Surface scratch-resistant TPV composition capable of achieving secondary coating forming with ABS base material and preparation method thereof

A secondary packaging and scratch-resistant technology, which is applied in the field of polymer materials, can solve the problem of not fundamentally eliminating the wear marks or scratches on the surface of the material, so as to increase the surface aesthetics and service life, and the production process is easy to operate, The effect of excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

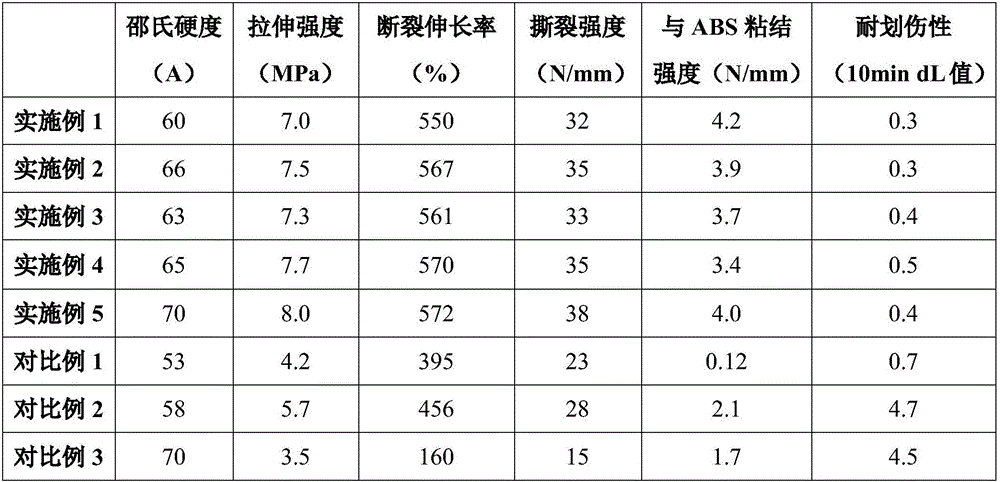

Examples

preparation example Construction

[0046] The preparation method of the surface scratch-resistant TPV composition with the secondary overmolding of the ABS substrate comprises the following steps:

[0047] 1) drying the polyester thermoplastic elastomer at 60-80°C for 4-8 hours;

[0048] 2) Mix the polyester thermoplastic elastomer, TPV, compatibilizer, ethylene-vinyl acetate copolymer and ethylene-acrylic acid ionomer in proportion, and then place them in a parallel co-rotating twin-screw extruder, melt extrude and granulation to obtain a surface scratch-resistant TPV composition that is overmolded with the ABS substrate for the second time.

[0049] Preferably, the screw aspect ratio L / D of the twin-screw extruder is (40-52):1, the screw speed is 200-280 rpm, and the extrusion temperature is 80-220°C.

Embodiment 1

[0052] A surface scratch-resistant TPV composition with secondary overmolding of ABS base material, its raw material components are as follows (mass percentage):

[0053] TPV (self-made, Shore hardness 35A): 31%;

[0054]TPU (C65AHPM, BASF): 40%;

[0055] EPDM-g-MAH (MC512, the light of energy): 8%;

[0056] EVA (40W, DuPont): 6%;

[0057] Na-E / MAA (Surlyn 8920, DuPont): 15%.

[0058] The preparation method of the above-mentioned surface scratch-resistant TPV composition with the secondary overmolding of the ABS substrate comprises the following steps:

[0059] 1) Dry the TPU in a vacuum oven with an oven temperature of 80°C and a drying time of 4 hours;

[0060] 2) Mix TPU, TPV, EPDM-g-MAH, EVA, and Na-E / MAA dried in step 1) uniformly in proportion, place them in a parallel co-rotating twin-screw extruder for melt extrusion, and granulate to obtain Surface scratch-resistant TPV composition with secondary overmolding of ABS substrate.

[0061] The screw length-to-diamete...

Embodiment 2

[0063] A surface scratch-resistant TPV composition with secondary overmolding of ABS base material, its raw material components are as follows (mass percentage):

[0064] TPV (self-made, Shore hardness 45A): 40%;

[0065] TPU (C65AHPM, BASF): 35%;

[0066] EPDM-g-MAH (MC512, the light of energy): 6%;

[0067] EVA (40W, DuPont): 4%;

[0068] Na-E / MAA (Surlyn 8920, DuPont): 15%.

[0069] The preparation method of the above-mentioned surface scratch-resistant TPV composition with the secondary overmolding of the ABS substrate comprises the following steps:

[0070] 1) Dry the TPU in a vacuum oven with an oven temperature of 80°C and a drying time of 4 hours;

[0071] 2) Mix TPU, TPV, EPDM-g-MAH, EVA and Na-E / MAA dried in step 1) uniformly in proportion, and place them in a parallel co-rotating twin-screw extruder for melt extrusion and granulation to obtain Surface scratch-resistant TPV composition with secondary overmolding of ABS substrate.

[0072] The screw length-to-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com