A kind of salt spray resistant vinylidene chloride copolymer latex and preparation method thereof

A technology of copolymer latex and vinylidene chloride, applied in coatings, anti-corrosion coatings, etc., can solve the problems of easy discoloration, discoloration, and foaming of films, and achieve improved storage stability, improved stability, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

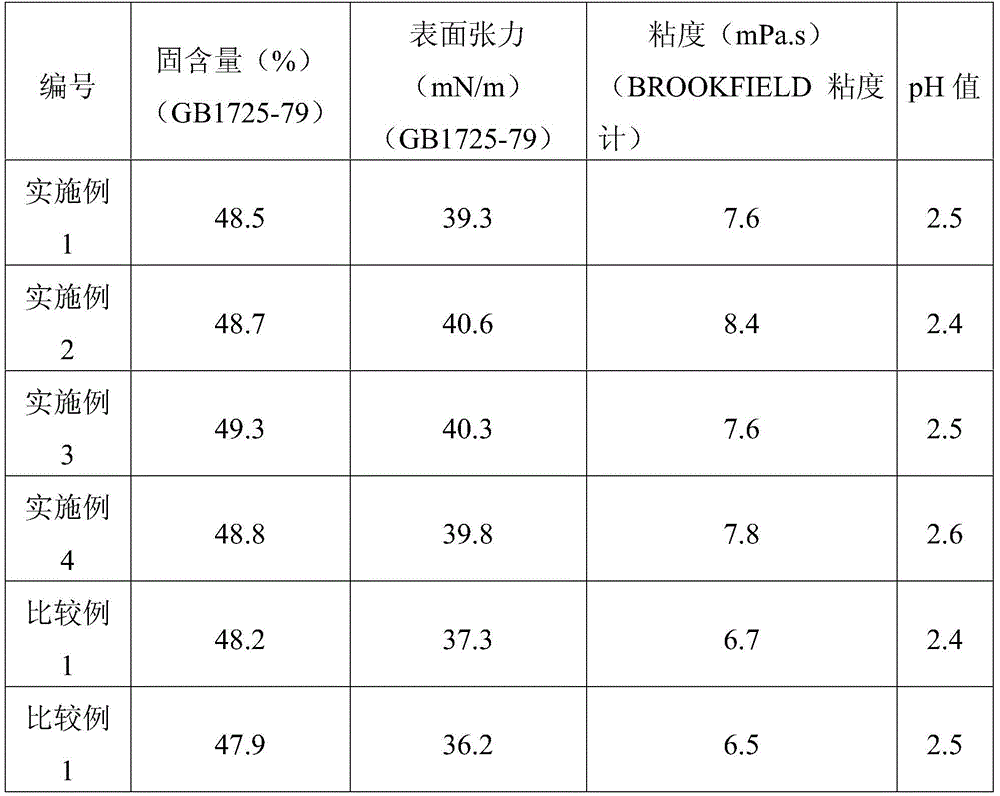

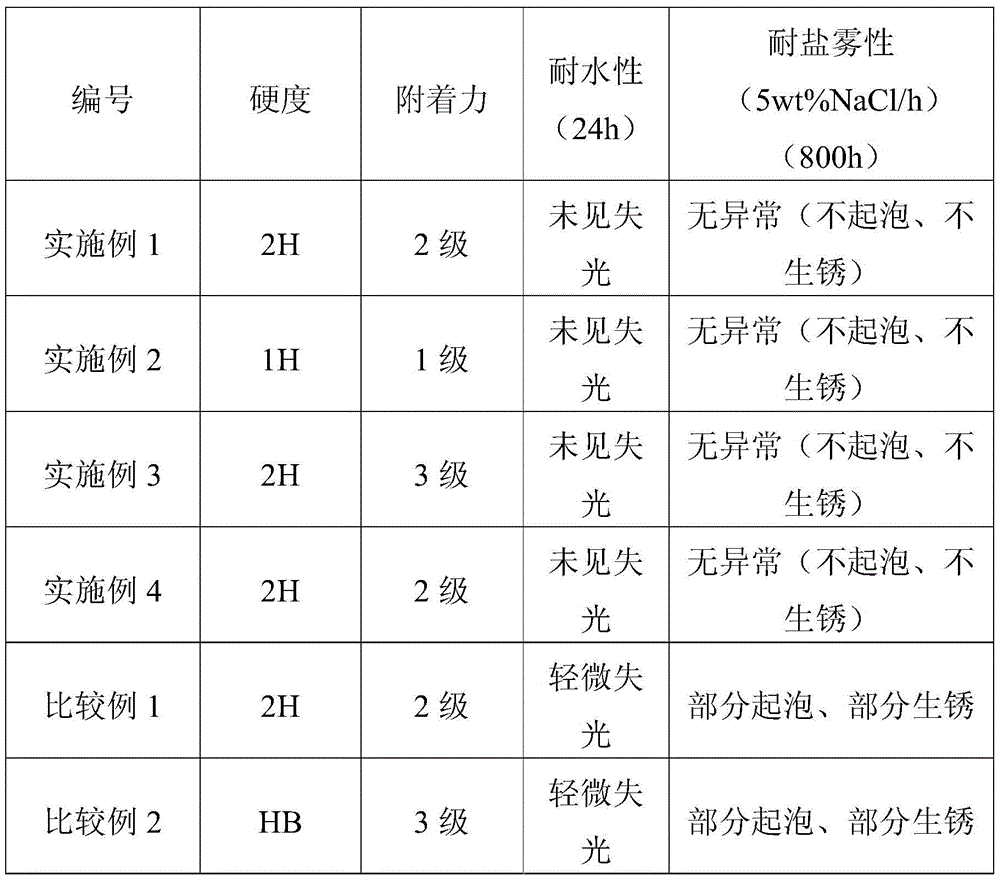

[0038] Add 500g of deionized water and emulsifier (10g of octylphenol polyoxyethylene ether (X-100)) into a 2L reaction kettle, start stirring, and replace the residual air in the system with high-purity nitrogen until the oxygen content in the kettle is lower than 30ppm; Add 90g of vinyl chloride monomer, 0.2g of potassium persulfate and 3g of sodium bicarbonate into the kettle, and stir for pre-dispersion at room temperature for 25min; Acrylic acid-2-ethylhexyl monomer and 0.8g potassium persulfate, keep the reaction pressure of the reactor at ±0.01MPa of the set polymerization pressure; then add 10g of N-methylolacrylamide monomer dropwise to control the reaction The temperature is 60°C; when the polymerization reaction pressure drops by 0.2 MPa, add 1 g of n-dodecyl mercaptan, stop stirring, lower the reaction temperature, release the remaining gas in the reactor, and discharge to obtain vinylidene chloride copolymer latex. The performance parameters of the prepared vinyli...

Embodiment 2

[0040]Add 500g of deionized water and (10g of octylphenol polyoxyethylene ether (X-100)) into the 2L reaction kettle, start stirring, and replace the residual air in the system with high-purity nitrogen until the oxygen content in the kettle is lower than 30ppm; Add 90g of