A kind of process of making magnesium oxide composite sheet

A production process, magnesium oxide technology, applied in the application of ultra-high pressure process, the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, etc., can solve the problem of harm to the human body, affecting the performance of pressure transmission and heat preservation, Environmental pollution and other issues, to achieve the effect of reducing heat dissipation, improving quality and synthesis stability, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The manufacturing process of the present embodiment magnesium oxide composite sheet is:

[0029] (1) Dry magnesia powder and zirconia powder at 300°C for 30 minutes;

[0030] (2) Take 80g of magnesia powder and 20g of zirconia powder dried in step (1), mix the magnesia powder and zirconia powder evenly, add 10g of distilled water, stir evenly, and make a mixed slurry;

[0031] (3) Pressing the mixed slurry produced in step (2) into a tablet to make a magnesium oxide prefabricated tablet;

[0032] (4) Put the magnesium oxide prefabricated sheet in an oven, set the temperature at 200°C for 60 minutes, at 800°C for 30 minutes, and at 1300°C for 120 minutes to prepare the magnesium oxide sheet.

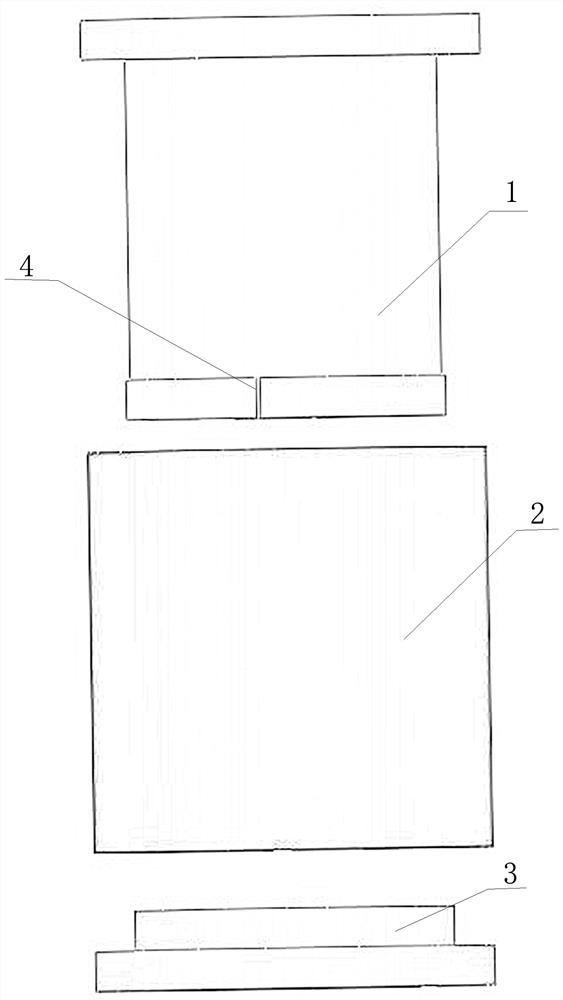

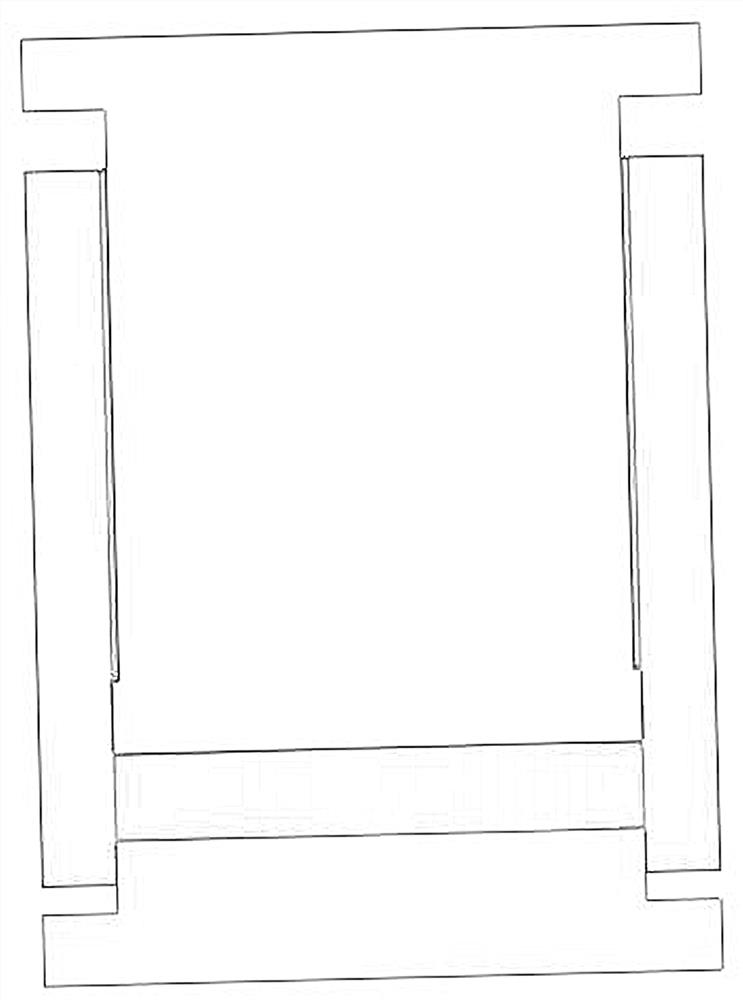

[0033] In this embodiment, the pressed abrasive tool used in step (3) is as figure 1 and 2 As shown, the pressed abrasive tool includes an upper indenter 1, a body 2, and a lower indenter 3, and at least two exhaust slots 4 are provided on the bottom side of the upper indenter 1...

Embodiment 2

[0035] The manufacturing process of the magnesium oxide composite sheet of this embodiment is the same as that of Example 1, and the difference is that

[0036] Magnesia powder is 80g, zirconia powder is 10g, distilled water is 5g;

[0037] The holding time is: 30 minutes at 200°C, 40 minutes at 800°C, and 100 minutes at 1300°C.

Embodiment 3

[0039] The manufacturing process of the magnesium oxide composite sheet of this embodiment is the same as that of Example 1, and the difference is that

[0040] Magnesia powder is 85g, zirconia powder is 15g, distilled water is 10g,

[0041] The holding time is: 50 minutes at 200°C, 50 minutes at 800°C, and 150 minutes at 1300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com