A kind of heat-resistant one-component polyurethane sealant and preparation method thereof

A polyurethane sealant, a single-component technology, applied in the field of sealants, can solve the problems of limiting the scope of use of single-component polyurethane sealants, the main chain is prone to breakage, degradation, and performance cannot be maintained for a long time, and achieves excellent heat resistance. , Improve hardness and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A heat-resistant single-component polyurethane sealant, consisting of the following raw materials: 20kg polyether polyol, 5kg polyester polyol, 5kg isocyanate, 14kg first plasticizer, 0.2kg water remover, 15kg filler, epoxy base Modified prepolymer 5kg, stabilizer 0.05kg, auxiliary agent 3kg and first catalyst 0.01kg;

[0051] The polyether polyol is a trifunctional polyoxypropylene ether with a molecular weight of 3000-6000;

[0052] The polyester polyol is a difunctional polycaprolactone polyol with a molecular weight of 1000-3000;

[0053] Described isocyanate is diphenylmethane diisocyanate;

[0054] The first plasticizer is epoxy soybean oil;

[0055] The water removal agent is p-toluenesulfonyl isocyanate;

[0056] The filler is obtained by mixing carbon black and light calcium carbonate according to a mass ratio of 2:1;

[0057] The stabilizer is 2-(2'-hydroxy-3',5'-dipentylphenyl)benzotriazole;

[0058] The auxiliary agent is obtained by mixing calcium oxid...

Embodiment 2

[0062] A heat-resistant single-component polyurethane sealant, consisting of the following raw materials: 40kg polyether polyol, 15kg polyester polyol, 14kg isocyanate, 28kg first plasticizer, 1kg water remover, 30kg filler, epoxy modified 15kg of permanent prepolymer, 0.7kg of stabilizer, 10kg of auxiliary agent and 0.4kg of the first catalyst;

[0063] The polyether polyol is a trifunctional polyoxyethylene ether with a molecular weight of 3000-6000;

[0064] The polyester polyol is a difunctional polycarbonate polyol with a molecular weight of 1000-3000;

[0065] The isocyanate is obtained by mixing diphenylmethane diisocyanate and toluene diisocyanate according to a mass ratio of 5:1;

[0066] The first plasticizer is phenyl alkylsulfonate;

[0067] The water removal agent is p-toluenesulfonyl isocyanate;

[0068] The filler is obtained by mixing carbon black and silicon micropowder according to a mass ratio of 1:1;

[0069] The stabilizer is 2-[2,4-bis(2,4-xylyl)-2-(1...

Embodiment 3

[0074] A heat-resistant single-component polyurethane sealant, consisting of the following raw materials: 25kg polyether polyol, 8kg polyester polyol, 8kg isocyanate, 15kg first plasticizer, 0.4kg water remover, 18kg filler, epoxy base Modified prepolymer 8kg, stabilizer 0.2kg, auxiliary agent 5kg and first catalyst 0.1kg;

[0075] The polyether polyol is a trifunctional polyoxypropylene ether with a molecular weight of 3000-6000;

[0076] The polyester polyol is a difunctional polycaprolactone polyol with a molecular weight of 1000-3000;

[0077] The isocyanate is obtained by mixing diphenylmethane diisocyanate and isophorone diisocyanate in a weight ratio of 3:1;

[0078] The first plasticizer is obtained by mixing diisodecyl phthalate and phenyl alkylsulfonate in a weight ratio of 1:4;

[0079] The water removal agent is p-toluenesulfonyl isocyanate;

[0080] The filler is obtained by mixing carbon black and talcum powder in a weight ratio of 1:1;

[0081] The stabilize...

PUM

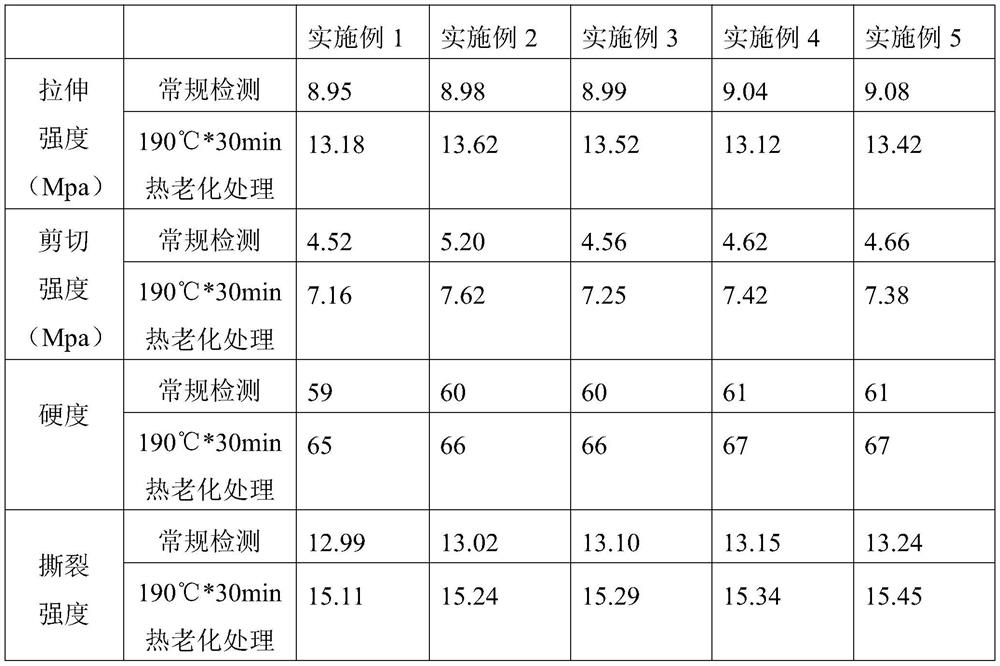

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com