AI-regulated mixing device for inner and outer ducts of afterburner

A technology of afterburner and connotation, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of uneven mixing, failure to meet the latest afterburner design requirements, fixed structure, etc., and reach the outlet temperature Uniform distribution of speed and speed, reduced loss, reduced pressure loss and flow resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose and effect of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

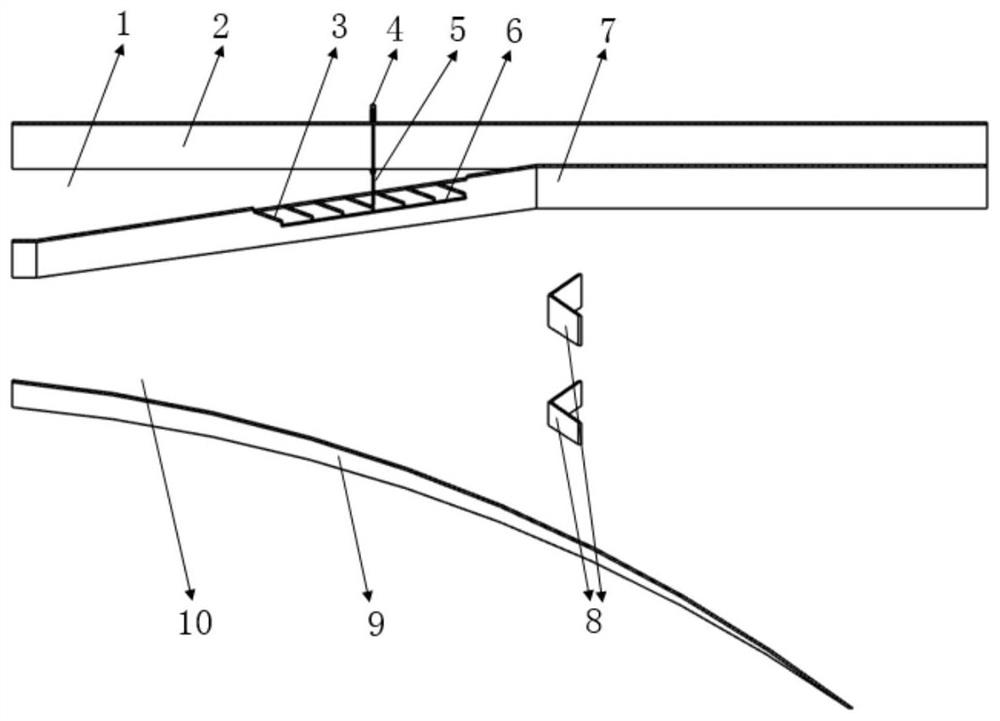

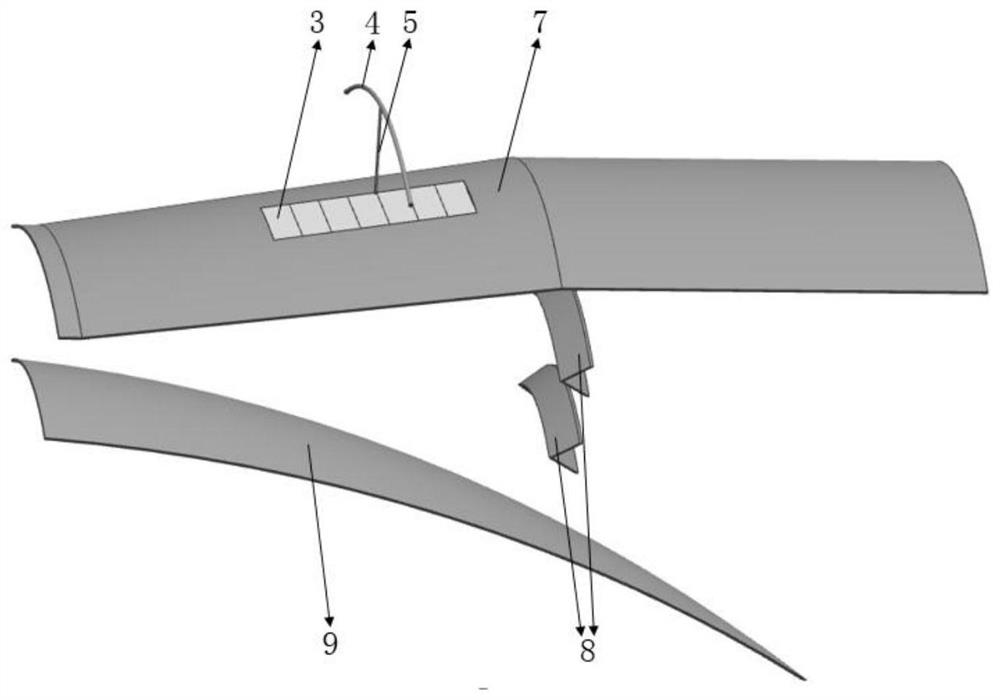

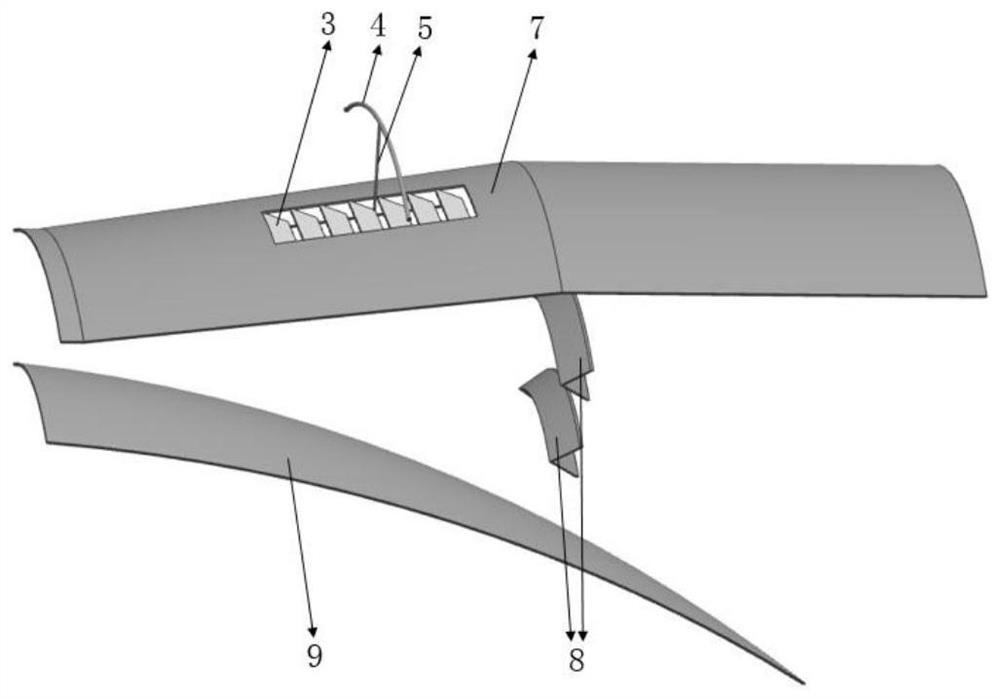

[0032] Such as figure 1 As shown, it is a sectional view of the mixing device inside and outside the afterburner under the control of AI in the present invention. The mixing device is arranged on the wall of the splitter ring 7; the mixing device is a louver structure, including several The mixing device blade 3, the mixing device blade 3 is connected to the connecting rod 6 through the first hinge support 004 at the end, the mixing device blade 3 and the connecting rod 6 form a blade row, and the mixing device blade 3 and the connecting rod 6 form a blade row. The device blade 3 is also connected with the telescopic strut 5 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com