Method for preparing biodiesel from oil with high acid value

A high-acid value grease and biodiesel technology, which is applied in biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of high acid value of pyrolysis oil, complex process, waste of raw materials, etc., and achieve low energy consumption and full reaction , the effect of reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

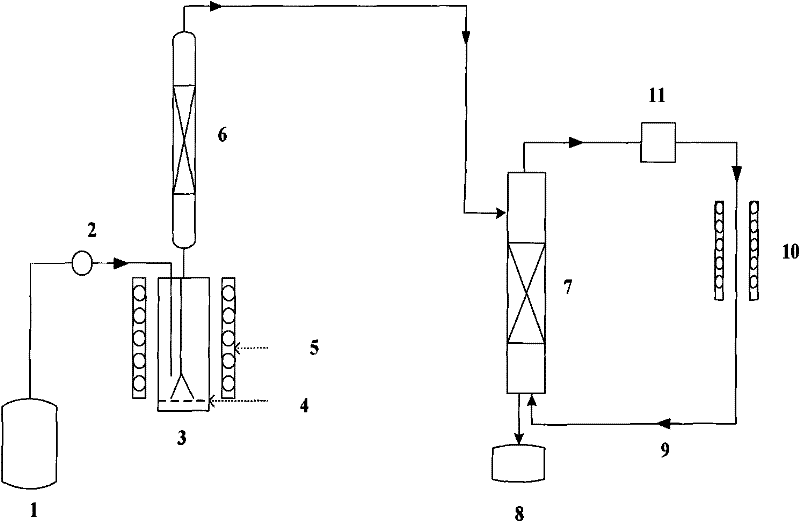

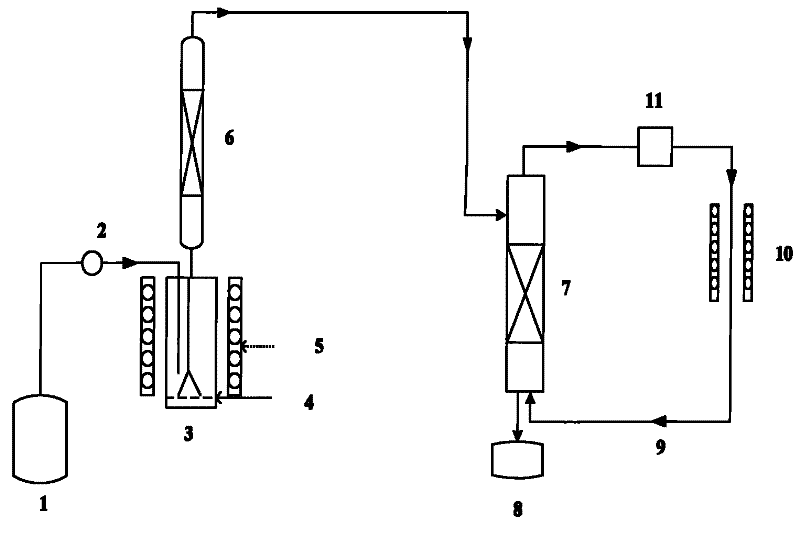

Method used

Image

Examples

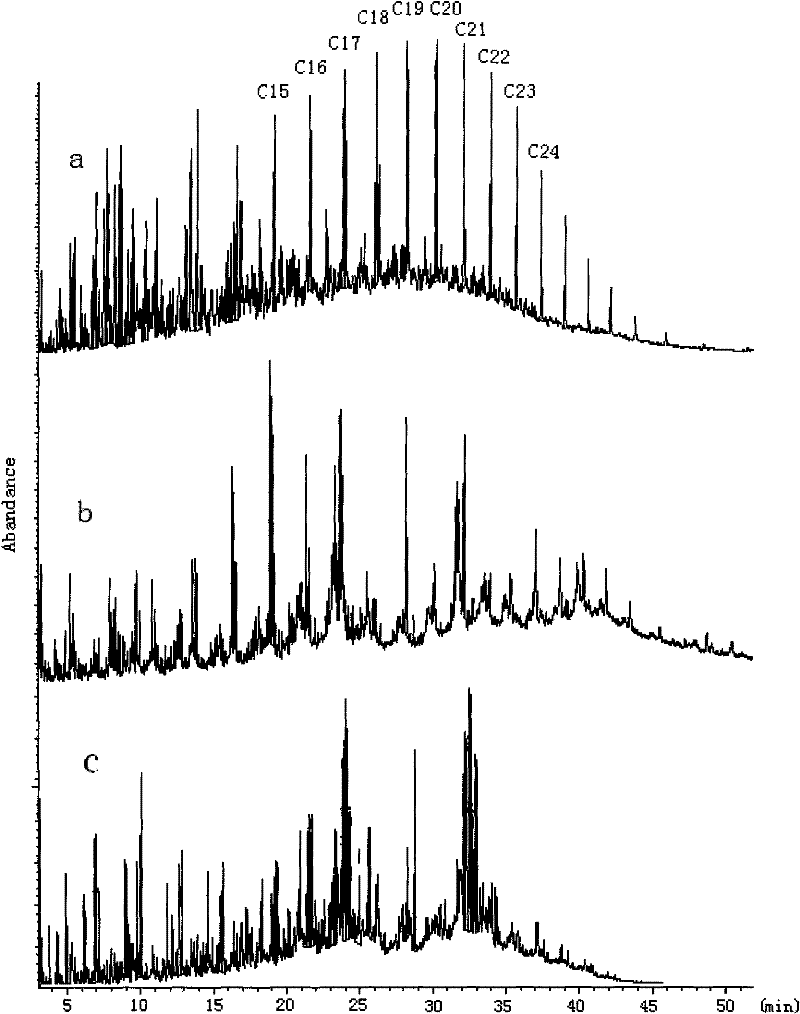

Embodiment 1

[0026] Add 5g of sodium carbonate catalyst in the reaction kettle, heat to 450°C, and the stirring speed is 220r / min; take 100g of waste oil (20mg KOH / g), drop into the reaction kettle through a constant flow pump at a speed of 50g / h, the After passing through the rectification column at 340°C, the generated steam is passed into the packed tower filled with formed acidic MCM-41 mesoporous molecular sieve, and reacts with methanol steam flowing in from the countercurrent. The temperature of the packed tower is kept at 120°C. After the top of the reaction packed tower is recovered and purified, it is heated by the heating device and then enters the countercurrent reaction packed tower for reaction. The acid value of the product after the countercurrent reaction packed tower is 2mg KOH / g, the yield is 80%, and the density is 0.82g / cm 3 , with a water content of 0.32%, a calorific value of 44.2kJ / g, and a viscosity of 2.7mm 2 / s, the cold filter point is -21°C, and the condensati...

Embodiment 2

