A brazing method for repairing bulging defects of thin-walled components

A component and thin-wall technology, which is applied in the field of repairing brazing defects of thin-wall components to achieve tight and reliable connections, avoiding rework, and tight connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0031] A brazing method for repairing bulging defects of thin-walled components, comprising the following steps:

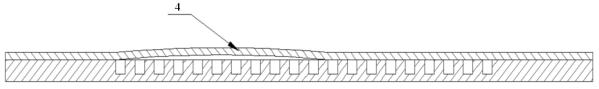

[0032] (1) Apply pressure to the bulging area 4 of the thin-walled component through tooling and pressure devices, and level the bulging area 4 of the thin-walled component;

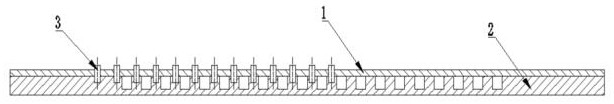

[0033] (2) Process the blind hole passing through the upper plate 1 on the rib of the runner groove below the bulging area 4 of the thin-walled component, and the vertical distance between the bottom of the blind hole and the bottom of the upper plate 1 of the thin-walled component is 1~2mm;

[0034] (3) Pour powdery solder into the bottom of the blind hole, apply paste solder around the reinforcing column 3, and then install the reinforcing column 3 in the blind hole;

[0035] (4) Put the thin-walled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com