Outdoor weather-proof compact laminate and preparation method thereof

A technology of anti-folding special board and weather resistance, applied in the field of building decoration materials, can solve the problems of poor weather resistance, falling off of decorative paper, affecting product quality and aesthetics, etc., to achieve strong chemical resistance, wear resistance and scratch resistance. Good adaptation to the effect of outdoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

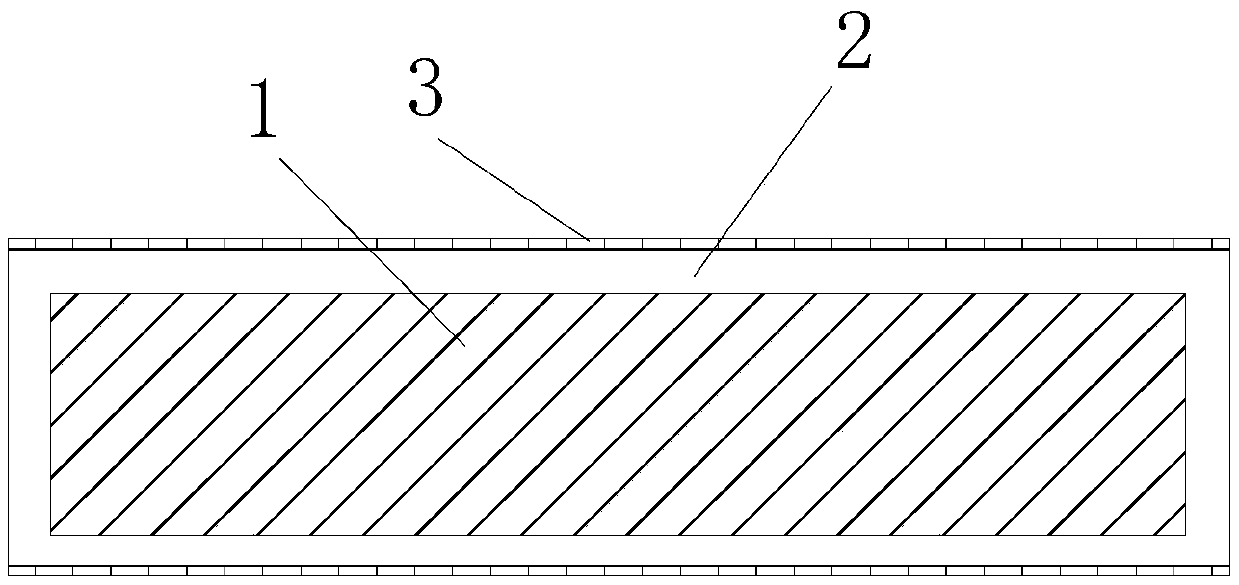

[0022] Such as figure 1 As shown, the weather-resistant and anti-folding board for outdoor use in this embodiment includes a substrate, and the outside of the substrate is coated with decorative paper treated with impregnated resin. The electron beam cured coating is composed of the following raw materials by weight percentage: polyurethane acrylic acid 50%, epoxy acrylic acid 7%, co-crosslinking agent 15%, hexanediol diacrylate 15%, light stabilizer 1%, flame retardant 3%, UV absorber 2%, antioxidant 5%, coupling agent 0.5%, leveling agent 0.5%, dispersant 1%, the above materials are stirred and mixed to obtain electron beam curing coating resin, wherein the co-crosslinking agent is Trimethylolpropane triacrylate, the light stabilizer is hindered amine light stabilizer.

Embodiment 2

[0024] The manufacturing method of the weather-resistant and anti-fold special board for outdoor use of embodiment 1 comprises the following steps:

[0025] A. Electron beam curing coating resin preparation: Add the following raw materials into the mixer by weight percentage, including 50% polyurethane acrylic acid, 7% epoxy acrylic acid, 15% trimethylolpropane triacrylate, and hexanediol diacrylate 15%, hindered amine light stabilizer 1%, flame retardant 3%, ultraviolet absorber 2%, antioxidant 5%, coupling agent 0.5%, leveling agent 0.5%, dispersant 1%, start the agitator and Heating to 50° C., stirring evenly, and vacuumizing to obtain an electron beam curing coating resin solution.

[0026] B. Impregnate the decorative paper with resin, dry and rewind to ensure that the obtained decorative paper has a uniform weight, a smooth surface, and the light fastness rating of the printing ink is not less than 6.

[0027] C. Glue coating and curing. Apply the electron beam curing c...

Embodiment 3

[0036] A method for manufacturing an outdoor weather-resistant and anti-folding board. On the basis of Embodiment 2, the manufacturing method of this embodiment has the following differences:

[0037] In step B, the grammage of the decorative paper before impregnation is 100 g / m2, the amount of glue applied during impregnation is 75 g / m2, the volatile matter is 3%, and the light fastness rating of the printing ink is grade 8 to ensure uniform impregnation of the decorative paper.

[0038] In step B, the impregnated resin is a mixture of melamine-formaldehyde resin and phenol-formaldehyde resin, wherein the mass percentage of melamine-formaldehyde resin is 50%, and the mass percentage of phenol-formaldehyde resin is 50%, so as to ensure the decoration after impregnation The paper retains its toughness while retaining its affinity for electron beam cured coating resins.

[0039] In step C, the coating thickness is 0.17mm; in step D, the substrate is made of fiberboard substrate im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com