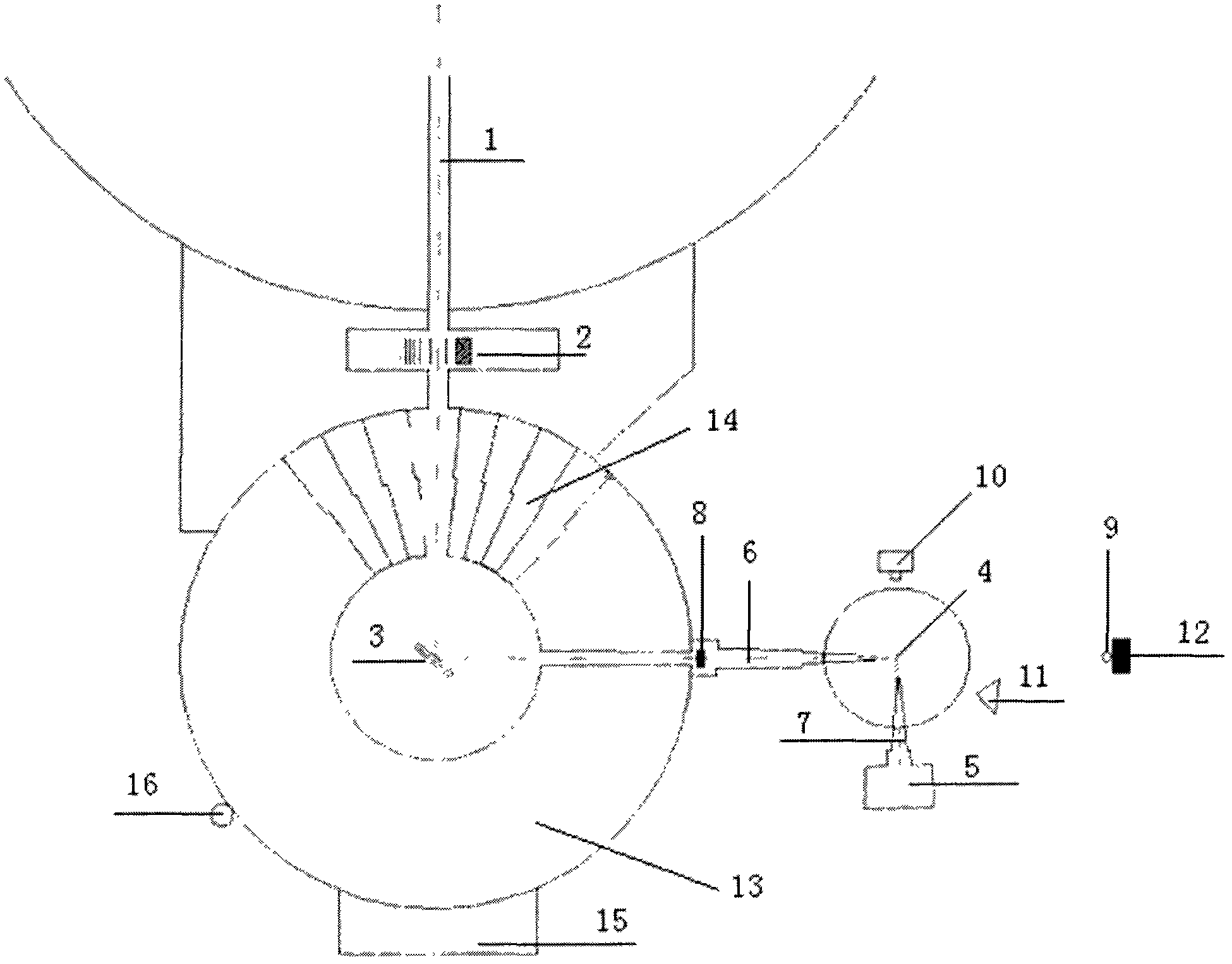

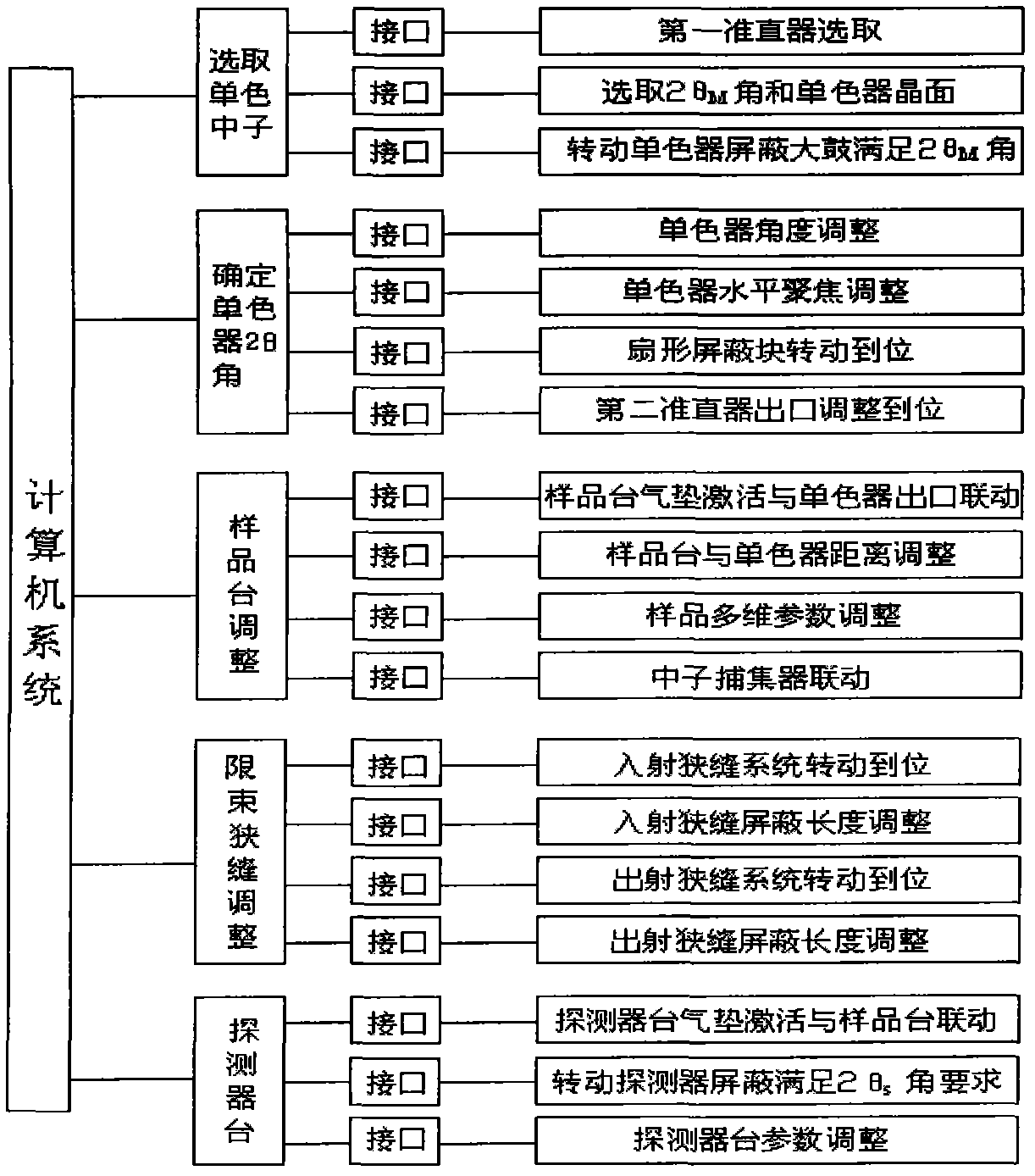

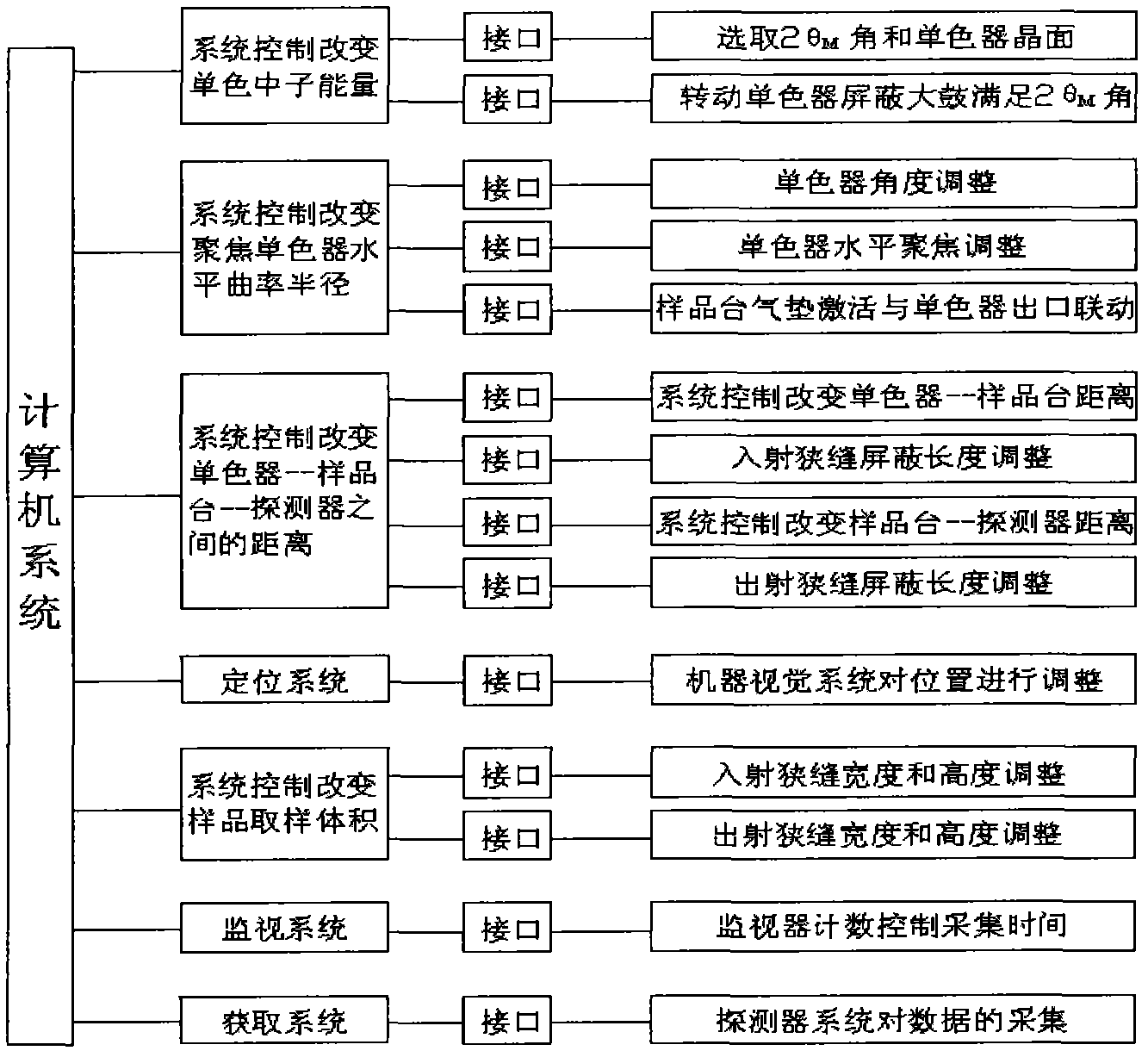

Neutron diffraction residual stress determination device and method

A technology of residual stress and measurement device, which is applied in the direction of material analysis using radiation diffraction, etc. It can solve the problems of heavy workload for delamination measurement, inability to perform such correction, and poor measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] In this embodiment, the material used in the experiment is low carbon steel (WA300 grade) with a length of 200mm, a width of 60mm, and a thickness of 8mm. The schematic diagram is as follows Figure 9 and Figure 10 As shown, the axial-flow 5kW CO2 laser is used to scan the surface three times along the width direction of the sample to achieve a bending angle of 0.9° (high-energy laser metal sheet forming is an emerging plastic processing method, which has high efficiency, flexibility, no mold, no external force And no noise and other advantages. It uses laser scanning metal sheet to produce obvious temperature gradient in the heat action area, resulting in non-uniform distribution of internal stress. When the internal stress exceeds the yield strength of the material, the sheet will be deformed. Therefore, laser forming Often referred to as laser bending forming or laser bending.Laser forming process overcomes the shortcomings of high cost and long production cycle cau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com