Method for etching suspending type etch blocking layer contact hole in embedded flash memory device

A technology for etching barrier layers and flash memory devices, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as loss of metal contact silicide, so as to reduce leakage loss, cut through depth, and reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

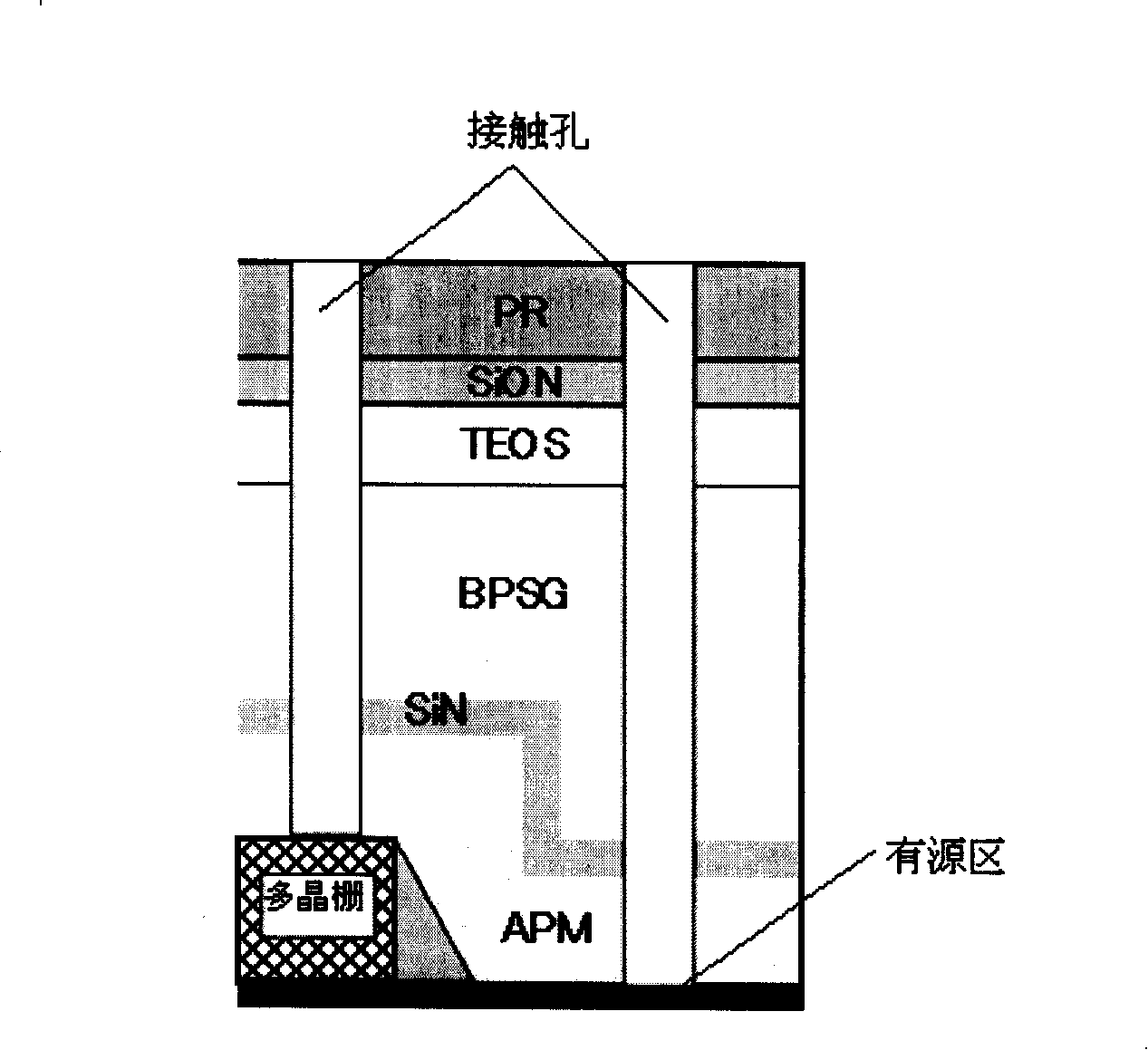

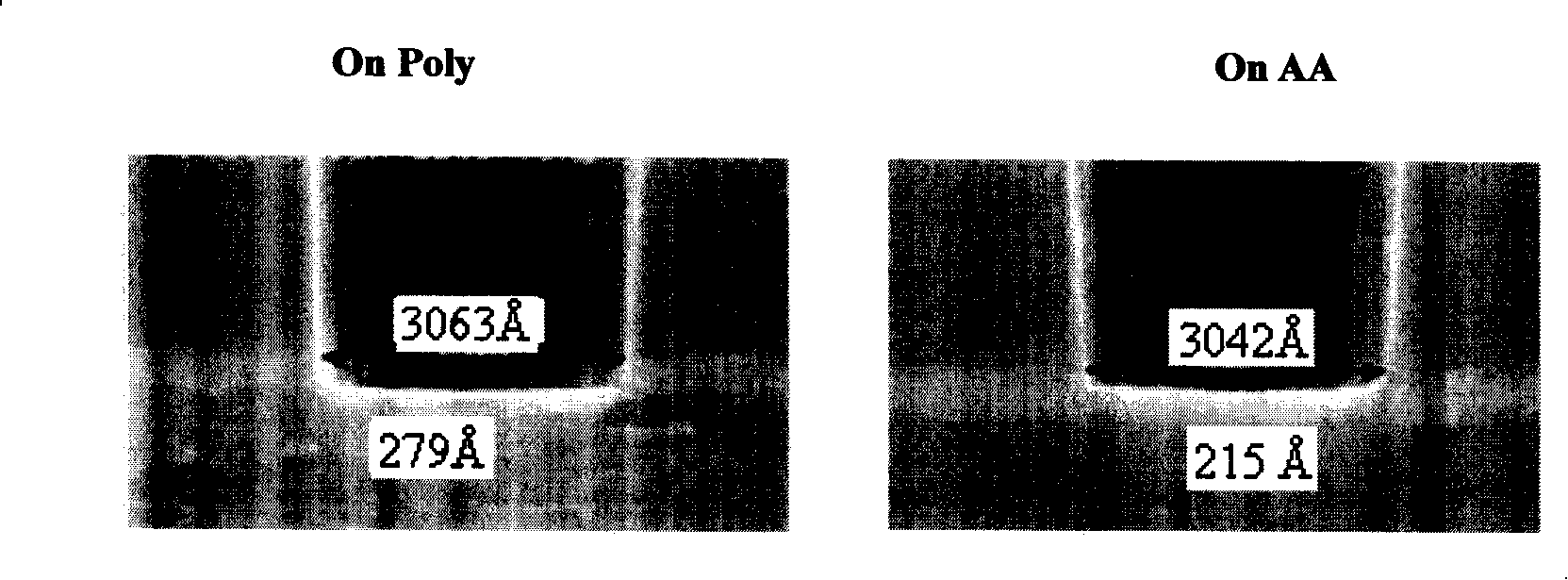

[0028] Since the etching of the contact hole needs to be etched sequentially from top to bottom DARC (SiON) / TEOS / BPSG / SiN / APM (see figure 1 ), so for films of different materials, use corresponding etching conditions.

[0029] The first step: etching of the top silicon oxynitride. If this layer of film is not etched clean (silicon oxynitride remains), it will affect the etching of the oxide film, and the opening will stop halfway (etch stop). Main parameters of this step: pressure 30-90 millitorr; upper / lower electrode power: 800-1200 / 800-1200 watts; argon 150-250sccm; trifluoromethane 15-25sccm; oxygen 5-25sccm; back helium pressure: 4-12 Torr in the middle, 10-20 Torr in the edge.

[0030] The second step: the rapid etching of the main etching of the oxide film. Considering the requirements of production efficiency, this step adopts the conditions of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com