Bias ply tire bead structure and carcass tire cord fabric reverse coating forming method

A technology of carcass cord and forming method, which is applied in the direction of tires, tire edges, tire parts, etc., can solve the problems of uneven force on the steel ring, shorten the service life of bias tires, and gas leakage, etc., to solve the problem of sidewall drum kit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

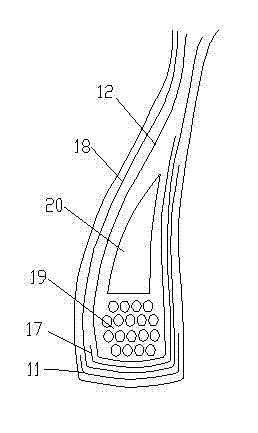

[0016] Please refer to figure 1 The bias tire bead structure according to the first embodiment of the present invention is shown, including a steel ring 19, an apex 20 adjacent to the steel ring 19, a first turn-up ply 12 surrounding the steel ring 11 and the apex 20, and a The front ply 17 outside the first turn-up ply 12, the outer turn-up ply 18 outside the front ply 17, and the toe pad rubber 11 arranged below the above-mentioned layers of ply.

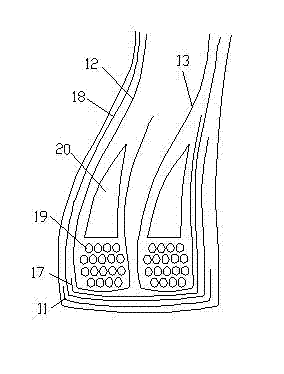

[0017] Please refer to figure 2 The bias ply tire bead structure according to the second embodiment of the present invention is shown, including two steel rings 19, two apex rubbers 20 adjacent to the two steel rings 19 respectively, and a first rubber apex 20 covering the two steel rings 19 and the apex rubber 20 respectively. A turn-up ply 12 and a second turn-up ply 13, while forward wrapping the positive wrap ply 17 at the bottom of the first and second turn-up ply 12, 13, reversely wrapping the outer ply 17 of the turn-up p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com