Printing color paste and printing silk twill production technology

A printing color paste and production process technology, applied in dyeing, textile and papermaking, etc., can solve the problems of large difference in printing color, high density of warp and weft, and high fabric tightness, and achieve clear printing, increased fineness, and good penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

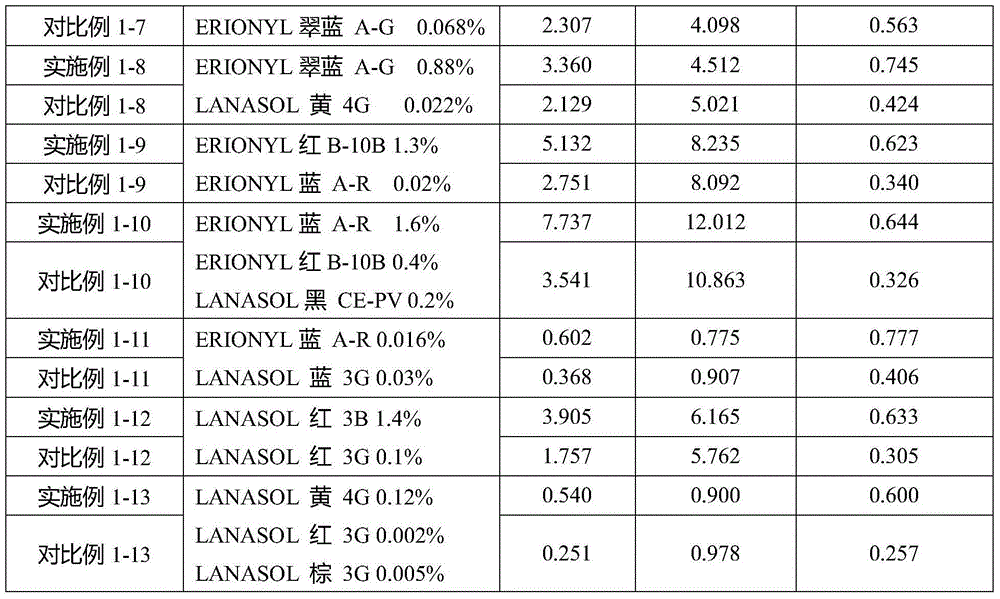

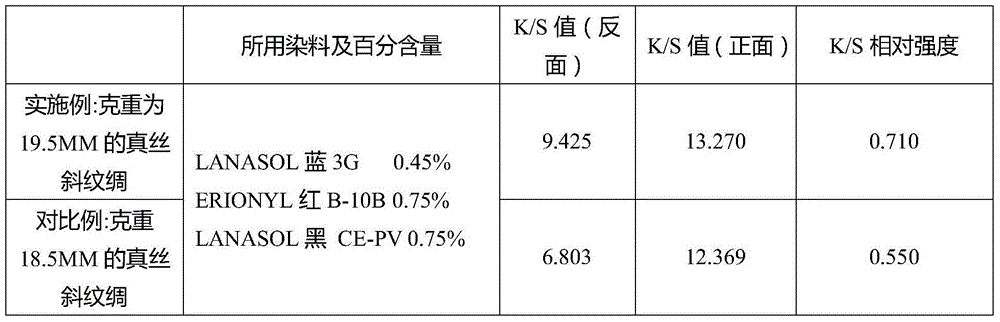

Embodiment 1

[0039] A printing color paste, comprising the following components by mass fraction:

[0040] Printing paste 8%;

[0041] Urea 10%;

[0042] Dyes, the dyes used and the percentage content are shown in Table 1 below;

[0043] Water 79.92%;

[0044] The printing paste is prepared from 20% modified guar gum seed extract, 1% preservative, and 79% water.

[0045] The preparation method of the printing paste: after mixing the modified guar gum seed extract, preservative and water according to the mass fraction, the mixer stirred for 45 minutes, and then added 5% H 2 SO 4 , after fully mixing, hydrolyze at 70°C for 2 hours, add NaOH to neutralize until the pH is 6.5-7, and obtain a printing paste with a molecular weight of 10,000-15,000 and a paste rate of 18%-20%, which can be directly used to prepare printing colors Paste, the printing paste viscosity of modulation is 4000CPS.

[0046] Among them, the modified guar gum seed extract (PS-14) was purchased from Italy LAMBERTI (N...

Embodiment 2

[0075] A printing color paste, comprising the following components by mass fraction:

[0076] Printing paste 12%;

[0077] Urea 8%;

[0078] Dye 0.628%;

[0079] Water 79.372%.

[0080] The molecular weight range of the dye is 500-800; the dye is LANASOL yellow 4G 0.56;

[0081] Composition of ERIONYL Turquoise A-G 0.068%.

[0082] The remainder is water;

[0083] The printing paste consists of 18-20% modified guar gum seed extract, 0.8-1.2% preservative and the rest is water.

[0084] The preparation method of the printing paste: after mixing the modified guar gum seed extract, preservative and water according to the mass fraction, the mixer stirred for 50 minutes, and then added 5% H 2 SO 4 , after fully mixing, hydrolyze at 70°C for 2.5 hours, add NaOH to neutralize to pH 6.5-7, and obtain printing paste with a molecular weight of 10,000-15,000 and a paste rate of 20%, which can be directly used to prepare printing paste. The printing paste viscosity is 5000CPS.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com