Stator in an electric motor

An electric motor and stator technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing torque fluctuation, torque loss, magnetic flux loss, etc., to reduce magnetic flux loss, simplify manufacturing, reduce The effect of small flux resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The same components are identified in the figures with the same reference numerals.

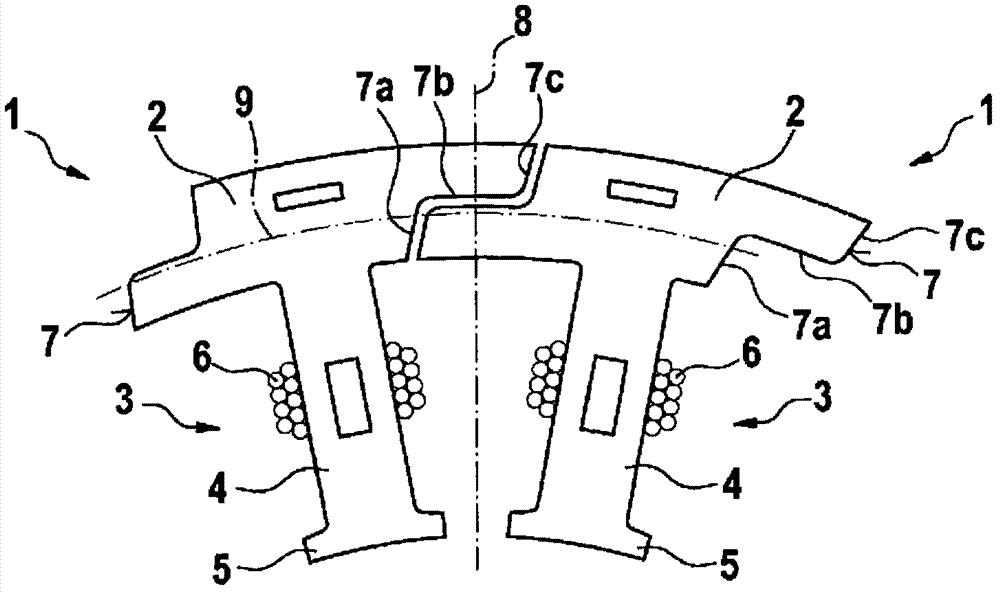

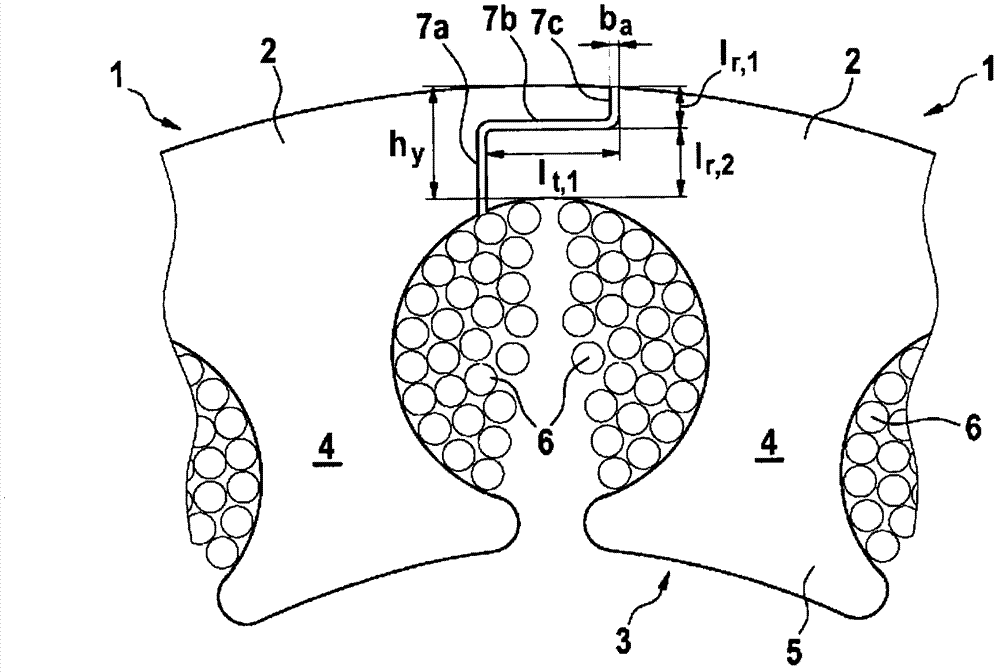

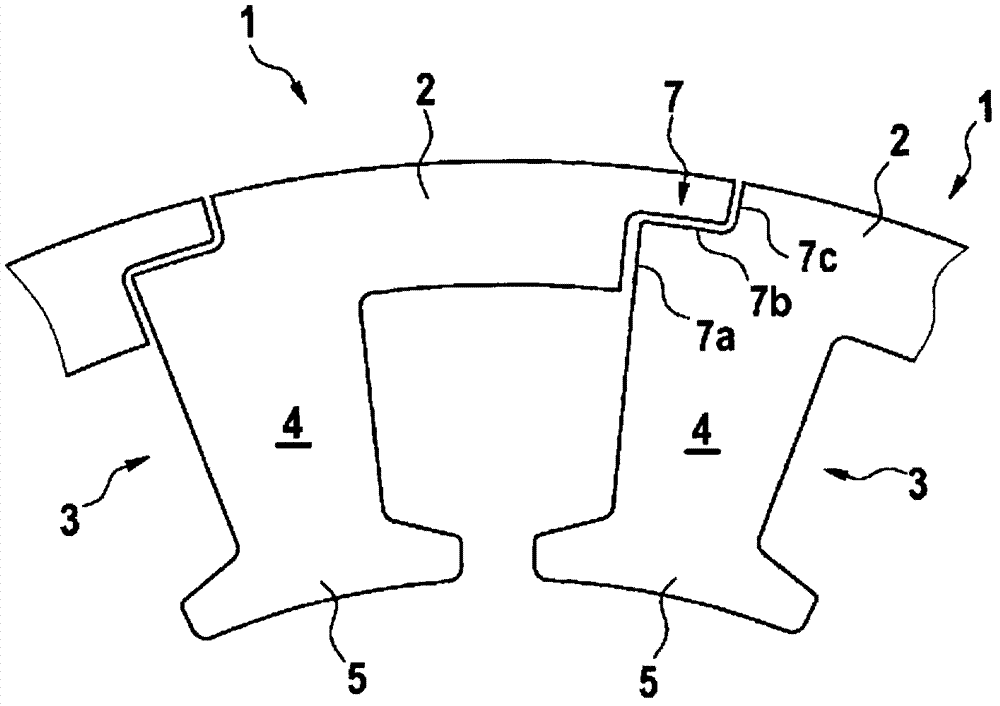

[0027] exist figure 1 Two adjacent tooth segments 1 of a stator for an EC inner rotor electric motor are shown in . Each tooth segment 1 comprises a tangentially extending yoke segment 2 on the radially outer side, and supporting teeth 3 integrally formed with the yoke segment 2 , extending radially inward and respectively accommodating energizable coils 6 . A plurality of such tooth segments 1 are distributed on the circumference and jointly form a continuous stator ring.

[0028] The bearing tooth 3 consists of a radially facing base body 4 and a radially inner tooth crown 5 , wherein a coil 6 is wound around the side surface of the base body 4 , the tooth crown 5 being tangentially wider than the base body 4 and Form the pole shoe. The radial inner side of the tooth crown 5 is arranged directly adjacent to the rotor surrounded by the stator, wherein an annular air gap exists betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com