Method for realizing surface flattening of pit-shaped microarray structural unit by secondary pressing

A microarray structure and surface planarization technology, applied in the mechanical field, can solve problems such as residual stress, and achieve the effects of reducing surface energy, high achievability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

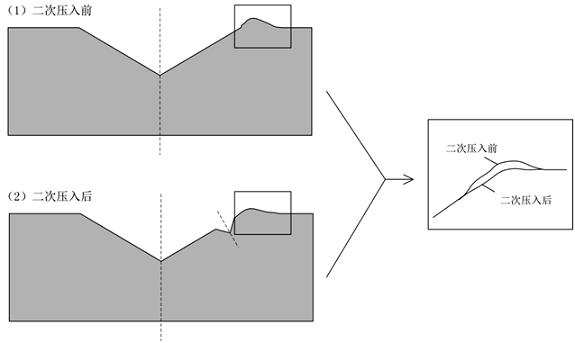

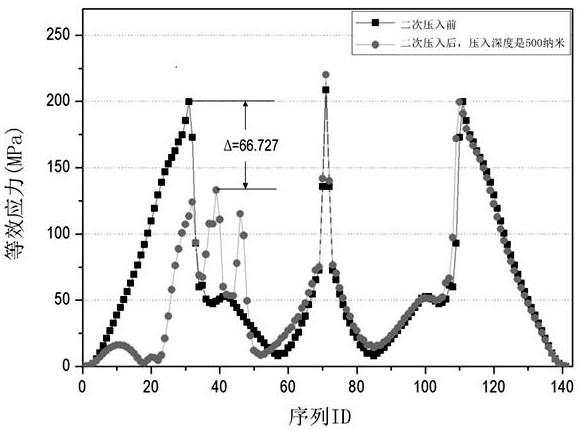

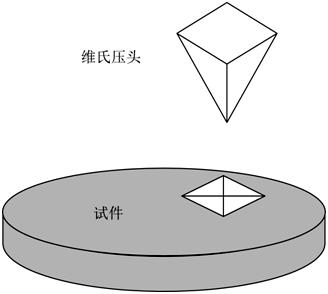

[0032] see Figure 1 to Figure 7As shown, the method for flattening the surface of the dimple-shaped microarray structural unit by secondary pressing of the present invention is applied to the dimple-shaped microarray structural unit. The operation is simple, the equipment has rich functions, and can be used for large-scale Batch machining. This method simulates the machining process of the pit-shaped microarray structure unit, that is, the Vickers indenter is used to press the surface of the material to form a pit unit with a characteristic size of micron. The formation of bulging phenomenon is accompanied by the existence of residual stress. In order to flatten the surface and reduce the residual stress on the surface, a cube-corner indenter is used to press vertically into the side of the pit unit with a char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com