarityImprove color vibrancyDry-cleaning apparatus for textilesDyeing processEngineeringDigital printing

The invention relates to a production method of a double-layer high-definition digital printing towel. A terry pile structure with double-layer gauze is designed and developed, and the double-layer high-definition digital printing towel is prepared through the combination of the terry pile structure and a digital printing technology. According to the production method of the double-layer high-definition digital printing towel, color brilliance and printing definition of a product are sharply improved, the disadvantages that a loop-velvet type fabric is poor in printing effect, prone to dry plate, low in definition and the like are effectively solved, flower-type definition can be sharply improved, the effect of the product on the whole is more fine and smooth, and the advantages of being exquisite in flower-type and rich in color of the digital printing are given full play.

Owner:LOFTEX INDS

Comfortable elastic wrinkle fabric

InactiveCN107881621AEvenly distributedEvenly dressedSucessive textile treatmentsTwo or more solvent application treatmentYarnEngineering

The invention relates to a fabric, in particular to a comfortable elastic wrinkle fabric. Against the technical problems to be solved, the invention provides the comfortable elastic wrinkle fabric which brings users a concave-convex sense, enables bubble sizes to be adjusted and distributed evenly and is durable and washable. The adopted technical scheme includes that warp yarn includes first warpyarn and second warp yarn, wherein the first warp yarn is formed by blending combed cotton and modal, and the second warp yarn is formed by blending combed cotton and SORONA yarn, and the proportionof the first warp yarn to the second warp yarn is 24:12. Weft yarn includes first weft yarn and second weft yarn. The proportion of the first weft yarn to the second weft yarn is 16:8. The comfortableelastic wrinkle fabric is of a 1 / 1 weave structure, and the front structure and the reverse structure are the same. The comfortable elastic wrinkle fabric is formed by weaving a blended fabric according to the structure and then performing dyeing and finishing. The comfortable elastic wrinkle fabric is widely applied to the technical field of textile fabrics.

Owner:临猗县鑫得利纺织印染有限公司

Method of using ceramic precursors to prepare patterned ceramic

The invention relates to patterned ceramic, in particular to a method of using ceramic precursors to prepare patterned ceramic. The method includes: mixing polydimethylsiloxane with crosslinking agent, adding the mixture into a metal box, heating, placing in a master pattern, heating until PDMS (polydimethylsiloxane) is solidified, adding liquid PDMS, placing in a drying oven for solidification, and taking out the master pattern to obtain a PDMS mould with a mould cavity identical to the master pattern in shape; mixing the ceramic precursors with initiator, injecting the mixture into the mould cavity of the PDMS mould, and stripping the PDMS mould after the ceramic precursors in the mould cavity are solidified to obtain solidified patterned ceramic precursors; heating the solidified patterned ceramic precursors, and taking out the solidified patterned ceramic precursors after cooling to obtain patterned ceramic. The method is simple, feasible, safe, efficient and applicable to various ceramic precursors, can be used for preparing crack-free and high-precision three-dimensional ceramic with various fine patterns, and can be widely applied to the fields of high-temperature MEMS (micro electromechanical system) devices, engine parts, micro engine combustors, chemical reactors and the like.