vinyl chloride monomer, 0.2g of potassium persulfate and 3g of sodium bicarbonate, stir and pre-disperse at room temperature for 25min; the temperature of the reaction kettle is raised to 60°C, increase the stirring speed of the reaction kettle, and add 325g of vinylidene chloride monomer and 76g of acrylic acid- 2-Ethylhexyl ester monomer and 0.8g potassium persulfate, keep the reaction pressure of the reactor at ±0.01MPa of the set polymerization pressure; then add 10g of N-methylolacrylamide monomer dropwise, and control the reaction temperature at 60 °C; when the polymerization reaction pressure drops by 0.2 MPa, add 1 g of n-dodecyl mercaptan, stop stirring, lower the reaction temperature, release the re...

Embodiment 3

[0042] Add 500g of deionized water and emulsifier (10g of octylphenol polyoxyethylene ether (X-100)) into a 2L reaction kettle, start stirring, and replace the residual air in the system with high-purity nitrogen until the oxygen content in the kettle is lower than 30ppm; Add 90g of vinyl chloride monomer, 0.1g of potassium persulfate and 3g of sodium bicarbonate into the kettle, stir and pre-disperse for 25min at room temperature; the temperature of the reaction kettle is raised to 60°C, increase the stirring speed of the reaction kettle, and add 334g of vinylidene chloride monomer and 50g of Acrylic acid-2-ethylhexyl monomer and 0.9g potassium persulfate, keep the reaction pressure of the reactor at ±0.01MPa of the set polymerization pressure; then add 24g of N-methylolacrylamide monomer dropwise to control the reaction The temperature is 60°C; when the polymerization reaction pressure drops by 0.2 MPa, add 1 g of n-dodecyl mercaptan, stop stirring, lower the reaction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com