Sandwich structure radar radome and preparation method thereof

A technology of radome and sandwich structure, which is applied to antennas, antenna parts, chemical instruments and methods, etc., can solve the problem of debonding between honeycomb and skin, and achieve the effect of improving environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a second aspect, the present invention provides a method for preparing the sandwich structure radome described in the first aspect of the present invention, said method comprising the steps of:

[0038] (1) Paste the radome skin I prepreg on the radome mold to obtain the radome skin green body;

[0039] (2) bonding the honeycomb core layer through an adhesive film on the radome skin blank, and curing and molding in an autoclave (autoclave forming) to obtain a prefabricated body comprising the radome skin I and the honeycomb core layer;

[0040] (3) mix the resin material and the hollow glass microspheres uniformly with a solvent and / or diluent and fill them in the grid of the honeycomb core layer included in the prefabricated body;

[0041] (4) Adhesive film and radome skin II prepreg are pasted on the surface of the honeycomb core layer filled with the resin material and the hollow glass microspheres, and the sandwich structure radome is obtained by curing and moldi...

Embodiment 1

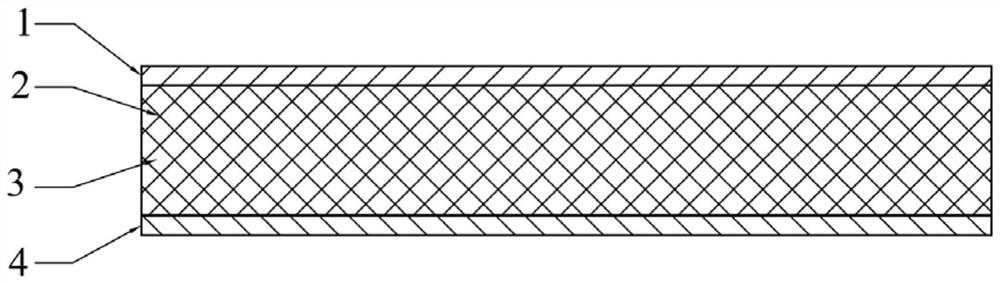

[0051] A kind of sandwich structure radar radome is made up of radome outer skin, filling core layer and radome inner skin; Described filling core layer comprises honeycomb core layer and the honeycomb filler that fills in the grid of described honeycomb core layer, The honeycomb filler is formed by mixing and curing resin materials and hollow glass microspheres. The inner skin of the radome and the outer skin of the radome are both quartz fiber / cyanate composite materials with a thickness of 0.6mm, the honeycomb core layer is Nomax honeycomb core layer with a thickness of 8.5mm, and the honeycomb filler is cyanate resin For the blended hollow glass microspheres, the mass ratio of cyanate resin and hollow glass microspheres is 1:1.5; the lowest wave transmittance of the radome in the L and S frequency bands of this structure is 85%.

[0052] The preparation method is as follows: firstly, cyanate quartz cloth prepreg (radome outer skin prepreg) is pasted on the female mold of t...

Embodiment 2

[0055] A kind of sandwich structure radar radome is made up of radome outer skin, filling core layer and radome inner skin; Described filling core layer comprises honeycomb core layer and the honeycomb filler that fills in the grid of described honeycomb core layer, The honeycomb filler is formed by mixing and curing resin materials and hollow glass microspheres. The inner skin of the radome and the outer skin of the radome are both glass fiber / epoxy resin composite materials with a thickness of 1.0mm, the honeycomb core layer is Nomax honeycomb core layer with a thickness of 15.2mm, and the honeycomb filler is epoxy Hollow glass microspheres blended with resin, the mass ratio of epoxy resin and hollow glass microspheres blended is 1:1.5; the minimum wave transmittance of the radome of this structure is 75% in the C frequency band.

[0056] The preparation method is as follows: firstly, paste epoxy resin glass cloth prepreg (radome outer skin prepreg) on the female mold of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com