Low-density high-temperature plugging agent as well as preparation method and application thereof

A low-density, plugging agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high density of inorganic plugging agents, low recyclability, reduced foam stability, etc. High temperature, good blocking performance, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

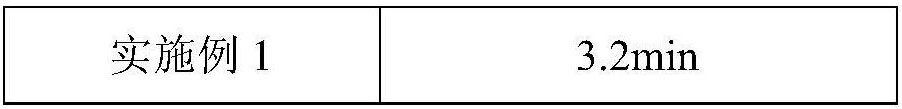

Embodiment 1

[0034] Add 40 parts of water glass and 2 times the volume of distilled water into the reaction vessel, add 30% phosphoric acid solution to adjust the pH to 3 while stirring, add ammonia water to adjust the pH to 6.5 after hydrolysis for 1 hour, stir until the gel precipitates, and let it stand for 2 hours; The ethanol and isopropanol solutions were used for surface modification, and after standing for 24 hours, the gel was press-filtered, dried and pulverized at 65°C, soaked in 80% n-hexane solution for 16 hours, desolvated and dried again. Add the obtained low-density silica powder and 7.5 parts of polypropylene resin powder into a high-speed pre-mixer, mix and stir for 25 minutes, and spray 10% silane coupling agent solution on the mixed material under high-speed stirring, and continue Mix for 30 minutes, and dry at 110° C. for 2 hours to obtain the sample of Example 1.

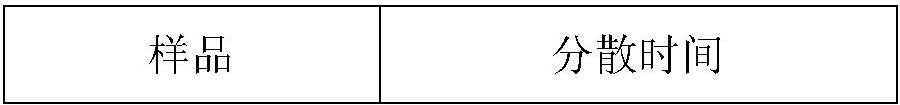

[0035] Test 1: Example 1 Dispersibility Test.

[0036] Measure 50mL of clear water, put it on a magneti...

Embodiment 2

[0068] Add 35 parts of water glass and 2 times the volume of distilled water into the reaction vessel, add 30% phosphoric acid solution to adjust the pH to 2.5 while stirring, add ammonia water to adjust the pH to 6 after hydrolysis for 1 hour, stir until the gel precipitates, and let it stand for 2 hours; The ethanol and isopropanol solutions were used for surface modification, and after standing for 24 hours, the gel was press-filtered, dried and pulverized at 65°C, soaked in 80% n-hexane solution for 16 hours, desolvated and dried again. Add the obtained low-density silica powder and 6.5 parts of polypropylene resin powder into a high-speed pre-mixer, mix and stir for 25 minutes, and spray 10% silane coupling agent solution on the mixed material under high-speed stirring, and continue Mix for 30 minutes and dry at 115°C for 2 hours. Mix the powder obtained by secondary drying with 11 parts of rosin resin to obtain the sample of Example 2.

[0069] Test 1: Example 2 Dispers...

Embodiment 3

[0102] Add 25 parts of water glass and 2 times the volume of distilled water into the reaction vessel, add 30% phosphoric acid solution to adjust the pH to 2 while stirring, add ammonia water to adjust the pH to 5.5 after hydrolysis for 1 hour, stir until the gel is precipitated, and stand for 2 hours; The ethanol and isopropanol solutions were used for surface modification, and after standing for 24 hours, the gel was press-filtered, dried and pulverized at 65°C, soaked in 80% n-hexane solution for 16 hours, desolvated and dried again. Add the obtained low-density silica powder and 4.7 parts of polypropylene resin powder into a high-speed pre-mixer, mix and stir for 25 minutes, and spray 10% silane coupling agent solution on the mixed material under high-speed stirring, and continue Mix for 20 minutes and dry at 120°C for 2 hours. Mix the powder obtained by secondary drying with 3.6 parts of polyethylene powder to obtain the sample of Example 3.

[0103] Test 1: Example 3 Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com