Method for reducing gas production bumps of soft package lithium ion battery and soft package lithium ion battery

A lithium-ion battery, ion battery technology, used in secondary battery charging/discharging, electrical components, secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

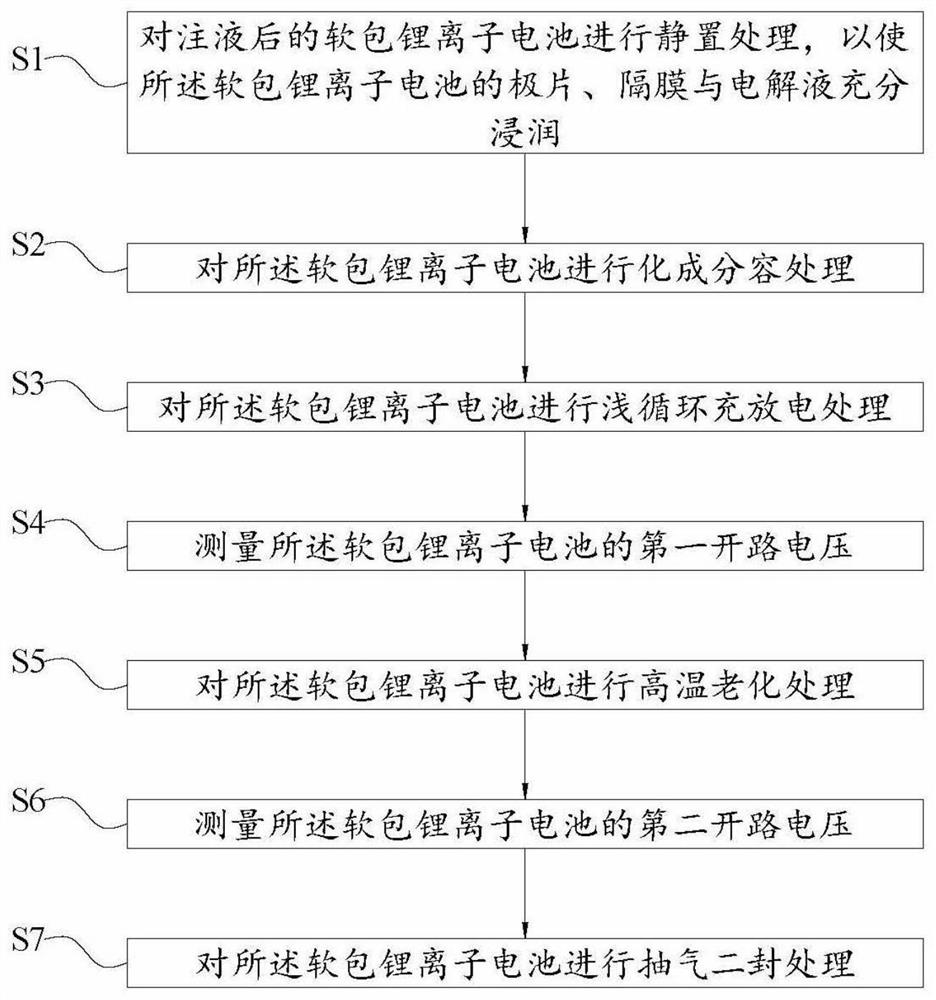

[0044] see figure 1 As shown, the soft-pack lithium ion battery of this embodiment is made by reducing the gas bulging of the soft-pack lithium-ion battery. The method for reducing the gas bulging of the soft-pack lithium-ion battery includes the following steps:

[0045] S1. Static treatment is performed on the soft-packed lithium-ion battery after liquid injection, so that the pole piece, diaphragm and electrolyte of the soft-packed lithium-ion battery are fully infiltrated;

[0046] S2. Carrying out chemical composition and capacity processing on the soft-pack lithium-ion battery;

[0047] S3, performing shallow cycle charge and discharge treatment on the soft-pack lithium-ion battery;

[0048] S4. Measuring the first open circuit vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com