Preparation method of cationic plugging agent for drilling fluid

A cationic, plugging agent technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as formation clay mineral expansion, damage to formation cementation stability, and borehole wall tensile fracture, etc., to achieve sealing Blocking, strong blocking, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

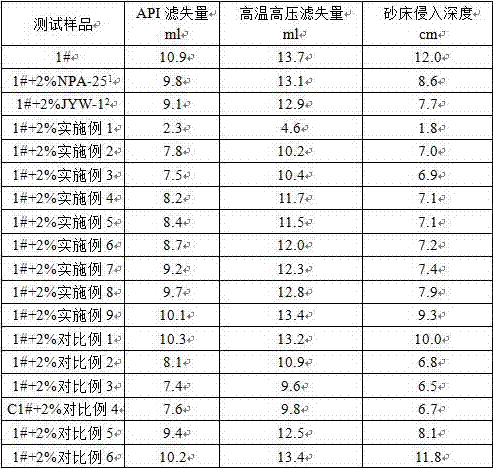

Examples

Embodiment 1

[0010] Dissolve 30 parts of butyl acrylate in a small amount of deionized water, mix with 45 parts of styrene and 30 parts of dimethyl diallyl ammonium chloride, add 52 parts of deionized water to prepare the water phase, add 0.32 parts by weight of emulsifier SDS , OP-10, stir in a shear emulsification mixer at a shear speed of 500r / min for 1h to emulsify and disperse to form an emulsion. Transfer the emulsion into the reaction kettle, add 0.42 parts by weight of regulator while stirring, and raise the temperature. Weigh 0.21 parts by weight of the initiator to prepare an aqueous solution. When the temperature in the reactor reaches 65-80°C, add 0.21 parts by weight of the initiator to the system twice, adjust the stirring speed to 300-400r / min, and keep warm for 6 After ~7h, the material is discharged and cooled to obtain a cationic plugging agent.

[0011] Above-mentioned regulator preparation method is as follows:

[0012] Add 2 parts by weight of phenol, 5 parts by weig...

Embodiment 2

[0014] Exactly the same as Example 1, the difference is: 30 parts of styrene added, 15 parts of butyl acrylate, 15 parts of dimethyl diallyl ammonium chloride, 30 parts of deionized water, 0.18 parts of emulsifier, 0.24 parts of regulator Parts, 0.12 parts of initiator.

Embodiment 3

[0016] Exactly the same as Example 1, the difference is: 45 parts of styrene added, 30 parts of butyl acrylate, 15 parts of dimethyl diallyl ammonium chloride, 45 parts of deionized water, 0.27 parts of emulsifier, and 0.36 parts of regulator Parts, 0.18 parts of initiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com