Efficient collecting agent for hematite reverse flotation and application of efficient collecting agent

A collector and hematite technology, applied in flotation, solid separation, etc., can solve the problems of failure to reduce the cost of collectors, high cost, and poor comprehensive benefits, and achieve excellent separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

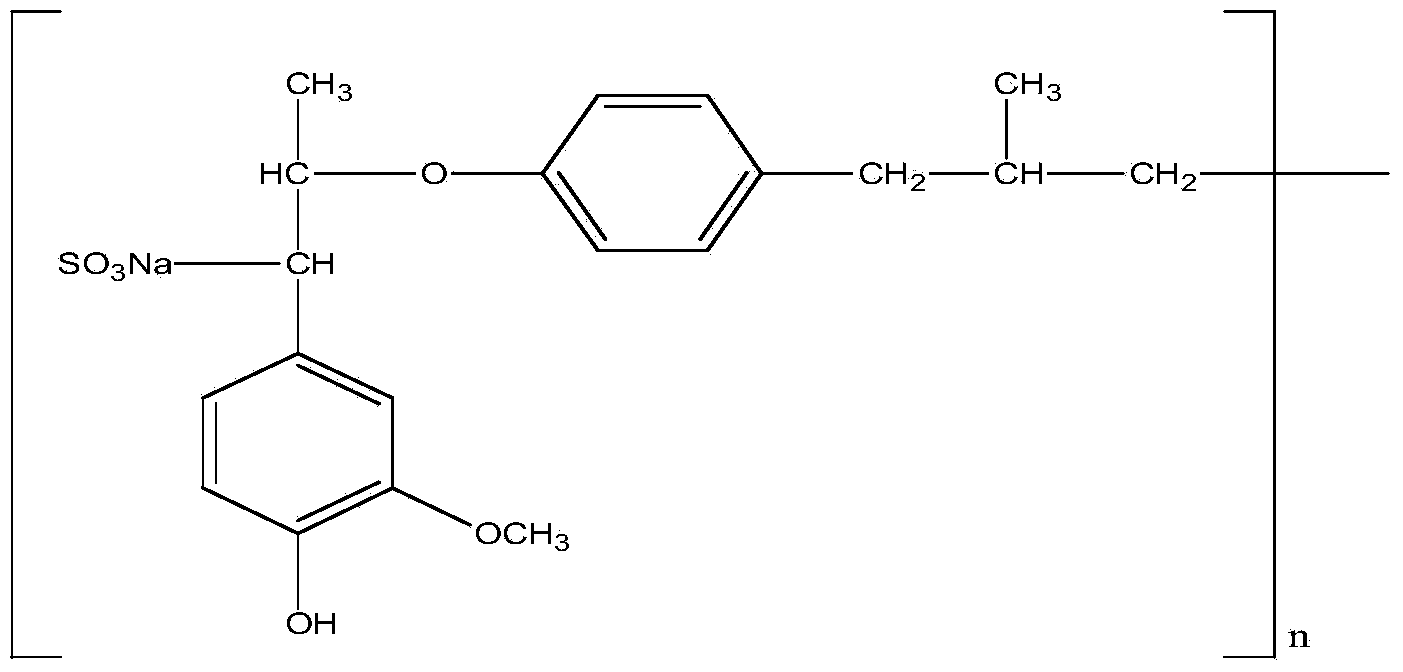

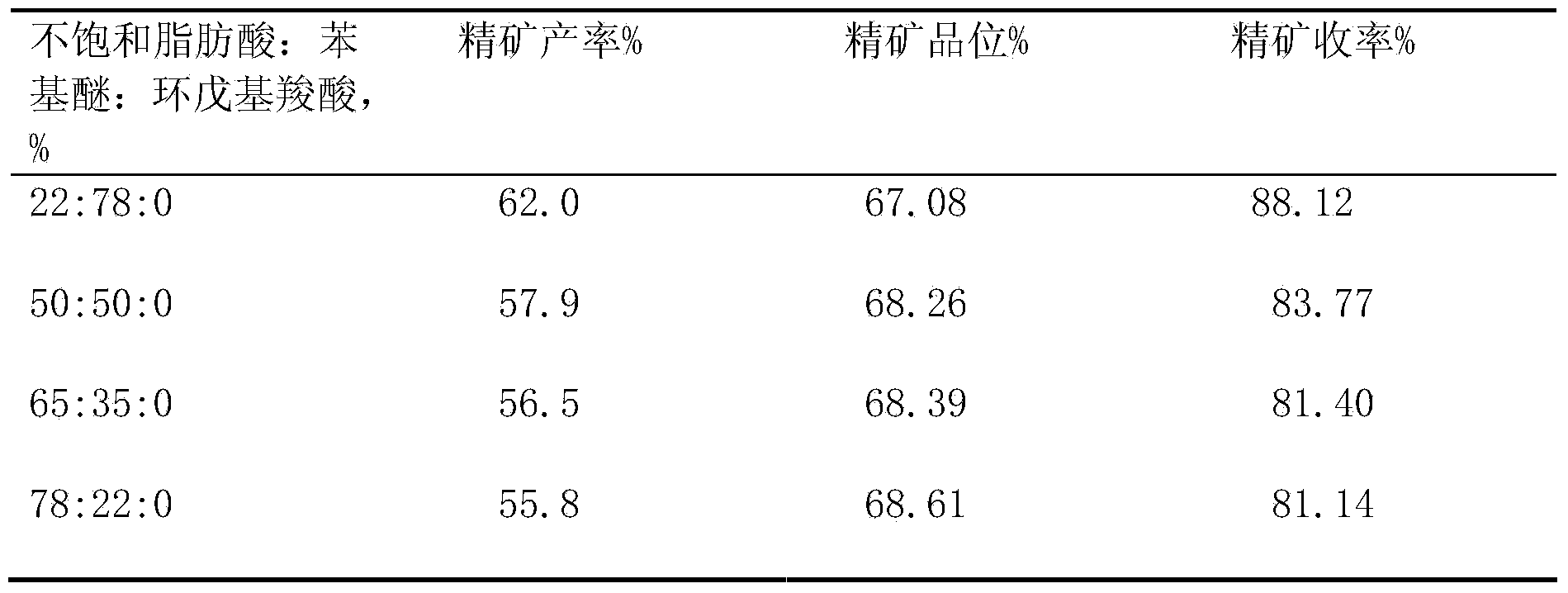

[0019] 200 for the ore, the ore grade is 47.43%, and the mass percentage concentration of the pulp is 35%. Caustic soda is made into a solution with a mass percentage concentration of 2.0%, starch is made into a solution with a mass percentage concentration of 2.5%, and lime is made into an emulsion with a mass percentage concentration of 2.5%. Add caustic soda, starch and lime solution 9.0mL, 6.5mL and 6.0mL respectively to the pulp. Preparation of poly(4-hydroxy-3 methoxyphenyl) glycerol-phenyl ether-sodium sulfonate, unsaturated fatty acid (carbon chain number = 10-22), and bis(4-cyclopentyl) carboxylic acid capture The concentration of the collector is 2.0% by mass, and it is added to the ore pulp. The addition amount of roughing is 3.0mL, and the addition amount of fine selection is 1.0mL. Stir for 3 minutes after adding a chemical agent, control the pH at 11.3-11.7, and carry out a rough-fine open-circuit reverse flotation in the temperature range of 39-41°C. Table 1 s...

