Patents

Literature

30results about How to "Effective control of molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

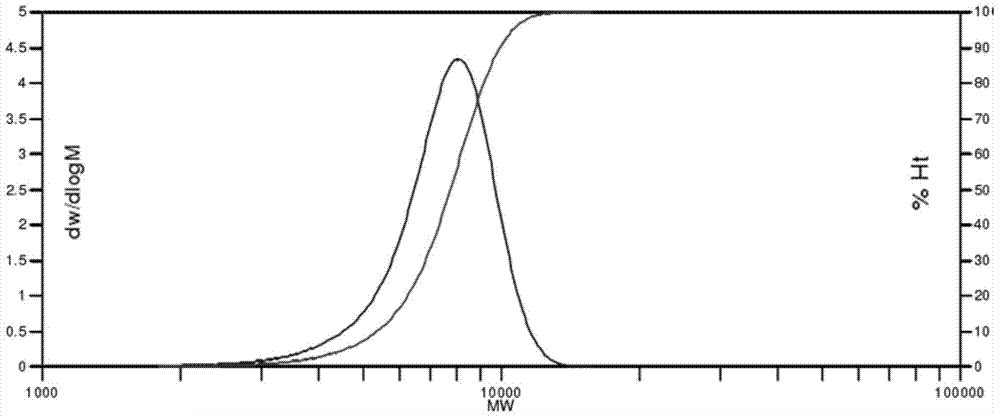

Dissolving pulp sodium lignosulfonate dispersant, and reducing preparation method and application thereof

ActiveCN102441339AHigh activityEffective control of molecular weightTransportation and packagingMixingCoal waterSodium lignosulfonate

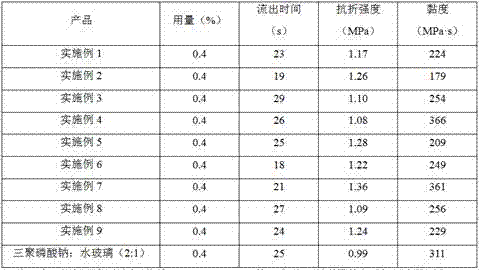

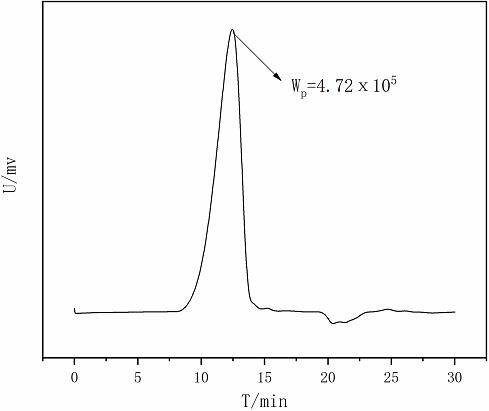

The invention discloses a dissolving pulp sodium lignosulfonate dispersant, and a reducing preparation method and application thereof. Based on a concentrated dissolving pulp waste liquid, the lignose activity is improved under the action of a catalyst, then subjected to sulfomethylation reaction, subjected to reducing reaction to obtain a brownish-black or dark brown liquid, and subjected to spray drying to obtain a dark brown or nut-brown powdered sodium lignosulfonate dispersant, wherein the weight-average molecular weight Mw is 6000-40000, and the number-average molecular weight Mn is 3000-20000. The product can be widely used for concrete admixtures, dye dispersants and coal water slurry additives; each property of the product can meet the related quality standard requirements; and the product has the advantages of simple preparation process, moderate conditions, conventional equipment, low production cost and no emission of three wastes in the production process, and can achieve the purpose of changing wastes into valuables, thereby having popularization and application values.

Owner:FUZHOU UNIVERSITY

Method for preparing hexafluoropropylene oxide oligomer

InactiveCN104513390AEffective control of molecular weightImprove conversion rateProduction effectBiological activation

The invention discloses a method for preparing hexafluoropropylene oxide oligomer. Alkali-metal fluoride salt, aprotic inertia polarity organic solvents, fluorine-containing organic solvents and perfluoro(2-methyl-3-oxahexanoyl)fluoride are used for preparing a homogeneous activation initiator, the homogeneous activation initiator is used for initiating a hexafluoropropylene oxide monomer to have a polymerization reaction, and then the hexafluoropropylene oxide oligomer with a high molecular weight is obtained. Meanwhile, a part of products and related solvents are recycled, and an environment-friendly recycle production effect is achieved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Extraction and preparation method of small molecular fish skin collagen peptide

InactiveCN109486891AIncrease the speed of enzymatic hydrolysisReduce dosageConnective tissue peptidesPeptide preparation methodsPeptideChemistry

The invention discloses an extraction and preparation method of small molecular fish skin collagen peptide. The extraction and preparation method comprises the following steps: preparing raw materials, carrying out enzymolysis pre-treatment, carrying out enzymolysis treatment and the like. According to the extraction and preparation method of the small molecular fish skin collagen peptide, provided by the invention, fish skin is firstly subjected to degreasing treatment and then is subjected to the enzymolysis treatment; and in an enzymolysis treatment process, various types of different proteinases are used for carrying out enzymolysis on the fish skin, so that the enzymolysis speed can be improved, the dosage of the proteinase also can be reduced, and the yield of the small molecular fish skin collagen peptide can be effectively improved. According to the extraction method provided by the invention, modified activated carbon is used for de-coloring, the adsorption performance is excellent and enzymolysis liquid can be uniformly distributed; good de-coloring and deodorization effects can be realized under the conditions of small dosage and short time and effective components are not lost; and the extraction method has the advantages of low investment, simplicity in operation, good protein degradation effect and high yield of the fish skin collagen peptide, the industrial large-scale production is easy to realize and the extraction method has good application value and market potential.

