Heat shrink tube and manufacturing method of the same

A manufacturing method and heat-shrinkable tube technology, which are applied in the installation of electrical components, cable accessories, cables, etc., can solve the problems of heat-shrinkable tube wrinkles and irregular shape of the heat-shrinkable tube coating, and improve the surface aesthetics. and subsequent processing assembly performance, the effect of solving surface wrinkles and bulging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

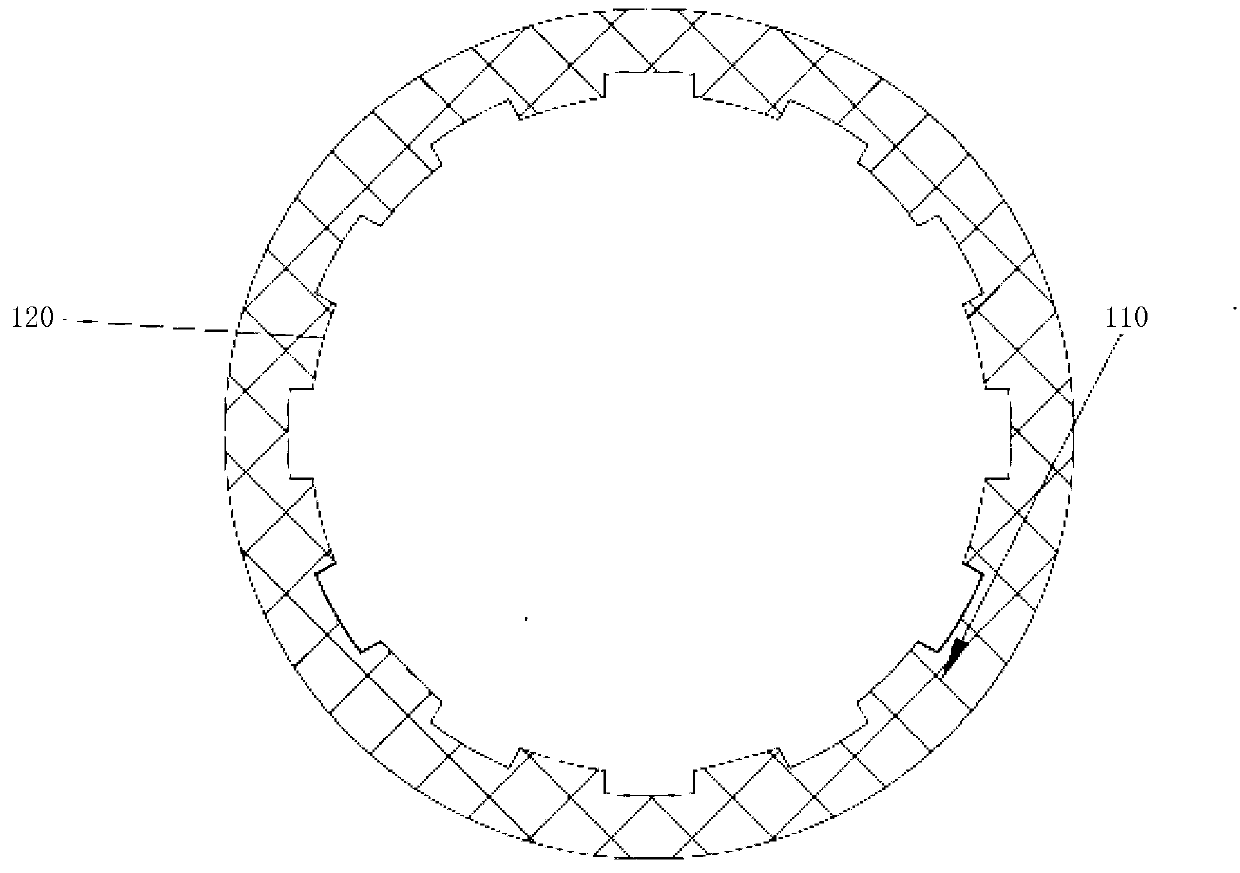

[0019] See figure 1 , which is a schematic cross-sectional structure diagram of a heat-shrinkable tube provided by an embodiment of the present invention.