Owner:LVNA TECH CO LTD

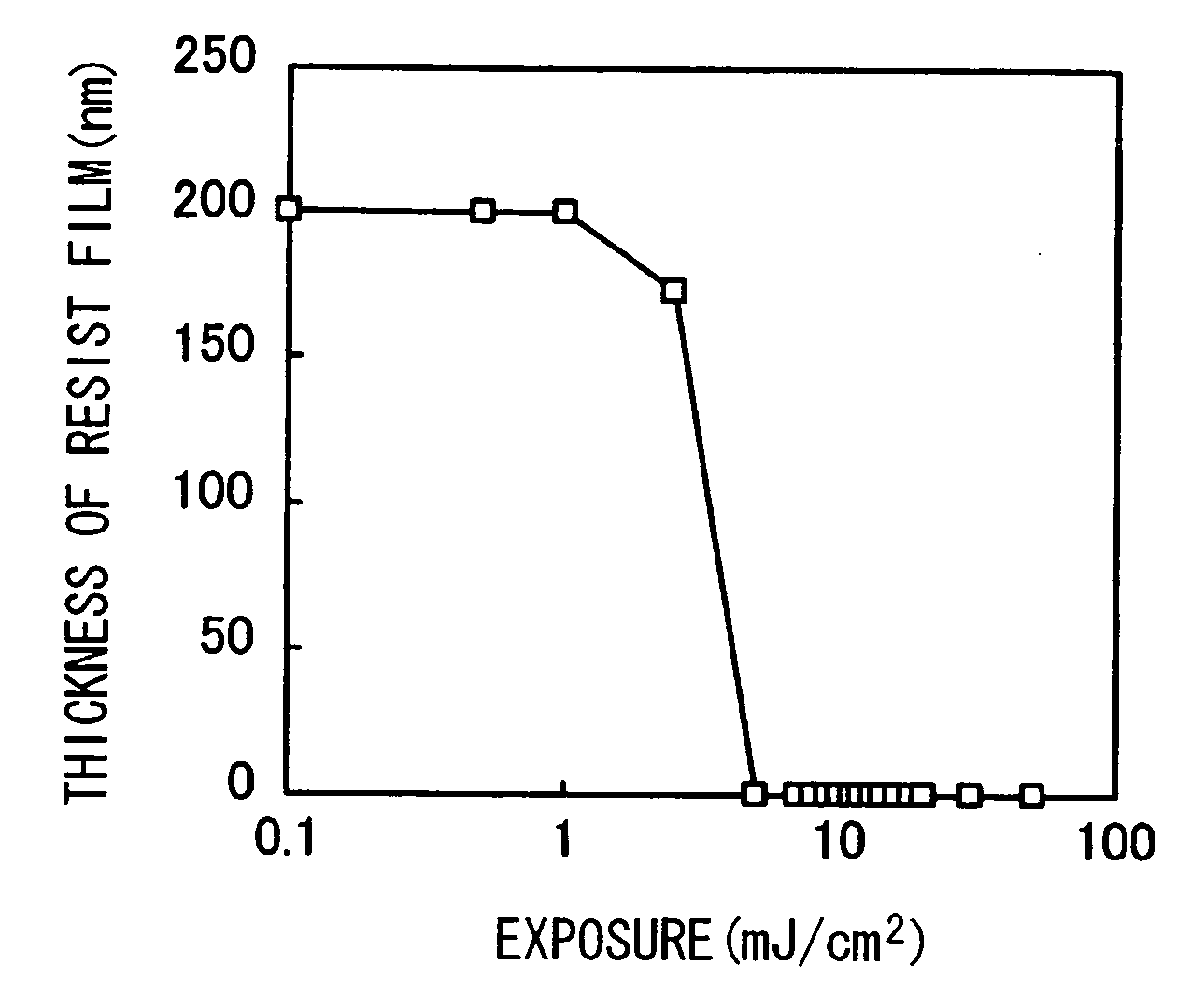

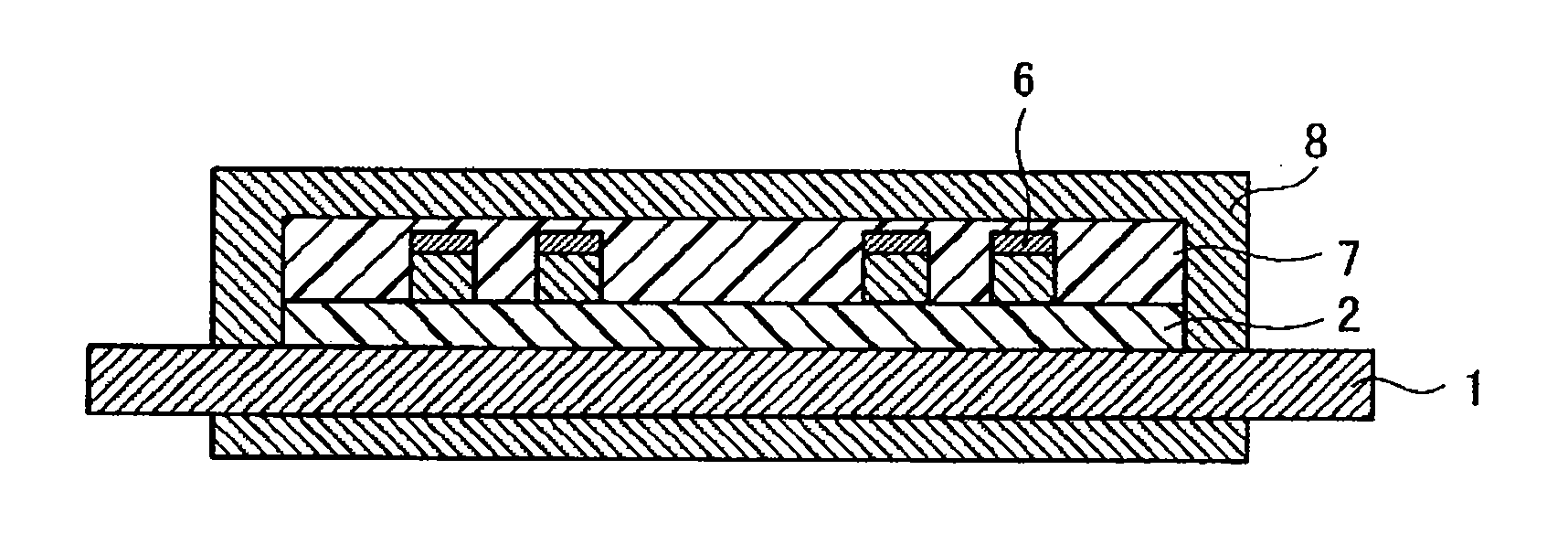

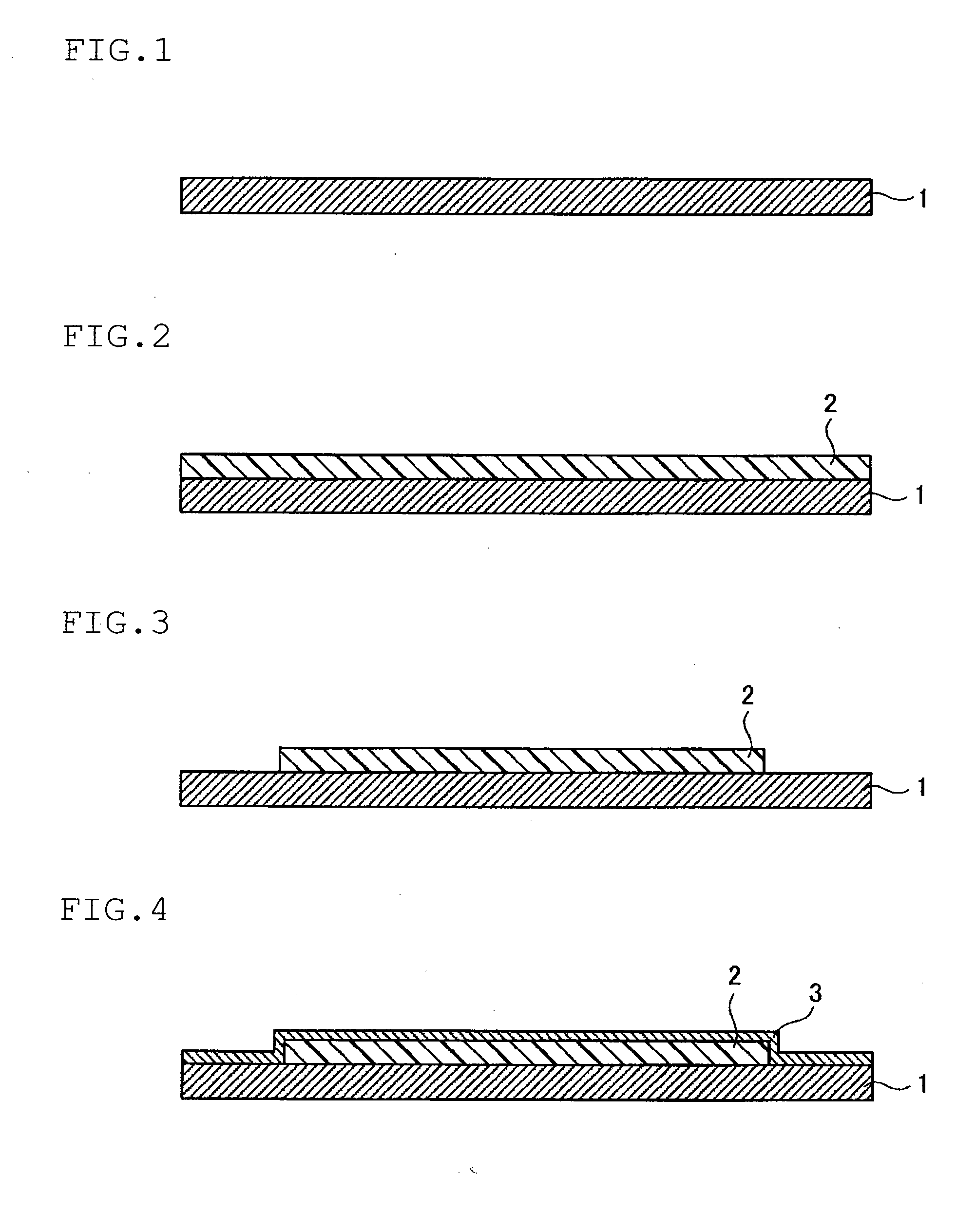

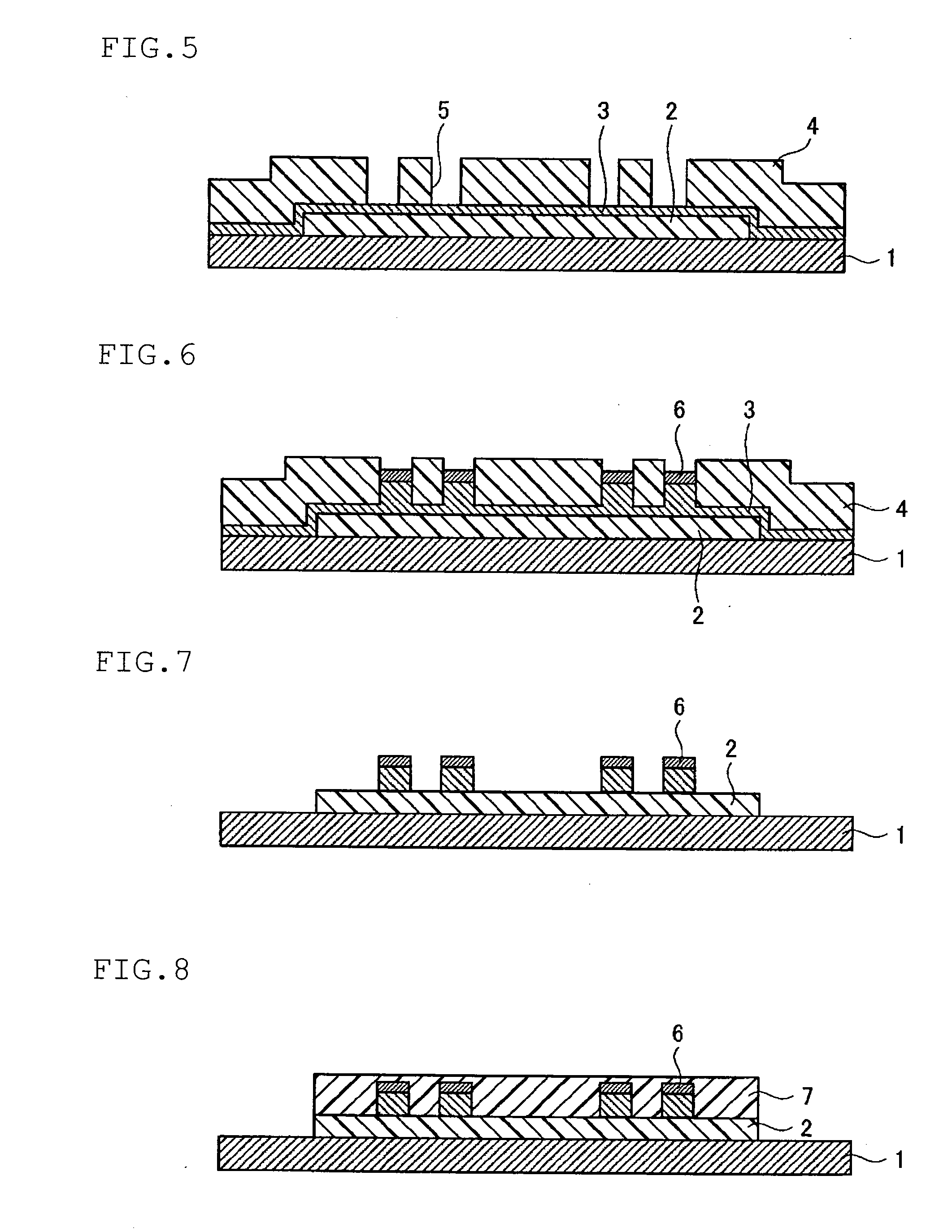

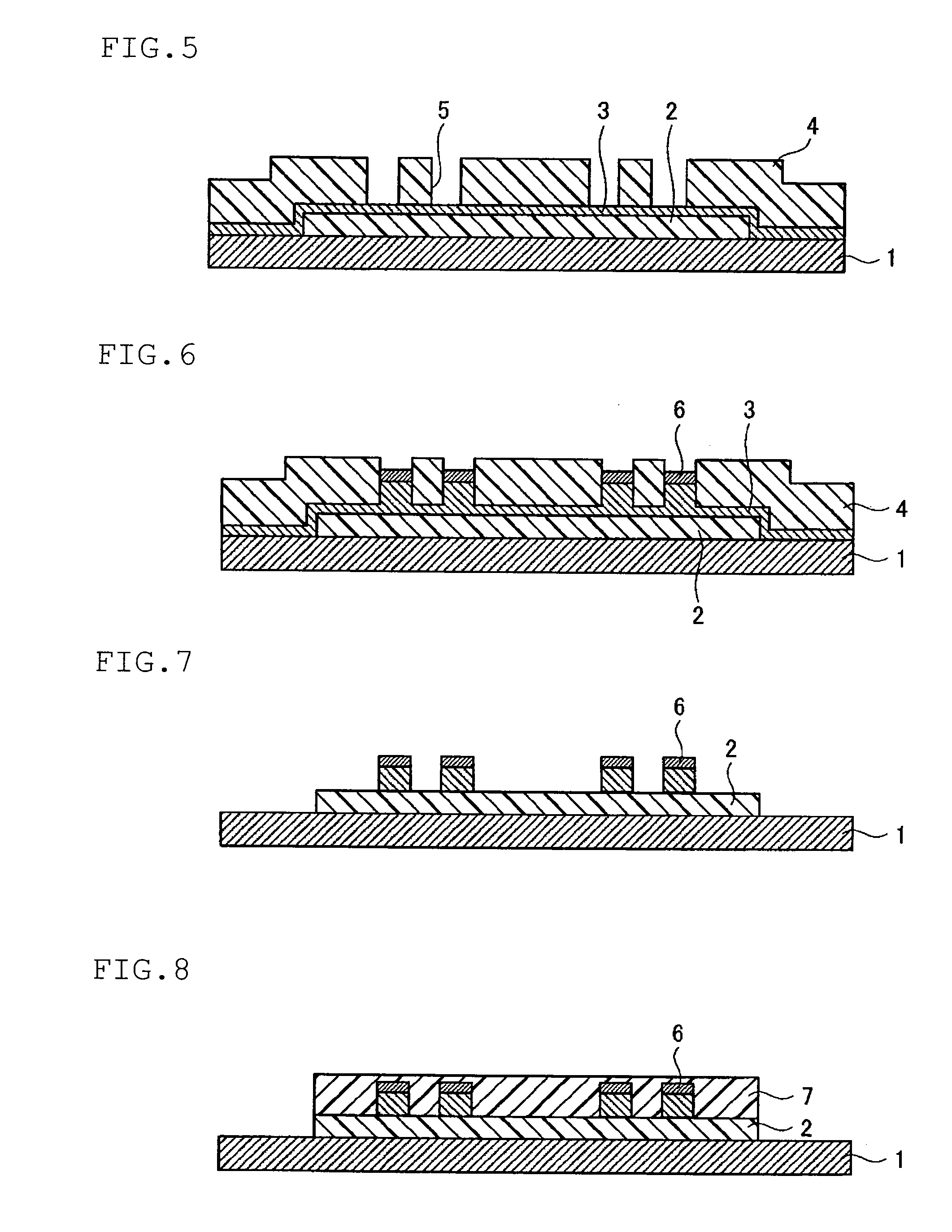

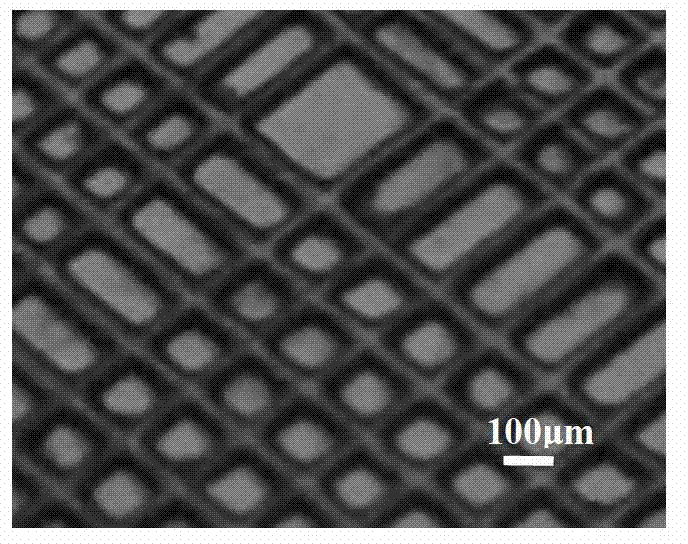

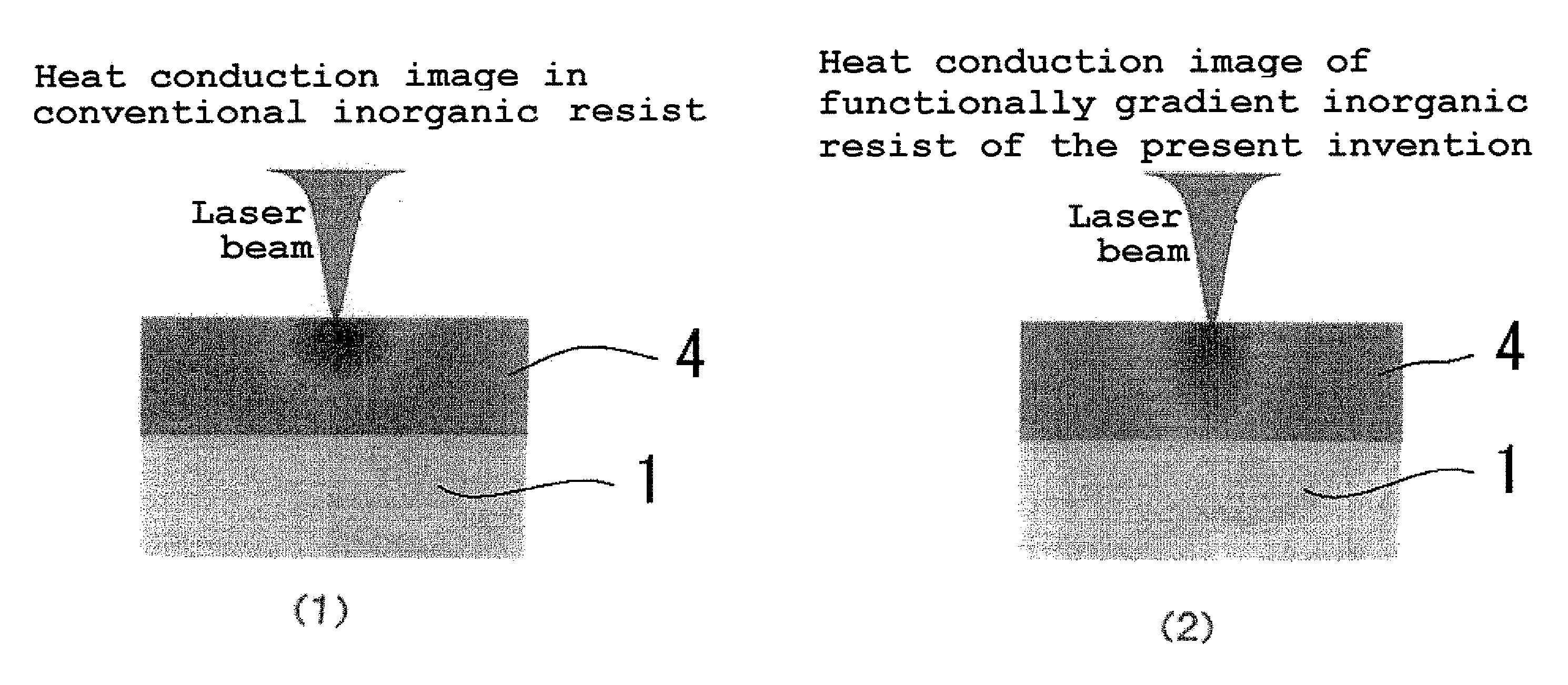

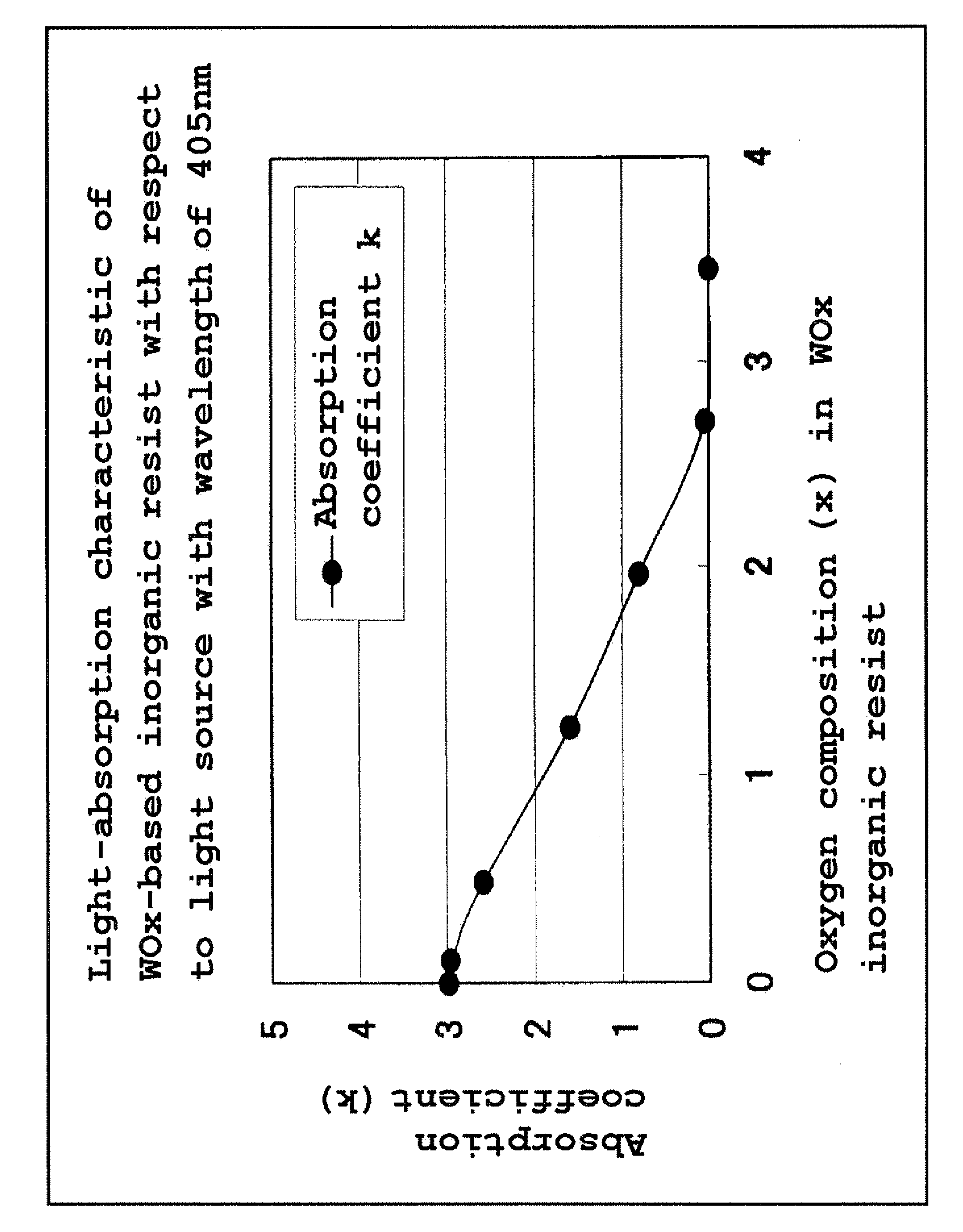

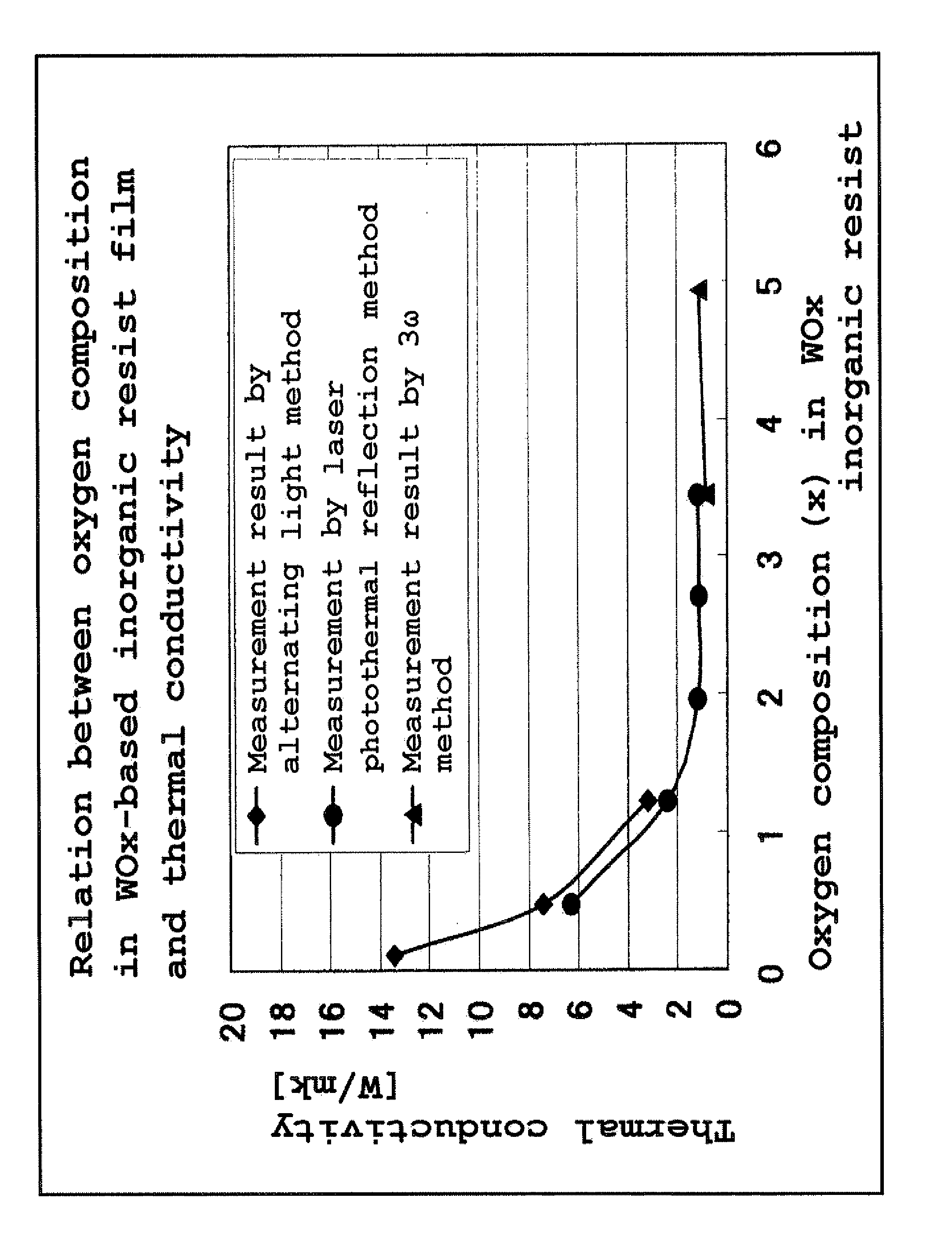

Functionally gradient inorganic resist, substrate with functionally gradient inorganic resist, cylindrical base material with functionally gradient inorganic resist, method for forming functionally gradient inorganic resist and method for forming fine pattern, and inorganic resist and method for forming the same

InactiveUS20120135353A1Low costImprove time resolutionChromate compound compositionsSemiconductor/solid-state device manufacturingResistLight beam

A functionally gradient inorganic resist that changes in its state by heat, having a main surface irradiated with laser beams and a rear surface opposed to the main surface; the functionally gradient inorganic resist including a single layer resist, wherein at least a composition of the single layer resist is continuously varied from the main surface side to the rear surface side, and anisotropy of an area in which a temperature reaches a fixed temperature when being irradiated with laser beams locally, is continuously increased from the main surface side to the rear surface side in the single layer resist.

