Preparation of biomass-based dispersant using landfill leachate, method and application thereof

A technology of landfill leachate and base dispersant, which is used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of complex composition of landfill leachate, demanding reaction conditions, strong irritating odor, etc. The effect of value utilization, low cost, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

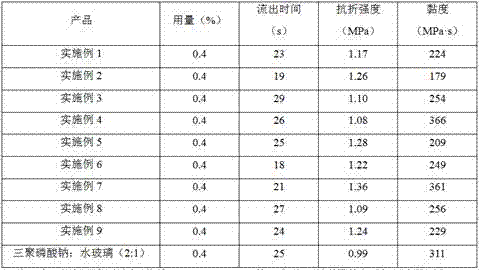

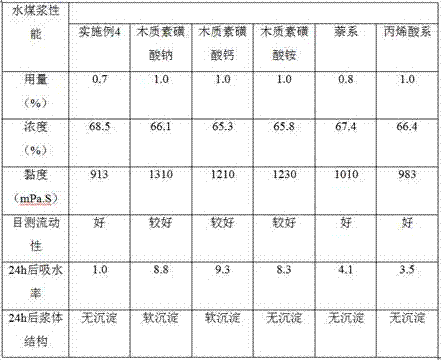

Examples

preparation example Construction

[0036] The preparation method of the biomass-based dispersant comprises the following steps: respectively concentrating the raw liquid of the leachate of the comprehensive garbage disposal site and the pulping black liquor to a solid content of 15-50%, homogeneously mixing with ultrasonic waves, adding a catalyst, and heating at 60-110° C. React at low temperature for 0.3~1.5h; add pH regulator to adjust the pH value of the system to 9~12, adjust the temperature to 60~120°C, add sulfonating agent, aldehyde compound, water, and react the system for 1.5~6h; properly adjust the temperature of the system to 50~100°C, add reducing agent and react for 0.5~1.5h to obtain dark gray or brown-black liquid, and obtain dark brown or dark gray powder dispersant after spray drying; the mass percentage of each raw material is as follows:

[0037] Concentrated solution of landfill leachate stock solution: 30~50%,

[0038] Concentrate of pulping black liquor: 20~35%,

[0039] pH regulator: 1....

Embodiment 1

[0049] (1) Raw materials and dosage

[0050] Concentrate of landfill leachate stock solution (20% solid content): 350kg,

[0051] Concentrated solution of bamboo pulp black liquor (solid content 30%): 150kg,

[0052] Mixture of phosphoric acid and sulfamic acid (mass ratio is 6:1): 26.8kg,

[0053] Mixture of ferrous sulfate, cobalt sulfate and nickel sulfate (mass ratio is 8:1:1): 1.0kg,

[0054] Mixture of formaldehyde and paraformaldehyde (mass ratio 1:1): 37.7kg,

[0055] Mixture of sodium sulfite, sodium bisulfite and sodium metabisulfite (mass ratio 1:2:2): 54.4kg,

[0056] The mixture of sodium borohydride and sodium formaldehyde sulfoxylate (mass ratio is 1:1): 100kg,

[0057] Water: 270kg;

[0058] (2) The preparation method, including the following steps:

[0059] The concentrated solution of 350kg landfill leachate stock solution and the concentrated solution of 150kg bamboo pulp black liquor are mixed homogeneously by ultrasonic and stand-by; pumped into the ...

Embodiment 2

[0061] (1) Raw materials and dosage

[0062] Concentrated solution of landfill leachate stock solution (22% solid content): 402 kg,

[0063] Concentrate of poplar and masson pine pulping black liquor (mass ratio 1:3, solid content 35%): 204 kg,

[0064] Mixture of oxalic acid and sulfamic acid (mass ratio is 1:1): 52.8 kg,

[0065] Mixture of ferrous sulfate, cobalt sulfate and copper sulfate (mass ratio is 8:2:1): 0.9 kg,

[0066] Mixture of formaldehyde and acrolein (4:1 mass ratio): 47.7 kg,

[0067] The mixture of sodium bisulfite and ammonium bisulfite (mass ratio is 3:1): 32.6 kg,

[0068] The mixture of sodium dithionite and sodium formaldehyde sulfoxylate (mass ratio is 1:2): 71.0kg,

[0069] Water: 189.0 kg;

[0070] (2) The preparation method includes the following steps:

[0071] Mix 402 kg of the concentrated solution of the landfill leachate stock solution and 204 kg of the concentrated solution of poplar and masson pine pulping black liquor, and mix them ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com