Fireproof, moistureproof and corrosion-resistant photoelectric composite cable

A photoelectric composite and corrosion-resistant technology, applied in the direction of power cables, insulated cables, cables with shielding/conducting layers, etc., can solve the problems of poor fire resistance, outer skin bulging of cable shielding layers, and tying and threading cores, etc., to prevent Corrosion by oxidation, good fire performance, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

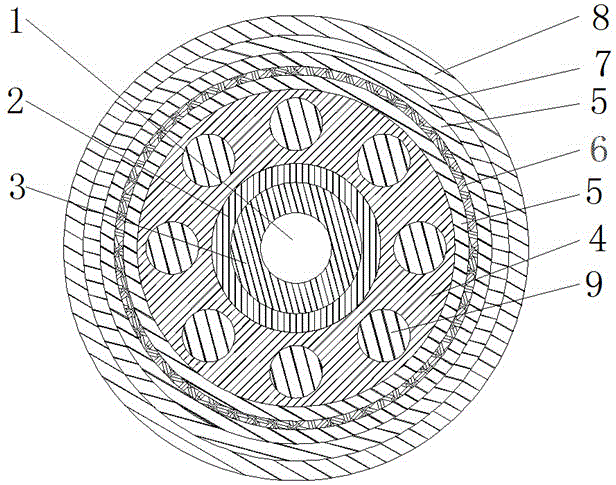

[0018] A fire-proof, moisture-proof and corrosion-resistant photoelectric composite cable, characterized in that it includes an optical fiber 2, an optical fiber ointment 2, a steel armor sheath layer 3, a dielectric filling layer 4, an anti-corrosion asphalt layer 5, and a fire-resistant layer sequentially arranged from the inside to the outside 7. The outer sheath layer 8, the anti-corrosion asphalt layer 5 is wrapped with a shielding layer 6, the shielding layer 6 includes an inner layer of copper-plastic composite tape, an outer layer of aluminum-magnesium braided tape, and the medium filling layer 4 includes a fiber with micropores. Tape, flame-retardant layer, waterproof layer, flame-retardant layer, fiber tape, waterproof layer bonded in sequence.

[0019] According to the above technical solution, the flame retardant layer includes a copper wire mesh, an expanded particle layer, and a mica layer arranged in sequence, the thickness of the mica layer is 0.3-0.8mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com