Antistatic compact laminate and preparation method thereof

An anti-folding board and anti-static technology, which is applied in the field of building decoration materials, can solve the problems of limited use and the anti-static performance of anti-folding boards cannot meet the requirements, and achieve antistatic performance improvement, strong chemical resistance and durability Effect of improving friction performance and surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

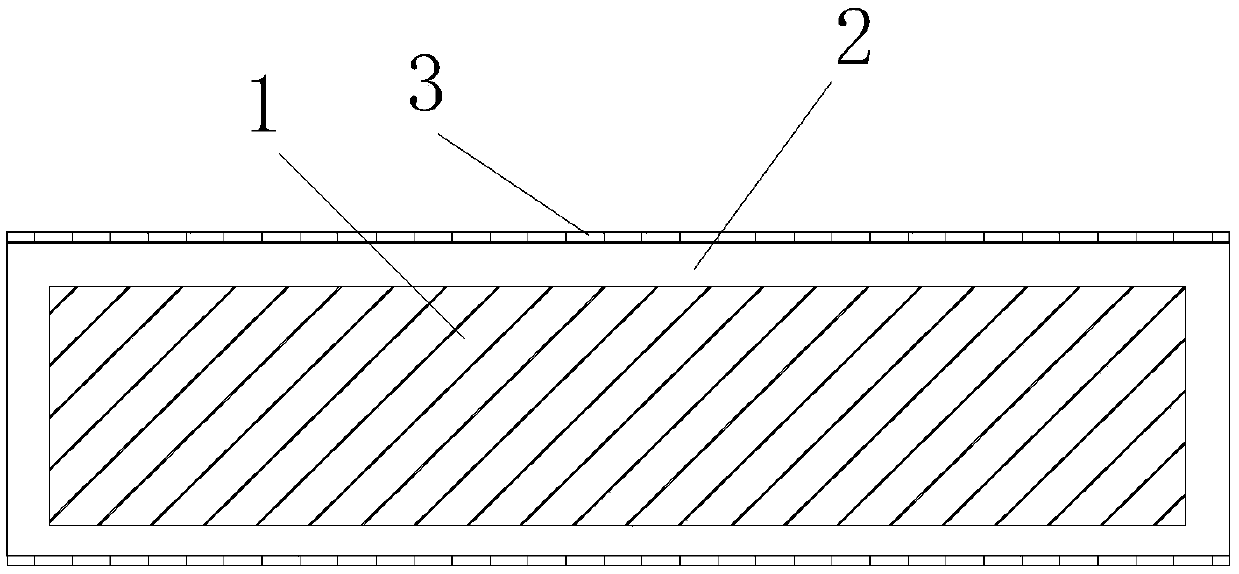

[0021] Such as figure 1 As shown, the antistatic and anti-folding board of this embodiment includes a substrate 1, and the outside of the substrate 1 is coated with a decorative paper 2 treated with impregnated resin. Cured coating 3, the electron beam cured coating 3 is composed of the following raw materials by weight percentage: 30% polyester acrylic acid, 19% phenolic acrylic acid, 15% co-crosslinking agent, 15% hexanediol diacrylate, flame retardant 4%, coupling agent 0.5%, leveling agent 0.5%, nano-silver powder 10%, dispersant 1%, antistatic agent 5%, the above materials are stirred and mixed to obtain electron beam curing coating resin, wherein the co-crosslinking agent is Trimethylolpropane Triacrylate.

Embodiment 2

[0023] The manufacture method of the antistatic anti-fold special board of embodiment 1, comprises the steps:

[0024] A. Electron beam curing coating resin preparation: Add the following raw materials into the mixer by weight percentage, including polyester acrylic acid 30%, phenolic acrylic acid 19%, co-crosslinking agent 15%, hexanediol diacrylate 15%, barrier Combustion agent 4%, coupling agent 0.5%, leveling agent 0.5%, nano silver powder 10%, dispersant 1%, antistatic agent 5%, start the agitator and heat to 50 ° C, stir evenly, vacuumize, and obtain electrons Beam cured coating resin solution.

[0025] B. Impregnate the decorative paper with resin, dry and rewind to ensure that the obtained decorative paper has a uniform weight, a smooth surface, and the light fastness rating of the printing ink is not less than 6.

[0026] C. Glue coating and curing. Apply the electron beam curing coating resin in step A to the impregnated decorative paper obtained in step B by rollin...

Embodiment 3

[0035] A kind of manufacturing method of antistatic anti-fold special board, on the basis of embodiment 2, there is following difference in the manufacturing method of present embodiment:

[0036] In step B, the grammage of the decorative paper before impregnation is 130 g / m2, the amount of glue applied during impregnation is 80 g / m2, the volatile matter is 3%, and the light fastness rating of the printing ink is grade 7 to ensure uniform impregnation of the decorative paper.

[0037] In step B, the impregnated resin is a mixture of melamine-formaldehyde resin and phenol-formaldehyde resin, wherein the mass percentage of melamine-formaldehyde resin is 50%, and the mass percentage of phenol-formaldehyde resin is 50%, so as to ensure the decoration after impregnation The paper retains its toughness while retaining its affinity for electron beam cured coating resins.

[0038]In step C, the coating thickness is 0.15 mm; in step D, the substrate is made of fiberboard substrate impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com