Owner:GUANGDONG OCEAN UNIVERSITY

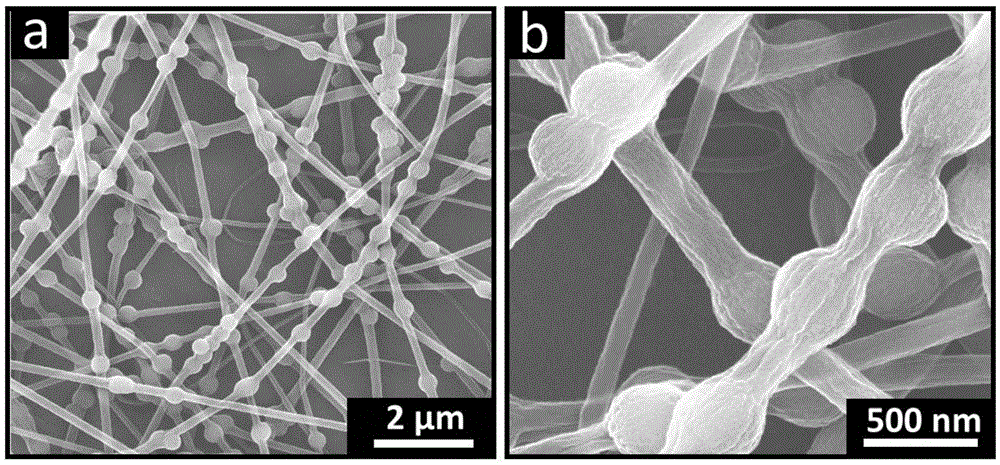

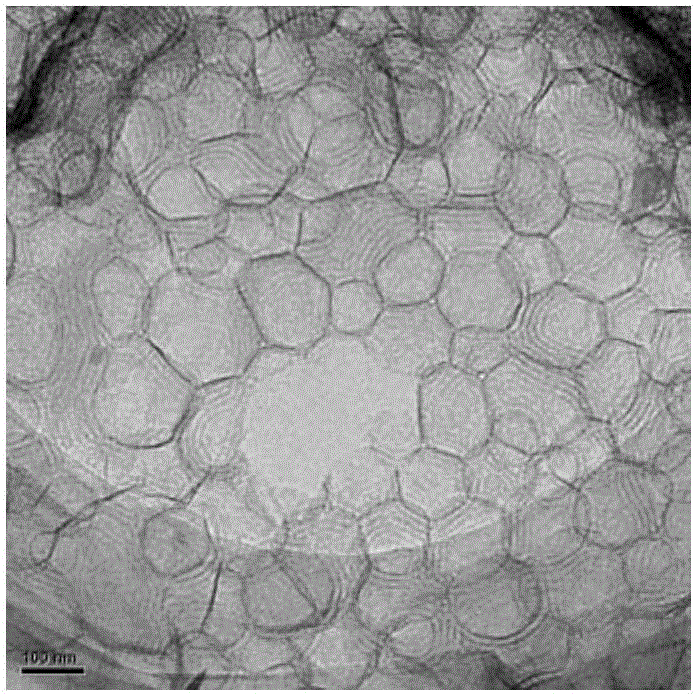

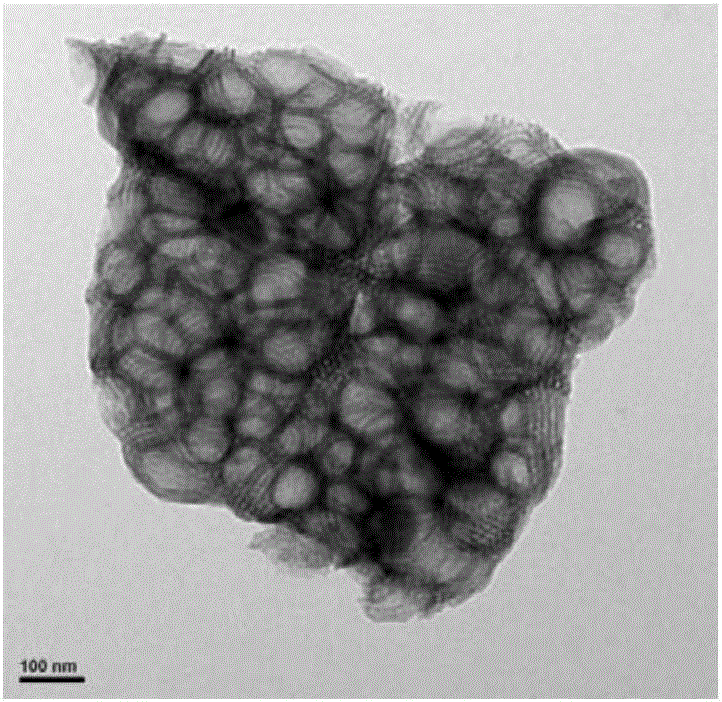

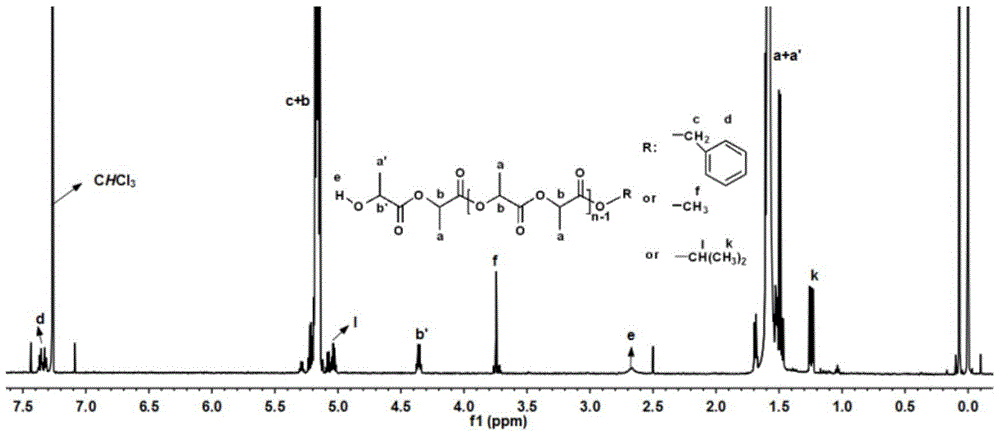

A kind of preparation method of beaded nanofiber

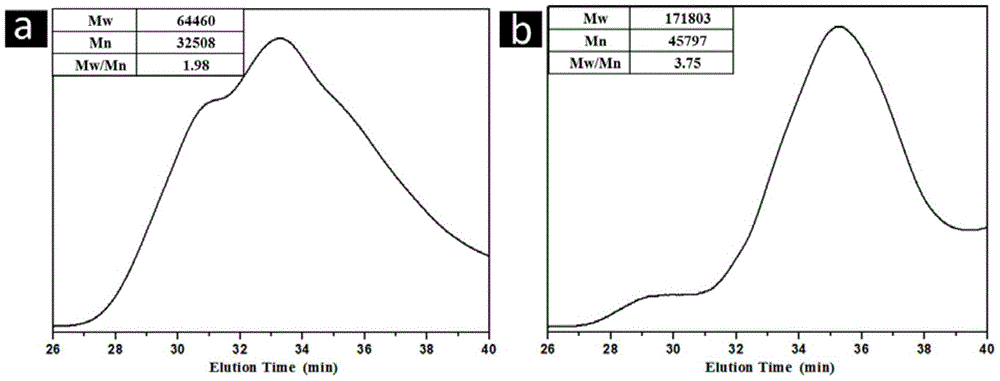

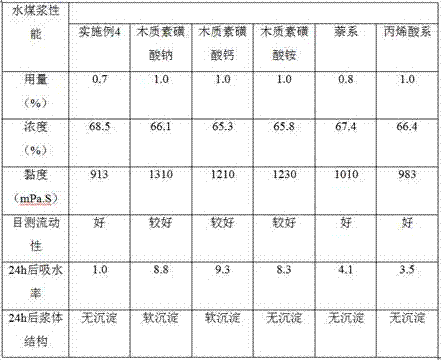

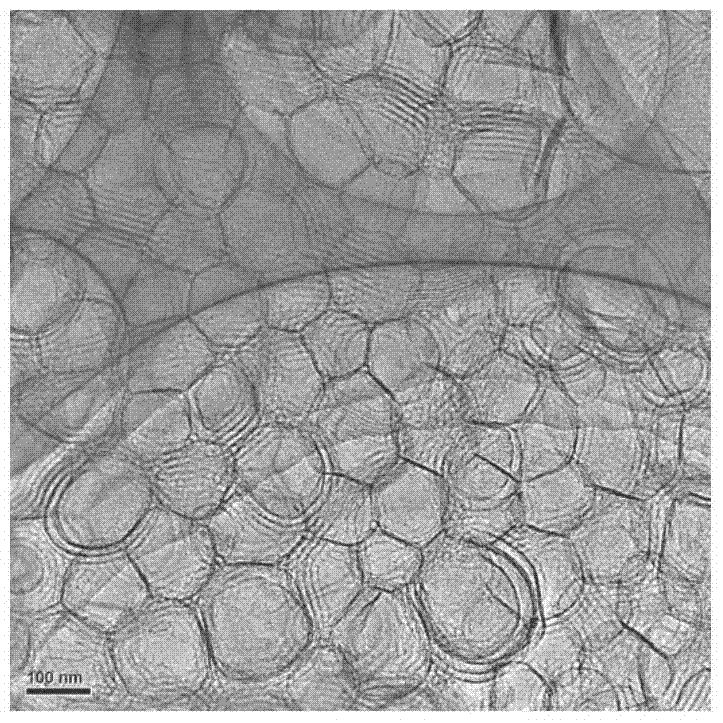

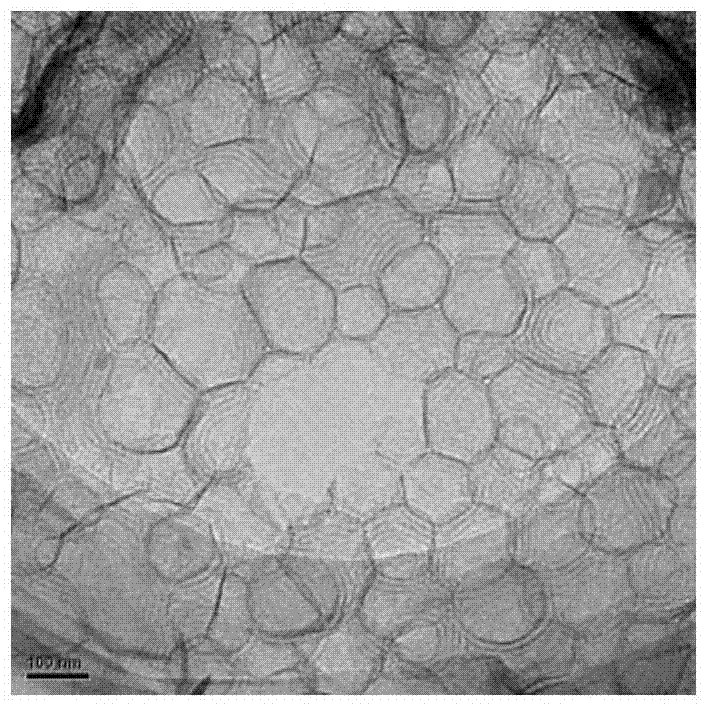

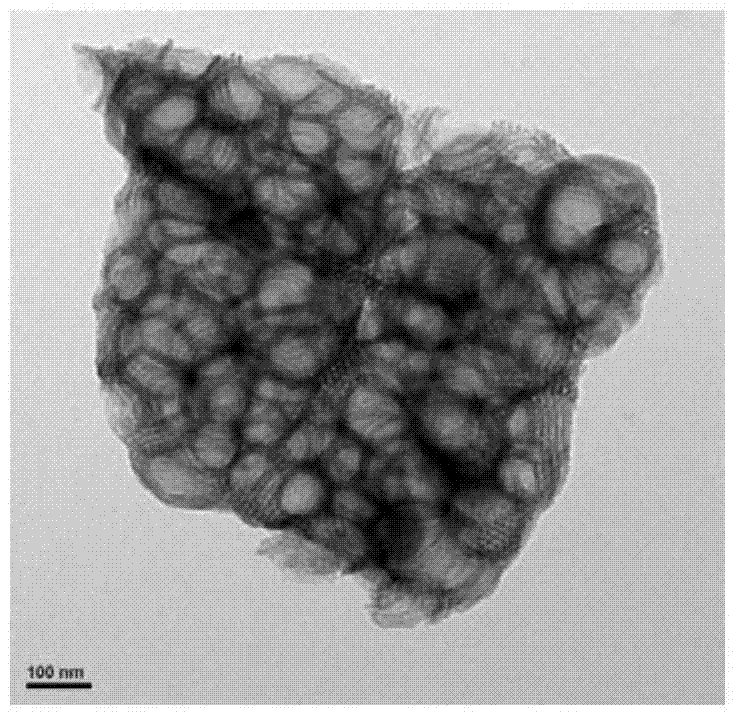

ActiveCN103643337BEffective control of molecular weightGood dispersionFilament/thread formingMonocomponent synthetic polymer artificial filamentElectrospinningNanofiber

The invention discloses a preparation method of a beaded nanofiber, and belongs to the field of preparation of nanofibers. The method comprises the following steps: firstly, grafting functional groups on inorganic nanoparticles; grafting a high-molecular polymer on the surfaces of the functional inorganic nanoparticles by a chemical polymerization method; and finally, preparing the beaded organic / inorganic nanoparticle fiber by adopting an electrospinning technique. The nanofiber prepared by the method has the advantages that the fiber structure is controllable, the nanoparticles are evenly dispersed in the fiber, the nanoparticle and the polymer interfaces are well combined and the like, the problems that positions of the inorganic nanoparticles are uncontrollable, the nanoparticles are seriously agglomerated, interface combination between an organic phase and an inorganic phase is poor and the like in an organic / inorganic nanoparticle fiber prepared by adopting the traditional method are solved, and a new idea and a new method are provided for preparation of the nanofiber containing the inorganic nanoparticles.

Owner:BEIJING UNIV OF CHEM TECH

Orthopaedic internal fixation fibroin component and preparation method thereof

ActiveCN108126247AStable alkalineSo as not to damageChemical industrySurgeryFreeze-dryingBiocompatibility Testing

The invention discloses an orthopaedic internal fixation fibroin component and a preparation method of the component. The preparation method comprises the steps of: 1, performing desalination by a diffusion dialysis-electrodialysis integrated technology to prepare a high-purity fibroin solution, 2, converting the fibroin solution into anhydrous fibroin by a vacuum freeze drying technology, 3, dissolving the anhydrous fibroin in hexafluoroisopropanol to form a hexafluoroisopropanol solution of the fibroin, 4, injecting the hexafluoroisopropanol solution of the fibroin into a mold to prepare a fibroin solid by a methanol treatment and airing technology, and 5, machining the fibroin solid into a bone nail and a bone plate. The orthopaedic internal fixation fibroin component prepared by adjusting molecular weight, molecular distribution, crystallization forming parameters and processing parameters has excellent mechanical strength and biocompatibility, is not required to be taken out by secondary operations, is controllable in a degradation rate and free from toxic and immunological rejection effects, and has wide clinical application prospects, and degradation products are amino acidand polypeptide capable of being absorbed by a human body.

Owner:GUANGZHOU ANZE REGENERATIVE MEDICINE TECH CO LTD

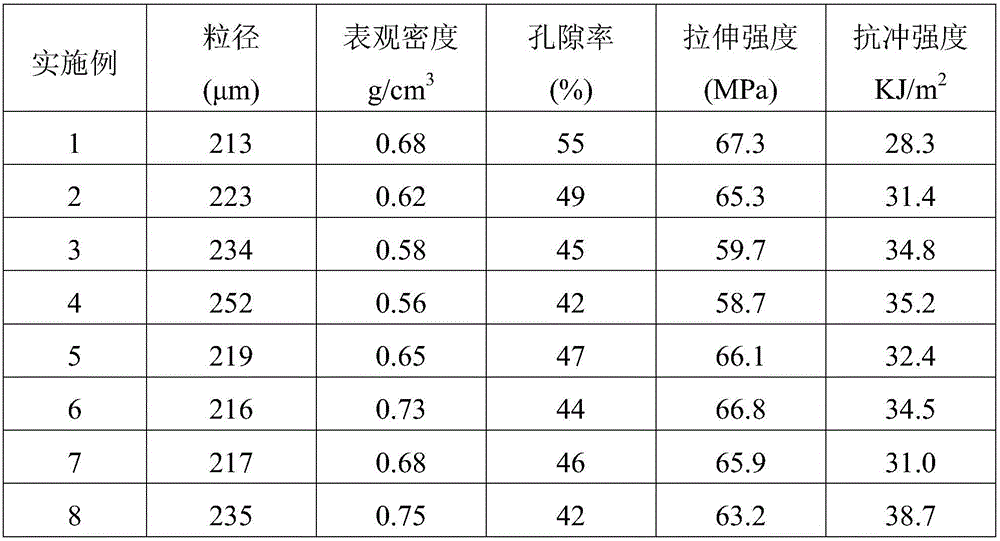

Preparation method of shock-resistant vinyl chloride copolymer resin

Owner:广州飞粤新材料有限公司

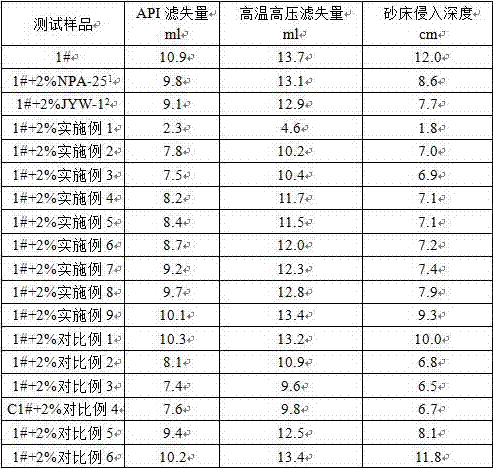

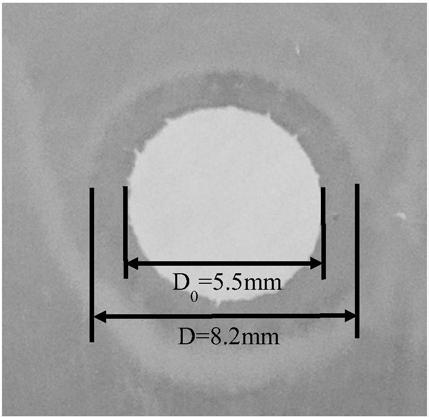

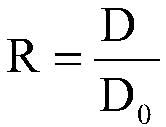

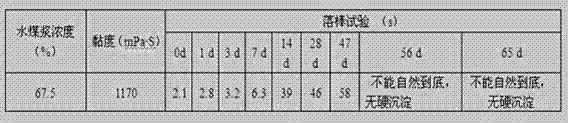

Preparation method of cationic plugging agent for drilling fluid

ActiveCN107501456AEasy accessEffective control of molecular weightDrilling compositionFiltrationEmulsion polymerization

The invention discloses a preparation method of a cationic plugging agent for a drilling fluid. The cationic plugging agent is prepared by emulsion polymerization from raw materials in parts by weight as follows: 30-90 parts of styrene, 5-75 parts of butyl acrylate and 15-75 parts of dimethyl diallyl ammonium chloride. Monomers are initiated by an initiator to be subjected to a polymerization reaction, and the cationic plugging agent with the macromolecular chain is obtained; with addition of a small quantity of the product to the drilling fluid, the filtration loss of the drilling fluid and the invasion depth in the sand bed can be effectively reduced, plugging of underground pore cracks is realized, and drilling safety is guaranteed.

