Method for producing automobile axle rear cover by using precoated sand process

A technology for coated sand and automobiles, which is applied to axles, wheels, manufacturing tools, etc., can solve the problems of high residual strength of sand shells, unstable surface quality, low production efficiency, etc., achieve uniform product thickness, shorten the production process, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

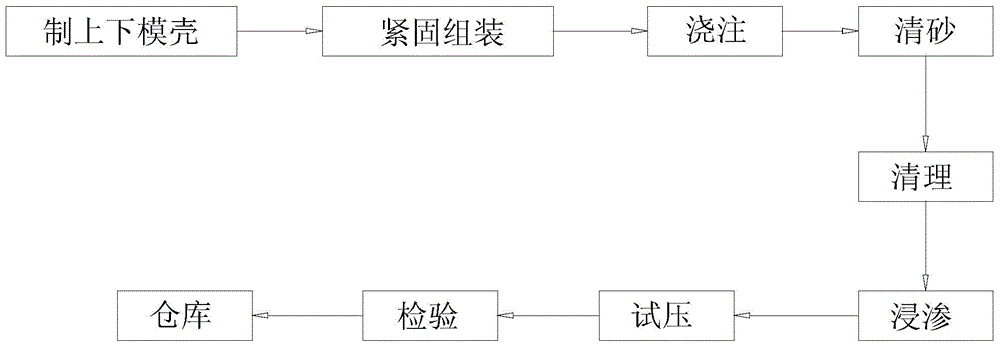

[0021] Please refer to figure 1 , the method for producing the automobile axle rear cover with the coated sand process comprises the steps:

[0022] (1) Use the core shooter to manufacture the upper and lower mold shells of the coated sand.

[0023] (2) Fasten and assemble the upper and lower mold shells together to form a casting mold. In this step, the clamping device is used to clamp the upper and lower mold shells to prevent dislocation of the upper and lower mold shells during casting and leakage of pouring liquid from the periphery.

[0024] (3) Inject molten steel into the pouring formwork from the pouring riser of the pouring formwork, allowing the molten steel to cool naturally and form a casting. In this step, the molten steel goes up and down the formwork, and the natural cooling time is 20 minutes.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com