Rubber fabric clamped film sheet and manufacturing method thereof

A technology of rubber cloth and manufacturing method, applied in the field of pressure reducing valve, can solve the problems of restricting the delivery schedule of products, difficult to separate diaphragms, low qualified rate of diaphragms, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1] Soak the reinforced fabric in peroxysilane, take it out after 2 hours and let it dry naturally.

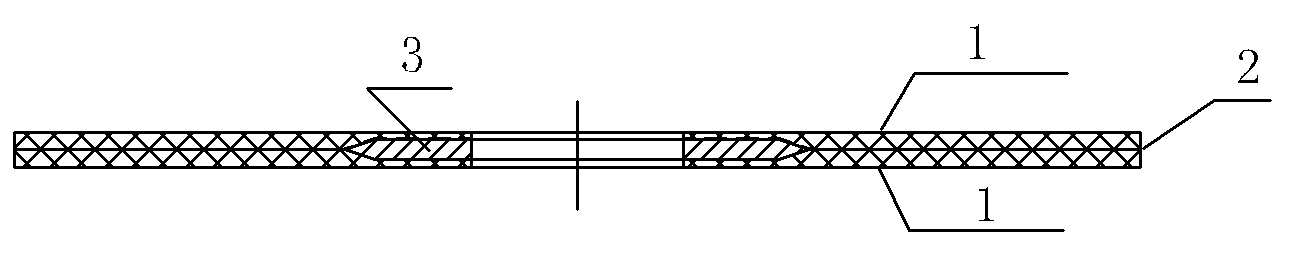

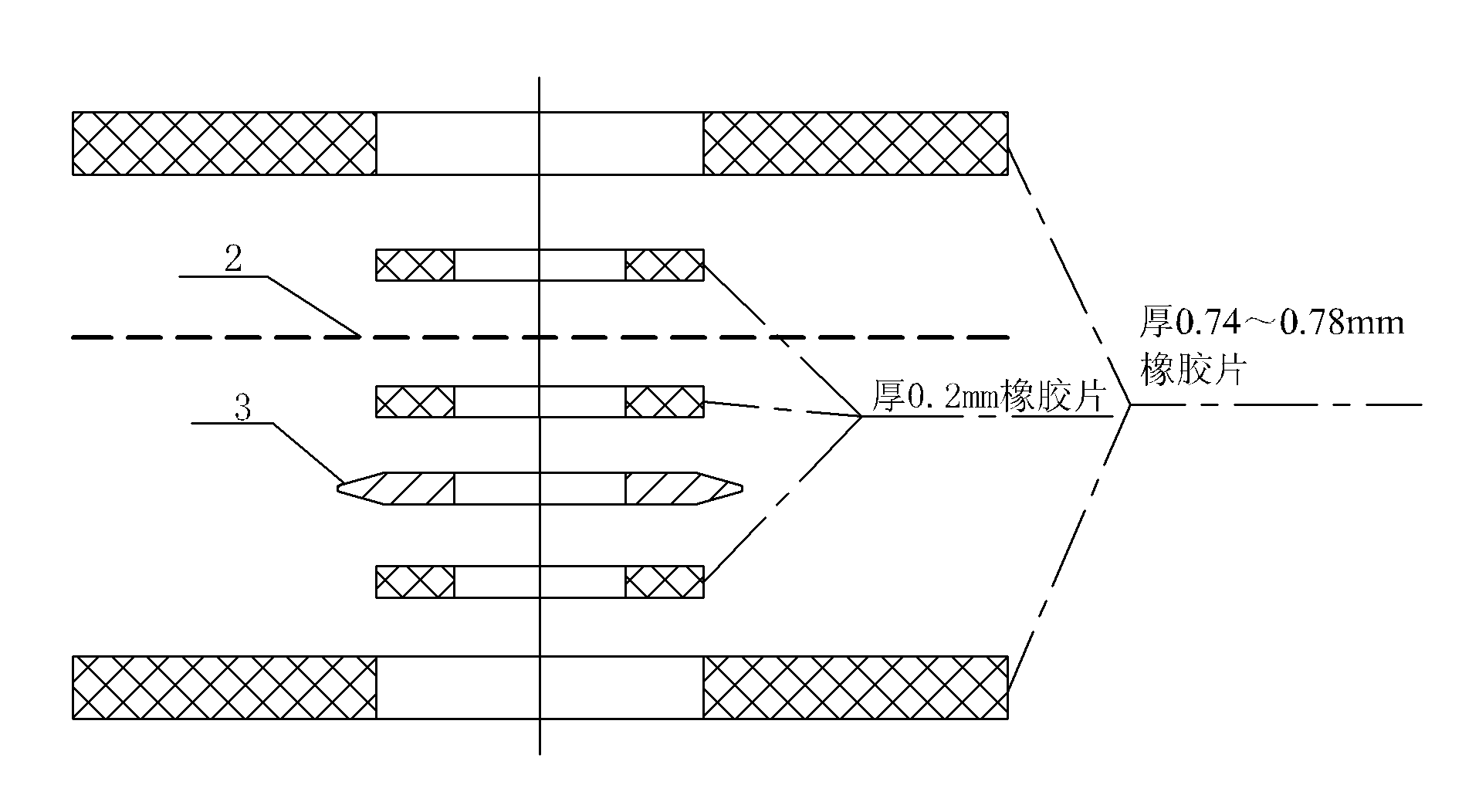

[0038] 2] The diaphragm is molded and vulcanized, and the stacking sequence of rubber, reinforced fabric and metal skeleton is as follows: figure 2 , The vulcanization temperature is 151±2°C, the vulcanization pressure is 20-50kN, and the vulcanization time is 40min. After opening the mold, store the diaphragm at an ambient temperature of 0-15°C.

[0039] 3] Coat the surface of 13 diaphragms with grease and stack them together, clamp and fix the outer circle, and use a high-precision grinder to grind the inner hole, the size reaches Then clamp and fix the inner hole of the diaphragm, grind the outer circle, and the size reaches During the grinding process, spray alcohol to the diaphragm to cool down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com