[0020] Axial shrinkage rate: (length L2 of heat-shrinkable empty tube after heating and shrinkage - length L2 before shrinkage) / length L2 before shrinkage × 100%.

[0021] The inner wall 110 of the heat-shrinkable tube is provided with grooves 120 extending axially through it.

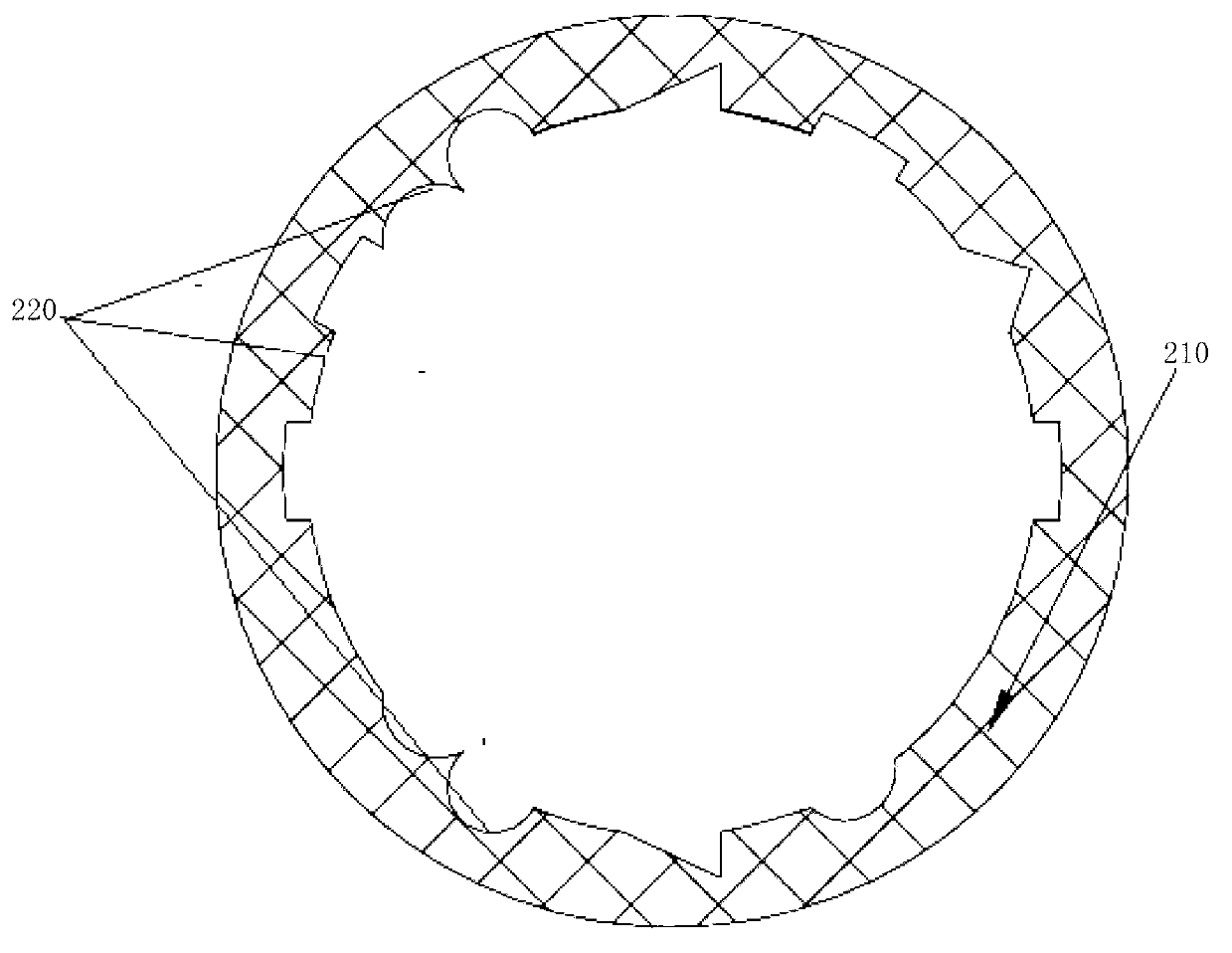

[0022] In the embodiment of the present invention, please refer to figure 2 , the cross section of the groove 210 is helical, square, zigzag or circular arc.