[0028] Add 5g of sodium carbonate catalyst in the reaction kettle, heat to 450°C, and the stirring speed is 220r / min; take 100g of waste oil (20mg KOH / g), drop into the reaction kettle through a constant flow pump at a speed of 50g / h, the After passing through the 340°C rectification column, the generated steam is passed into the packed tower filled with acidic MCM-41 mesoporous molecular sieves, and reacts with the ethanol vapor flowing in the countercurrent, and the temperature of the packed tower is maintained at 120°C. The acid value of the product after passing through the countercurrent reaction packed tower is 3mg KOH / g, the yield is 77%, and the density is 0.81g / cm 3 , with a water content of 0.34%, a calorific value of 42.2kJ / g, and a viscosity of 2.8mm 2 / s, the cold filter point is -21°C, and the condensation point is -28°C.

Embodiment 3

[0030] Add 5g of sodium carbonate catalyst in the reaction kettle, heat to 450°C, and the stirring speed is 220r / min; take 100g of waste oil (20mg KOH / g), drop into the reaction kettle through a constant flow pump at a speed of 50g / h, the After passing through the 340°C rectification column, the generated steam is passed into the packed tower filled with acidic MCM-41 mesoporous molecular sieves, and reacts with the butanol vapor flowing in countercurrently. The temperature of the packed tower is kept at 120°C. The acid value of the product after passing through the countercurrent reaction packed tower is 3mg KOH / g, the yield is 81%, and the density is 0.83g / cm 3 , with a water content of 0.32%, a calorific value of 42.0kJ / g, and a viscosity of 2.8mm 2 / s, the cold filter point is -20°C, and the condensation point is -27°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com