Forming method of L-shaped variable cross-section hollow-structure composite material wave-absorbing component with sawteeth

A composite material and molding method technology, which is applied in the molding field of a serrated L-shaped variable-section hollow structure composite wave-absorbing component, can solve the problems of difficulty in cleaning, poor dimensional stability, weak structural strength, etc., and saves time and labor. cost, improved power resistance, and improved structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

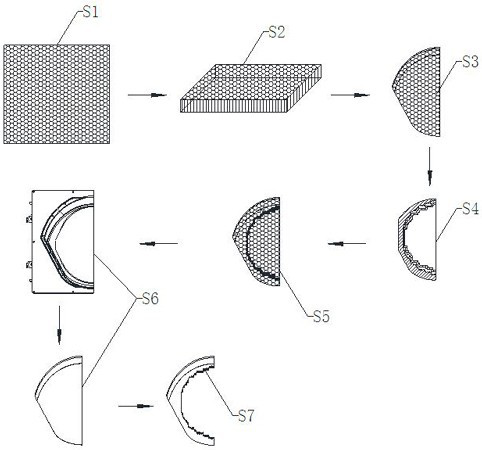

[0033] like figure 1 As shown, a forming method of a sawtooth L-shaped variable cross-section hollow structure composite material absorbing part includes the following steps:

[0034] S1. According to the external dimensions of the product, cut the honeycomb after leaving the margin, and cut out the honeycomb blank that meets the processing requirements. The blank size is: 1400mm*1300mm*170mm;

[0035] S2. According to the performance requirements, select the impregnation system to impregnate the absorbent in the honeycomb, and carry out the gradient design of the impregnation. According to the performance simulation results, impregnate the absorbent with different concentrations in the thickness direction, and the concentration of the absorbent gradually increases from botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com