Owner:XUZHOU NORMAL UNIVERSITY

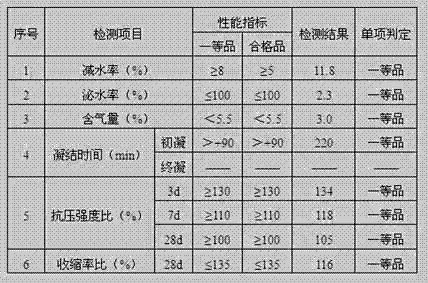

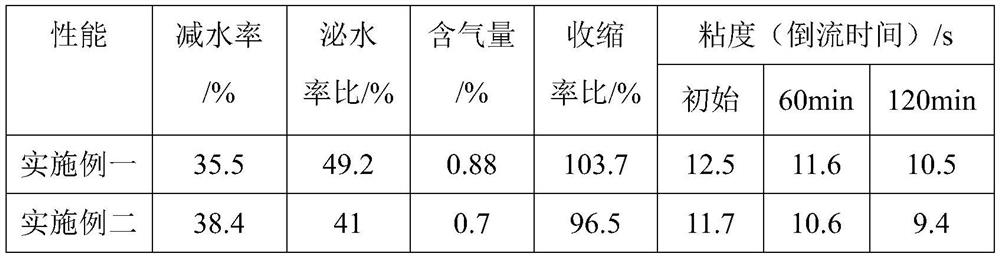

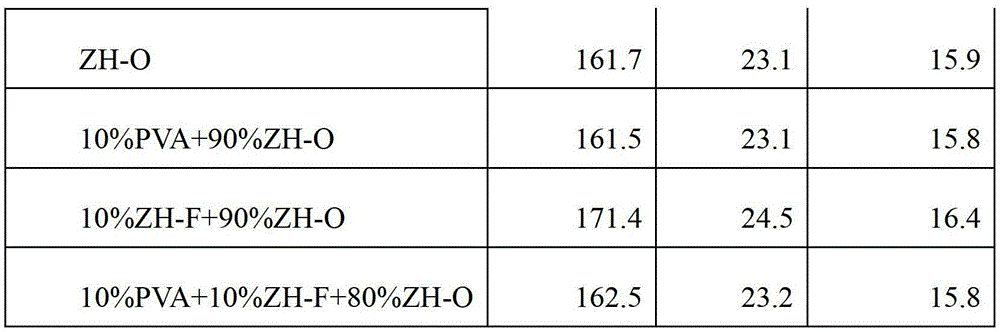

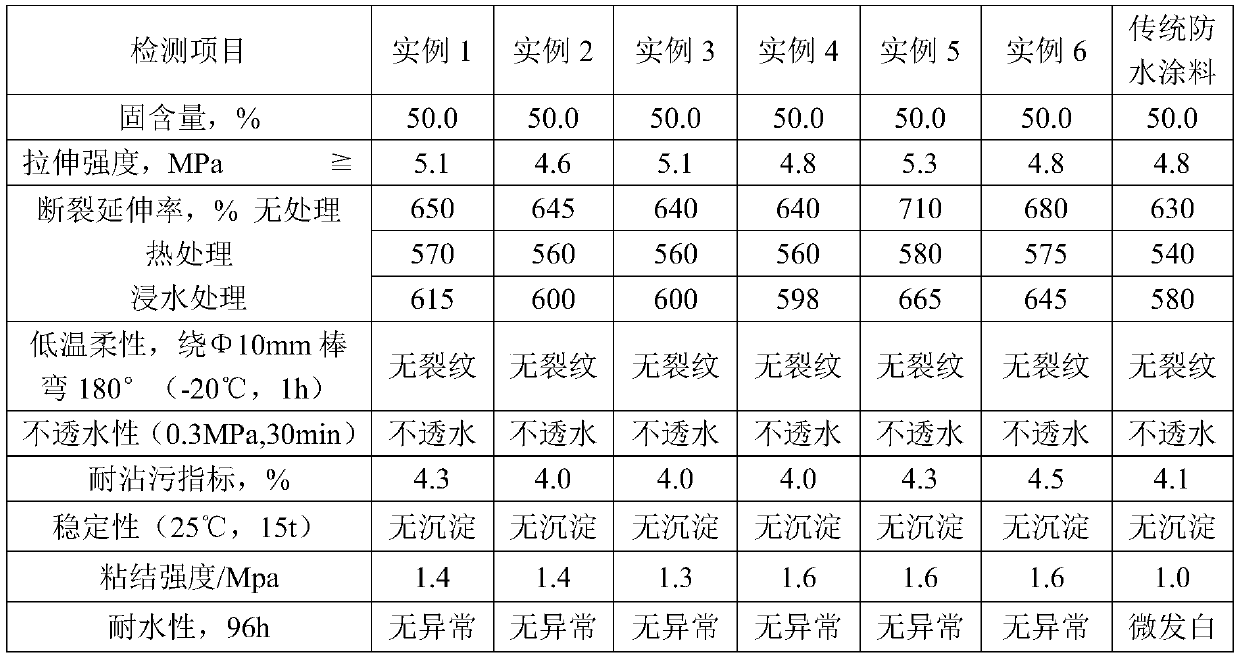

Water reducing agent for high-strength concrete and preparation method thereof

The invention belongs to the technical field of concrete admixtures, in particular to a high-strength concrete water reducer and a preparation method thereof. The problems of complex preparation process and high cost of the high-performance water reducing agent and high viscosity and poor volume stability of concrete in the prior art are solved; the water reducing agent for the high-strength concrete is prepared from the following raw materials: acrylic acid, a chain transfer agent, ammonium persulfate, methoxy polyethylene glycol, polyethylene glycol ether, 1,3-dimethylimidazole methyl sulfate, sucrose fatty acid ester, carbon fiber powder, a defoaming agent and sodium hydroxide. The water reducing agent prepared by the invention has high water reducing rate and good fluidity and permeability; the concrete admixture has the advantages of low consumption, obvious improvement of the dispersion effect of concrete particles, improvement of the bonding strength among the concrete particles, improvement of the mechanical properties and the mechanical properties of concrete, and good wear resistance and corrosion resistance.