Owner:HOYA CORP

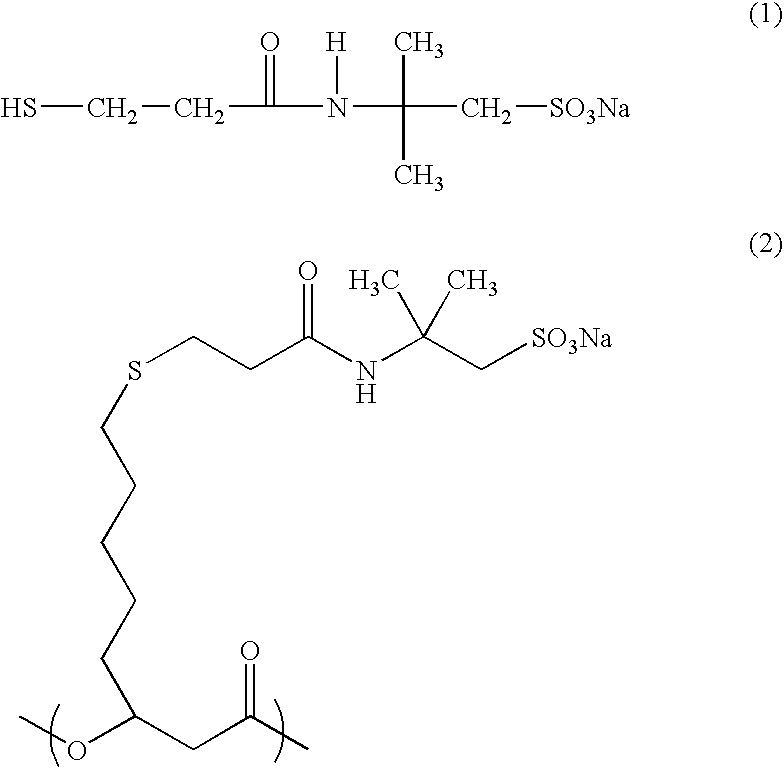

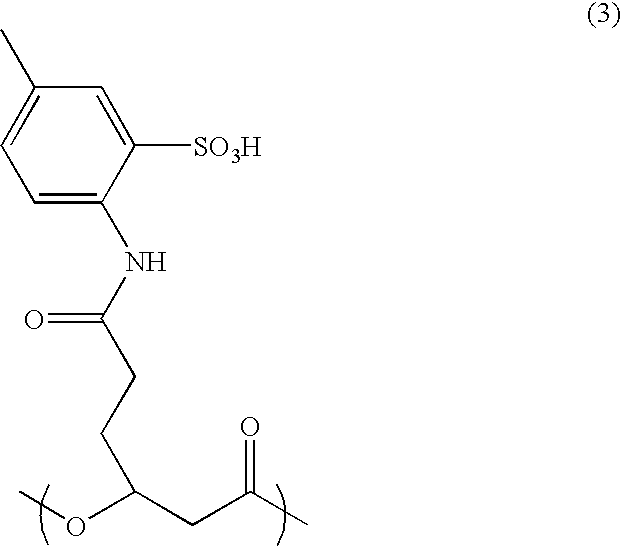

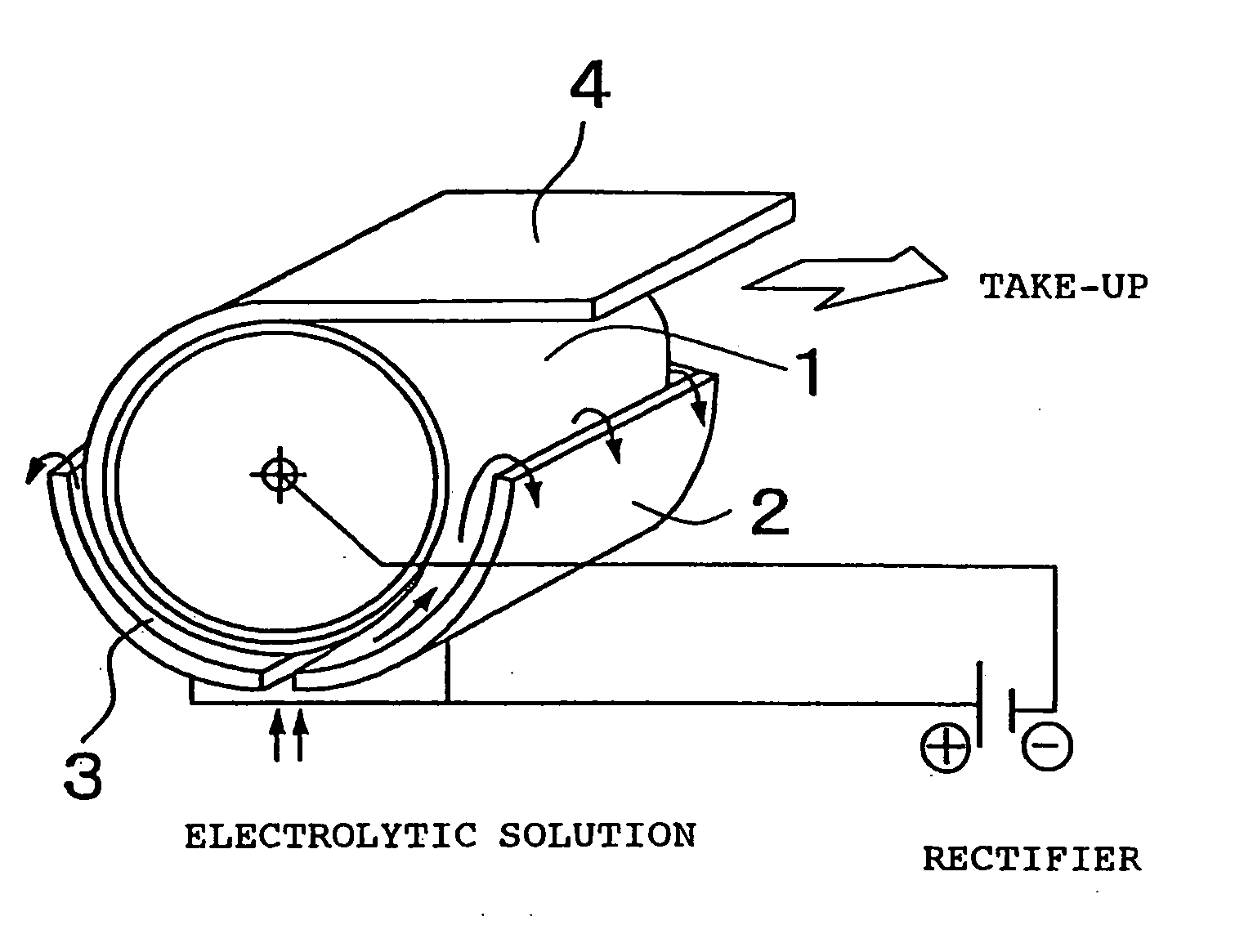

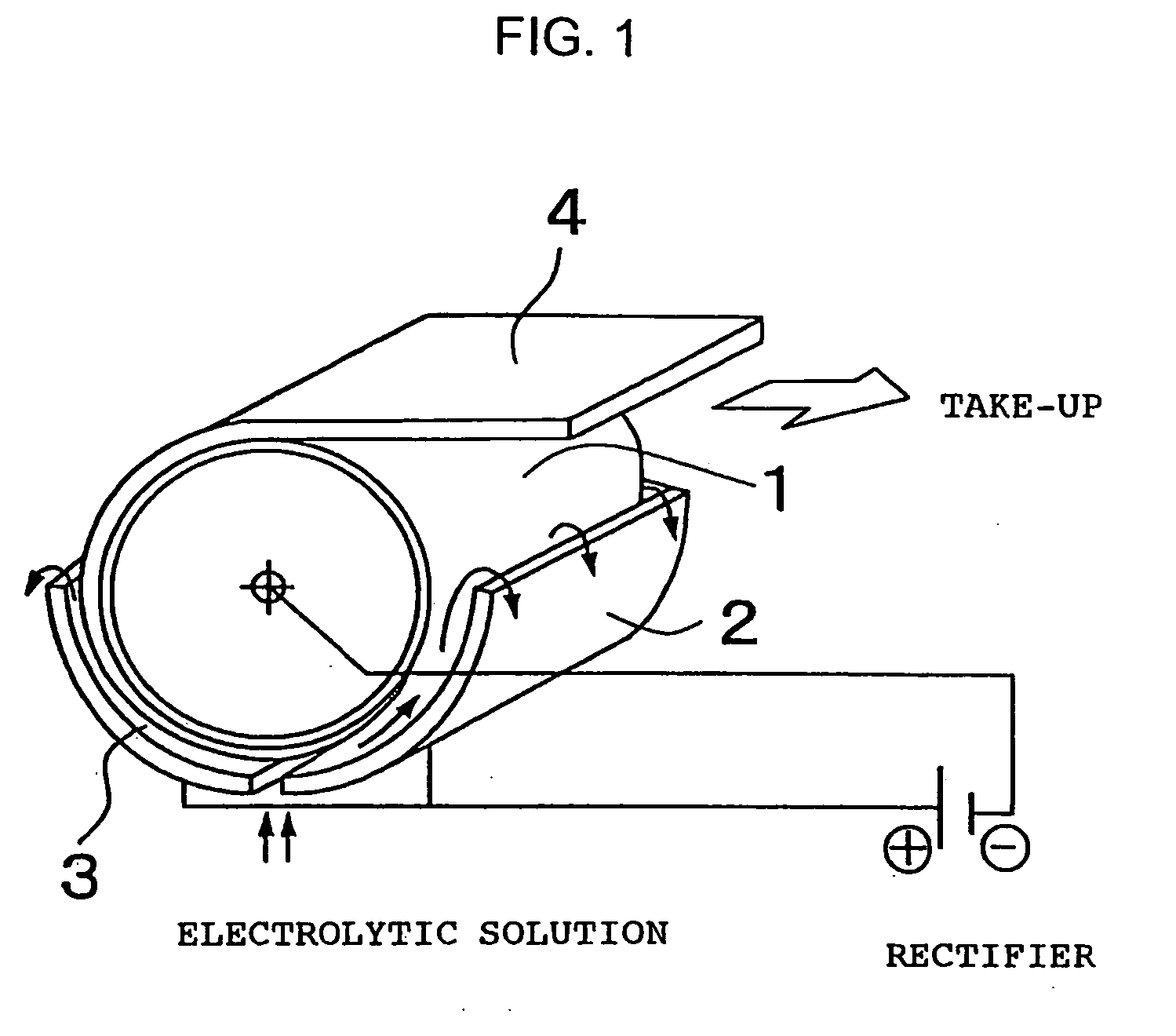

Copper electrolytic solution containing as additive compound having specific skeleton, and electrolytic copper foil manufactured therewith

InactiveUS20100224496A1Effectively maintains elongation propertyLow profileDuplicating/marking methodsActive material electrodesRough surfaceElectrolysis

The object of the present invention is to obtain a low profile electrolytic copper foil with low surface roughness at the rough surface side (opposite side from the glossy side) in the electrolytic copper foil manufacture using a cathode drum, and particularly to obtain an electrolytic copper foil with excellent elongation and tensile strength that permits fine patterning. Another object is to obtain a copper electrolytic solution that allows uniform copper plating without pinholes on a 2-layer flexible substrate. This copper electrolytic solution comprises as an additive a compound having the specific skeleton represented by General Formula (1) below which is obtained by an addition reaction in which water is added to a compound having in a molecule one or more epoxy groups:wherein A is an epoxy compound residue and n is an integer of 1 or more.

Owner:JX NIPPON MINING & METALS CORP

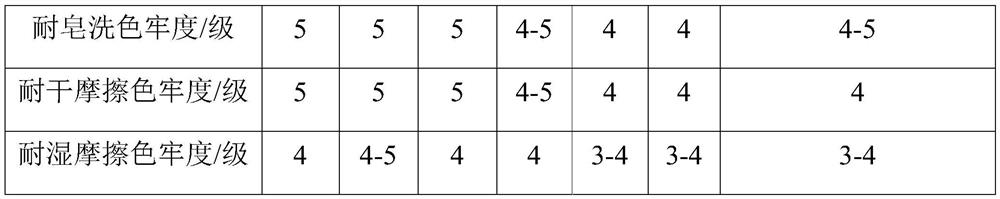

Digital transfer printing method using plant dye ink

PendingCN114016308AReduced controllabilityImprove controllabilityDuplicating/marking methodsTransfer printing processPaper sheetWoven fabric

The invention relates to the technical field of textile dyeing and finishing, and discloses a digital transfer printing method using plant dye ink. The method comprises the following steps: (1) coating the surface of blank paper with a paste material, drying and calendering to obtain transfer paper; (2) mixing a humectant with a part of ultrapure water to obtain a humectant solution, mixing a plant dye with a part of ultrapure water to obtain a plant dye color paste, adding the plant dye color paste, a surface tension regulator, a viscosity regulator, a pH buffer agent, an antiseptic bactericide and the rest ultrapure water into the humectant solution, stirring, and carrying out ultrasonic treatment, and carrying out filtering through a water-based filter membrane to obtain plant dye ink; (3) spraying and printing the plant dye ink onto transfer paper, forming a printing pattern on the transfer paper, attaching the dry fabric to the printing surface of the transfer paper, then ageing, and stripping the fabric from the transfer paper to obtain a transfer printing fabric; and (4) washing the transfer printing fabric, and carrying out color fixation treatment. The method has the advantages of simple process, high controllability and the like.

Owner:WUHAN TEXTILE UNIV

Pigment printing hydro-entangled non-woven fabric

InactiveCN102168386ARapid responseRich layersDyeing processNon-woven fabricsTextile printerPolymer science

The invention relates to a type of pigment printing hydro-entangled non-woven fabric, belonging to the weaving material technical field. The pigment printing hydro-entangled non-woven fabric consists of hydro-entangled non-woven fabric, the upper surface layer of which is coated with a pigment printing layer. The pigment printing hydro-entangled non-woven fabric of the invention endows the non-woven fabric with brilliant and abundant colors, enhances its aesthetic taste, improves product class and added value, and meanwhile pigment printing is energy-saving and environment-friendly, so the pigment printing hydro-entangled non-woven fabric of the invention has bright prospect.

Owner:郑雅华 +1

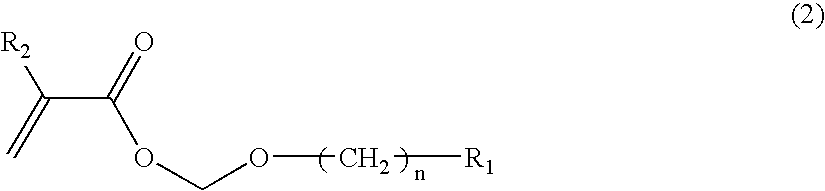

Acrylic copolymer and radiation-sensitive resin composition

ActiveUS20060074139A1Exquisite patternWide process marginPhotosensitive materialsPhotomechanical apparatusResistPolyresin

An acrylic copolymer having a specific structure and a radiation-sensitive resin composition comprising the acrylic copolymer having high transparency to radiation, excelling in basic properties as a resist such as sensitivity, resolution, dry etching resistance, and pattern shape, and, in particular, excelling in forming contact holes and lines-and-spaces.

