Vacuum-resistant inner liner PTFE container and manufacturing process thereof

A PTFE and container technology, which is applied to the field of lined PTFE containers, can solve the problems of pressure containers that affect the strength of container steel parts, large workload, and unsuitable for use, and achieves the effect of easy procurement and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

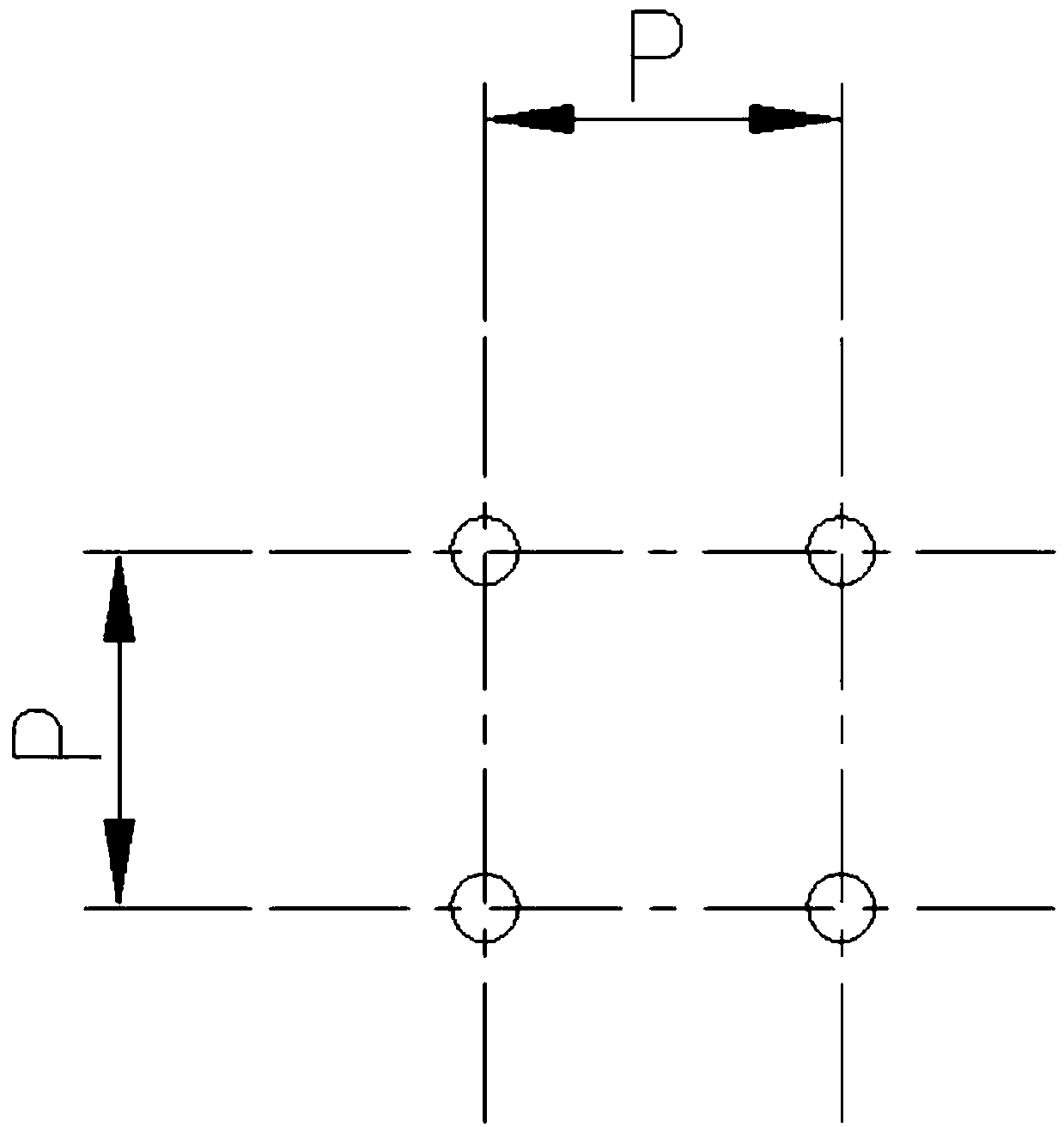

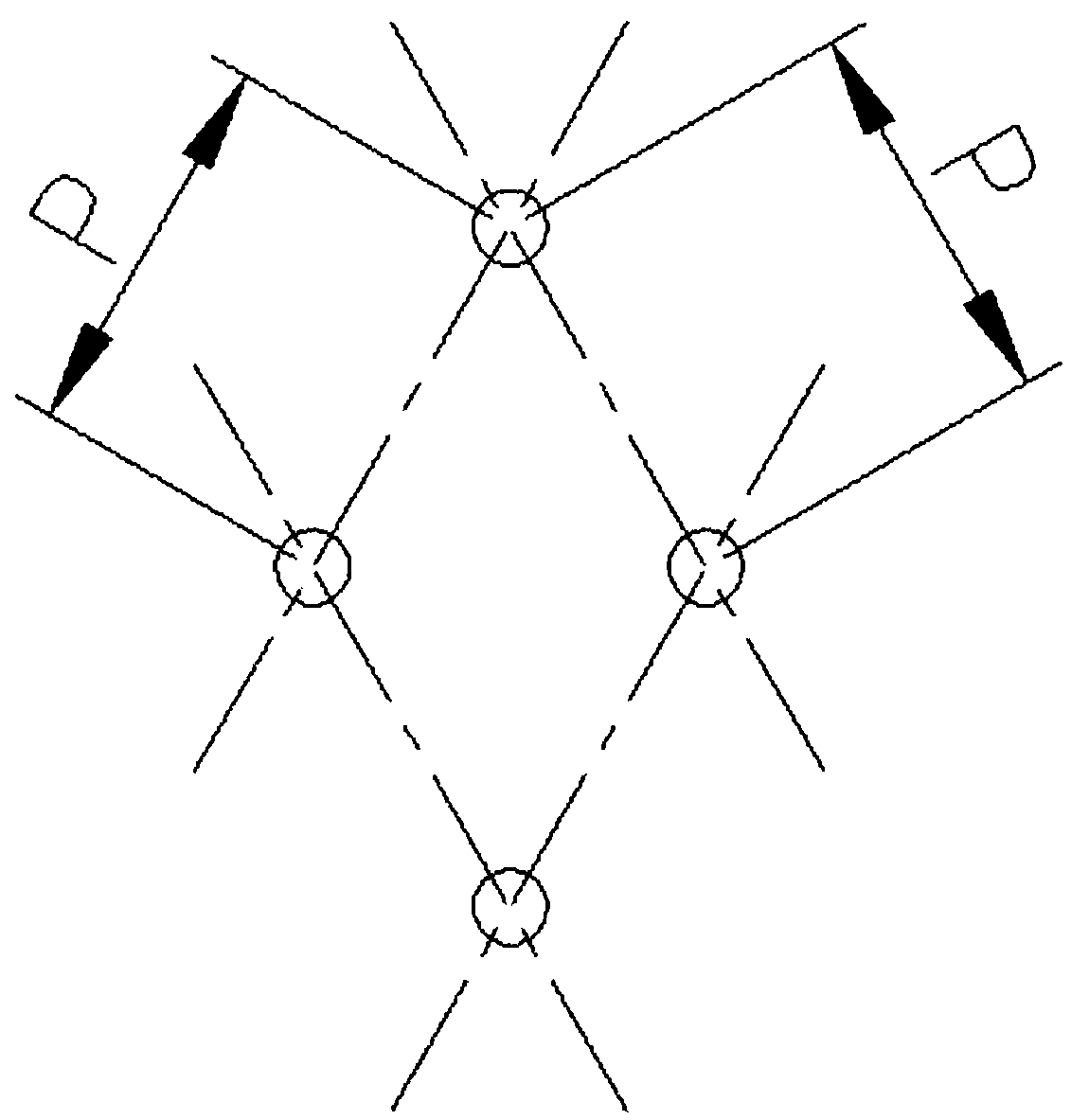

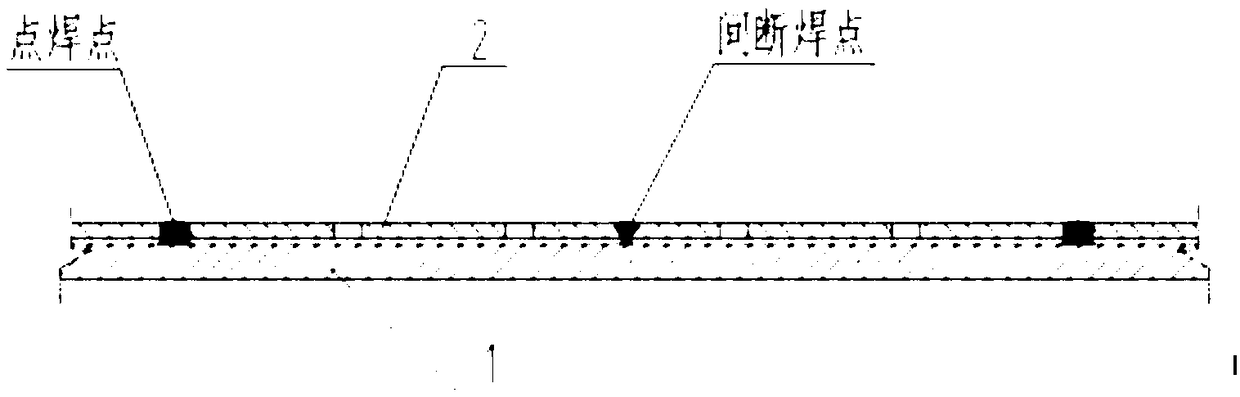

[0033] Such as Figure 1-Figure 7 As shown, the vacuum-resistant lined PTFE container provided by the present embodiment includes a container steel part 1, a layer of PTFE3 is arranged in the container steel part 1, a perforated plate 2 is arranged between the container steel part 1 and PTFE3, and the container steel part 1 There are several vacuum balance ports 7, and the container steel part 1 is connected with a temporary vacuum tube group 6 through the vacuum balance port 7, and the temporary vacuum tube group 6 is connected with a vacuum pump. After the container steel part 1 completes the vacuum extraction and the electric spark test, the temporary The vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com