Owner:BOZHOU WOYE INTPROP SERVICE CO LTD

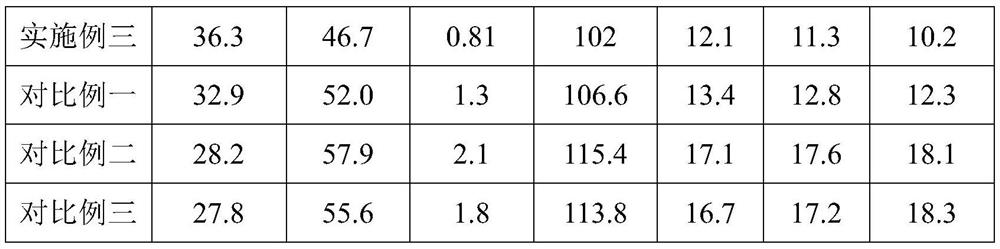

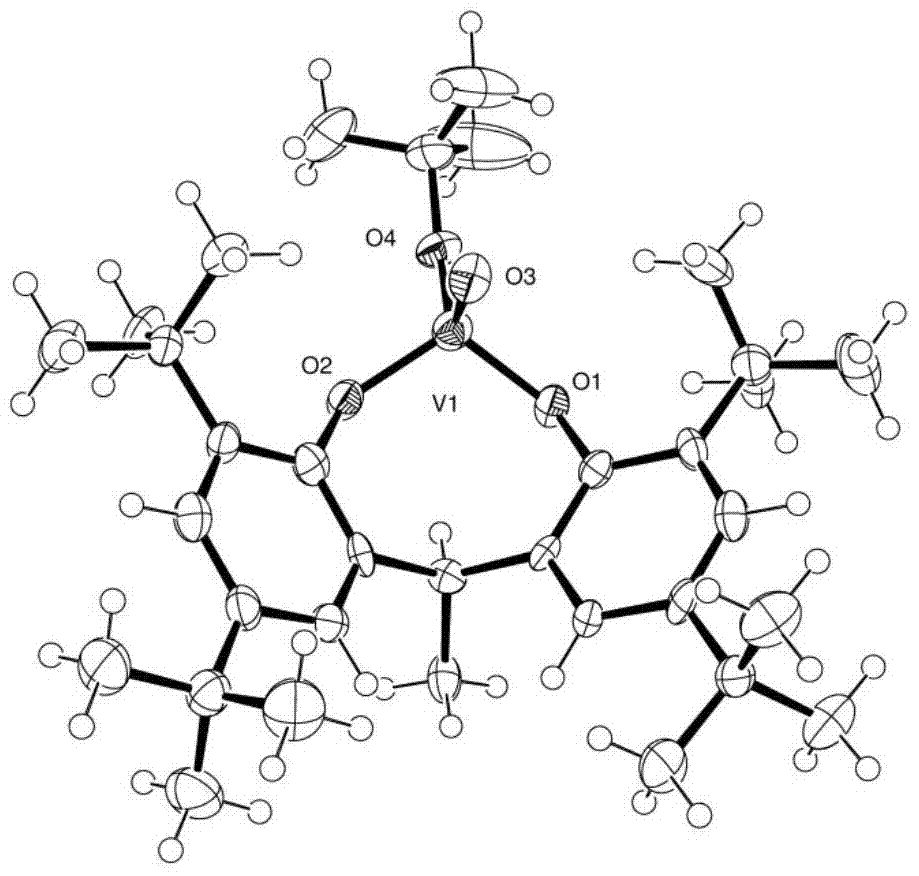

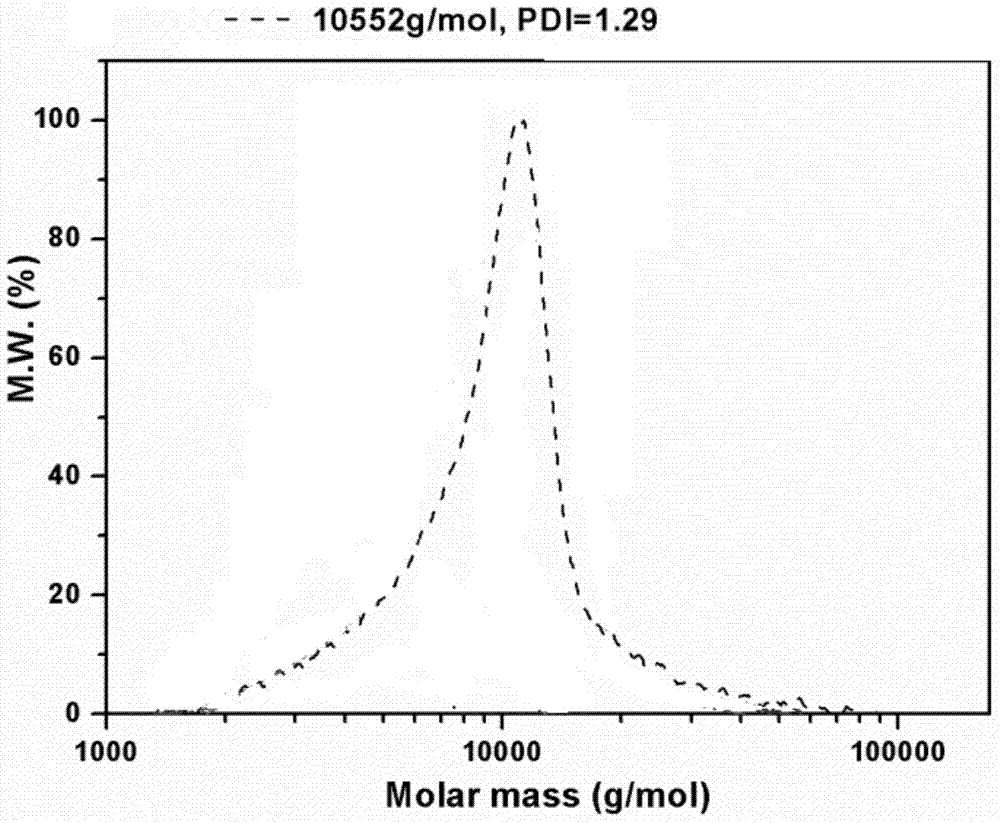

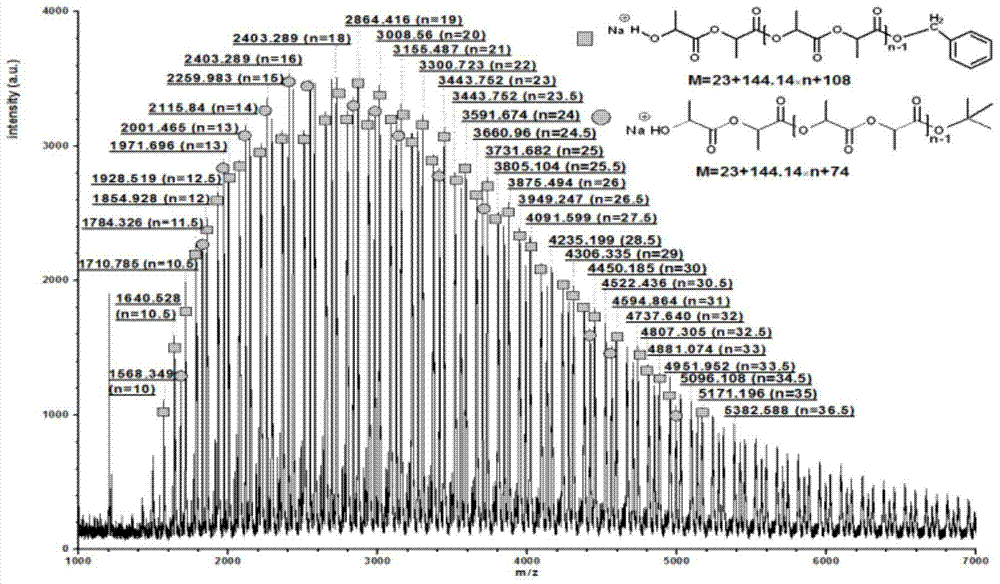

Binuclear vanadium complex, and preparation method and application thereof

ActiveCN105037415AEasy to prepareShorten the timeGroup 5/15 organic compounds without C-metal linkagesPolymerWeight distribution

The present invention provides a binuclear vanadium complex shown as formula I, and also provides a preparation method and application of the complex. The binuclear vanadium complex has the advantages of simple preparation method, low toxicity, high catalytic activity and narrow molecular weight distribution; and the method can effectively control the molecular weight of the polymer according to the needs, and has a broad market prospect.

Owner:ASTATECH CHENGDU BIOPHARM CORP

Bio-based reactive polyurethane hot melt adhesive and preparation method thereof

PendingCN113736416AImprove performanceWith green and environmental protection attributesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a bio-based reactive polyurethane hot melt adhesive and a preparation method thereof. The bio-based reactive polyurethane hot melt adhesive comprises the following components in parts by weight: 40-80 parts of bio-based polyester glycol; 15 to 35 parts of polyether polyol; 10 to 25 parts of polyisocyanate; 0.1 to 2 parts of an antioxidant; 0.1-2 parts of a first catalyst; 0-35 parts of thermoplastic resin; 0-5 parts of a silane coupling agent; and 0-10 parts of an auxiliary agent; the bio-based polyester glycol is polyester glycol with the number-average molecular weight of 1500-5000, which is synthesized by using micromolecular diol as an initiator and carrying out random copolymerization on lactide and caprolactone under the action of a second catalyst. According to the present invention, the bio-based raw material is adopted to prepare the polyester glycol, and the polyester glycol is applied to the reaction type polyurethane hot melt adhesive, such that the high-performance environment-friendly adhesive can be green and environmentally friendly, and the advantages of good mechanical property, good bonding strength, excellent heat resistance and the like can be ensured.

Owner:XIAMEN WELDTONE TECH CO LTD

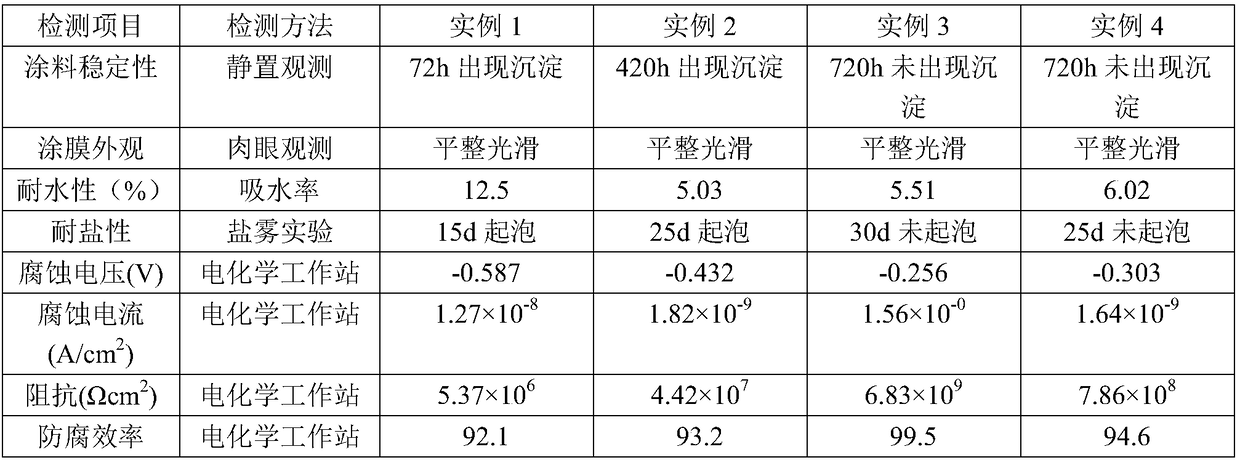

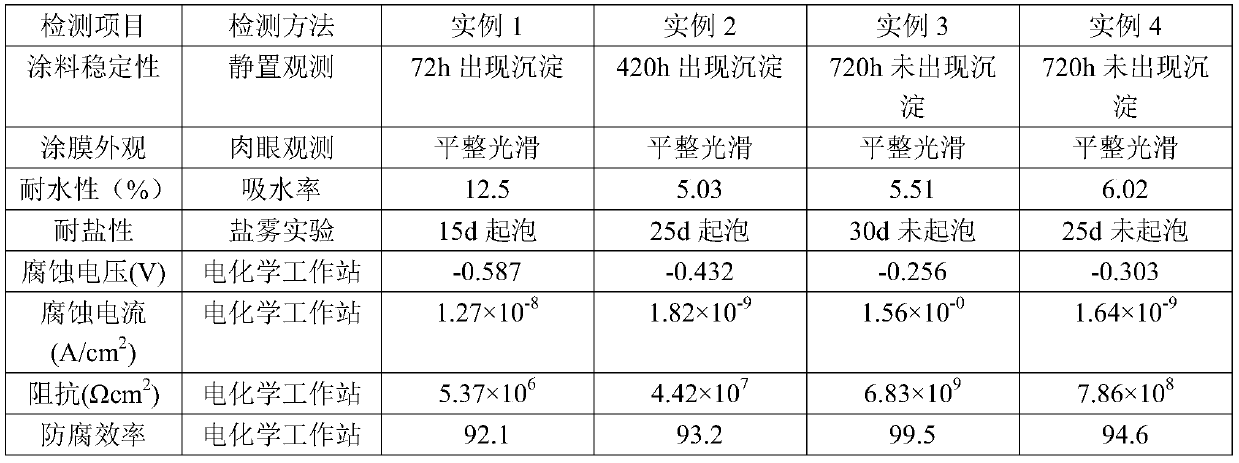

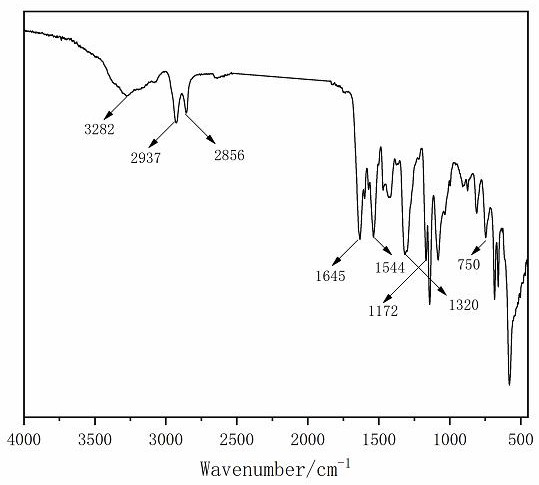

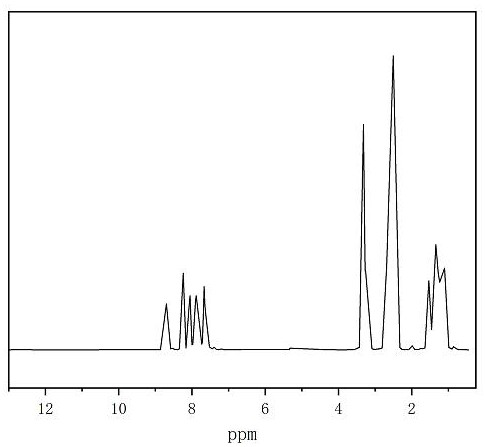

Preparation method for modified aniline terpolymer/water-based resin composite anti-corrosive coating

ActiveCN108531053AGood water dispersibilityGood dispersionAnti-corrosive paintsPolyester coatingsWater basedEpoxy

The invention discloses a preparation method for a modified aniline terpolymer / water-based resin composite anti-corrosive coating. The method comprises the following steps: a microemulsion polymerization method is adopted, aniline, o-hydroxyaniline and p-phenylenediamine are used as monomers, APS (ammonium persulfate) is used as an oxidant, and therefore an aniline-o-hydroxyaniline-p-phenylenediamine terpolymer with good water dispersibility is prepared under the action of an acid dopant and a surfactant having a sulfonic acid group; and water-based alkyd resin is used as a substrate, a modified polyaniline aqueous dispersion liquid is used as an additive, a mixed manner of ultrasonic treatment and mechanical stirring is utilized, and therefore the water-based alkyd resin / polyaniline composite heavy anticorrosive coating is prepared. The preparation method disclosed by the invention has the advantages of being friendly to the environment and convenient to operate, and having no pollution and low costs; and the prepared modified aniline terpolymer can also be compounded with other water-based resin substrates such as water-based epoxy resin, water-based polyurethane resin and water-based polyacrylate resin to prepare the composite anticorrosive coating.