Owner:JSR CORPORATIOON

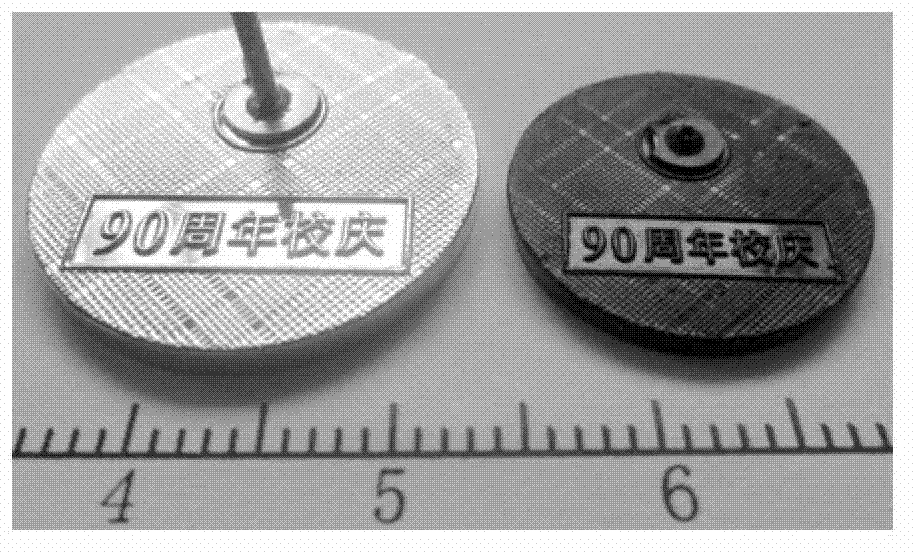

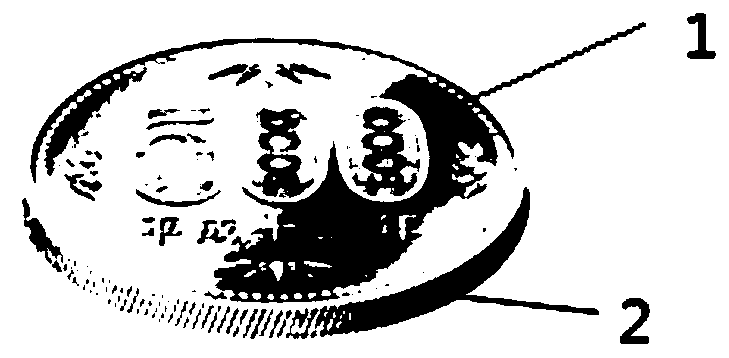

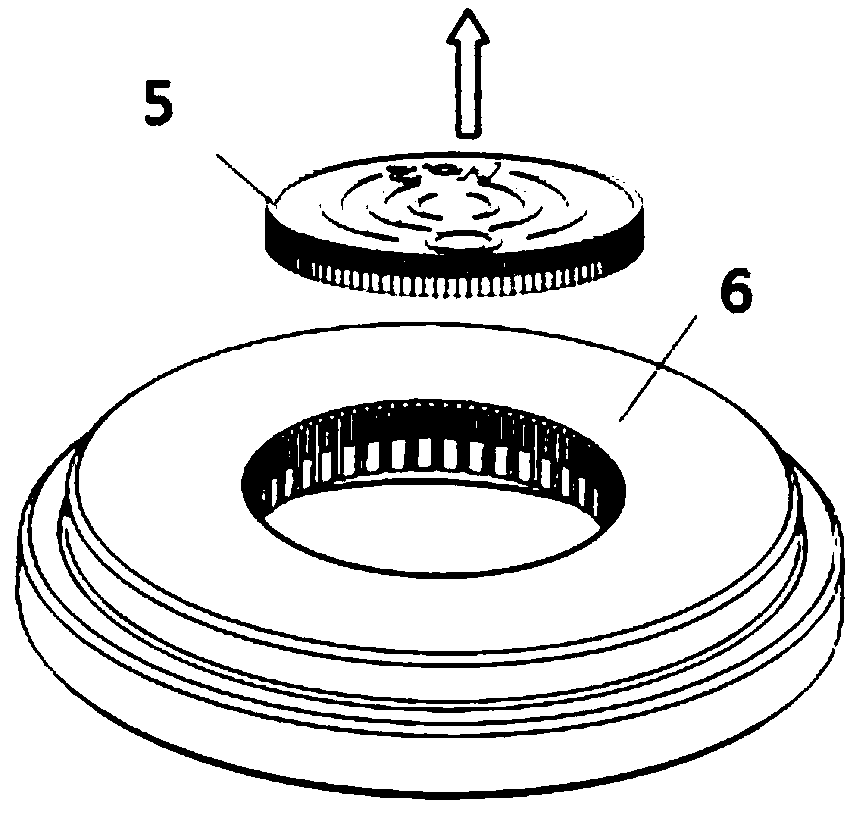

Silk tooth at edge part of coin and manufacturing method thereof

The invention relates to a silk tooth at the edge part of a coin. The silk tooth at the edge part of the coin comprises a silk tooth of a single structure and a silk tooth of a composite structure, wherein the silk tooth of the single structure is a spot-shaped silk tooth, a linear silk tooth or a curve silk tube; the silk tooth of the composite structure is a free combination formed by two or more than two materials from the spot-shaped silk tooth, the linear silk tooth or the curve silk tooth; after the arrangement of the adjacent silk teeth, at least one group of silk teeth pattern is formed at the edge part of the coin. The silk tooth of the composite structure concretely comprises a curve multidirectional silk tooth, a spot and line separated silk tooth, an embedded silk tooth and a miniature symbol form silk tooth form. The silk tooth form range is expanded through the silk tooth patterns; the appearance is novel and attractive; the changeful and colorful effects are achieved; the anti-counterfeiting and identification performance is realized. The manufacturing method comprises a sandwich plate splicing type silk tooth module opposite twisting manufacturing method and a silktooth split module sleeve manufacturing method.