[0023] In an embodiment of the present invention, the grooves are evenly distributed on the inner wall.

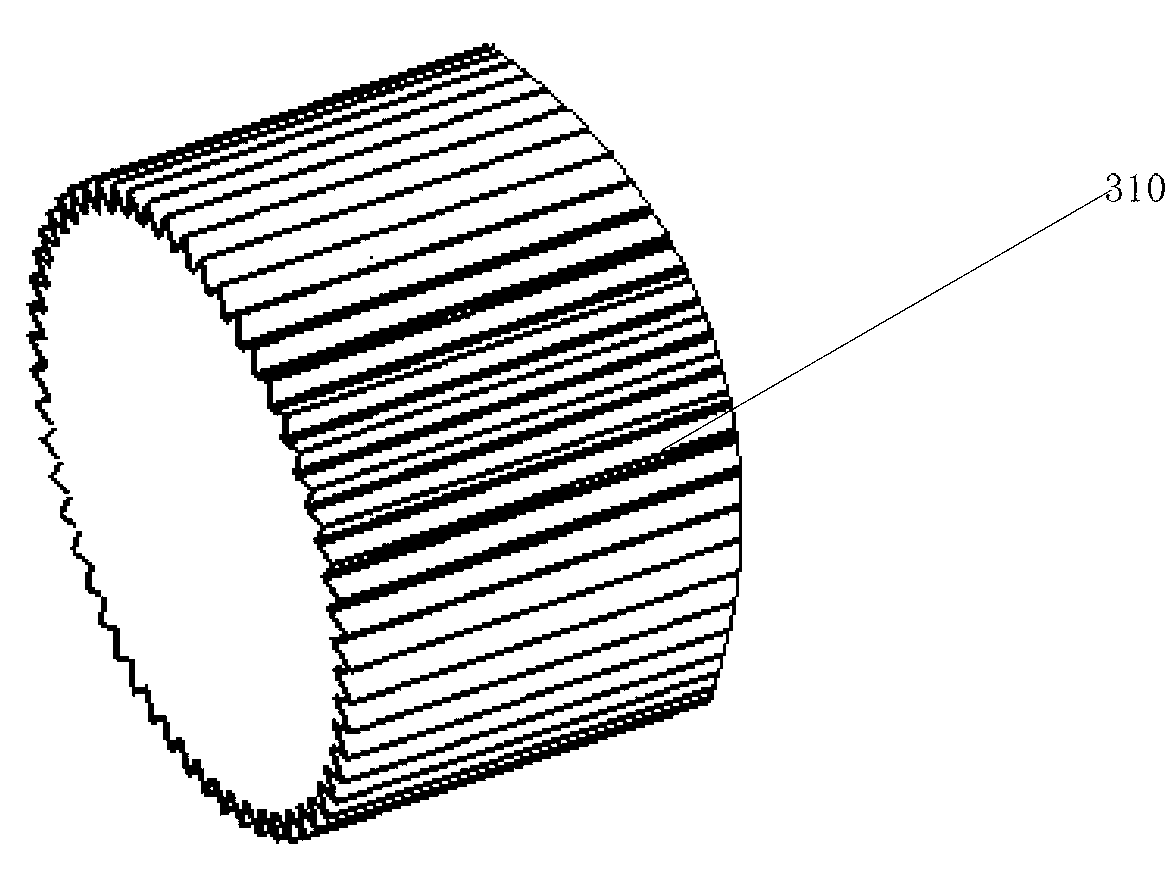

[0024] In the embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com