Owner:SHAANXI UNIV OF SCI & TECH

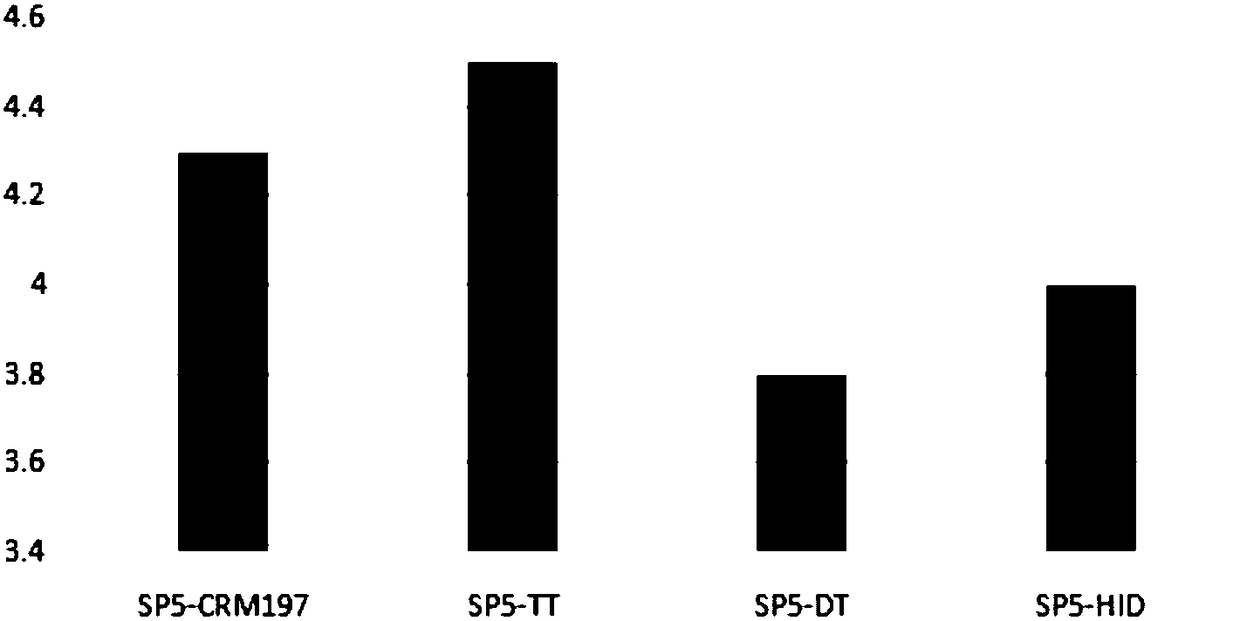

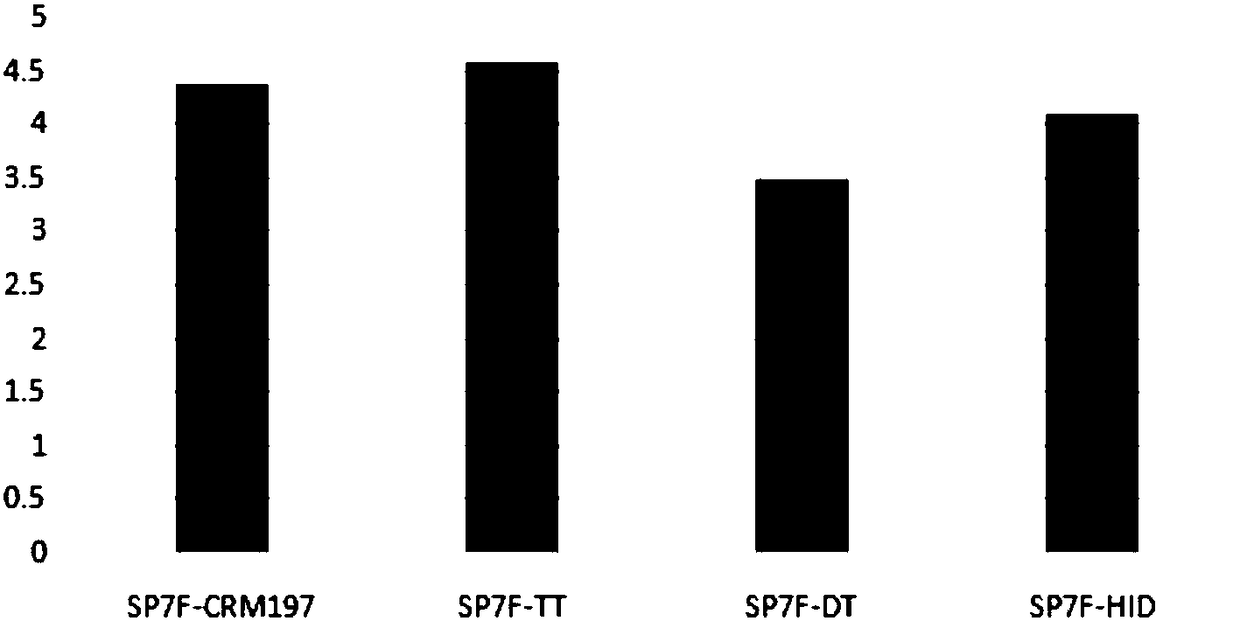

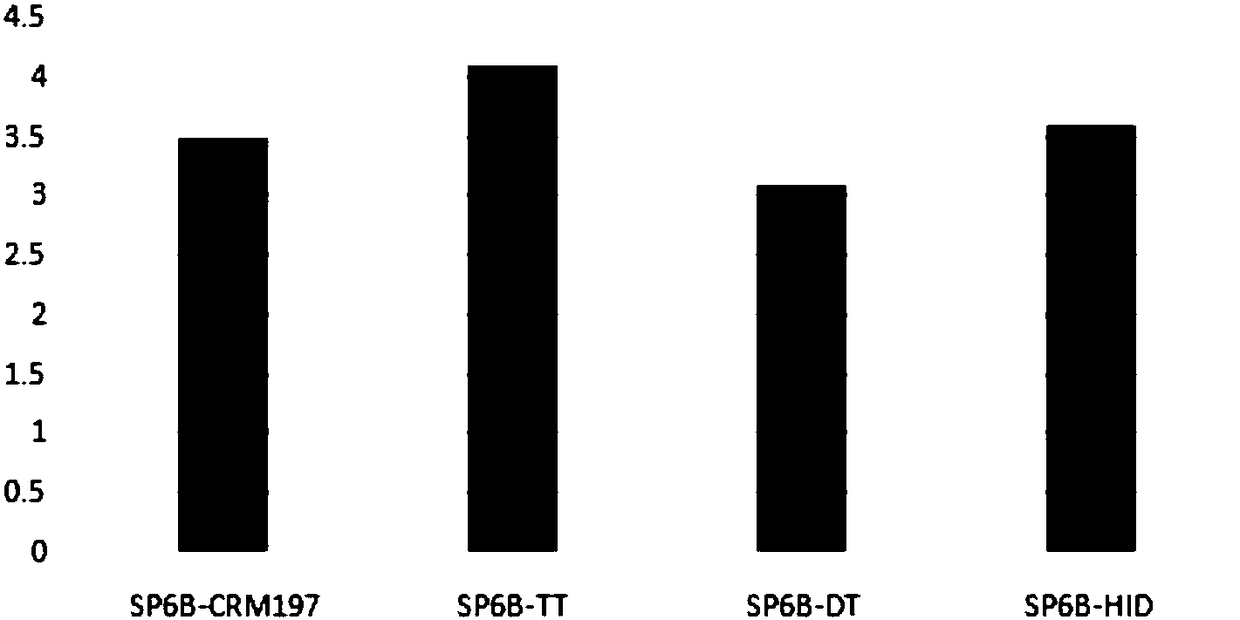

Preparation combination of multivalence pneumococcal conjugate vaccine and application thereof

ActiveCN108524926AResolving Serum InhibitionEffective control of molecular weightAntibacterial agentsBacterial antigen ingredientsSerum igeDisease

The invention provides a preparation combination of multivalence pneumococcal conjugate vaccine, a preparation method thereof and application in medicine preparation for preventing and treating diseases caused by pneumococcus. The invention further discloses a control method for conjugate molecular weight in the preparation combination of the multivalence pneumococcal conjugate vaccine. The seruminhibition problem in the multivalence pneumococcal conjugate vaccine is solved by the provided pneumococcal conjugate vaccine, and the immunogenicity in the preparation combination can be effectivelyimproved. The preparation method for the preparation combination of the multivalence pneumococcal conjugate vaccine can effectively control the molecular weight in the conjugate, and free protein andfree polysaccharide which do not join in conjugation can be easily removed.

Owner:CANSINO BIOLOGICS INC

Method for preparing low-molecular-weight guar gum

InactiveCN101544704BEffective control of molecular weightMolecular weight controllableProcess equipmentFreeze-drying

The invention discloses a method for preparing low-molecular-weight guar gum, which comprises the following steps: irradiating guar gum hydrosol with 200-450-nanometer ultraviolet light; and obtaining solid low-molecular-weight guar gum through freeze-drying, spray drying or ethanol precipitation filtration drying. The method can obtain an oligosaccharide (a polysaccharide consisting of 2 to 10 sugar units), has the advantages of simplicity, convenience and quickness, high yield, easily-controllable molecular weight, good reproducibility, simple process equipment, safety and no pollution, lowcost and the like, and can be applied to rapid preparation of a small amount of low-molecular-weight guar gum, and can be further industrialized and applied to the production of a large amount of low-molecular-weight guar gum. The obtained product can be used for the production of foods and health products, and can also be used as medicine and chemical raw materials.

Owner:武汉拓扑科技发展有限公司

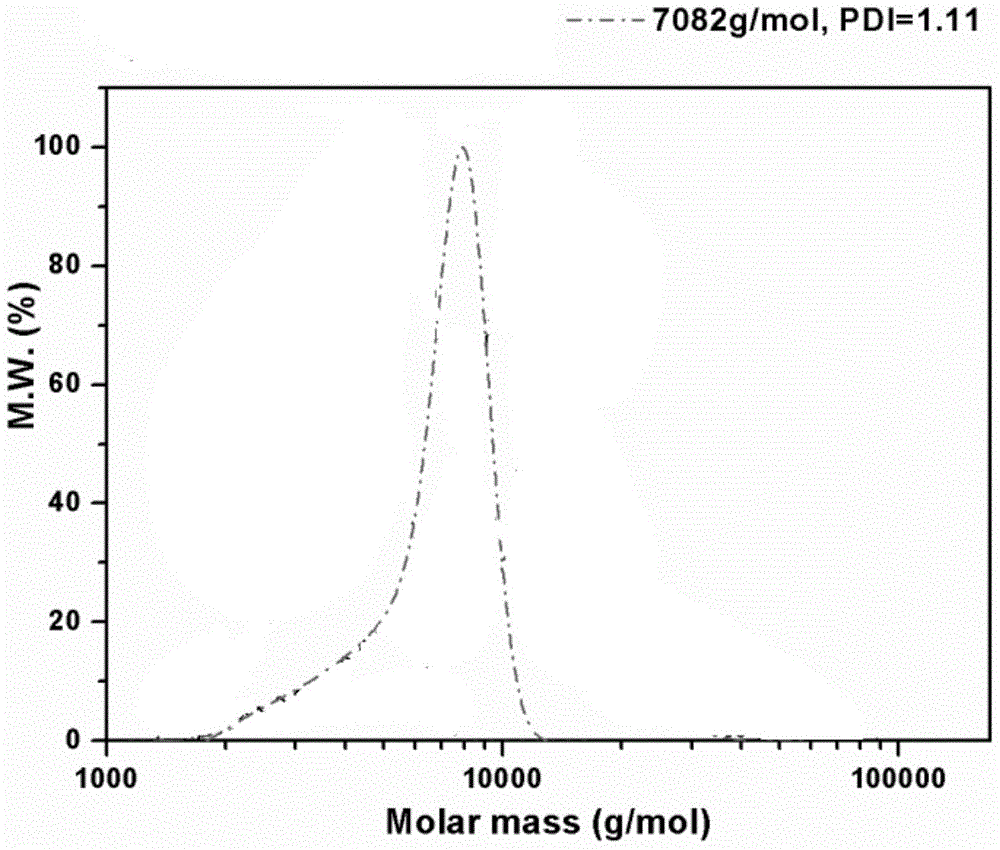

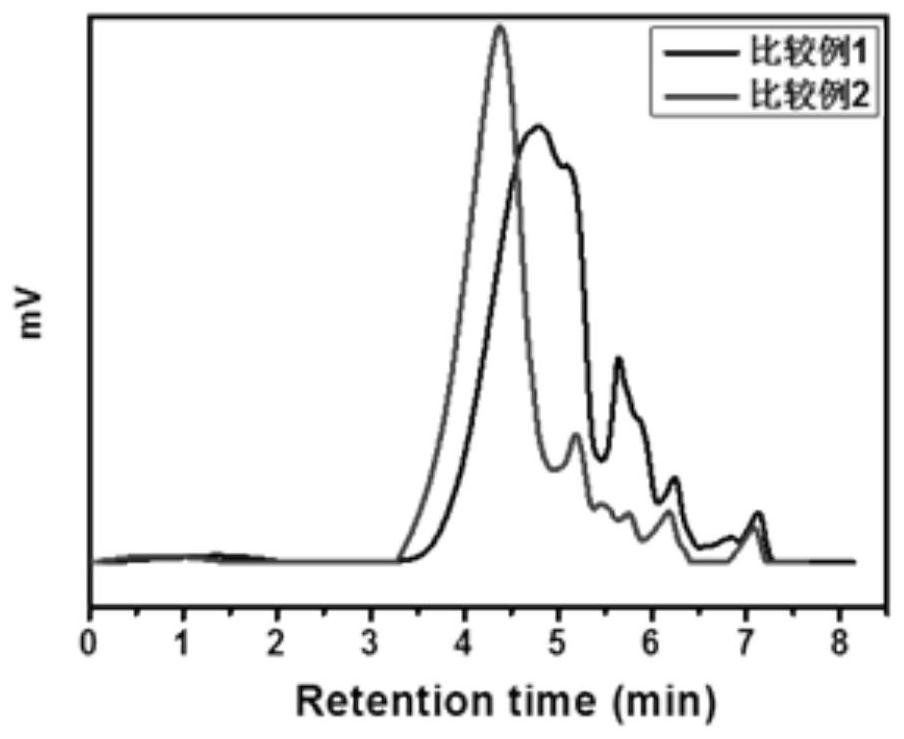

Grafted copolymer, grafted copolymer/silver nanocomposite and preparation method thereof

ActiveCN109134868AEffective control of the numberEffective control of molecular weightPolymer sciencePolyvinyl alcohol

The invention relates to the field of synthesis and preparation of high polymer materials, and provides a grafted copolymer, a grafted copolymer / silver nanocomposite and a preparation method thereof.According to the grafted copolymer, polyvinyl alcohol or an ethylene-vinyl alcohol copolymer is adopted as a main chain, and polyisobutene is adopted as a branch chain; the main chain and the branch chain are in keyed joint in a grafted mode; the absolute weight-average molecular weight of the grafted copolymer ranges from 80 kg / mol to 700 kg / mol, and on the basis that the total mass of the grafted copolymer is 100%, the mass percentage content of polyisobutene as the branch chain ranges from 15% to 95%, and the grafting density ranges from 0.2% to 19%. According to the grafted copolymer, thegrafted copolymer / silver nanocomposite and the preparation method thereof, the number of the branch chain and the molecular weight of the branch chain are effectively controlled, the water contact angle of the composite ranges from 28 degrees to 110 degrees, the hydrophily / hydrophobicity is adjustable, and the antibacterial property, the biocompatibility and cell nontoxicity are achieved.