Owner:上海舟韧科技有限公司

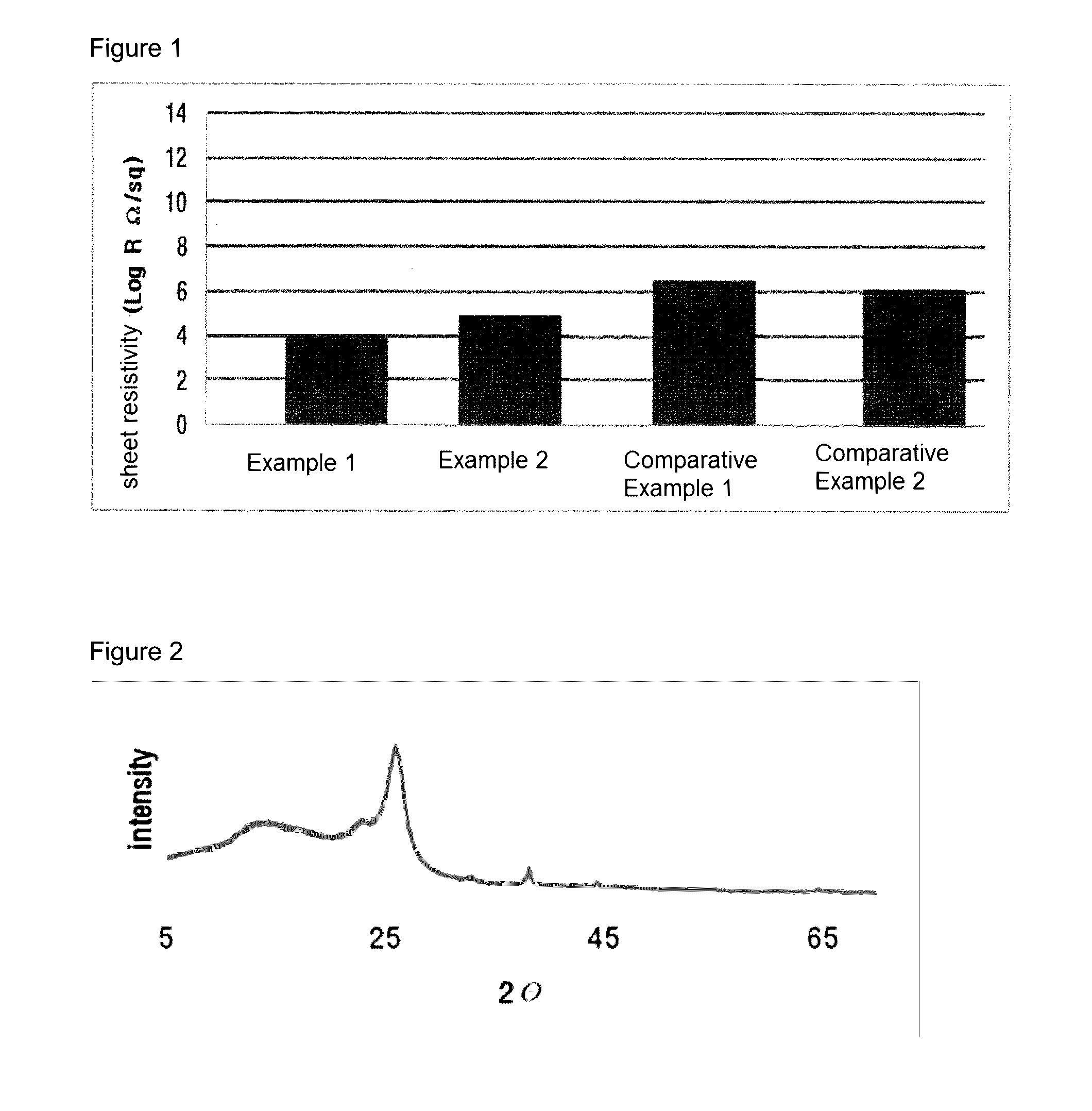

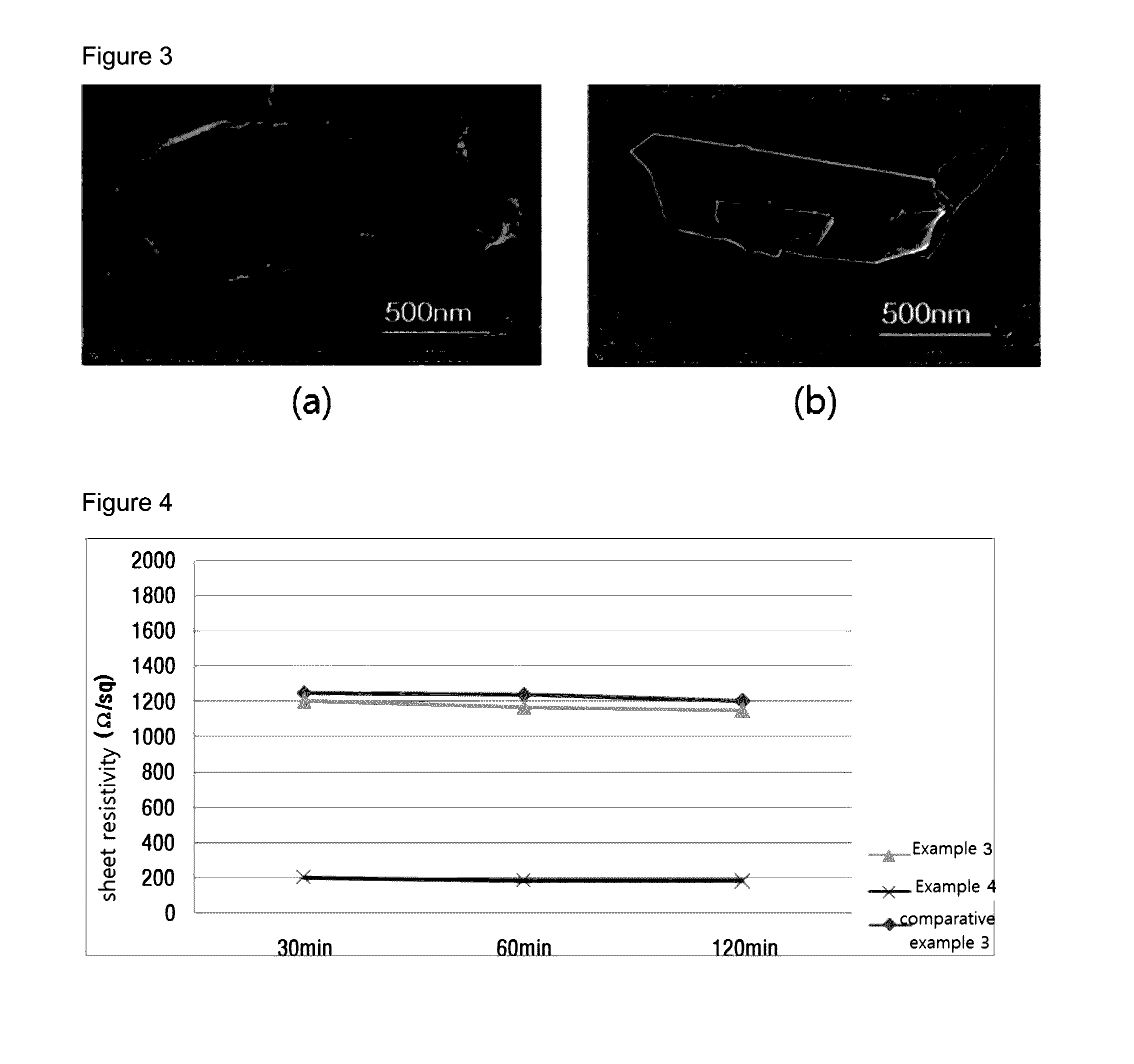

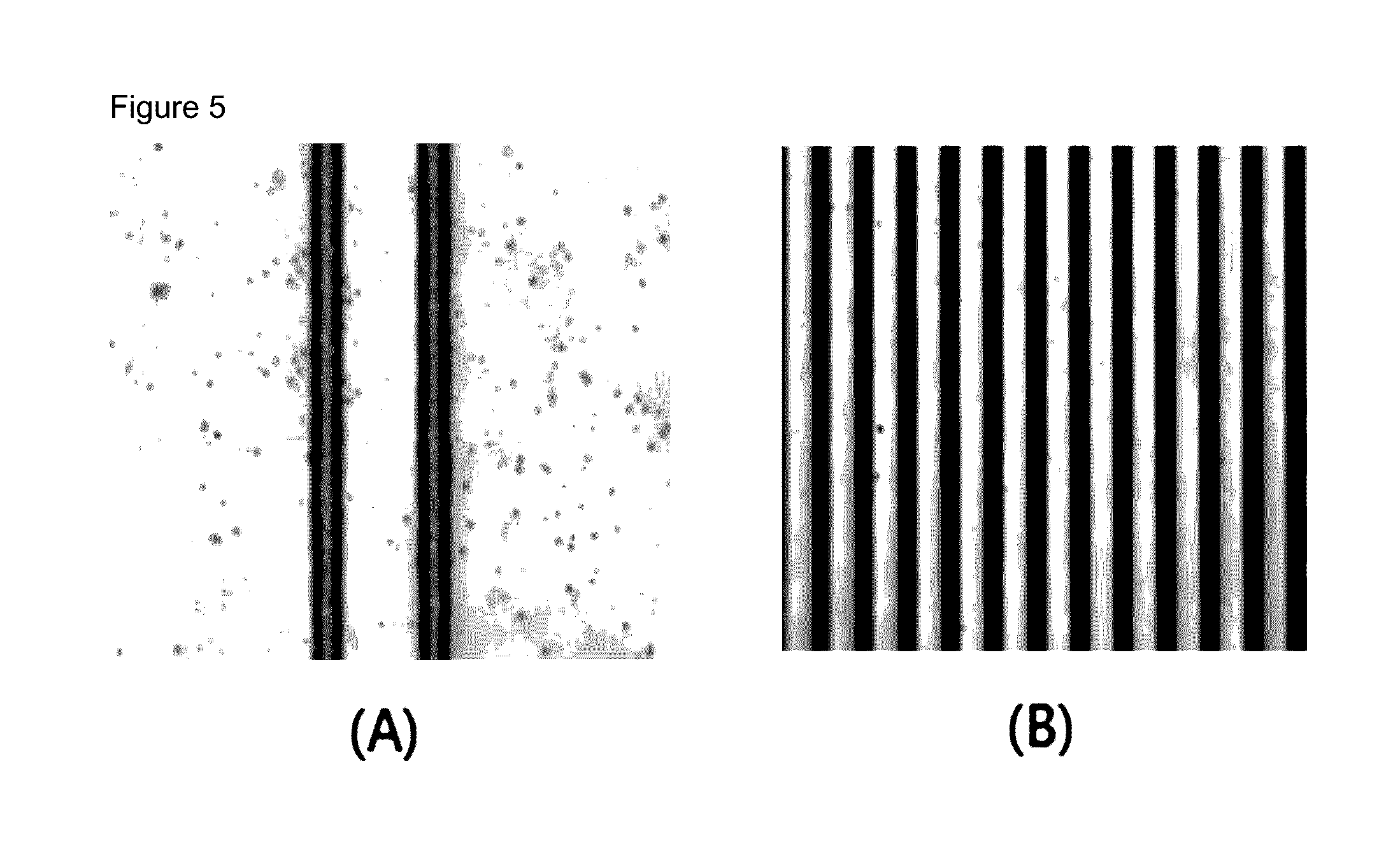

Carbon-Metal Composite and Method for Preparing the Same

The present invention relates to a carbon-metal composite and a method for preparing carbon-metal composite, and more particularly to a method for preparing carbon-metal composite, which: is capable of reducing graphene oxide; which is capable of decreasing the steps and the time for hybridization of graphene which is obtained from the reduction, graphene or carbon nanotube, with metal; which is done under mild condition and; also which is capable of lowering resistivity of the carbon-metal composite. The method for preparing the carbon-metal composite comprises the steps of: reacting a composition containing a carbon compound selected from a group consisting of graphene, graphene oxide and carbon nanotube, a metallic precursor, a reducing agent and a solvent; and removing solvent partially or wholly from the composition reaction-completed. Wherein the reducing agent is selected from a group consisting of ethylene glycol, diethylene glycol, 1,2-propylene glycol, triethylene glycol, tetraethylene glycol, 1,3-propylene glycol, glycerol, and mixtures thereof.

Owner:DONGJIN SEMICHEM CO LTD

Preparation method of quickly demolded flexible facing brick

ActiveCN110078424AQuick recyclingReduce production energy consumptionCeramic shaping apparatusBrickFreeze-drying

The invention discloses a preparation method of a quickly demolded flexible facing brick. The preparation method comprises the following steps: uniformly mixing raw materials into slurry in a certainproportion; molding in a mold; drying briefly first and then placing in low temperature conditions for freeze drying and demolding; and then naturally drying to obtain the flexible facing brick. The facing brick prepared with the preparation method provided by the invention can be separated from a mold and molded in a very short time, and has performance indexes reaching national standards; and acombined antifreezing agent adopted by the preparation method can be quickly freeze-dried and quickly demolded under low temperature conditions, so as to greatly improve production efficiency and reduce energy consumption and production costs; and the preparation method has wide market popularization and application prospects.