Embodiment 2

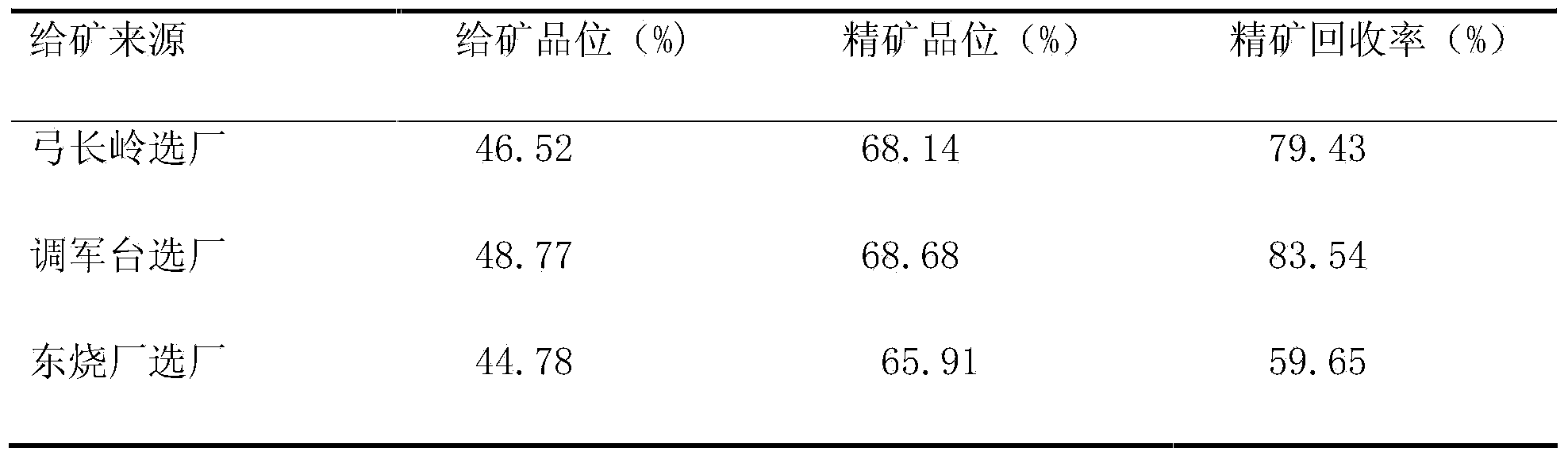

[0024] 200 for the ore feed, the mass percentage concentration of the pulp is 35%, and the temperature of the pulp is controlled at 39-41°C. Add 9.0 mL of a 2% mass percent sodium hydroxide solution, 6.5 mL of a 2.5% mass percent starch solution, and 6.0 mL of a 2.5% mass percent calcium oxide solution. Adopt fixed unsaturated fatty acid and poly(4-hydroxyl-3 methoxyphenyl) glycerol-phenyl ether-sodium sulfonate to each account for 50% of the collector, the mass percent concentration of the prepared collector is 2.0%, adding Into the ore pulp, the amount of roughing added is 3.0mL, and the amount of beneficiated is 1.0mL. The situation of ore dressing from different sources is investigated, and the specific results are shown in Table 2.

[0025] Table 2 Open-circuit-coarse-finish open-circuit flotation index of reverse flotation for different mines

[0026]

[0027] Unsaturated fatty acid and poly(4-hydroxy-3 methoxyphenyl) glycerin-phenyl ether-sodium sulfonate are used a...

Embodiment 3

[0029] The ore weight and pulp concentration are the same as in Examples 1 and 2, and the ore is the most difficult to select Dong'anshan Concentrator, and the grade is particularly low 44.78% of the ore sample. The concentration and addition of caustic soda, starch, lime are identical with embodiment 1 and 2, and collector consists of: unsaturated fatty acid, poly(4-hydroxyl-3 methoxyphenyl) glycerin-phenyl ether-sodium sulfonate and the mass percent concentration of two (4-cyclopentyl) carboxylic acid are respectively 40%, 55% and 5%, and the collector that the preparation mass percent concentration is 2.0% joins in the ore pulp, and the addition is the same as example 1 and example 2, the flotation effect comparison with the control sample is listed in Table 3.

[0030] Table 3 Comparison of open-circuit flotation results for ultra-difficult mineral processing containing iron carbonate

[0031]

[0032] Note: The comparison sample is the collector being used in the mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com