Owner:北京引发科技有限公司 +1

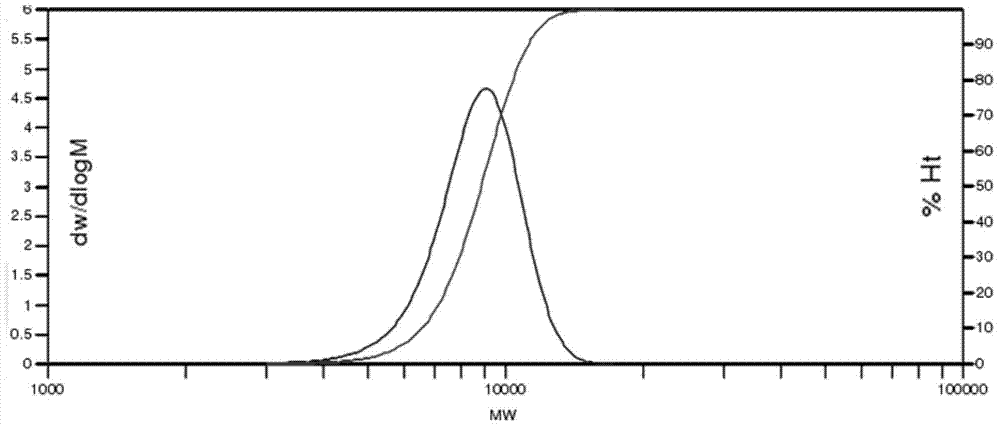

Dissolving pulp sodium lignosulfonate dispersant, and reducing preparation method and application thereof

ActiveCN102441339BHigh activityEffective control of molecular weightTransportation and packagingMixingCoal waterPtru catalyst

The invention discloses a dissolving pulp sodium lignosulfonate dispersant, and a reducing preparation method and application thereof. Based on a concentrated dissolving pulp waste liquid, the lignose activity is improved under the action of a catalyst, then subjected to sulfomethylation reaction, subjected to reducing reaction to obtain a brownish-black or dark brown liquid, and subjected to spray drying to obtain a dark brown or nut-brown powdered sodium lignosulfonate dispersant, wherein the weight-average molecular weight Mw is 6000-40000, and the number-average molecular weight Mn is 3000-20000. The product can be widely used for concrete admixtures, dye dispersants and coal water slurry additives; each property of the product can meet the related quality standard requirements; and the product has the advantages of simple preparation process, moderate conditions, conventional equipment, low production cost and no emission of three wastes in the production process, and can achieve the purpose of changing wastes into valuables, thereby having popularization and application values.

Owner:FUZHOU UNIV

A kind of preparation method of cationic plugging agent for drilling fluid

ActiveCN107501456BEasy accessEffective control of molecular weightDrilling compositionFiltrationEmulsion polymerization

The invention discloses a preparation method of a cationic plugging agent for a drilling fluid. The cationic plugging agent is prepared by emulsion polymerization from raw materials in parts by weight as follows: 30-90 parts of styrene, 5-75 parts of butyl acrylate and 15-75 parts of dimethyl diallyl ammonium chloride. Monomers are initiated by an initiator to be subjected to a polymerization reaction, and the cationic plugging agent with the macromolecular chain is obtained; with addition of a small quantity of the product to the drilling fluid, the filtration loss of the drilling fluid and the invasion depth in the sand bed can be effectively reduced, plugging of underground pore cracks is realized, and drilling safety is guaranteed.

Owner:XUZHOU NORMAL UNIVERSITY

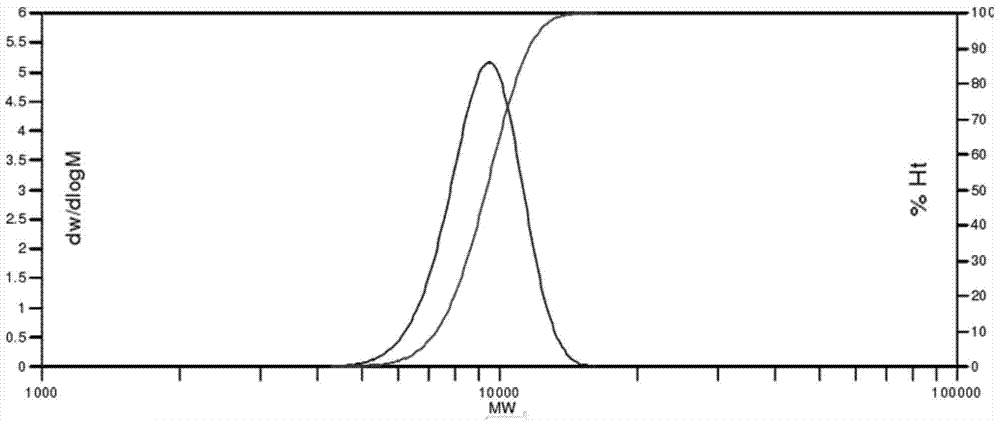

Preparation of biomass-based dispersant using landfill leachate, method and application thereof

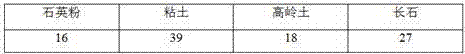

ActiveCN105418079BHigh activityEffective control of molecular weightLiquid carbonaceous fuelsFuel additivesCoal waterBlack liquor

The invention relates to a biomass-based dispersant prepared by using landfill leachate and a method for preparing the biomass-based dispersant and application of the biomass-based dispersant. The method comprises the following steps: adding pulping black liquor into condensed original liquor of leachate of a comprehensive garbage disposal plant for ultrasonically homogeneous mixing; accelerating a sulfomethylation reaction through catalyst activation to obtain dark grey or brownish black liquid; and spraying and drying the liquid to obtain a deep brown or dark grey powdery dispersant, wherein the weight-average molecular weight (Mw) of the dispersant is 5000-45000 and the number-average molecular weight (Mn) of the dispersant is 2800-22000. The product is widely applied to the fields of ceramic additives, coal-water slurry dispersants and the like. Through detection, the indexes of the product meet related quality standard requirements. The production process is simple, the condition is mild, and waste is turned into wealth through conventional industrial equipment and low-price raw materials, and moreover the production process is free of three-waste discharge, so that the dispersant has wide promotional and application values and social meanings.

Owner:FUZHOU UNIV

Silane coupling olefin polymer modified porous composite material and preparation method

ActiveCN105111389AEffective control of molecular weightNarrow molecular weight distributionOther chemical processesPolymer modifiedPolymer science

The invention provides a silane coupling olefin polymer modified porous composite material and a preparation method. A silane coupling olefin polymer has a structure shown in a formula (I) in the specification, wherein hydroxy on the surface of an inner duct of a silicon-based vesicle material is connected with the silane coupling olefin polymer; R1 is H or CH3; R2 is COOCH3, COOC4H9 or phenyl; R3 and R4 are respectively C1-C3 alkyl independently; X2 is Cl, Br and I; and m is an integer between 3 and 6. The method has the advantages that the polymer is grafted in the duct of the vesicle material in situ, so that the diameter of the macropore of the vesicle material can be effectively regulated, the microenvironment of the duct can be changed and the duct of the modified vesicle material can be endowed with certain elasticity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of graft copolymer and graft copolymer/silver nanocomposite material and preparation method thereof

ActiveCN109134868BEffective control of the numberEffective control of molecular weightPolymer sciencePolyvinyl alcohol

The invention relates to the field of synthesis and preparation of high polymer materials, and provides a grafted copolymer, a grafted copolymer / silver nanocomposite and a preparation method thereof.According to the grafted copolymer, polyvinyl alcohol or an ethylene-vinyl alcohol copolymer is adopted as a main chain, and polyisobutene is adopted as a branch chain; the main chain and the branch chain are in keyed joint in a grafted mode; the absolute weight-average molecular weight of the grafted copolymer ranges from 80 kg / mol to 700 kg / mol, and on the basis that the total mass of the grafted copolymer is 100%, the mass percentage content of polyisobutene as the branch chain ranges from 15% to 95%, and the grafting density ranges from 0.2% to 19%. According to the grafted copolymer, thegrafted copolymer / silver nanocomposite and the preparation method thereof, the number of the branch chain and the molecular weight of the branch chain are effectively controlled, the water contact angle of the composite ranges from 28 degrees to 110 degrees, the hydrophily / hydrophobicity is adjustable, and the antibacterial property, the biocompatibility and cell nontoxicity are achieved.

Owner:北京引发科技有限公司 +1

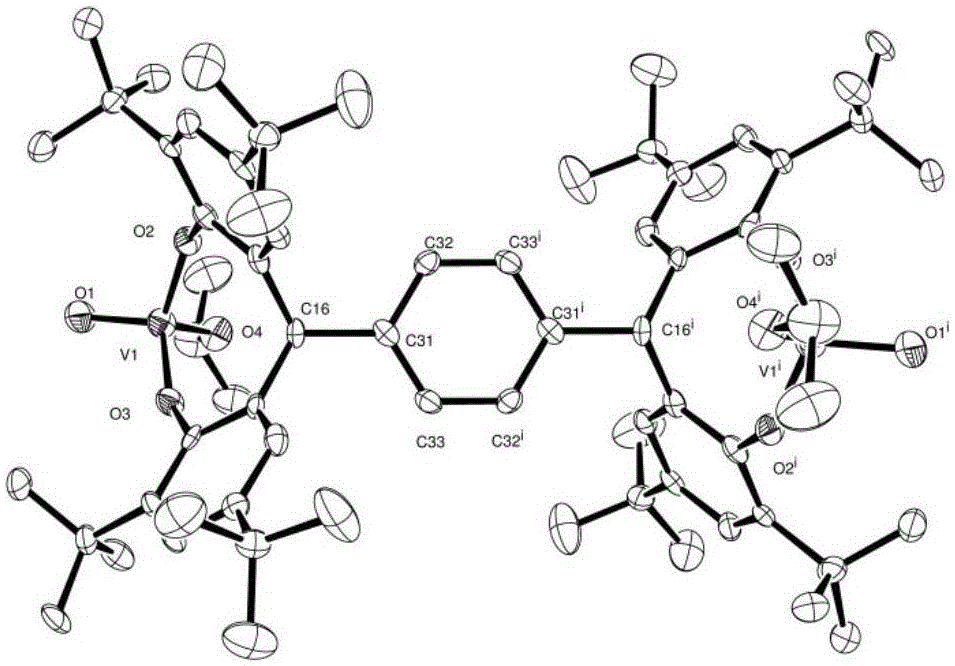

A kind of mononuclear vanadium complex and its preparation method and application

ActiveCN105037416BEasy to prepareShorten the timeGroup 5/15 element organic compoundsCombinatorial chemistryHigh molecular mass

The present invention provides a mononuclear vanadium complex shown as formula I, and also provides a preparation method and application of the complex. The mononuclear vanadium complex has the advantages of simple preparation method, low toxicity, high catalytic activity and narrow molecular weight distribution; and the method can effectively control the molecular weight of the polymer according to the needs, and has a broad market prospect.

