Cold transfer printing process of fine denier high-density polyester fabric

A cold transfer printing and cold transfer technology, applied in the field of textile and clothing, can solve the problems of thermal migration of disperse dyes in polyester, inability to print by screen printing technology, unstable sublimation fastness, etc., and achieve good anti-velvet effect and excellent color fastness. quality, guaranteed style, and continuous productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A cold-transfer printing process for fine-denier high-density polyester fabrics. The prepared disperse ink is printed on the coating film by a printing machine, and then the transfer film and the fabric are sent to the cold-transfer printing machine; the fabric is cold-transfer printed After the pre-treatment liquid of the machine pre-treatment device is treated, it is tightly bonded with the transfer film and transferred by the cold transfer device to make printed fabrics; the printed fabrics are fixed by high-temperature steaming or baking, and then washed and shaped. Finished printed fabric.

[0024] Among them, the specific operation of cold transfer printing is as follows: by padding the fabric with the pretreatment liquid, the liquid rolling rate is controlled at 40-60%, and the printing surface of the transfer film is contacted with the cloth surface, and the contact is carried out under a transfer pressure of 50-100kg. The time is 1-2min; after the membrane and ...

specific Embodiment 1

[0037] Fabric name: polyester spinning; fabric specification: raw material is polyester 20dtex (FDY)╳20dtex (FDY), density 220╳160 / inch, weight 38g / m2.

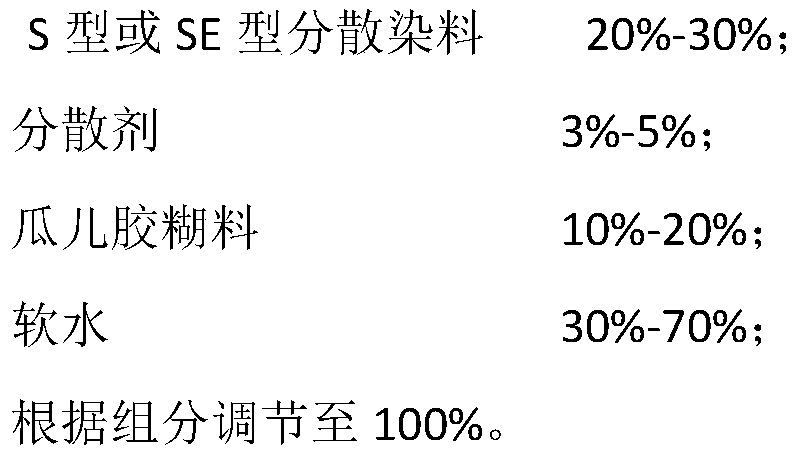

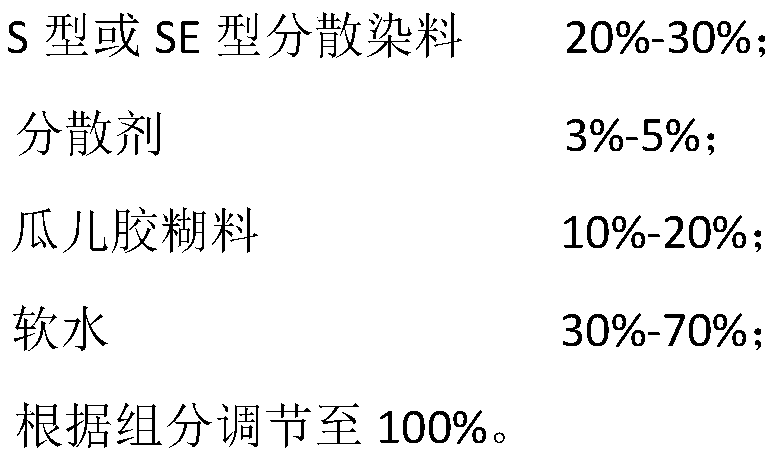

[0038] Disperse dye ink: The total weight of the disperse ink suitable for polyester fine denier high-density fabric cold transfer is 100%. In terms of weight percentage, the components of the disperse dye ink are: 25% disperse dye, 15% guar gum paste, dispersant 5%, adjust to 100% with soft water.

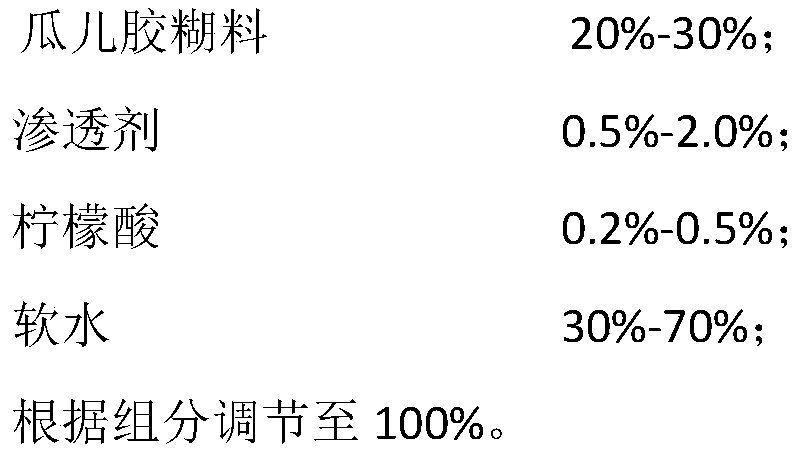

[0039] Pretreatment liquid: the total weight of the pretreatment liquid suitable for cold transfer printing of polyester fine denier high-density fabrics is 100%, and the components of the pretreatment liquid are: 20% of guar gum paste, 2.0% of penetrating agent, Citric acid 0.3%, adjusted to 100% with soft water.

specific Embodiment 2

[0041] Fabric name: polyester crepe; fabric specification: raw material is polyester 30dtex (DTY)╳30dtex (DTY), density 170╳140 / inch, weight 52g / m2.

[0042] Disperse dye ink: The total weight of the disperse ink suitable for polyester fine denier high-density fabric cold transfer is 100%, and the components of the disperse dye ink are as follows: 30% of disperse dye, 14% of guar gum paste, disperse Agent 4%, adjusted to 100% with soft water.

[0043] Pretreatment liquid: the total weight of the pretreatment liquid suitable for cold transfer printing of polyester fine denier high-density fabrics is 100%, and the components of the pretreatment liquid are: guar gum paste 30%, penetrant 1.5%, Citric acid 0.4%, adjusted to 100% with soft water.

[0044] The invention utilizes the cold transfer printing technology to prepare disperse dye ink, print the ink on the transfer material through the gravure printing machine to form a pattern, and transfer the pattern to the fabric at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com