Processing method of 2.5D mobile phone front and rear covers

A processing method and technology for mobile phone covers, which are applied in the fields of telephone structure, telephone communication, electrical components, etc., can solve the problems of complex processing technology, unstable manufacturing process and high manufacturing cost of the front and rear covers of mobile phones, so as to solve the problems of after-sales cost and low processing difficulty. , Increase the effect of beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

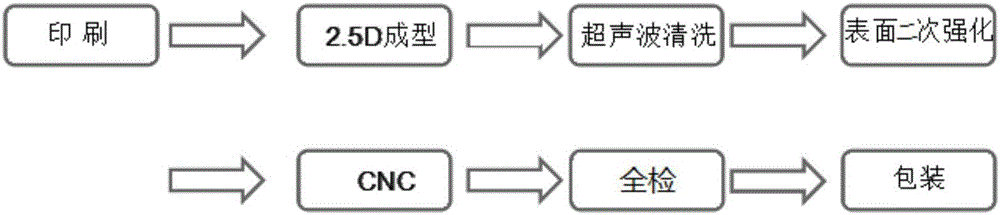

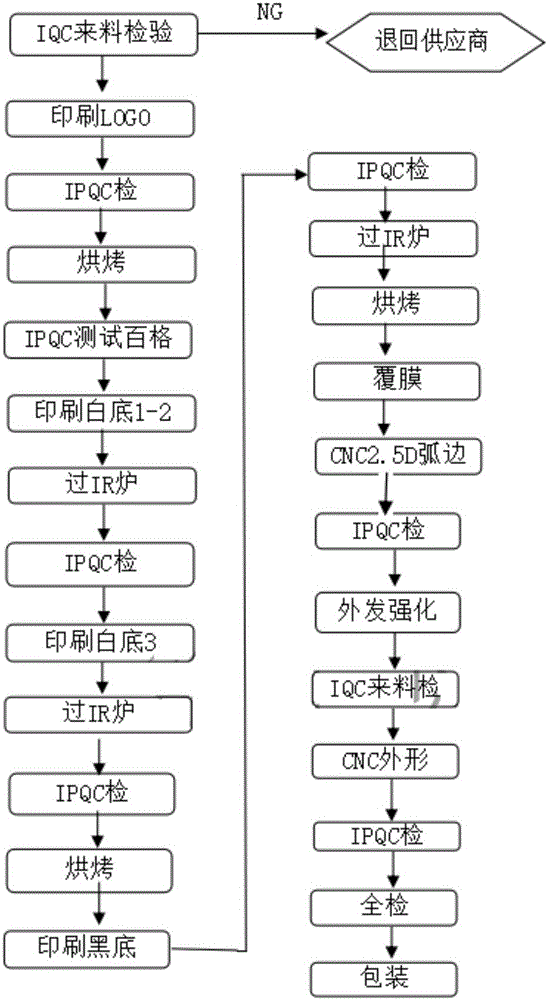

[0043] see Figure 1-3 Shown, a kind of 2.5D mobile phone front and back cover processing method, its method comprises the steps:

[0044] Step A: Cutting: After purchasing large sheets of raw materials, cut them into sheets of reasonable size according to internal needs;

[0045] Step B: printing: screen printing the sheet cut in step A;

[0046] Step C: 2.5D forming: the sheet printed in step B is processed and formed by a CNC machine with a 2.5D tool;

[0047] Step D: Ultrasonic cleaning: The front cover of the mobile phone processed and formed in step C is professionally cleaned by ultrasonic waves;

[0048] Step E: secondary strengthening of the surface: secondary strengthening and hardening layer on the front of the front cover of the mobile phone after cleaning in step D;

[0049] Step F: CNC engraving: Cut the front cover of the mobile phone after the secondary strengthening in step E into finished products by engraving machine;

[0050] Among them, the CNC carving...

Embodiment 2

[0075] When applied to process the mobile phone back cover, a 2.5D mobile phone front and rear cover processing method, the method comprises the following steps:

[0076] Step A: Cutting: After purchasing large sheets of raw materials, cut them into sheets of reasonable size according to internal needs;

[0077] Step B: printing: screen printing the sheet cut in step A;

[0078] Step C: 2.5D forming: the sheet printed in step B is processed and formed by a CNC machine with a 2.5D tool;

[0079] Step D: Ultrasonic cleaning: The back cover of the mobile phone processed and formed in Step C is professionally cleaned by ultrasonic waves;

[0080] Step E: secondary strengthening of the surface: secondary strengthening and hardening of the front of the back cover of the mobile phone after step D cleaning;

[0081] Step F: CNC engraving: Cut the back cover of the mobile phone after the secondary strengthening in step E into a finished product by engraving machine;

[0082] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com