Owner:ASTATECH CHENGDU BIOPHARM CORP

A kind of textile auxiliary agent for textile sizing and preparation method thereof

ActiveCN103194902BReduce loadEffective control of molecular weightFibre treatmentPolymer scienceCopolymer

The invention discloses a textile assistant for sizing textiles and a preparation method thereof. The textile assistant comprises 50-200 parts of lignin, 50-200 parts of water-soluble monomer, 50-200 parts of oil-soluble monomer, 1-50 parts of water-soluble initiator, 0.05-5 parts of oil-soluble initiator, 400-1600 parts of water, 10-50 parts of dispersing agent, 500-2000 parts of low-viscosity starch with water content of 2-4%, 50-100 parts of alkaline matter and 1-30 parts of antifoaming agent. The preparation method comprises the following steps: putting matters with formulation dosages in a reaction kettle for reacting, and uniformly mixing an obtained grafted copolymer with the low viscosity starch, the alkaline matter and the antifoaming agent in a mixing machine so as to obtain the textile assistant. By adoption of the invention, the environmental load is beneficially reduced, the production efficiency is improved, the production cost is beneficially lowered, the adhesive power is proper and the serosa flexibility is good.

Owner:徐州众恒淀粉科技有限公司

Synthesis method of special initiator for polyether polyol

InactiveCN113105598AImprove conversion rateEffective control of molecular weightChemical recyclingFree phenolHeat conservation

The invention discloses a synthesis method of a special initiator for polyether polyol, wherein the initiator is essentially octyl phenolic resin. The method comprises: adding a certain amount of octyl phenol, a formaldehyde solution and a catalyst into a reaction kettle, mixing, stirring, increasing the temperature to 50-70 DEG C, carrying out a heat preservation reaction for 2-4 hours, increasing the temperature to 80-130 DEG C, carrying out a heat preservation reaction for 3-5 hours, and then carrying out filtering, distillation, concentration, preparation, and other steps to obtain the octyl phenolic resin solution. According to the invention, by adopting a closed pressurized reaction mode, the conversion rate of octylphenol is increased, and the molecular weight and molecular weight distribution of target resin can be effectively controlled; the recyclable solid acid is used for replacing the traditional strong acid, so that the requirement on production equipment is reduced, and the production process is simple, few in three wastes and low in pollution; and the high-boiling-point solvent oil is added to remove free phenol, so that the content of the free phenol can be effectively controlled, the molecular weight of the obtained octyl phenolic resin is 1100-1600, and the content of the free phenol is smaller than 0.5%.

Owner:南京晶典抗氧化技术研究院有限公司

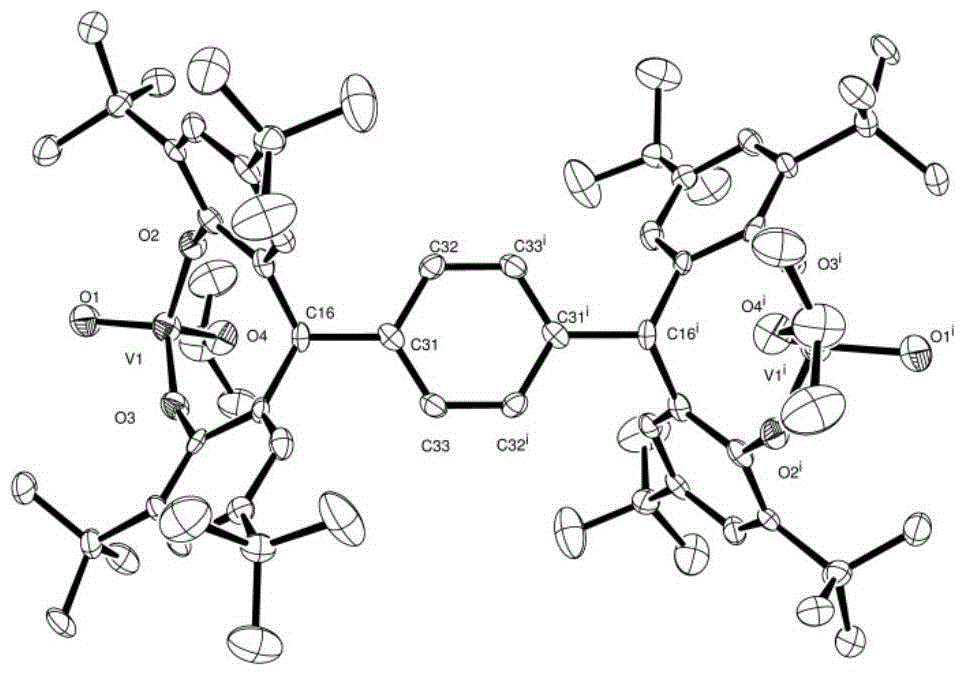

A kind of binuclear vanadium complex and preparation method and use

ActiveCN105037415BEasy to prepareShorten the timeGroup 5/15 organic compounds without C-metal linkagesPolymerWeight distribution

The present invention provides a binuclear vanadium complex shown as formula I, and also provides a preparation method and application of the complex. The binuclear vanadium complex has the advantages of simple preparation method, low toxicity, high catalytic activity and narrow molecular weight distribution; and the method can effectively control the molecular weight of the polymer according to the needs, and has a broad market prospect.

Owner:ASTATECH CHENGDU BIOPHARM CORP

A kind of preparation method of modified aniline terpolymer/waterborne resin composite anticorrosion coating

ActiveCN108531053BGood water dispersibilityGood dispersionAnti-corrosive paintsPolyester coatingsEpoxyActive agent

The invention discloses a preparation method for a modified aniline terpolymer / water-based resin composite anti-corrosive coating. The method comprises the following steps: a microemulsion polymerization method is adopted, aniline, o-hydroxyaniline and p-phenylenediamine are used as monomers, APS (ammonium persulfate) is used as an oxidant, and therefore an aniline-o-hydroxyaniline-p-phenylenediamine terpolymer with good water dispersibility is prepared under the action of an acid dopant and a surfactant having a sulfonic acid group; and water-based alkyd resin is used as a substrate, a modified polyaniline aqueous dispersion liquid is used as an additive, a mixed manner of ultrasonic treatment and mechanical stirring is utilized, and therefore the water-based alkyd resin / polyaniline composite heavy anticorrosive coating is prepared. The preparation method disclosed by the invention has the advantages of being friendly to the environment and convenient to operate, and having no pollution and low costs; and the prepared modified aniline terpolymer can also be compounded with other water-based resin substrates such as water-based epoxy resin, water-based polyurethane resin and water-based polyacrylate resin to prepare the composite anticorrosive coating.

Owner:SHAANXI UNIV OF SCI & TECH

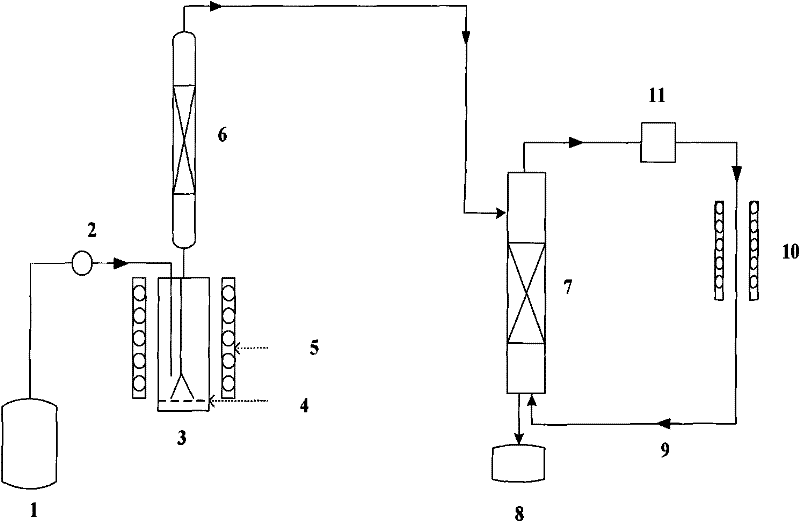

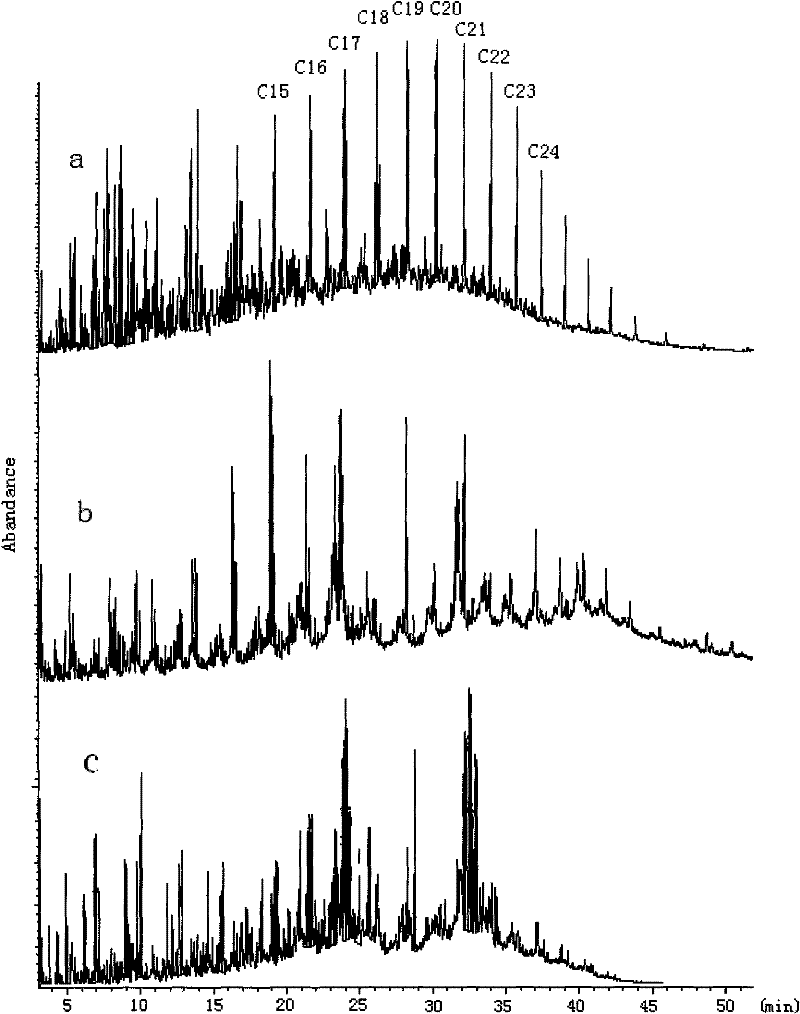

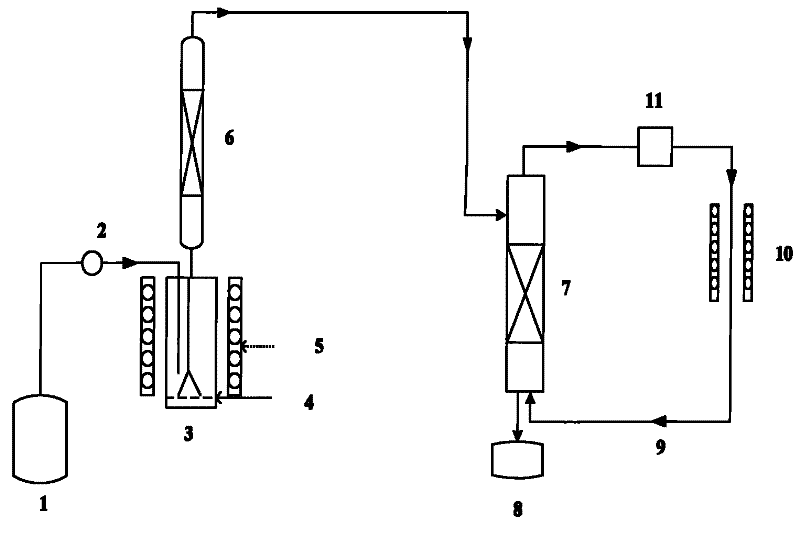

Method for preparing biodiesel from oil with high acid value

InactiveCN101701165BExtended service lifeIncrease contact areaBiofuelsLiquid carbonaceous fuelsAlcoholBiodiesel

