Preparation method of shock-resistant vinyl chloride copolymer resin

A technology of vinyl chloride copolymerization and impact resistance, applied in the field of vinyl chloride copolymer resin and its preparation, can solve the problems of wide molecular weight distribution, difficulty in obtaining particle size and porosity of resin, achieve high apparent density, eliminate large Particles and small particles, the effect of regular particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

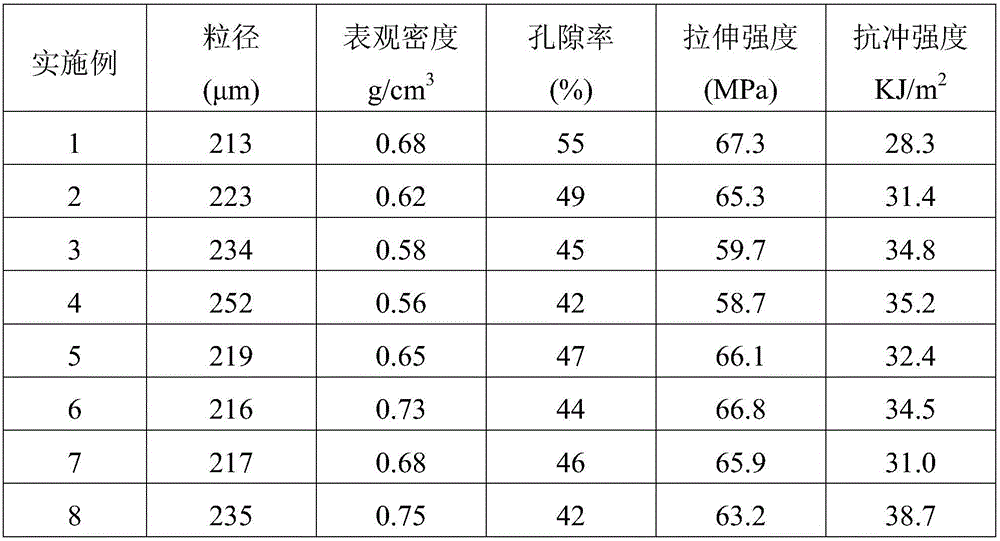

Examples

Embodiment 1

[0030] Under the protection of inert gas, 6L of high-purity deionized water, 2688g of vinyl chloride monomer, 18g of sodium persulfate, 28g of sodium bicarbonate and 185g of hydroxypropyl methylcellulose (hydroxypropyl methylcellulose) were added to a 10L stainless steel autoclave. The content is 6.3 mol%), stir pre-dispersion at room temperature for 25 minutes, increase the temperature and control the reaction temperature to react for 30 minutes at 55°C, then add 148g vinylidene chloride monomer and 93g n-butyl acrylate monomer. After the monomer is added, Add 2g of sodium persulfate and control the reaction temperature at 55℃ to react for 20min, then add dropwise 60g of maleic anhydride monomer, increase the temperature and control the reaction temperature at 60℃, when the polymerization pressure drops by 0.2MPa, add 18g of n-dodecane And stop stirring, lower the reaction temperature, release the remaining gas in the reactor, discharge the material, filter, wash and dry, to ob...

Embodiment 2

[0034] Under the protection of inert gas, 6L of high-purity deionized water, 2412g of vinyl chloride monomer, 16g of sodium persulfate, 28g of sodium bicarbonate and 185g of hydroxypropyl methylcellulose (hydroxypropyl methylcellulose) were added to a 10L stainless steel autoclave. The content is 6.3 mol%), stir pre-dispersion at room temperature for 25 minutes, increase the temperature and control the reaction temperature to react for 30 minutes at 55°C, then add 296g vinylidene chloride monomer and 242g n-butyl acrylate monomer. After the monomer is added, Add 4g of sodium persulfate and control the reaction temperature at 55℃ to react for 20min, then add dropwise 60g of maleic anhydride monomer, increase the temperature and control the reaction temperature at 60℃, when the polymerization pressure drops by 0.2MPa, add 18g of n-dodecane And stop stirring, lower the reaction temperature, release the remaining gas in the reactor, discharge the material and undergo filtration, was...

Embodiment 3

[0038] Under the protection of inert gas, 6L of high purity deionized water, 2088g of vinyl chloride monomer, 14g of sodium persulfate, 28g of sodium bicarbonate and 185g of hydroxypropyl methylcellulose (hydroxypropyl methylcellulose) were added to a 10L stainless steel autoclave. The content is 6.3 mol%), stir pre-dispersion at room temperature for 25 min, increase the temperature and control the reaction temperature to react for 30 min at 55°C, then add 603 g vinylidene chloride monomer and 153 g n-butyl acrylate monomer. After the monomer is added, Add 6g of sodium persulfate and control the reaction temperature at 55°C to react for 20min, then add 146g of maleic anhydride monomer dropwise, increase the temperature and control the reaction temperature to 60°C, when the polymerization pressure drops by 0.2MPa, add 18g of n-dodecane And stop stirring, lower the reaction temperature, release the remaining gas in the reactor, discharge the material, filter, wash, and dry to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com