One-pot catalytic synthesis method for polycondensation of aromatic polyamide sulfonamide solution

A technology of solution polycondensation of aromatic polyamide sulfonamide, which is applied in the field of one-pot catalytic synthesis of aromatic polyamide sulfonamide solution polycondensation, which can solve the problems of difficulty, low activity, and restrictions on the industrial application of polyamide sulfonamide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

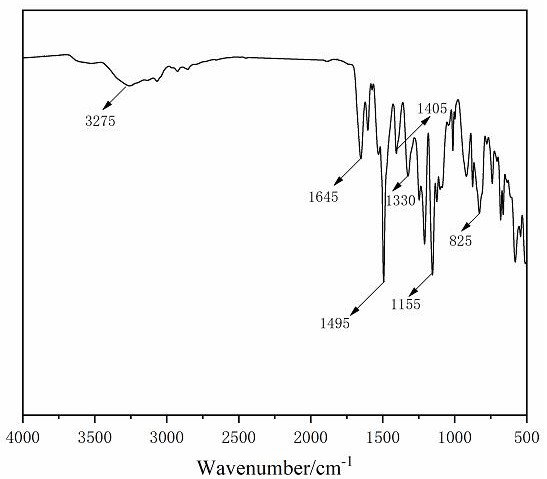

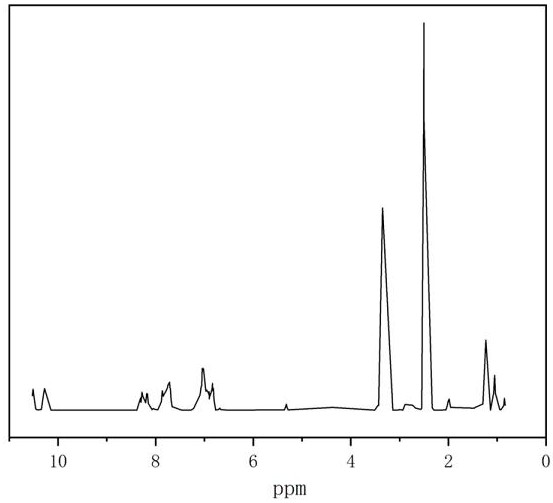

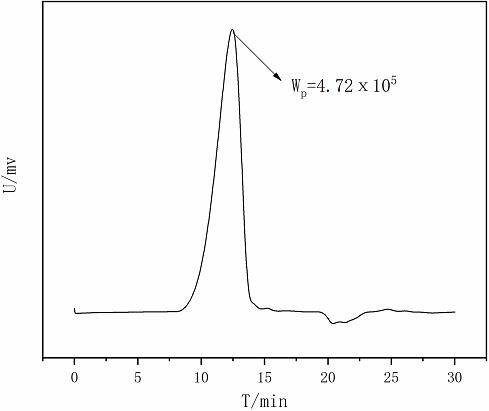

[0043] Example 1 One-pot catalytic synthesis method of aromatic polyamide sulfonamide solution polycondensation:

[0044] Under the protection of normal pressure and sufficient nitrogen, mix the aromatic diamine monomer, composite catalyst, and sulfolane, and stir until fully dissolved to obtain a mixed solution; add dropwise to the mixed solution three times at 0-8°C with an interval of 5 minutes between two times 3-Chlorosulfonylbenzoyl chloride monomer, after reacting for 25min, react at 27°C for 1h, then gradually raise the temperature to 60°C for 24h, until the solution becomes viscous. After the reaction is over, pour the viscous solution into deionized water while it is hot, and a white wire-like substance precipitates out, and then alternately wash it with boiled deionized water and absolute ethanol for 5 times, and the white precipitate is vacuum-dried at 100°C for 24 hours , to obtain the aromatic polyamide sulfonamide polymer with a yield of 93.82%.

[0045] Among ...

Embodiment 2

[0049] Example 2 One-pot catalytic synthesis method of aromatic polyamide sulfonamide solution polycondensation:

[0050] Under normal pressure and sufficient nitrogen protection, mix aromatic diamine monomers, composite catalysts, and N,N-dimethylacetamide, and stir until fully dissolved to obtain a mixed solution; divide in the mixed solution at 0-8°C Add 3-chlorosulfonylbenzoyl chloride monomer dropwise three times at intervals of 5 minutes, react for 45 minutes, then react at 30°C for 1 hour, then gradually raise the temperature to 70°C and react for 20 hours until the solution becomes viscous. After the reaction is over, pour the viscous solution into deionized water while it is hot, and a white wire-like substance precipitates out, and then alternately washes with boiled deionized water and absolute ethanol for 3 times, and the white precipitate is vacuum-dried at 100°C for 24 hours , to obtain the aromatic polyamide sulfonamide polymer with a yield of 88.92%.

[0051] ...

Embodiment 3

[0055] Example 3 One-pot catalytic synthesis method of aromatic polyamide sulfonamide solution polycondensation:

[0056] Under normal pressure and sufficient nitrogen protection, mix aromatic diamine monomers, composite catalysts, and N,N-dimethylformamide, stir until fully dissolved, and obtain a mixed solution; divide in the mixed solution at 0-8°C Add 3-chlorosulfonylbenzoyl chloride monomer dropwise three times at intervals of 5 minutes, react for 30 minutes, then react at 28°C for 1 hour, then gradually raise the temperature to 65°C and react for 22 hours until the solution becomes viscous. After the reaction is over, pour the viscous solution into deionized water while it is still hot, and a white stringy substance precipitates out, and then alternately wash it with boiled deionized water and absolute ethanol for 4 times, and the obtained white precipitate is vacuum-dried at 100°C for 24 hours , to obtain the aromatic polyamide sulfonamide polymer with a yield of 90.04%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com