Owner:海安海华新材料科技有限公司

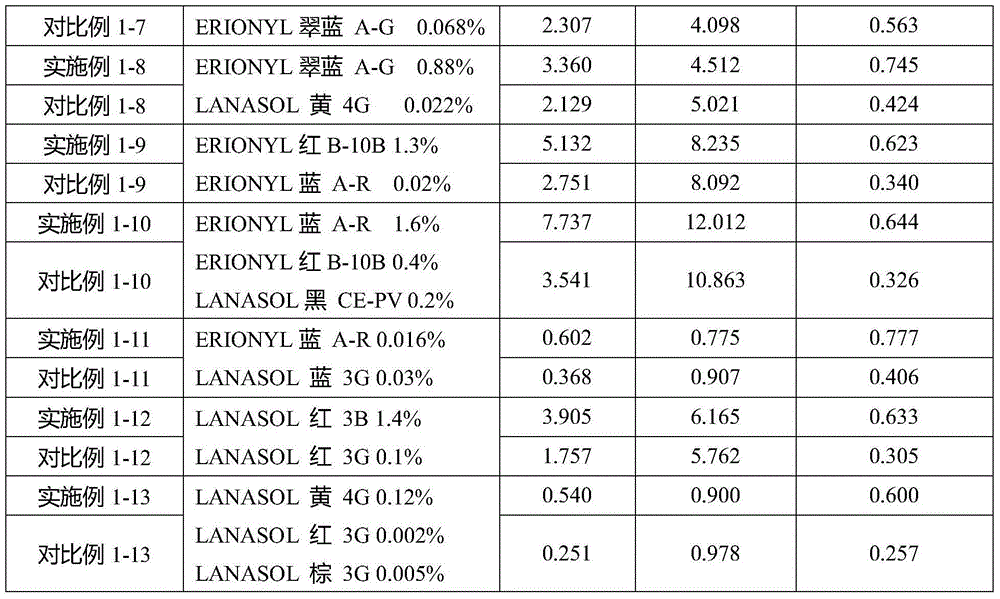

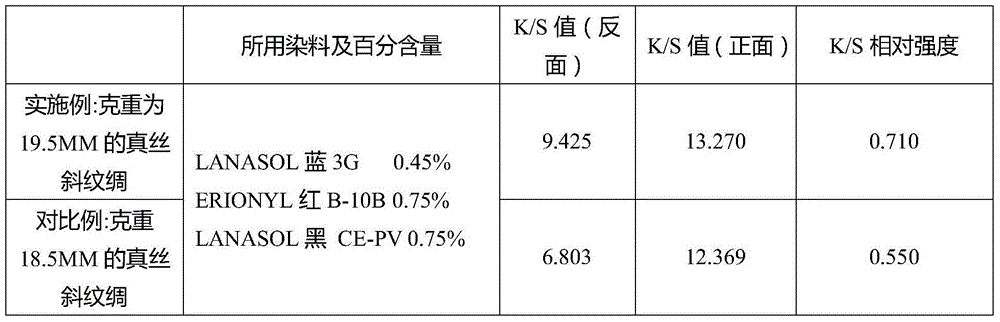

Printing color paste and printing silk twill production technology

InactiveCN104695246AImprove permeabilityReduce printing color differenceDyeing processPreservativeEngineering

The invention discloses printing color paste. The printing color paste comprises the following components in parts by mass: 8%-12% of a printing paste material, 8%-10% of urea, 0.01%-5% of dye, and the balance being water, wherein the range of the dye molecular weight is 500-800. The printing paste material is prepared from the following components in percentage by mass: 18-20% of a modified guar gum seed extract, 0.8-1.2% of a preservative and the balance being water. The invention also provides a printing silk twill production technology comprising the following steps: weaving silk twill, carrying out refinement treatment on the silk twill, printing the silk twill by adopting the printing paste, steaming, rinsing, drying, fixing color, tentering and thermosetting. By the improvement of the weaving process and the printing paste, the heavy printing silk twill prepared by adopting the printing silk twill production technology is delicate in pattern, is good in printing paste permeation, and is clear in color and pattern in front and back surfaces.

Owner:SHANGHAI WOO BRAND MANAGEMENT CO LTD

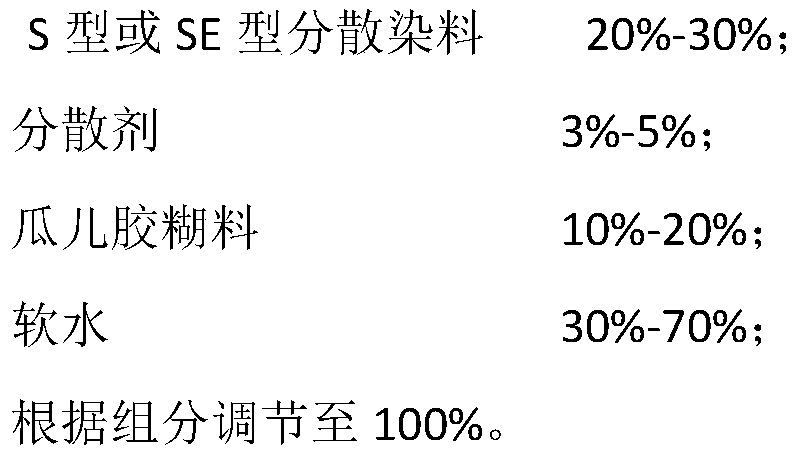

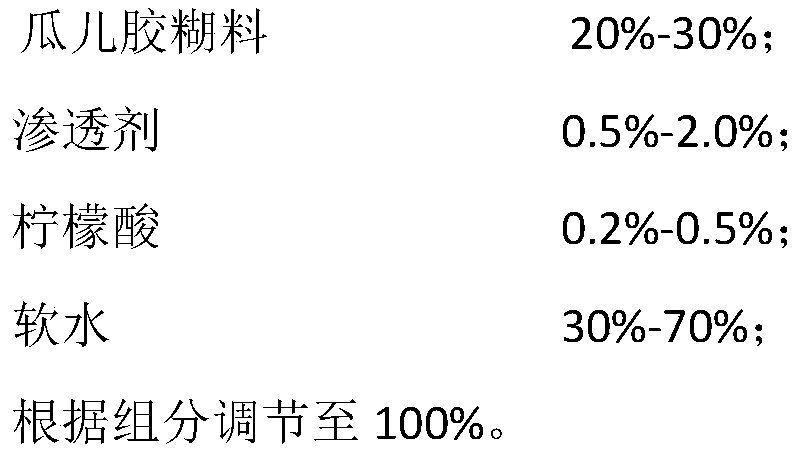

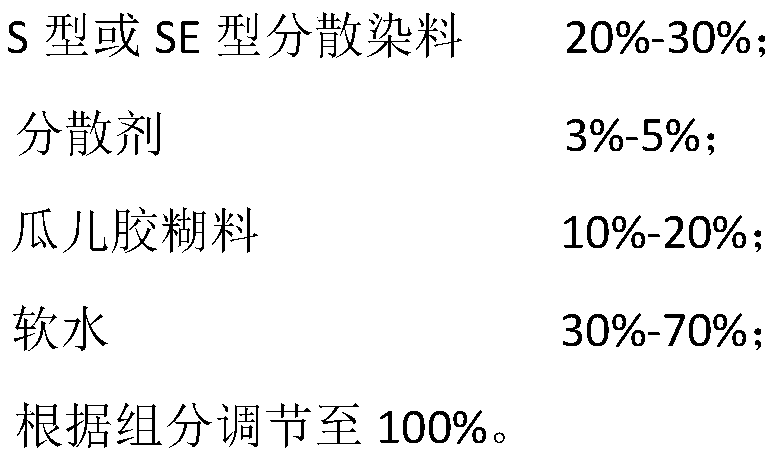

Cold transfer printing process of fine denier high-density polyester fabric

InactiveCN110055775ASignificant energy saving and emission reductionWon't spoil the feelTransfer printing processDyeing processPolyesterHigh density

The invention discloses a cold transfer printing process of a fine denier high-density polyester fabric. The cold transfer printing process of the fine denier high-density polyester fabric comprises the following steps: printing prepared dispersed ink on a coating film by using a printing machine, and then feeding the transfer film and a fabric into a cold transfer printing machine together; afterthe fabric is treated by pretreatment liquid of a pretreatment device of the cold transfer printing machine, tightly combining the fabric with the transfer film and jointly transferring the fabric and the transfer film through the cold transfer printing device to prepare a printed fabric; and carrying out high-temperature steaming fixation or baking fixation on the printed fabric, and then washing and shaping to obtain a printed fabric finished product. The fine denier high-density polyester fabric prepared by the invention has a good velvet-proof effect by utilizing a leading high-density weaving process. The polyester transfer printing technology is developed by adopting the advanced environmental protection concept, the fabric is endowed with colorful patterns, and the fineness and layering of high-definition photos are presented. The patterns are vivid, rich and clear, the patterns are fine, the artistry is high, the stereoscopic impression is strong, and the effect that general printing cannot be compared is achieved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

3D-pattern-printed mosquito net and manufacturing method thereof

PendingCN107190524ASave time oftenMeet individual requirementsTransfer printing processDyeing process3d patterningTextile printer

The invention provides 3D-pattern-printed mosquito netting and manufacturing method thereof. The 3D-pattern-printed mosquito netting includes a printing and dyeing pattern and a mosquito netting substrate, which is double-silk-thread-intersection mosquito netting and has rhombic or hexagonal meshes. Compared with common mosquito netting, the 3D-pattern-printed mosquito net is stronger, can be stored for a longer time, has more beautiful 3D patterns, and makes a consumer have a better view. Compared with conventional printing technology, the manufacturing method is simpler, is less in investment and saved in resources, is free of subsequent washing and drying, and is free of the problem of wastewater treatment and discharge.

Owner:许丽林

Porcelain polished tile and production method thereof

The invention discloses a porcelain polished tile and a production method of the porcelain polished tile. The production method comprises the steps of: (1) preparing a porcelain polished tile blank body powder material by a conventional method; (2) preparing a porcelain polished tile slurry; (3) preparing a porcelain polished tile blank body; (4) drying; (5) applying the slurry; (6) drying and sintering; (7) edging and polishing; and (8) sorting, packaging and warehousing. The porcelain polished tile and the production method have the beneficial effect of solving the technical problems of higher requirements of the traditional porcelain polished tile on a material and more waste, and provides a more environment-friendly and economic production method of the porcelain polished tile.

Owner:HANGZHOU NABEL CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com