The invention discloses a method for preparing biodiesel by high-acid value grease. The method comprises the following steps: dropwise adding plant or animal grease the acid value range of which is between 20 and 200mgKOH / g into a reaction kettle; carrying out catalytic cracking in a stirring state; adding sodium carbonate catalyst into the reaction kettle in advance, wherein the temperature in the reaction kettle is 450 DEG C; leading the generated cracking oil steam to pass through a rectifying column with the temperature of 320-360 DEG C and then charging the cracking oil steam into a reverse flow reaction packing tower from top to bottom; meanwhile, charging alcohol steam into the reverse flow reaction packing tower from bottom to top to carry out reverse flow reaction with the cracking oil steam; loading a bed layer of an acidic particle catalyst fixed bed into the reverse flow reaction packing tower with the temperature of 60-200 DEG C and obtaining the product biodiesel at the bottom of the reverse flow reaction packing tower. The product has the density of 0.80-0.86g / cm3, the water content of 0.31-0.39 percent, a heat value of 41.0-45.0kJ / g, the viscosity of 2.5-3.5mm2 / s, a cold filtering point of minus 8-minus 22 DEG C, a condensing point of minus 30-minus15 DEG C and an acid value of 1.0-5.0mgKOH / g. The method has simple process, low fuel acid value of the product and high conversion rate of the product.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

One-pot catalytic synthesis method for interfacial polymerization of aliphatic polyamide sulfonamide

The invention relates to a one-pot catalytic synthesis method for interfacial polymerization of aliphatic polyamide sulfonamide, which comprises the steps of adding deionized water in which an aliphatic diamine monomer, a composite catalyst and an acid-binding agent are completely dissolved into a container provided with a mechanical stirring device under the protection of normal pressure and sufficient nitrogen, and dropwise adding an organic solvent for dissolving a slightly excessive amount of 3-chlorosulfonyl benzoyl chloride monomer while continuously stirring; after dropwise adding for 10-15 minutes, reacting for 25-45 minutes at the temperature of 0-5 DEG C, then reacting for 2-4 hours at the temperature of 25-40 DEG C, alternately washing a product obtained after the reaction for 3-5 times by sequentially using boiled deionized water and absolute ethyl alcohol, and drying in vacuum to obtain the aliphatic polyamide sulfonamide polymer. The method is simple in process and easy to implement, and the obtained aliphatic polyamide sulfonamide polymer has good thermal stability, friction performance and solvent resistance and can be used as a potential reverse osmosis membrane material, an ultrafiltration membrane material and other membrane materials and a solid lubrication and special engineering material.

Owner:庆阳职业技术学院

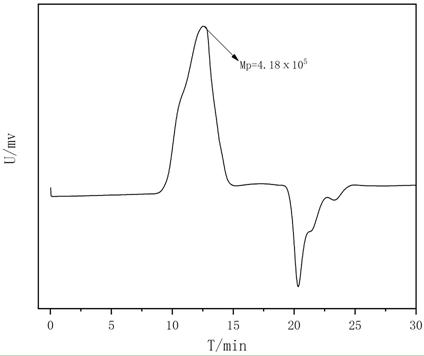

Preparation method of carboxyl alkyl type emulsion polymer

ActiveCN110835390AEffective control of particle size distributionReasonable control of particle size distributionCoatingsHydrophilic monomerPolymer science

A preparation method of a carboxyl alkyl type emulsion polymer is disclosed. A carboxyl strong-hydrophilic monomer and a long alkyl chain hydrophobic monomer are adopted as raw materials in the method. Polymer waterproof coating is prepared by a series of processes including dispersion pre-emulsification, constant-temperature polymerization, variable-speed stirring, and pH adjustment. Hydrogen bonds in carboxyl molecules can strengthen the internal binding force of the polymer, strong hydrophilic effect strengthens the adhesion with a matrix, the network-like binding effect of the cross-linking agent can significantly improve the mechanical properties between the polymers, and the polymer waterproof coating which is good in stability, high in adhesive force, and excellent and durable in waterproof effect can be produced.

Owner:HUBEI UNIV OF TECH

A kind of porous composite material modified by silane coupling olefin polymer and preparation method thereof

ActiveCN105111389BEffective control of molecular weightNarrow molecular weight distributionOther chemical processesPolymer scienceSilanes

The invention provides a silane coupling olefin polymer modified porous composite material and a preparation method. The silane-coupled olefin polymer has the structure of the following formula (I), and the silane-coupled olefin polymer is connected to the hydroxyl group on the surface of the inner pore of the silicon-based vesicle material; wherein R1 is H or CH3, and R2 is COOCH3, COOC4H9 or phenyl; R3 and R4 are independently C1-C3 alkyl; X2 is Cl, Br, I; m is an integer between 3 and 6; The branched polymer can effectively regulate the pore size of the macropores of the vesicle material, change the microenvironment of the channel, and also endow the channel of the modified vesicle material with a certain "elasticity".

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

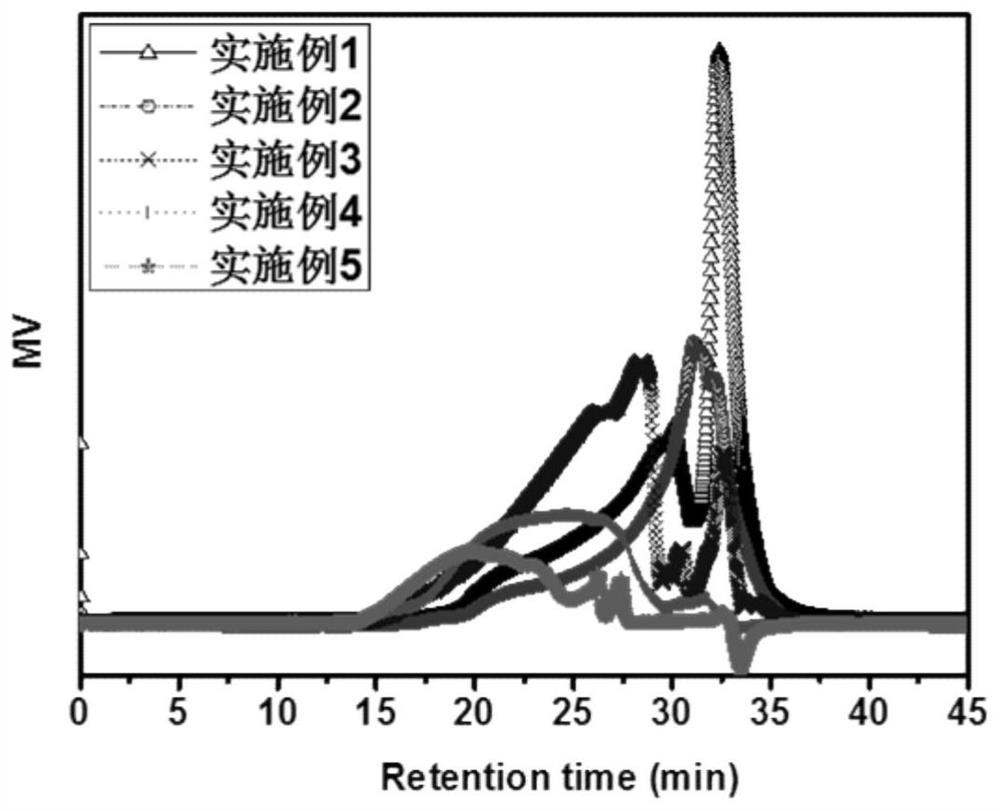

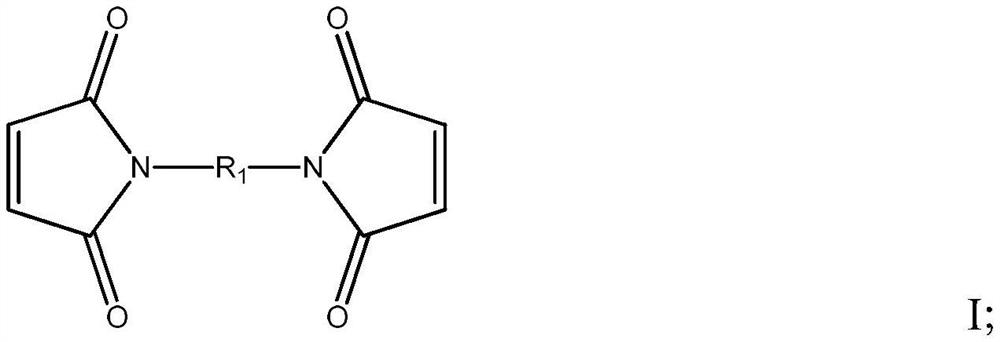

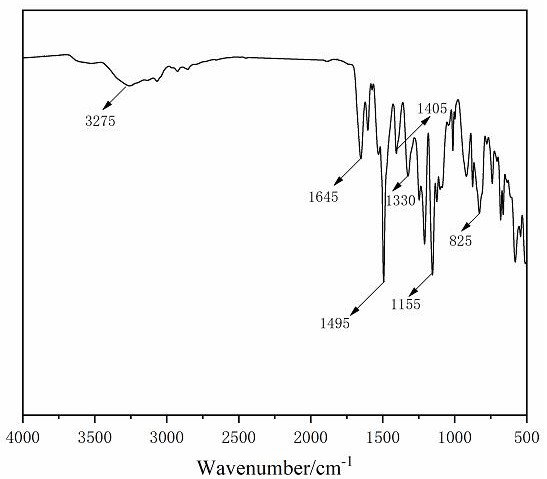

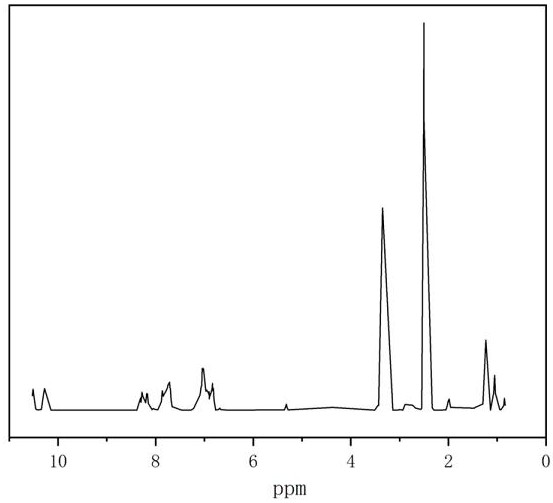

A kind of bismaleimide polymer and preparation method thereof

The invention relates to the field of polymers, in particular to a bismaleimide polymer and a preparation method thereof. The preparation method uses bismaleimide monomer and barbituric acid or its derivatives as raw materials to carry out polymerization reaction in a mixed solvent of good solvent and poor solvent to obtain bismaleimide polymer The mass ratio of described good solvent and poor solvent is (0.01-100):1. The process provided by the invention not only has a simple method, but also reduces the pressure of solvent recovery, saves costs, and is beneficial to popularization and application. Moreover, through the combined optimization of the used solvent and condition parameters, the molecular weight of the prepared polymer can be effectively controlled to ensure that the Mw range of the prepared bismaleimide polymer is 10,000-1,000,000.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

One-pot catalytic synthesis method for polycondensation of aromatic polyamide sulfonamide solution

The invention relates to a one-pot catalytic synthesis method for polycondensation of an aromatic polyamide sulfonamide solution, which comprises the steps of under normal pressure and sufficient nitrogen protection, mixing an aromatic diamine monomer, a composite catalyst and a polar aprotic organic solvent, and stirring until the components are fully dissolved to obtain a mixed solution; dropwise adding a 3-chlorosulfonyl benzoyl chloride monomer into the mixed solution for three times at the temperature of 0-8 DEG C at an interval of 5min, reacting for 25-45min, then reacting for 1h at thetemperature of 27-30 DEG C, gradually heating to the temperature of 60-70 DEG C, reacting for 20-24h, alternately washing a product obtained after the reaction with boiled deionized water and absoluteethyl alcohol for 3-5 times in sequence, and drying in vacuum to obtain the aromatic polyamide sulfonamide polymer. The method is simple in process and easy to implement, and the obtained aromatic polyamide sulfonamide polymer has good thermal stability, friction performance and solvent resistance and can be used as a potential membrane material for reverse osmosis, ultrafiltration and the like and a solid lubrication and special engineering material.

Owner:庆阳职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com