Ceramic prestress loading device and mounting method thereof

A technology of loading device and installation method, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of complex loading method and high equipment requirements, and achieve the improvement of anti-penetration ability and large Penetration resistance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

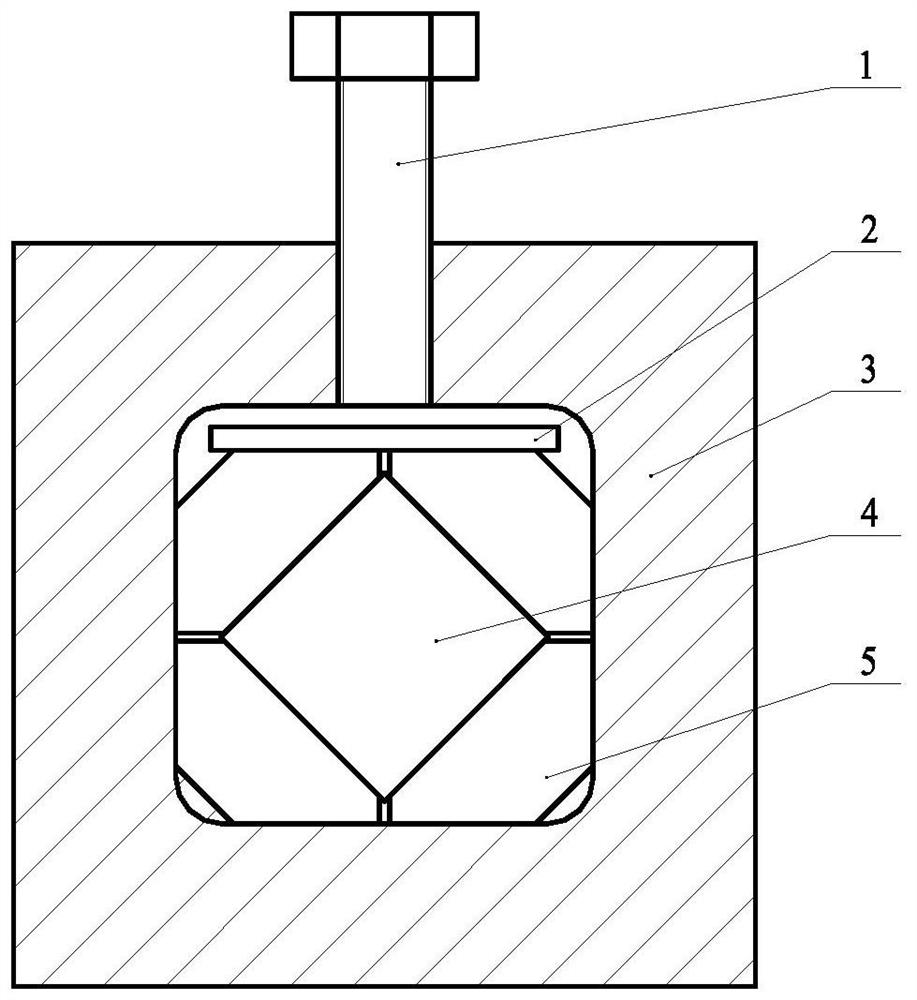

[0023] A ceramic prestressed loading device, comprising a prestressed loading part 1, a cushion block 2, a constraint frame 3, a ceramic block 4, and a plurality of positioning blocks 5,

[0024] The cushion block 2, the ceramic block 4 and a plurality of positioning blocks 5 are located in the constraint frame 3, the ceramic block 4 is surrounded by a plurality of positioning blocks 5, and the prestressed loading part 1 can pass through the spacer block 2 to many A positioning block 5 applies stress, and a plurality of positioning blocks 5 can apply stress to the ceramic block 4, so that the internal stress of the ceramic block 4 is uniformly distributed. Under the action of the positioning block 5, the ceramic 4 produces a certain deformation, and internal stress is generated. The constraint frame 3 ensures that the positioning block 5 can e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com